Grieve Corporation 7SL Installation Manual

INSTRUCTION MANUAL

1262-IN-023-0-02

January 1998

Model 7SL

High/Low Limitrol

1/16 DIN FOUR DIGIT HIGH/LOW LIMITROL

Model 0 7 S L - 9 1 - 0 0 - 0 - 0 0

Field No. 1 2 3 4 5 6 7 8 9 10 1112 13 14 15

Field 1 through 4. BASE

07SL - Limitrol (High/Low Limit. Shipped as

high limit)

Field 5. INPUT

9 - TC Types J, K, T, E, N, S, R, B, L, U, G, D

and Platinel II; and Pt 100 RTD;

0 to 20 mAdc and 4 to 20 mAdc

0 to 60 mVdc and 12 to 60 mVdc

0 to 5 Vdc or 1 to 5 Vdc

0 to 10 Vdc or 2 to 10 Vdc

Note: All inputs are factory calibrated and

selectable by jumper. Factory set at Type J.

Field 6. OUTPUT (High/Low Limit)

1 - Relay (Form C)

Field 7, 8. ALARMS, OPTIONS

00 -None

10 -One alarm - Relay Form A

11 -One alarm - Relay Form A, plus RS-485 and

one logic input.

Note: When code 11 is specified, instrument

length is 4.8 inches (122 mm)

Field 9. POWER SUPPLY

3 - 100 to 240 Vac

5 - 24 Vac/Vdc

Field 10. Mounting

0 - Panel Mount

R - Wall or Rail Mount

Fields 11 through 15. RESERVED

2

Congratulations

SV

. . . on your purchase of one of the easiest

to configure controllers on the market.

After a three step configuration procedure,

your process will be up and running.

If for any reason you encounter difficulty

with the controller set-up, please call your

supplier.

Unpack the

Instrument

Wiring

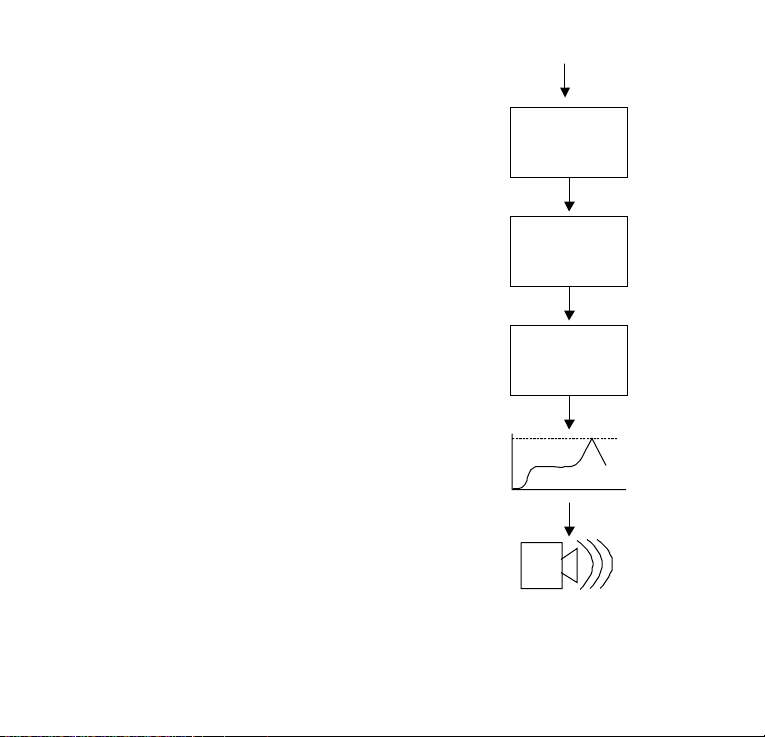

Guide to Simple Set-up

To set-up the controller, only four steps are

required:

