Grieve Corporation 3504 Installation Manual

SERIES

User guide

3500

E

UROTHERM

ENG

3508 and 3504 Process Controllers

Contents

1. CHAPTER 1 INSTALLATION...........................................................................................................................3

1.1 What Instrument Do I Have?...........................................................................................................................................3

1.2 3504 and 3508 Ordering Code ......................................................................................................................................... 6

1.3 Configuration Code (Quick Start Code) ..........................................................................................................................8

1.4 How to Install the Controller ........................................................................................................................................ 12

1.5 Electrical Connections .................................................................................................................................................. 15

1.6 Standard Connections................................................................................................................................................... 16

1.7 Plug in I/O Module Connections ...................................................................................................................................22

1.8 Digital Communications Connections ........................................................................................................................... 29

2. CHAPTER 2: GETTING STARTED..................................................................................................................39

2.1 Quick Start - New Controller (Unconfigured) ............................................................................................................... 39

2.2 To Re-enter Quick Start Mode ...................................................................................................................................... 48

2.3 Normal Operation ........................................................................................................................................................ 49

2.4 The Operator Buttons................................................................................................................................................... 51

2.5 To Set The Required Temperature (Setpoint) ............................................................................................................... 53

2.6 To Select Manual Operation ......................................................................................................................................... 54

2.7 Alarm Indication........................................................................................................................................................... 55

2.8 Message Centre ............................................................................................................................................................ 57

2.9 Introduction to Configuration using iTools................................................................................................................... 69

2.10 Device panel................................................................................................................................................................. 72

2.11 User Pages Editor.......................................................................................................................................................... 73

2.12 Recipe Editor in iTools .................................................................................................................................................. 75

2.13 Program Editor ............................................................................................................................................................. 77

2.14 Graphical Wiring Editor ................................................................................................................................................ 80

2.15 User Text ...................................................................................................................................................................... 83

2.16 Loop Naming ................................................................................................................................................................ 87

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 1

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 2

3. CHAPTER 3 SAFETY AND EMC INFORMATION ........................................................................................... 88

3.1 GENERAL .......................................................................................................................................................................88

3.2 Service and repair .........................................................................................................................................................89

3.3 Installation Safety Requirements ..................................................................................................................................90

3.4 Installation Requirements for EMC................................................................................................................................93

4. CHAPTER 4 TECHNICAL SPECIFICATION..................................................................................................... 94

4.1 Control Options ............................................................................................................................................................94

4.2 Display ..........................................................................................................................................................................94

4.3 Standard Digital I/O ......................................................................................................................................................95

4.4 All Analogue and PV Inputs...........................................................................................................................................95

4.5 PV Input........................................................................................................................................................................96

4.6 Analogue Input Module ................................................................................................................................................98

4.7 Digital Input Modules ...................................................................................................................................................99

4.8 Digital Output Modules.................................................................................................................................................99

4.9 Analogue Output Modules ............................................................................................................................................99

4.10 Transmitter PSU ............................................................................................................................................................99

4.11 Transducer PSU.............................................................................................................................................................99

4.12 Potentiometer Input ...................................................................................................................................................100

4.13 Digital communications ..............................................................................................................................................100

4.14 Master communications .............................................................................................................................................. 100

4.15 Alarms ........................................................................................................................................................................100

4.16 Setpoint programmer.................................................................................................................................................. 100

4.17 I/O Expander ............................................................................................................................................................... 101

4.18 Advanced functions ....................................................................................................................................................101

4.19 General specification ..................................................................................................................................................102

Issue status of this manual

Issue 7 section 4.19 - ‘With Ethernet or DeviceNet module fitted product is only suitable for industrial environments,

(class A emissions)’.

3508 and 3504 Process Controllers

1. Chapter 1 Installation

1.1 What Instrument Do I Have?

Thank you for choosing this Controller.

