Page 1

Model “400” OVENPAK

®

Gas Burner Page 2105

Design and Application Details

OVENPAK® Burners are nozzle-mixing gas burners

for many industrial direct-fired applications where

clean combustion and high turndown are required.

They are simple and versatile for use on a variety of

heating applications.

The Model “400” OVENPAK® Burner (shown at

right) includes a combustion air blower with nonsparking paddle wheel-type impeller, pilot, spark

ignitor, stainless steel discharge sleeve, mixing cone,

self-contained internal air and gas proportioning

valves, and provision for your flame safeguard

sensor.

Right: Model 415 OVENPAK® Gas Burner with optional:

• combustion air filter

• connecting base and linkage assembly

• electrical control motor (by others)

Cross sectional view of a Model “400” OVENPAK® Gas

Burner

Principle of operation (illustrated at left)

The OVENPAK® Burner is designed for industrial

air heating applications. It is available in two basic

versions: 1) packaged with integral combustion air

blower, or 2) for use with an external blower. Both

versions include a gas and air valve, internally linked

together to control the gas-air ratio over the full

operating range. The gas flows through the nozzle,

then along the inside of the burner cone where

combustion air is progressively and tangentially mixed

with the gas. This produces a very wide turndown

range and a highly stable flame under a variety of

operating conditions.

10/92

Page 2

Page 2106 Model “400” OVENPAK® Gas Burners

Design and Application Details

Model “EB” (external blower) OVENPAK® Burners

(shown at right), like all OVENPAK® Burner assemblies, are designed to deliver heat through a patented

mixing cone and stainless steel sleeve.

Flanged burner body design on all OVENPAK

Burner assemblies simplifies mounting and installation on your application. Burner can be installed in

any position that does not conflict with your control

motor or flame detector requirements.

Minimal torque requirements permit use of most

electric or air operators in conjunction with the optional (Maxon supplied) connecting base and linkage

assemblies.

Model “EB-MA” OVENPAK® Burner with discharge sleeve

and optional manual gas control

®

view into

cone of

EB version

Model EB-3 OVENPAK® Burner arranged for external

blower source with connecting base and linkage assembly

to adapt customer's automatic control motor

“400-MA” and “EB-MA” versions

Model “400-MA” versions include a combustion air

blower in your choice of the voltages shown on page

2107, but provide constant combustion air volumes.

They differ from “standard” versions by use of a

slotted adjustable air butterfly locking device as

shown in photo at left. Internally, the linkage normally

cross-connecting air and gas butterflies is omitted.

In normal operation, the air butterfly is set to the

desired air differential pressure, and the fuel only is

throttled by a separate control valve. Maximum

capacities match those cataloged for “standard”

burners of equivalent size. Minimum capacities with

full air flow will be higher than those of “standard”

burner.

“EB-MRV” versions (photo at right)

“EB-MRV” versions of OVENPAK® Burners permit

air/fuel ratio control via a Maxon MICRO-RATIO®

control valve throughout the firing range. They differ

from standard “EB” burners in that internal gas and air

butterflies and the related shafts and linkages are

omitted.

In normal operation, air and fuel will be proportioned by an external Maxon MICRO-RATIO® Control

valve.

Maximum capacities match those cataloged for

“EB” burners of equivalent size and differential air

pressure. Minimum capacity and air differential

pressure will vary with your application.

Model “EB-MRV” OVENPAK® Burner with optional 12"

discharge sleeve

Page 3

®

Gas Burners

Page 2107Model “400” OVENPAK

Capacities and Specifications – 60 Hertz

Standard Model “400” OVENPAK® Burner in-

cludes a combustion air blower with motor.

Maximum capacity of Model “400” OVENPAK

®

Burner is affected by the static pressure within the

combustion chamber. Data shown assumes firing in

the open, or into an airstream with enough oxygen to

complete the combustion process. If burner is fired into

an oxygen-starved chamber or airstream, capacities

may be reduced as much as 25-30%. Do not attempt

to operate beyond the duct static pressure range

shown. For higher back pressure applications, select

from Model “EB” or “EB-MRV” OVENPAK® Burner

options.

All gas pressures are differential pressures and

are measured at the gas pressure test connection on

the backplate of each OVENPAK

®

Burner. Differential

pressures shown are approximate.