1. Wire the instrument.

2. Configure the instrument.

3. Check the operating mode parameters.

Co nfigur ation

Operating

Parameters

3

Mounting Requirements ...................................... 5

Contents

Panel Mount Controller --------------------- 5

Mounting Requirements ...................................... 6

Wall or Rail Mount Controller -------------- 6

Dimensions and Rear Terminal Blocks ................ 7

Panel Mount Controllers ------------------- 7

Dimensions ......................................................... 9

Wall or Rail Mount Controller -------------- 9

Wiring Guidelines .............................................. 10

Panel Mount Controllers ------------------ 10

Wiring Guidelines .............................................. 14

Wall or Rail Mount Controller ------------- 14

Preliminary Hardware Settings .......................... 20

Configuration Procedur e ................................... 21

Operating Mode ................................................ 27

Error Messages ................................................. 32

General Specifications ...................................... 33

Calibration ......................................................... 37

Calibration Parameters -------------------- 38

Procedure ---------------------------------- 38

Maintenance...................................................... 44

APPENDIX A ..................................................... 45

Default parameters ------------------------ 45

APPENDIX B ..................................................... 47

Thermocouple Compensating Cable

Color Codes. ------------------------------- 47

CAUTION!

USE WIRE SUITABLE

FOR 75° MINIMUM

NOTES:

• For supply connections use 16 AWG or

larger wires rated for at least 75° C

• Use copper conductors only

• Class 2 wiring must be separated a

minimum of 1/4 inch from any class 1

conductor

IMPORTANT!

Terminal identification of the panel mount

controller is different from terminal identification of the wall/rail mount controller! This

manual contains wiring instructions for both

types of controllers.

Be sure to follow the instructions that pertain

to the controller you are using.

4

Mounting Requirements

Panel Mount Controller

Select a mounting location with the following

characteristics:

1) Minimal vibration.

2) An ambient temperature range between 0 and

50°C (32 and 122 °F).

3) Easy access to the rear of the instrument.

4) No corrosive gases (sulfuric gas, ammonia,

etc.).

5) No water or other fluid (i.e. condensation).

6) Relative humidity of 20% to 80% non

condensing.

Bracke t

Gasket

The instrument can be mounted on a panel up to 15

mm (0.591 in) thick with a square cutout of 45 x 45

mm (1.772 x 1.772 in). For outline refer to Dimensions

and Panel Cutout.

Panel surface texture must be better than 248

microinches.

The instrument is shipped with a rubber panel gasket

(50 to 60 Sh). To assure the IP65 and NEMA 4

protection, insert the panel gasket between the

instrument and the panel as shown below.

Install the instrument as follows:

1) Insert the instrument in the gasket.

2) Insert the instrument in the panel cutout.

3) Pushing the instrument against the panel,

insert the mounting bracket.

4) Torque the mounting bracket screws between

0.3 and 0.4 Nm (2.66 and 3.54 lbf-in).

5) To insure NEMA 4X/IP65 protection, make sure

the instrument does not move within the

cutout .

Panel

5

Mounting Requirements

Wall or Rail Mount Controller

WARNING:

1) The correct functionality of these instruments

is guaranteed only if transport, storage,

installation, wiring, working condition and

maintenance are executed in compliance

with this manual.

2) The protection degree of these instruments is

equal to IP 20 (according to IEC529) and they

are connected to dangerous power lines, for

these reasons:

-installation, wiring and maintenance must

be executed by qualified personnel;

-all warnings contained in this manual must

be complied.

3) The safety requirements for Permanently

Connected Equipment say:

-a switch or circuit-breaker shall be

included in the building installation;

-It shall be in close proximity to the

equipment and easy to reach for the

operator;

-it shall be marked as the disconnecting

device for the equipment.

NOTE: a single switch or circuit-breaker can

drive more than one instrument.

4) Before to executing any operation on the

connections, disconnect the instrument from

the power line by the circuit breaker.

GENERAL ASSEMBLING INFORMATION

Select a cleaned location, easy to reach, where

minimum vibrations are present and the ambient

temperature is within 0 and 50 °C (32 and 122 °F).

These instruments can be mounted either on wall

or DIN rail.

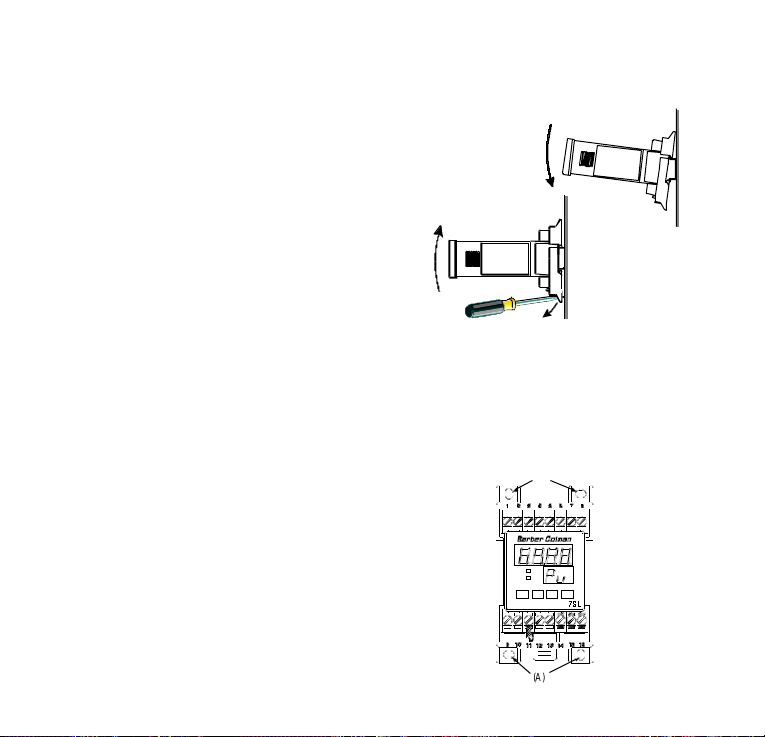

RAIL MOUNTING

Use DIN rail in accordance with EN 50 022 (35 x 7.5

mm or 35 x 15 mm).

WALL MOUNTING

For wall mounting, use the (A) holes.

In this case it is advisable to use four M4

screws with a torque of 1Nm.

(A )

ºF

RESET

AL M

6/

(A )

6

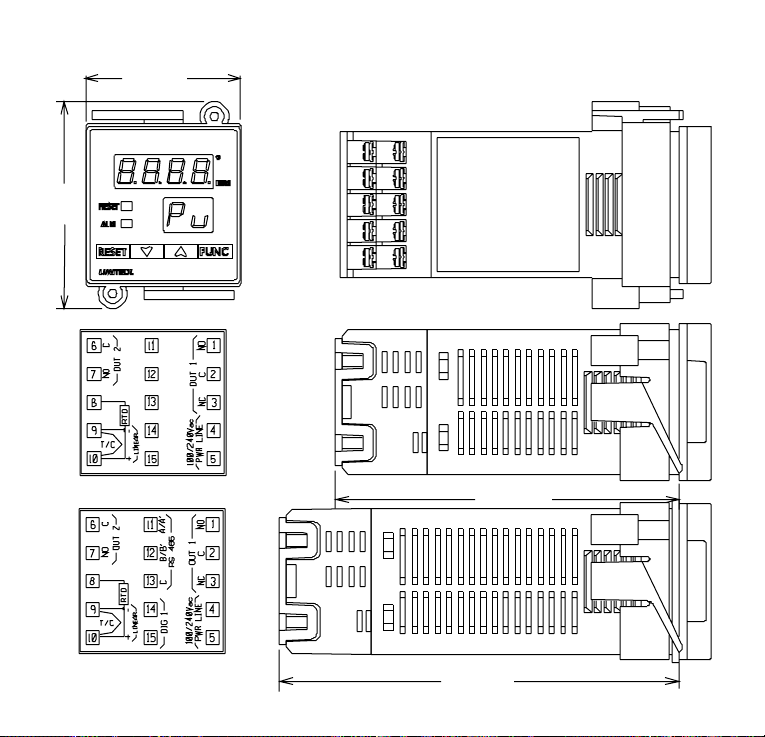

Dimensions and Rear Terminal Blocks

Panel Mount Controllers

1.89 (48)