–ataDgnitarepOdnaseiticapaC

ledoMrenruB504M704804M804M214M314514M224

rotoM

noitacificepS

D

U

C

T

mumixaM

seiticapaC

S

)rh/utBs'0001(

T

saGlarutaNhtiw

A

)cw"(serusserP

T

I

C

S

muminiM

seiticapaC

)rh/utBs'0001(

erusserp )cw"(telnirenrubot

riallitsni

:rewopesroH3/12/13/14/32/14/33/14/3

:rebmuNemarF8484846584658465

ot0.5-

cw"5.0-

cw"0±

cw"0.1+

cw"0.2+

cw"0.3+

cw"0.4+

cw"0.5+

tolipsulpniaM510273

ylnotoliP015102

laitnereffidsaglarutanderiuqeR

htgnelemalfetamixorppA

055

"8.2

005

"3.2

574

"1.2

054

"9.1

---

---

---------

--057

"5.2

007

"2.2

006

"6.1

015

"1.1

054

"9.0

0.35.31.45.42.52.42.7

.tf1ot2/1

elbaliavAsegatloVrotoMzH06

-802/511

06/1/032

XXX

XXX

toN

elbaliavA

2/1&3/1

1&4/3

rewopesroHepyT

3&2,2/1-1

yllatoT

desolcnE

yllatoT

desolcnE

yllatoT

desolcnE

M224hguorht504ledoM

088

"4.3

008

"8.2

067

"6.2

027

"3.2

---

---

ot1

.tf2/1-1

-------097

"7.2

057

"5.2

046

"8.1

055

"3.1

594

"1.1

574

"0.1

.tf1ot2/1.tf2/1-2ot1

0021

"8.2

0011

"4.2

529

"7.1

008

"3.1

057

"1.1

---

0031

"3.3

0911

"8.2

0011

"4.2

0001

"0.2

009

"6.1

008

"3.1

-802

06/3/064/032

XX

0561

"7.1

0051

"4.1

5241

"3.1

0531

"1.1

---

---

---

ot2/1-2

.tf2/1-3

06/3/575

--0512

"9.2

0002

"5.2

5271

"9.1

0161

"6.1

0051

"4.1

0241

"3.1

ot2/1-1

.tf2

5/93

Page 4

Page 2108 Model “400” OVENPAK® Gas Burners

Capacities and Specifications – 60 Hertz

–ataDgnitarepOdnaseiticapaC M784hguorht524ledoM

ledoMrenruB524M234534M244544M654M074M784

rotoM

noitacificepS

D

U

C

T

mumixaM

seiticapaC

S

)rh/utBs'0001(

T

saGlarutaNhtiw

A

)cw"(serusserP

T

I

C

S

muminiM

seiticapaC

)rh/utBs'0001(

erusserp )cw"(telnirenrubot

riallitsni

:rewopesroH4/34/34/311 2/1-123

:rebmuNemarF6565656565T341T541T281

ot0.5-

cw"5.0-

cw"0±

cw"0.1+

cw"0.2+

cw"0.3+

cw"0.4+

cw"0.5+

cw"0.6+

tolipsulpniaM0678011521051571

ylnotoliP535409501511711

laitnereffidsaglarutanderiuqeR

htgnelemalfetamixorppA

0572

"7.2

0052

"2.2

5732

"0.2

0522

"8.1

---

---

---

------------------

6.39.48.39.45.41.52.56.7

--0023

"6.3

0003

"2.3

0082

"8.2

0562

"5.2

0052

"2.2

0522

"8.1

.tf2/1-3ot2/1-2

0583

"2.2

0053

"8.1

5233

"6.1

0513

"4.1

---

---

---

ot2/1-3

.tf5

--0514

"5.2

0004

"4.2

0083

"1.2

0563

"9.1

0053

"8.1

0033

"6.1

.tf5ot4.tf6ot4.tf7ot5.tf8ot6.tf01ot8

5715

"4.3

0054

"6.2

0824

"3.2

5214

"2.2

---

---

---

0046

"6.3

0065

"8.2

0435

"5.2

0025

"4.2

0005

"2.2

0064

"9.1

0014

"5.1

0508

"7.3

0007

"8.2

0756

"5.2

0036

"3.2

0055

"7.1

0005

"4.1

0054

"2.1

0053

"7.0

06001

"6.4

0078

"4.3

0048

"2.3

0028

"0.3

0057

"5.2

0026

"7.1

0055

"4.1

0005

"1.1

Page 5

Page 2109Model “400” OVENPAK® Gas Burners

Capacities and Specifications – 50 Hertz

Standard Model “400” OVENPAK

®

Burner includes a combustion air blower

with motor.

Maximum capacity of Model “400”

OVENPAK

®

Burner is affected by the static

pressure within the combustion chamber.

Data shown assumes firing in the open, or

into an airstream with enough oxygen to

complete the combustion process. If burner

is fired into an oxygen-starved chamber or

airstream, capacities may be reduced as

much as 25-30%. Do not attempt to operate

beyond the duct static pressure range

shown. For higher back pressure applications, select from Model “EB” or “EB-MRV”

OVENPAK

®

Burner options.

All gas pressures are differential

pressures and are measured at the gas

pressure test connection on the backplate

of each OVENPAK® Burner. Differential

pressures shown are approximate.