Dimensions shown in inches;

millimeters in parenthesis

Barber-Colman

2.47

(62.8)

Without RS-485

With RS-485

F

7SL

4.13 (105)

4.80 (122)

7

PANEL CUTOUT

Dimensions shown in inches;

millimeters in parentheses

2.9 5 (75)

2.36 (60)

1.772

+0 .024, -0

(45 +0.6 , -0 )

1.772 +0.024, -0

(45 + 0.6, - 0)

8

Dimensions

Wall or Rail Mount Controller

Dimensions shown in inches;

millimeters in parentheses

4.17 (106.)

2.26 (57.5)

RE SE T

ALM

1.69 (43)

7SL

5

(0. 20 in .)

0.20 (5.)

1.81 (46)

°F

3.78 (96)

0. 1 8 ( 4 .5 )

5.67 (144) for models with serial interface

5 (127) for models without serial interface

9

1.89 (48)

Wiring Guidelines

Panel Mount Controllers

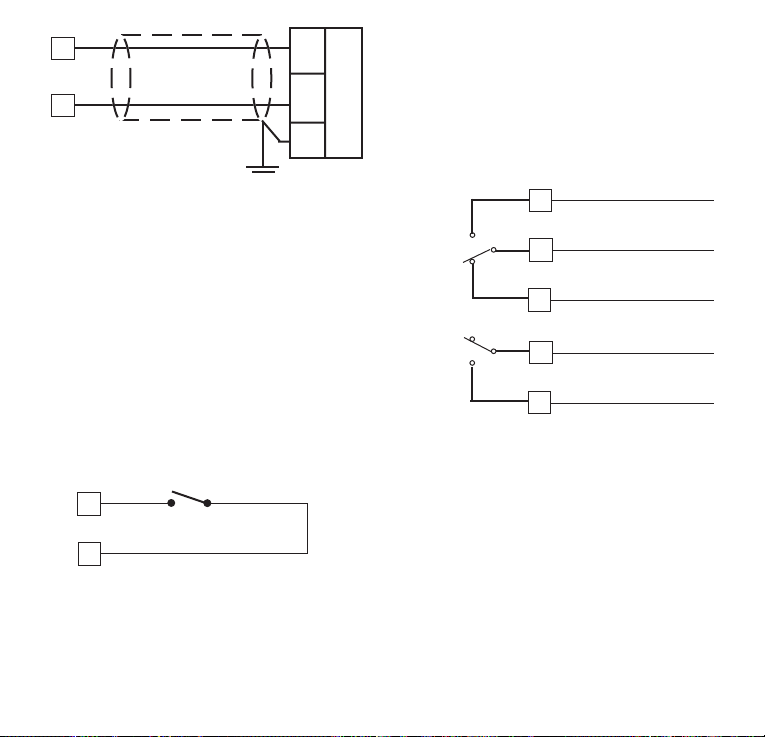

A) Measuring Inputs

NOTE: Any external components (like Zener diodes,

etc.) connected between sensor and input terminals

may cause errors in measurement due to excessive

and/or not balanced line resistance or possible

leakage currents.

RTD INPUT -- Panel Mount Controller

RTD

RTD

TC Input

10

+

_

9

Shield

10

+

_

9

Shield

Thermocouple Input Wiring

NOTE:

1) Do not run input wires with power cables.

2) For TC wiring use proper compensating cable,

preferably shielded (see Appendix B).

3) Shielded cable should be grounded at one end

only.

8

NOTE:

1) Don’t run input wires with power cables.

2) Pay attention to the line resistance; a high line

resistance may cause measurement errors.

3) When shielded cable is used, it should be

grounded at one side only to avoid ground loop

currents.

4) Resistance of the 3 wires must be the same.

LINEAR INPUT - Panel Mount Controller

109 8

RTD Input Wiring

10

9

mA, mV, and V Inputs Wiring

10

109

+

_

Shield

mA,

mV

or

V

10

9

+

mA

mV

_

or

V

G

mA, mV and V Inputs Wiring

NOTE:

1) Don’t run input wires together with power

cables.

2) Pay attention to the line resistance; a high line

resistance may cause measurement errors.

3) When shielded cable is used, it should be

grounded at one side only to avoid ground loop

currents.

4) The input impedance is equal to:

Less than 5 Ω for 20 mAdc input

Greater than 1 MΩ for 60 mVdc input

Greater than 400 KΩ for 5 Vdc and 10 Vdc

input

B) Logic Input - Panel Mount Controller

14

15

This input is used for remote acknowledgement

(reset).

Safety note:

- Do not run logic input wiring with AC power

cables.

Logic input

- Use an external dry contact capable of

switching 0.5 mA, 5 Vdc.

- The instrument needs 100 ms to recognize a

contact status variation.

- The logic inputs are NOT isolated from the

measuring input.

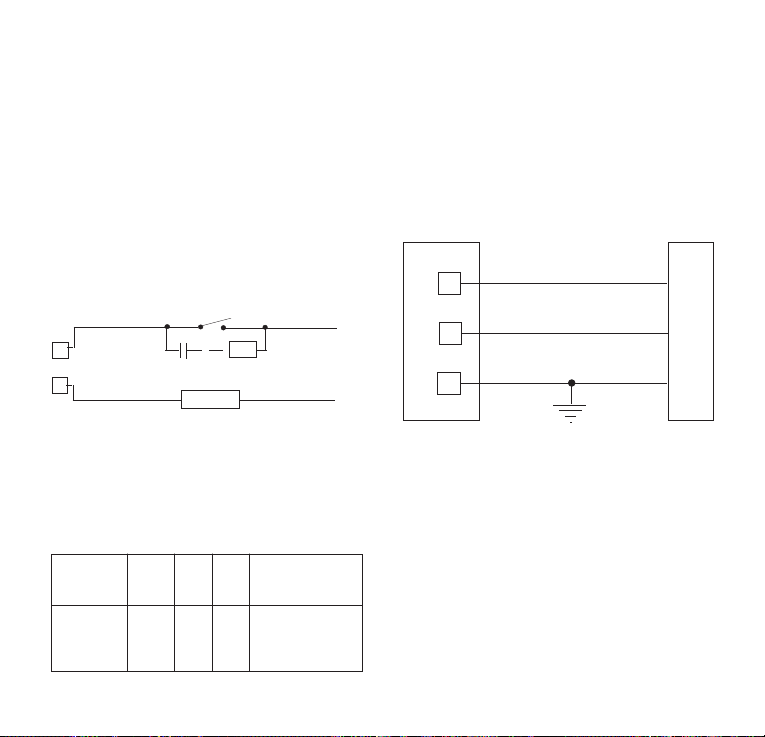

C.1) Relay Outputs Panel Mount Controller

OUT 1

Class 1

OUT 2

Class 1

(Alarm)

The OUT 1 contact rating is 3A/250V AC on

resistive load.

The OUT 2 contact rating is 2A/250V AC on

resistive load.

The number of operations is 1 x 10

rating.

NOTES 1) To avoid electric shock, connect power

line at the end of the wiring procedure.

2) For power connections use No 16 AWG

or larger wires rated for at last 75 °C.