-ataDgnitarepOdnaseiticapaC

ledoMrenruB504M704804M804M214M314514M224

rotoM

noitacificepS

D

U

C

T

mumixaM

seiticapaC

S

)rh/utBs'0001(

T

saGlarutaNhtiw

A

)cw"(serusserP

T

I

C

S

muminiM

seiticapaC

)rh/utBs'0001(

erusserp )cw"(telnirenrubot

riallitsni

:rewopesroH3/12/13/14/32/14/33/14/3

:rebmuNemarF8484846584658465

cw"0.5-

cw"0.3-

cw"0±

cw"0.1+

cw"0.2+

tolipsulpniaM5102510273

ylnotoliP015102

laitnereffidsaglarutanderiuqeR

htgnelemalfetamixorppA

064

"0.2

064

"0.2

514

"6.1

093

"4.1

---------------

2.23.20.36.25.31.49.26.5

elbaliavAsegatloVrotoMzH05

rewopesroHepyT05/1/002-09105/3/514-08305/3/005

2/1&3/1

1&4/3

3&2,2/1-1

yllatoT

desolcnE

yllatoT

desolcnE

yllatoT

desolcnE

XXX

XXX

XXX

)tsocartxetenelbissop(

M224hguorht504ledoM

---

--526

"7.1

585

"5.1

.tf1ot2/1

537

"4.2

537

"4.2

076

"0.2

036

"7.1

ot1

.tf2/1-1

---------

--------066

"9.1

526

"7.1

.tf1ot2/1.tf2ot1

0001

"0.2

029

"7.1

0801

"5.2

099

"4.2

029

"7.1

5731

"2.1

5731

"2.1

0521

"0.1

0911

"9.0

---

ot2/1-1

.tf2

---

--0081

"0.2

0761

"8.1

0441

"3.1

ot2

.tf2/1-2

8/00

Page 6

Page 2110 Model “400” OVENPAK® Gas Burners

Capacities and Specifications – 50 Hertz

-ataDgnitarepOdnaseiticapaC

ledoMrenruB524M234534M244544M654M074M784

rotoM

noitacificepS

D

U

C

T

mumixaM

seiticapaC

S

)rh/utBs'0001(

T

saGlarutaNhtiw

A

)cw"(serusserP

T

I

C

S

muminiM

seiticapaC

)rh/utBs'0001(

erusserp )cw"(telnirenrubot

riallitsni

:rewopesroH4/34/34/311 2/1-123

:rebmuNemarF6565656565T341T541T281

cw"0.5-

cw"0.3-

cw"0±

cw"0.1+

cw"0.2+

cw"0.3+

tolipsulpniaM0678011521051571

ylnotoliP535409501511711

laitnereffidsaglarutanderiuqeR

htgnelemalfetamixorppA

0032

"9.1

0032

"9.1

0902

"6.1

0791

"4.1

---------

---------------------

5.28.32.28.31.36.30.50.5

---

--0762

"5.2

0432

"0.2

.tf3ot2

0292

"3.1

0292

"3.1

0872

"1.1

---

ot3

.tf2/1-4

M784hguorht524ledoM

---

--0643

"8.1

0433

"6.1

0223

"5.1

ot2/1-3

.tf4

5234

"4.2

5234

"4.2

0673

"8.1

---

---

.tf5ot4.tf6ot5.tf8ot7

0535

"5.2

0535

"5.2

0764

"9.1

0544

"8.1

0434

"7.1

0076

"6.2

0076

"6.2

0585

"0.2

0055

"7.1

0525

"6.1

0048

"2.3

0048

"2.3

0527

"3.2

0507

"1.2

0586

"1.2

0526

"7.1

Page 7

®

Gas Burners

Capacities and Specifications

External Blower (EB) versions

Page 2111Model “400” OVENPAK

dnanoitsubmoC

riAgnilooC

deriuqer

1-BE

®

KAPNEVO

sesaeleRtaeH

)rh/utBs'0001(

renruB

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

dnanoitsubmoC

riAgnilooC

deriuqer

2-BE

®

KAPNEVO

sesaeleRtaeH

)rh/utBs'0001(

renruB

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

dnanoitsubmoC

riAgnilooC

deriuqer

3-BE

®

KAPNEVO

sesaeleRtaeH

)rh/utBs'0001(

renruB

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

)MFCS(emuloV051071091012042552072082

tolip&muminiM0606060606060606

ylnotoliP5454545454545454

telnirenrubtA1.24.31.51.66.73.82.90.01

riallitsnI eveelsegrahcsidfodnednoyeb"51ot"4

)MFCS(emuloV022052082013553573593514

tolip&muminiM0606060607075708

ylnotoliP5252525203035353

telnirenrubtA32.58.75.93.111.219.218.31

riallitsnI eveelsegrahcsidfodnednoyeb"03ot"21

)MFCS(emuloV053504554594575516056576

tolip&muminiM0959501511031041051551

ylnotoliP5454055556075757

telnirenrubtA1.46.50.73.80.115.219.314.51

riallitsnI eveelsegrahcsidfodnednoyebteef3ot2

)cw"(erusserPriAlaitnereffiD

345689 0111

yticapaCmumixaM

noitcennoctsetsagrenrubtA0.21.37.46.50.76.75.82.9

)cw"(erusserPriAlaitnereffiD

yticapaCmumixaM

noitcennoctsetsagrenrubtA5.22.43.67.72.98.95.012.11

)cw"(erusserPriAlaitnereffiD

yticapaCmumixaM

noitcennoctsetsagrenrubtA6.12.28.23.34.40.56.52.6

0640855170870780190690001

345689 0111

057089002103310541005105510061