3) Use cupper conductors only.

4) Don’t run input wires with power cables.

All relay contacts are protected by varistor against

inductive load with inductive component up to 0.5 A.

NO - OUT 1

1

C - OUT 1

2

NC - OUT 1

3

C

6

NO

7

5

at specified

11

The following recommendations avoid serious

problems which may occur, when relay outputs

are used with inductive loads.

C.2) Inductive Loads

High voltage transients may occur switching

inductive loads.

Through the internal contacts these transients

may introduce disturbances which can affect the

performance of the instrument.

For all the outputs, the internal protection

(varistor) assures a correct protection up to 0.5 A

of inductive component.

The same problem may occurs when a switch is

used in series with the internal contacts as

shown below:

C

R

LOAD

External Switch in Series with Internal Contact

In this case it is recommended to install an

additional RC network across the external contact

as shown above.

The value of capacitor (C) and resistor (R) are

shown in the following table.

LOAD

(mA)

<40 mA

<150 mA

<0.5 A

C

(µF)

0.047

0.1

0.33

(Ω)

100

22

47

R

P.

(W)

1/2

2

2

POWER

LINE

OPERATING

VOLTAGE

260 V AC

260 V AC

260 V AC

Anyway the cable involved in relay output wiring

must be as far away as possible from input or

communication cables.

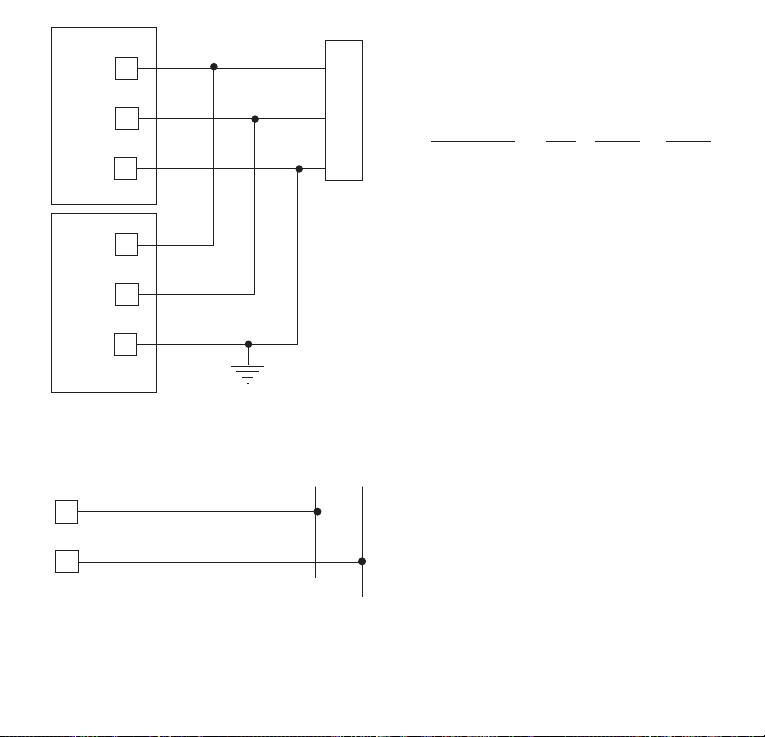

D) Serial Interface

Panel Mounted Controllers

SERIAL INTERFACE

For units built with optional RS-485 communication

RS-485 interface allows to connect up to 30

devices with one remote master unit.

I

N

S

T

R

U

M

E

N

T

11

12

13

A/A'

B/B'

COMMON

A'/A

B'/B

RS-485 Wiring

The cable length must not exceed 9/10 mile (1.5

km) at 9600 baud.