345689 0111

02610091021202320762048200030513

12/92

dnanoitsubmoC

riAgnilooC

deriuqer

4-BE

®

KAPNEVO

sesaeleRtaeH

)rh/utBs'0001(

renruB

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

)MFCS(emuloV05553601757759805900010501

tolip&muminiM001511031041061071081091

ylnotoliP0404045405555506

telnirenrubtA5.27.39.48.54.71.88.80.01

riallitsnI eveelsegrahcsidfodnednoyebteef2/1-3ot2/1-2

)cw"(erusserPriAlaitnereffiD

345689 0111

yticapaCmumixaM

noitcennoctsetsagrenrubtA9.18.27.33.45.51.66.65.7

02320082032300530593051403340064

Page 8

Page 2112 Model “400” OVENPAK® Gas Burners

Capacities and Specifications

External Blower (EB) versions

dnanoitsubmoC

riAgnilooC

deriuqer

5-BE

®

KAPNEVO

sesaeleRtaeH

)rh/utBs'0001(

renruB

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

dnanoitsubmoC

riAgnilooC

deriuqer

6-BE

®

KAPNEVO

renruB

7-BE

®

KAPNEVO

renruB

sesaeleRtaeH

)rh/utBs'0001(

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

dnanoitsubmoC

riAgnilooC

deriuqer

sesaeleRtaeH

)rh/utBs'0001(

saGlarutaN

laitnereffid

serusserp )cw"(

shtgneLemalF

)MFCS(emuloV5660770680490801051101210721

tolip&muminiM551081002022552072582003

ylnotoliP5203535304540505

telnirenrubtA2.21.30.49.46.65.73.81.9

riallitsnI eveelsegrahcsidfodnednoyebteef5ot3

)MFCS(emuloV5790621095107810522093204620672

tolip&muminiM533093094575596537518058

ylnotoliP001001001511041541561071

telnirenrubtA8.26.53.117.518.226.523.131.43

riallitsnI

)MFCS(emuloV5790621095107810522093204620672

tolip&muminiM533093094575596537518058

ylnotoliP001001001511041541561071

telnirenrubtA8.16.33.71.018.416.612.021.22

riallitsnI

)cw"(erusserPriAlaitnereffiD

345689 0111

yticapaCmumixaM

noitcennoctsetsagrenrubtA3.18.13.29.29.34.48.43.5

)cw"(erusserPriAlaitnereffiD

yticapaCmumixaM

noitcennoctsetsagrenrubtA0.20.41.82.113.613.813.223.42

)cw"(erusserPriAlaitnereffiD

yticapaCmumixaM

noitcennoctsetsagrenrubtA0.10.21.46.52.82.92.112.21

04920053089302440315054504750006

358 1161812242

0174007600590021100531003410085100561

fodnednoyebteef8ot3

eveelsegrahcsid

358 1161812242

0174007600590021100531003410085100561

fodnednoyebteef8ot3

eveelsegrahcsid

fodnednoyebteef21ot8

eveelsegrahcsid

fodnednoyebteef21ot8

eveelsegrahcsid

Page 9

®

Gas Burners

Accessory Options

Air filter assemblies and silencers

Page 2113Model “400” OVENPAK

Air filter assemblies help to trap airborne particu-

late matter. They are offered with washable replaceable

filter elements or with permanent metallic elements (as

shown in photograph above). Filters mount onto

OVENPAK

®

Burner's blower housing (or silencer

housing of burners so equipped) and surround the

blower motor and combustion air inlet.

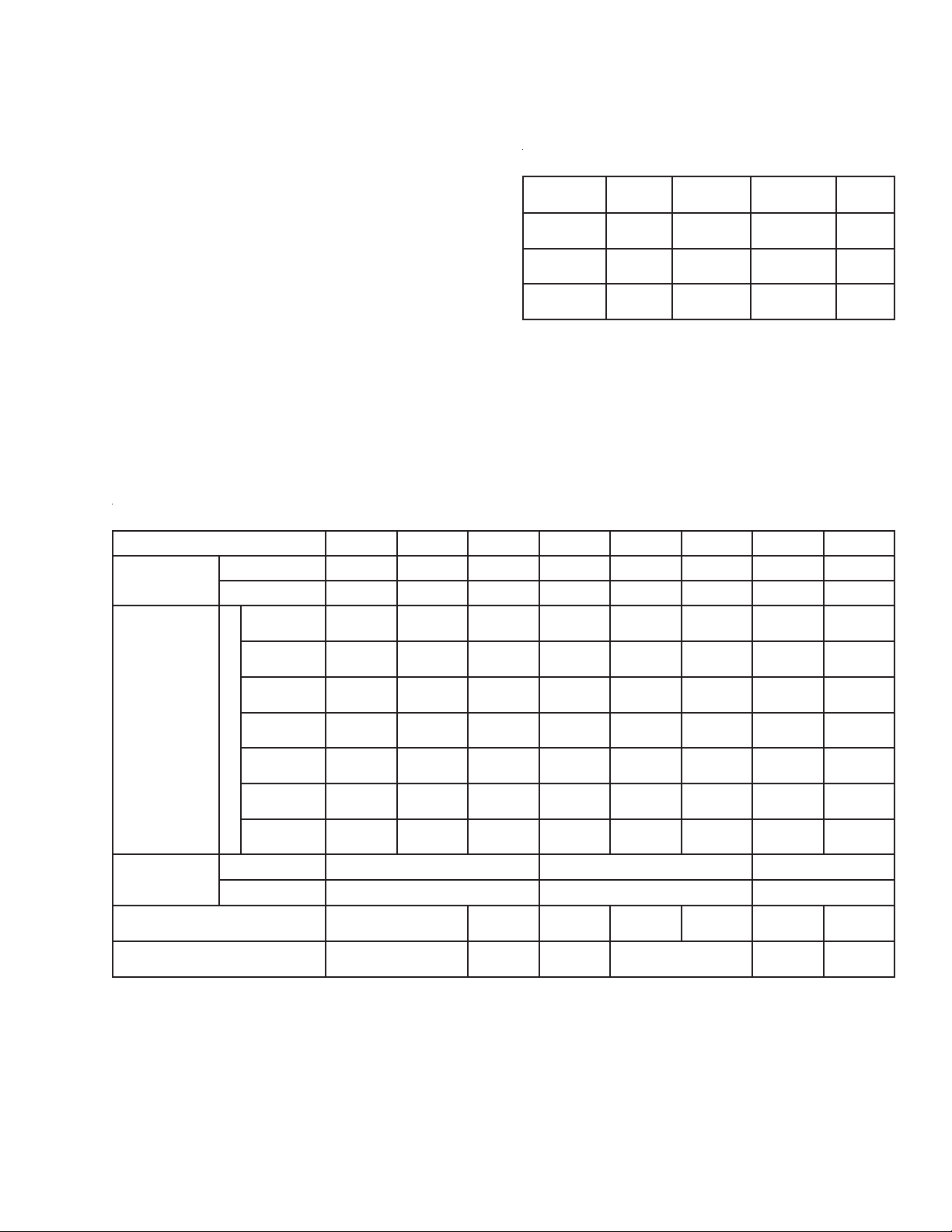

dB(A) sound levels

from actual tests conducted at full-rated 60 Hz

capacity are shown in table

at right. Measurement point

is shown in sketch below.

(Meter was set to A-scale,

slow response.)

Operation on 50 Hz

power results in lower

rotational speed of blower,

and so reduces air output,

capacity, and resulting

noise levels. 50 Hz noise

levels should not exceed

the above data measured

on 60 Hz operation.

Burner

Model

405

407M

408M

408

412M

413M

415

422M

425

432M

435

442M

445

456M

470M

487M

Sound Level dB(A)

Standard

Burner

84

83

84

87

81

82

89

88

89

88

87

89

89

90

92

94

with

Silencer

75

77

75

78

73

72

77

79

78

80

78

80

81

83

83

85

Filter silencers help reduce noise levels. They

mount onto OVENPAK® Burner's blower housing and

enclose the blower motor and combustion air inlet (as

shown in above photograph). They can be furnished in

conjunction with a permanent or replaceable filter

element assembly described above.