NOTE: The following report describes the signal

sense of the voltage appearing across the

interconnection cable as defined by EIA for

RS-485.

a) The ” A ” terminal of the generator shall

be negative with respect to the ” B ” terminal

for a binary 1 (MARK or OFF) state.

b) The ” A ” terminal of the generator shall

be positive with respect to the ” B ” terminal

for a binary 0 (SPACE or ON)

12

M

A

S

T

E

R

I

N

S

T

R

U

M

E

N

T

I

N

S

T

R

U

M

E

N

T

11

12

13

11

12

13

A/A'

B/B'

A'/A

B'/B

COMMON

RS-485 Wiring for Multiple Instruments

E) Power Line and Grounding Panel Mount Controllers

N, L2

4

5

NOTE:

1) Before connecting the power line, check that

the voltage is correct (see Model Number).

2) For supply connections use 16 AWG or larger

wires rated for at least 75 °C.

R (S,T), L1

POWER SUPPLY

100 to 240 Vac

24 Vac/Vdc

N, L2

R (S,T), L1

3) Use copper conductors only.

4) Do not run input wires with power cables.

M

A

S

T

E

R

5) Polarity does not matter for 24 Vdc wiring.

6) The power supply input is NOT fuse

protected.

Please provide it externally.

Power supply Type Current Voltage

24 V AC/DC T 500 mA 250 V

100/240 V AC T 125 mA 250 V

When fuse is damaged, it is advisable to verify the

power supply circuit, so that it is necessary to

send back the instrument to your supplier.

7) Safety requirements for permanently

connected equipment:

- Include a switch or circuit-breaker in the

installation.

- Place switch in close proximity to the

equipment and within easy reach of the

operator.

- Mark the switch as the disconnecting

device for the equipment.

NOTE: A single switch or circuit-breaker can

drive more than one instrument.

8) When the NEUTRAL line is present, connect it

to terminal 4.

9) To avoid shock and possible instrument

damage, connect power last.

13

Wiring Guidelines

S h ie ld

Wall or Rail Mount Controller

Connections have to be executed when the

instrument is placed in its proper location.

Out 1

T/C (b)

T/C (a ): G, D, C , B , R, S

T/C (b ): J, K , L, N , T, E, U , Plati ne l

Model 7SL Terminal Block

Without RS-485 or Logic Input

Out 1

T/C (b)

Digi

Out 2

T/C(a)

Out 2

T/C(a)

MEASURING INPUTS

NOTES:

1) Any external components (like zener

barriers etc.) connected between

sensor and input terminals may cause

measurement errors due to excessive and/or not balanced line

resistance or possible leakage

currents.

2) The input accuracy is equal to +/- 0.2

% f.s.v. (**) +/- 1 dgt. @ 25 degrees

Celsius of ambient temperature.

(**) For TC input, the f.s.v. should be

referenced to the higher f.s.v. of the

TC selected.

TC INPUT

TC Type G, D, C, B, R and S

(Wall & Rail Mount)

+

15

-

14

S h ie ld

+

15

T/C (a ): G, D, C , B , R, S

T/C (b ): J, K , L, N , T, E, U , Plati ne l

Model 7SL Terminal Block

With RS-485 and Logic Input

-

14

Input Wiring for TC

Type G, D, C, B, R and S

14

TC Type J, K, L, N, T, E, U and

1615RTD

Platinel (Wall & Rail Mount)

+

15

-

11

S hie ld

+

15

-

11

S hie ld

Input Wiring for

TC Types J, K, L, N, T, E, U and Platinel

NOTE:

1) Do not run input wires with power

cables.

2) For T/C wiring use proper compensating cable, preferably shielded (see

appendix B).

3) When a shielded cable is used, it

should be connected to one side only.

RTD INPUT (Wall & Rail Mount)

RTD

16 15

14

14

RTD Input Wiring

NOTE:

1) Don’t run input wires together with

power cables.

2) Pay attention to the line resistance; an

high line resistance may cause

measurement errors.

3) When shielded cable is used, it should

be grounded at one side only to avoid

ground loop currents.

4) The resistance of the 3 wires must be

the same.

15

Loading...

Loading...