6/96

Page 10

Page 2114 Model “400” OVENPAK® Gas Burners

Accessory Options

Universal Joint Arrangements (for all

versions except EB-MRV) allow control of as many as

5 burners by a single control motor. Torque requirement is 10 in-lbs for EACH burner driven. Primary

burner should drive no more than 2 Secondary burners

to either side of itself.

Miniature universal joints simplify burner alignment.

Aluminum connecting rod can be cut to fit actual

burner spacing. (

burner centerlines is 21" – 33" for 422M and smaller,

23.5" – 36" for larger burners.)

1. Primary and secondary burners

2. Any other accessories desired

3. Required quantity of Universal Joint Assemblies

Allowable distance between adjacent

To order, specify:

Auxiliary Switches

Maxon offers 4 types, all cam-actuated by the

burner main operating shaft. (If Universal Joint Arrangements are used, switch must mount on furthest

left burner.) Field installation MAY require burner

modification per instructions provided in Product

Information Sheet 2000-7/8.

Low Fire Start Switch Assembly (SPDT) opens

the circuit when burner leaves minimum position. Also

available in Weatherproof and Hazardous Location/

Weatherproof versions.

High and Low Fire Position Switch Assembly

includes 2 SPDT switches. One switch may be fieldset to activate at high fire position, while other is set to

activate at low fire position. Switch assemblies are

also available in a weatherproof version.

Manual Handle Kit permits setting and locking

air and fuel valves at a constant firing rate. See photo

below.

Low Fire Start Switch shown

Discharge Sleeve Mounting Gaskets

Standard discharge sleeve gasket provides

adequate sealing in most applications.

High Back Pressure Gasket Kit includes 2 additional gaskets to provide sealing against back pressures as shown in sketch below.

Standard

Arrangement

High Back Pressure Kit

With

Page 11

Model “400” OVENPAK® Gas Burners

Accessory Options

Page 2115

Hi/Lo Control Motor Sets for high or low firing.

Optional set includes 2-position unidirectional 11second 120v 50/60 Hz motor and connecting base with

mounting linkage. See table below for dimensions

which differ from standard burner.

sehcnInisnoisnemiD

2,1-BEM314-504

3-BEM224-514

5,4-BEM244ot524

7,6-BEM784-544

ledoMrenruB

PRT

52.0136.7157.7

91.0165.7157.7

96.1160.9157.8

96.6160.4257.8

Discharge Sleeves are available in 3 versions:

– Standard sleeve is 8" long, made of #310 SS, and

is suitable for downstream temperatures up to

1000°F (538°C).

– For higher velocities, specify 12" long sleeve made

of #310 SS for downstream temperatures up to

1000°F (538°C).

– For higher downstream temperatures between

1000°F (538°C) and 1500°F (816°C), specify 8" long,

#RA 330 SS sleeve.

9/94

Page 12

Page 2116 Model “400” OVENPAK® Gas Burners

Dimensions (in Inches)

Model “400” and “400-MA” OVENPAK® Burners

NOTE: Use of auxiliary switches will add to dimension D.

ledoMA*BCDEF GHJK LMN CCDDEEFFGGHHJJKK

504

M704

804

57.31

M804

M214

M314

514

57.44/1-196.718.852.0173.0152.873.0144.4

M224

524

M234

534

M244

544

M654

M074

M784

2/1-1

57.5

2

18.683.4188.6113.9126.415.652.2157.4196.673.5

3 57.7197.719118.6249.52

44.5

60.626.8

TPNtelnisagleufniaM*

26.678.803.01

60.0188.1196.4105.2144.552.015.2126.5

44.8

91.31

73.4

13.644.826.3

52.0

73.0

18.873.114166.3

52.5178.518196.496.9196.1226.81

18.873.114166.321.9118.7173.4160.71

52.5178.518196.4

18.873.1141

52.5178.51

21.2144.4149.3

52.5178.5118.252.1265.3226.92

21.2144.4149.35.0252.0257.91

52.5178.51

95.313.71

81

18.252.1265.32

42

13.71

13.71

21.91

52.81

5.22

18.7173.4160.71

96.9196.1226.81

57.7173.4160.71

65.9196.1226.81

5.0252.0257.91

525.32

26.92

Pipe threads on this page conform to NPT (ANSI Standard B2.1)

Page 13

Dimensions (in Inches)

Model EB, EB-MA, and EB-MRV OVENPAK

Page 2117Model “400” OVENPAK® Gas Burners

®

Burners

NOTE: Use of auxiliary switches will add to dimension D.

ledoMABCDEFGHJKLMNUVWXYAABB

1-BE

57.3

2-BE

3-BE

4-BE

5-BE

6-BE

7-BE

4/1-144.5

57.496.773.0152.873.0144.483.5

57.52

18.63 83.4188.6113.9126.415.652.2157.4196.626.921.11

60.626.8

26.6

78.813.0191.31

60.0188.1196.415.2144.552.015.2126.5

44.8

73.4

13.644.826.3

52.052.726.873.644.044.5

52.926.0178.8

73.0

65.0

-7.11

5

Refractory Lined Discharge Sleeve

.562 dia.

8 holes

D dia.

22.5˚

45˚

A

BC

renruB

eziS

M314-504

2BE,1BE

M224,514

3BE

M244-524

5BE,4BE

M784-544

7BE,6BE

ABC .aidD

83.831.0160.4136.21

83.80.2149.515.41

83.860.410.8135.61

83.860.610.0235.81

44.5

4

57.766

52.015.88

10/03

Pipe threads on this page conform to NPT (ANSI Standard B2.1)

Page 14

Page 2118 Model “400” OVENPAK® Gas Burners

Accessory Dimensions (in Inches)

Filter with silencer for Model “400” OVENPAK® Burner

ledoMJJLLMMNNPPRRSSTTUU

504

M704

804

M804

M214

M314

514

M224

524

M234

534

M244

544

M654

M074

M784

4.414.21

7.121.519.128.77.424.131.53

4.414.213.914.012.329.926.33

7.121.519.128.77.424.131.53

4.414.213.914.01

7.121.51

2.025.413.8429.526.233.63

6.321.81229.428.019.429.135.833.24

52.025.41614.123.8429.526.233.63

6.32

5.32 6.82

9.522.02422.928.216.929.337.243.44

1.81229.428.01

61

3.914.01

9.12

2.329.926.33

2.32

8.77.424.131.53

1.32

9.42

2.329.926.33

9.135.833.24

Pipe threads on this page conform to NPT (ANSI Standard B2.1)

Page 15

Component Identification

Page 2119Model “400” OVENPAK® Gas Burners

Suggested spare parts

– Spark Ignitor – Discharge Sleeve and Gasket

– Flame Rod, if used – Motor

– Filter Elements, if used – Impeller

– Mixing Cone – Gas/Air Valve Linkage Kit

To order parts for an existing OVENPAK® Burner assembly, list:

1. Name(s) of part(s) from above illustration

2. Quantity of each required

3. OVENPAK® Burner nameplate information:

• size and model number of burner

• assembly number

• date of manufacture

• if available, serial number of Maxon fuel shut-off valve in-line to OVENPAK

Burner (This serial number is on Maxon valve's nameplate.)

9/03

Nameplate

®

Page 16

Page 2120 Model “400” OVENPAK® Gas Burners

Suggested Maintenance/Inspection Procedures

Discharge sleeve and cone alignment

Centering of the mixing cone provides a small

annular opening for the flow of some cooling combustion air along the discharge sleeve wall. We SUGGEST

periodic inspection from the discharge side of the

burner to assure that this alignment is maintained.

Caution: Tightening can lead to cone distortion

and greatly reduce cone and discharge sleeve

life. Cone should be free to move and allow for

thermal expansion.

If re-adjustment is necessary, back out the four lock

nuts and re-center mixing cone with adjusting screws

handtight. Back each screw out one-half turn before relocking. This allows for thermal expansion as cone

gets hot.

Filters should be inspected regularly and cleaned,

using a vacuum to remove loose/dry accumulations,

then washing and/or degreasing as appropriate for the

filter type used.

To replace flame rod or spark ignitor:

1. Check Table 1 at right for dimension “Y” and cut tip

to length shown.

2. Insert 1/2" NPT collar into burner and snug into

position.

3. Insert insulator through collar into burner.

4. Check table for dimension “X”, position accordingly,

and tighten locking bushing until insulator is held

firmly.

WARNING: Over-tightening locking bushing may

damage insulator.

NOTE: A full-wave 6000 volt spark ignition transformer

is suggested for use with Maxon burner equipment.

Flame Rod

NOTE: 1/2" x 1" adapter bushing supplied by others

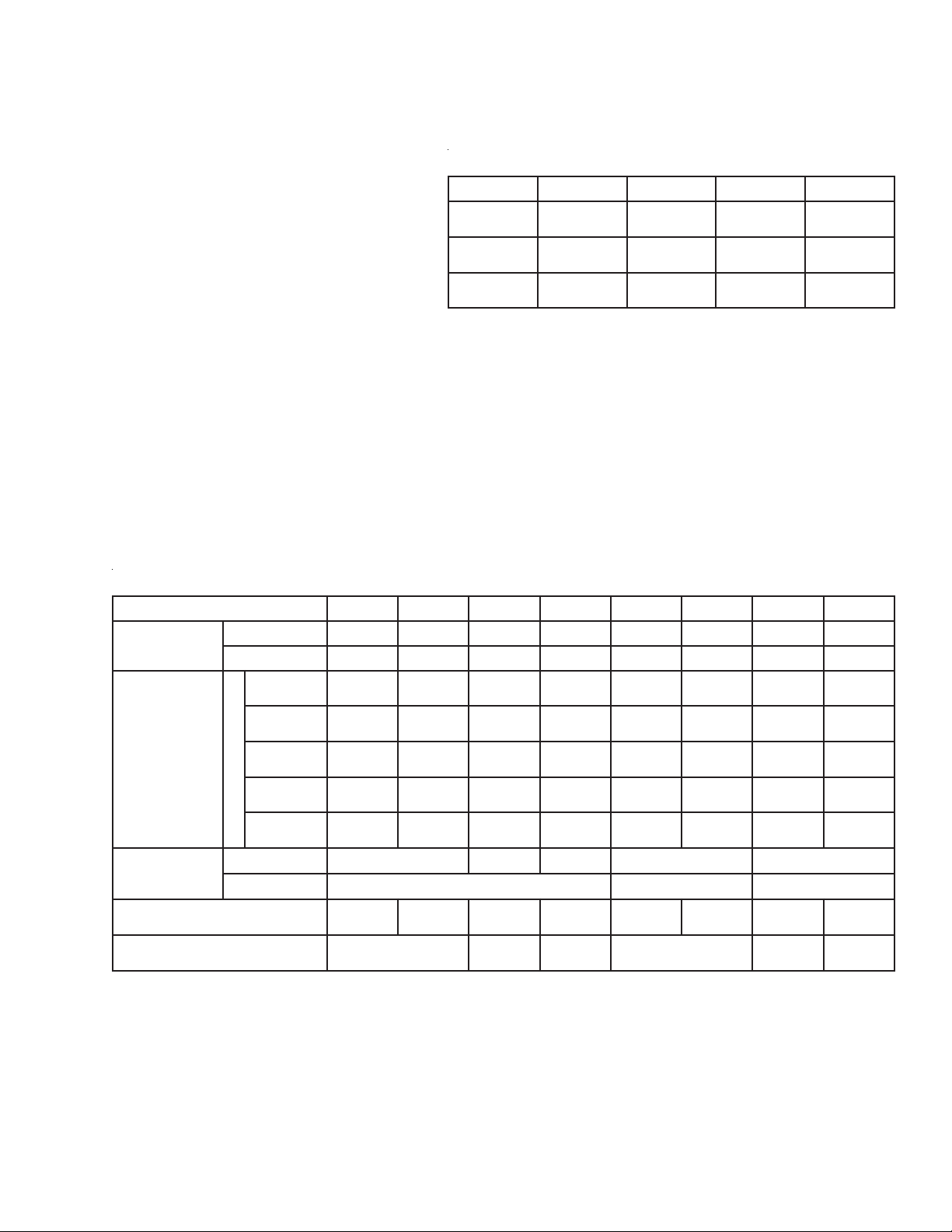

Table 1: Flame rod and spark ignitor dimensions

for all Model “400” OVENPAK® Burners

manufactured after 1/1/91 ①

rotingIkrapS

ledoMrenruB

XYXYZ

504

M704

1-BE

2-BE

3-BE

4-BE

5-BE

6-BE

7-BE

M804

804

M214

M314

514

M224

524

M234

534

M244

544

M654

M074

M784

3.14.

5.14.

2.14.8.8.015.3

3.14.4.8.219.2

snoisnemiD

4.69.2

doRemalF

snoisnemiD

①

Manufactured date is stamped on metal nameplate

of Model “400” OVENPAK® Burner. For specifics

relative to units manufactured prior to 1/1/91, see

Product Information Sheet 2100-3.

Page 17

Page 2121Model “400” OVENPAK® Gas Burners

Maxon Pre-Assembled P acka ge

Model “400” OVENP AK® Gas Burner System

Save time and reduce your installation costs with a

completely assembled and pre-wired burner and pipe

train “package”.

All system components have been carefully selected to match the high performance characteristics of

the Model “400” OVENPAK® Gas Burner.

The compact design of this “packaged system”

makes mounting to your duct fast and easy. Connect

to the gas line and bring in electricity. It's wired and

piped, ready to go.

425 OVENPAK

package system

installed and

mounted onto a

Maxon

pre-fabricated

heater/duct section

All pre-assembled package systems include a

Model “400” OVENPAK® Burner and pipe train. The

pipe trains are available with “Block and Bleed” arrangement options only.

Additional application flexibility is provided with five

different sized systems, all with 40:1 turndown

capacity ranges.

Packaged OVENPAK® Burner systems may also be

mounted in a pre-fabricated combustion heater/duct

section by Maxon. This option is value-engineered to

give you the most for your dollar spent.

®

6/03

Page 18

Page 2122 Model “400” OVENPAK

Design / Application Summary

Five Model "400" OVENPAK® pre-assembled package options:

®

KAPNEVO

rotoMrewolBdesolcnEyllatoT

yticapaCmumixaM )rh/utB(

yticapaCmuminiM tolipsulpniam)rh/utB(

erusserpsaglarutanmuminiM telniniartepiptaderiuqer

ezisniartepiptelnI TPN

>ledoMrenruB504804514524534

rewopesroH

rebmuNemarF

000,005000,008000,005,1000,005,2000,005,3

000,51000,02000,73000,06000,78

snoisnemidepolevnellarevoetamixorppA

3/14/3

8465

cw"6cw"01cw"9cw"41

"52.1"5.1

®

Gas Burners

ediw"42xhgih"04xgnol"24

Pre-assembled pipe train “package”

includes the following components:

– Burner gas shut-off cock

– Main inlet gas shut-off cock

– Pilot gas train consisting of:

• Pilot gas shut-off cock

• Pilot gas pressure regulator (maximum 1 PSIG

natural gas inlet pressure)

• Pilot gas solenoid valve, 115/60VAC

– Main gas pressure regulator (maximum 1 PSIG

natural gas inlet pressure)

– Combustion air pressure switch, automatic reset,

NEMA 1, 115/60VAC

– Combination high and low gas pressure switch,

manual reset, NEMA 1, 115/60VAC

– Spark ignition transformer, 6000 volts, NEMA 1, 115/

60VAC

– NEMA type 12 and 13 junction box with terminal

wiring strip

– Normally open vent solenoid valve, 115/60VAC

A complete packaged system also includes:

• Maxon Model “400” OVENPAK® Burner assembly

– Connecting base and linkage assembly to adapt

customer-supplied automatic control motor

(optional)

– Low fire start switch (mounted to OVENPAK

Burner)

– Air filter assembly

• Maxon main gas shut-off valve, position “L”, 115/

60VAC

• Maxon main gas “blocking” shut-off valve, position

“L”, 115/60VAC00000000

®

Factory pre-wiring includes the following

components for 115 volts 60 hertz AC:

– Low fire start switch

– Combustion air pressure switch

– Combination high and low gas pressure switch

– Pilot gas solenoid valve

– Normally-open vent solenoid valve (when used)

– Spark ignition transformer

– Maxon “main” and/or “blocking” gas shut-off valve(s)

– NEMA type 12 and 13 junction box with terminal

wiring strip

Field wiring is required:

– To the packaged system's junction box wiring strip

– To the Model “400” OVENPAK® Burner's combustion

air blower motor

– Between your flame safeguard relay and the

OVENPAK® Burner's flame sensor

NOTE: A flame rod may be furnished by Maxon; UV

detector is a part of the control package when

supplied by Maxon or may be supplied by others.

– Other field wiring connections may be required if your

control circuit includes high/low temperature limits,

automatic temperature controller, and/or other

miscellaneous safety limit switches.

Page 19

®

Gas Burners

Page 2123Model “400” OVENPAK

Maxon Packaged Heater/Duct Sections

Reduce your fabrication time with a complete

combustion heater/duct including the prewired and

prepiped Model “400” OVENPAK® Burner system

package.

Easy installation is provided by flanged duct

connection joints. Burner is mounted to a .312" mild

steel wall, lined with 6" thick fiber insulation. The other

16 gauge aluminized steel heater/duct walls are ready

for your insulation.

Application flexibility is offered by three sizes of

ducts. All sizes can be fabricated to have return/inlet

opening at any 90° increment position (viewing from

the back of the OVENPAK

®

Burner). Continuous welds

on all joint seals permit duct section installation on

pressure-side or suction-side applications.

6/03

snoisnemidnoitcestcudetamixorppA )sehcnini(

ledoMAB)edisni( CD)edisni( EFGHJ)edisni( K

804-504

514

534-524

2142501638426.2126.625.773

5103621240626.4126.235.984

8163861842726.8126.835.1185

Page 20

Page 2124 Model “400” OVENPAK

®

Gas Burners

Maxon Packaged Heater/Duct Sections

Design and Application Details

Maximum discharge temperature 600°F (316°C)

Duct static pressures may range between +2" wc and -5" wc

Optimum design parameters permit up to 3000 feet per minute air velocity through return/inlet duct.

semulovriaegrahcsidmumixamdednemmoceR

®

KAPNEVO"004"ledoM

To select your packaged system, specify:

1. Quantity ________

renruB504804514524534

emulovriaegrahcsidmumixaM MFCSni

00050057000,21

2. Model “400” OVENPAK

– Arranged for UV detector, or with flame rod

– Furnished with blower motor for ___________ AC

– With low fire start switch _________ , General Purpose, 115/60 AC

– With combustion air filter assembly ____________ (optional)

– With connecting base and linkage assembly ____________ to adapt customer's automatic electric

control motor. Specify/select which one of these electric operators will be used:

– Barber-Colman #EA51–58, also with prefix MC, MP or MF

– Honeywell #M644, #M744, #M941, or #M944

– Penn/Johnson #M-80 or #M81

3. Arranged into pre-assembled and wired pipe train package, 115/60VAC,

– With Block and Bleed arrangement assembly ______________.

4. With _______ 1-1/4" or 1-1/2" Maxon Series __________ Automatic Reset, Manual Reset

Shut-Off Valve(s), for natural gas, in top assembly position “L” for 115/60VAC

– With electrical terminal block (option)

– With 6 second, or 2.5 second opening time (automatic reset valve(s) only)

– With ______________ auxiliary signal switch(es) (optional)

NOTE: Specify which switch(es) go in main valve and which switch(es) in blocking valve, if different.

®

Gas Burner Assembly _________, for natural gas

5. With heater/duct section assembly ____________ (optional)

with return/inlet duct positioned on top, right, bottom, or left

Page 21

®

Gas Burners

Page 2125Model “200” OVENPAK

Model “200” OVENPAK

®

Burners

Model “200” OVENPAK® Gas Burners

provide a broad range of heat without a

combustion blower by firing through-the-wall

into your combustion chamber on the suction

side of the circulating fan. An internal mixing

cone blends air drawn through the burner (by

chamber suction) with fuel gas delivered

through its central gas nozzle. The Model

“200” OVENPAK

® Burner is designed for

applications involving suction-side firing from -

0.2" to -1.6" wc static chamber conditions.

They provide:

– low initial and operating cost

Model “200” OVENPAK

Burner arranged with air inlet

guard and optional UV scanner

®

– easy installation

– simple adjustment

– heavy duty cast iron construction in a

compact burner configuration

Performance data

NOTE: Maximum capacity varies with the range of suction provided at operating temperature

atadecnamrofreP

noitcusrebmahcnoitsubmoC )cw"( 2.0-3.0-4.0-5.0-6.0-7.0-8.0-9.0-0.1-6.1-

yticapacmumixaM )rh/utBs'0001(

yticapacmuminiM )rh/utBs'0001(

emulovrianoitsubmoC )MFCS(deriuqer

erusserplaitnereffidsaglarutaN )cw"(deriuqer

erusserplaitnereffidsagenaporP )cw"(deriuqer

shtgnelemalfetamixorppA fodnednoyeb

)sehcni(eveelsegrahcsid

0010915720630540455260070080001

01213141517181910252

56080959011021031531541481

1.04.07.02.19.17.27.36.40.64.9

------3.05.08.01.15.18.14.28.3

3-09-681-2112-5142-8172-1203-4262-42

Air volumes shown are for burners without damper,

or with damper in full-open position. If damper is used

to restrict air flow, maximum capacity will be similarly

reduced.

Pilot flame issues from the same gas ports as

main flame, so proof of pilot gas ignition assures

ignition of main gas supply.

Flame sensing can be either by flame rod or UV

scanner when natural gas is the fuel, but only with UV

scanner if propane is the fuel.

Installation is simple, utilizing the built-in, directmounting flange provided.

A complete combustion system utilizing Model

“200” OVENPAK® Burners also includes gas train,

fuel-throttling valve and control system. Your Maxon

representative can help you choose from the broad

range of options available.

seiticapacmumixaM laitnereffidsagleufgnidnopserrochtiw)rh/utBs'0001(

snoitidnocerusserpcitatsrebmahcnoitsubmoccificepstaserusserp

Typical pipe train

12/89

Page 22

Page 2126 Model “200” OVENPAK

Design and Application Details

®

Gas Burners

Differential gas pressures in inches water column

(" wc) for both natural gas and propane are those that

should be measured by connecting a manometer

between test points shown in the photo below.

Model “208” OVENPAK® Burner shown with air damper

and flame rod

Suction (shown in inches wc) should be that

available at operating temperature. It can be determined by a two-step procedure: First, measure cold

suction (chamber to atmosphere). Second, multiply

that reading by the correction factor shown in Graph

"A" for your desired operating temperature.

For example, if you anticipate running the system at 600°F,

follow that dotted line to the right until it intersects curve,

then read downward to a correction factor of 0.5. Therefore,

if you read a cold suction of 1" wc, your expected suction

“at temperature” would be 1" x 0.5 = 0.5" wc.

Dimensions (in inches)

Burner

Assembly

Flame Rod Assembly

Loading...

Loading...