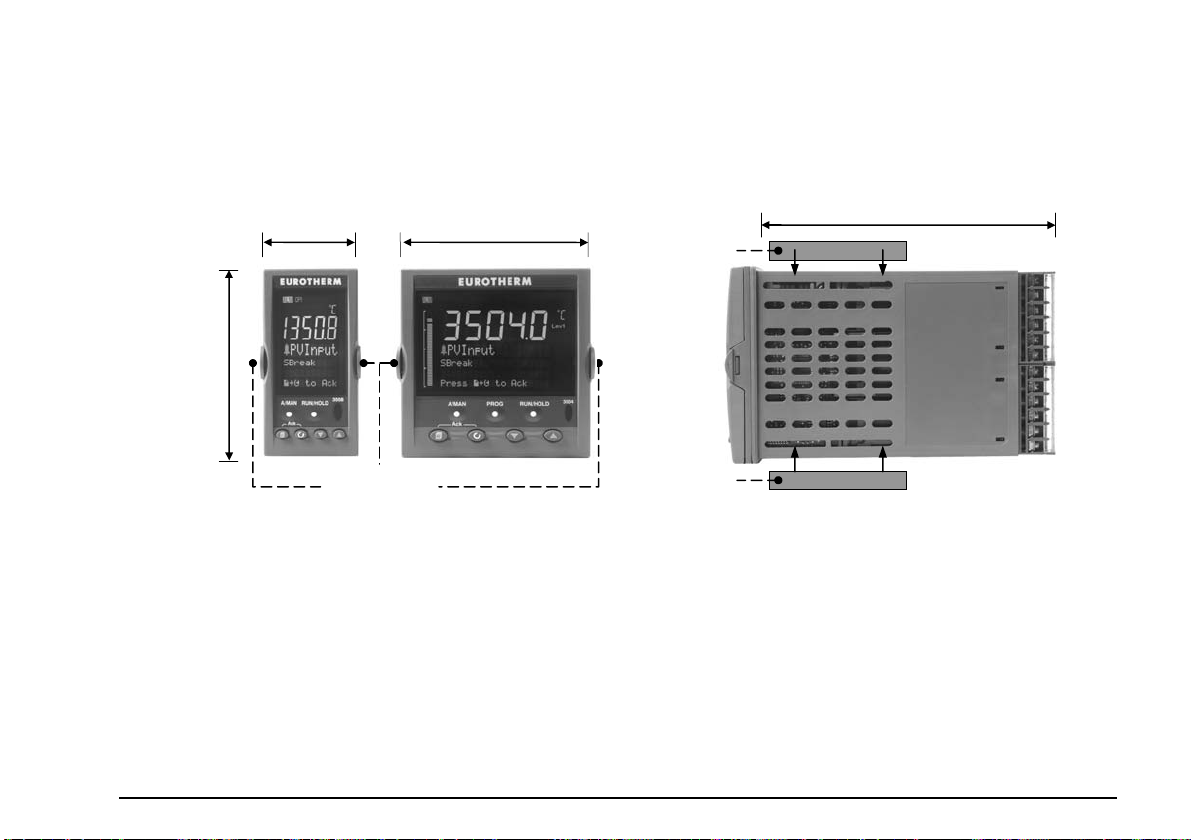

The 3508 controller is supplied in the standard 1/8 DIN size

(48 x 96mm front panel). The 3504 controller is supplied in

the standard ¼ DIN size (96 x 96mm front panel). They are

intended for permanent installation, for indoor use only, in

an electrical panel which encloses the rear housing,

terminals and wiring on the back.

Whenever the symbol

☺ appears in this handbook it indicates a helpful hint

3508 Controller 3504 Controller

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 3

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 4

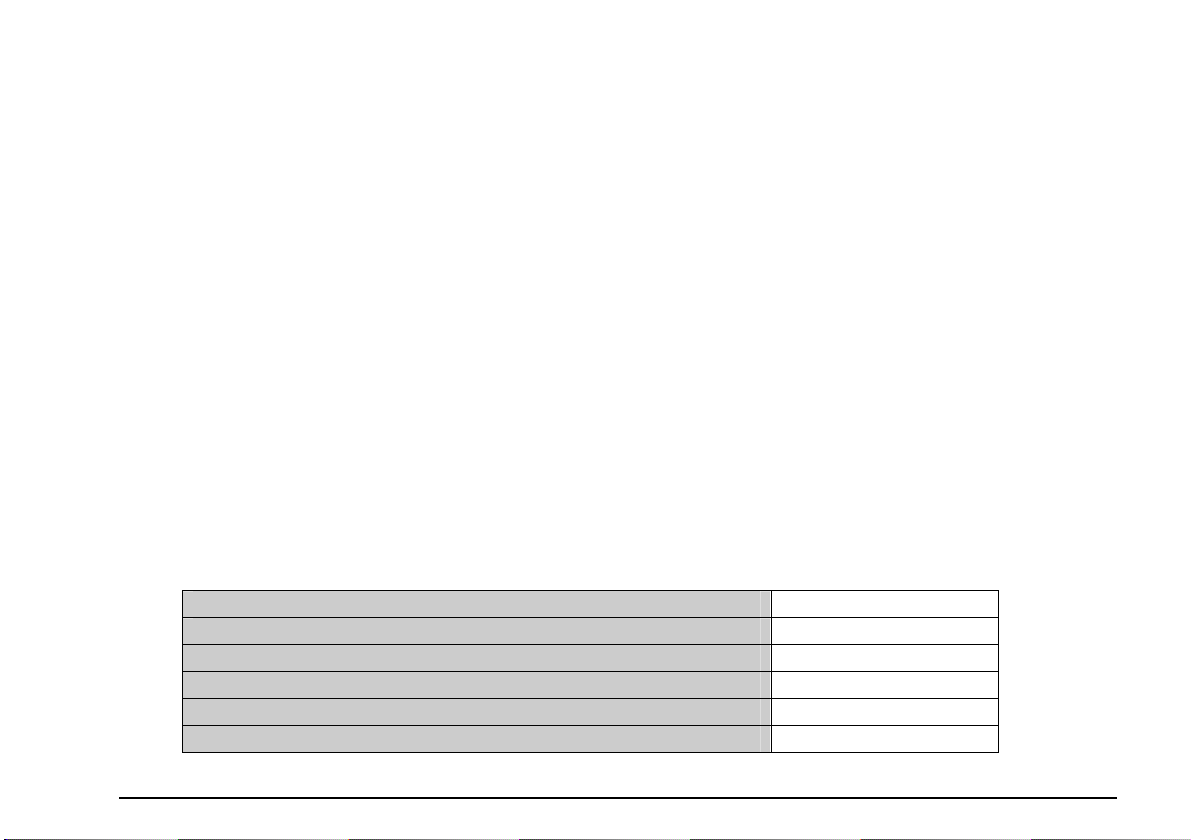

1.1.1 Contents of Package

When unpacking your controller please check that the following items have been included.

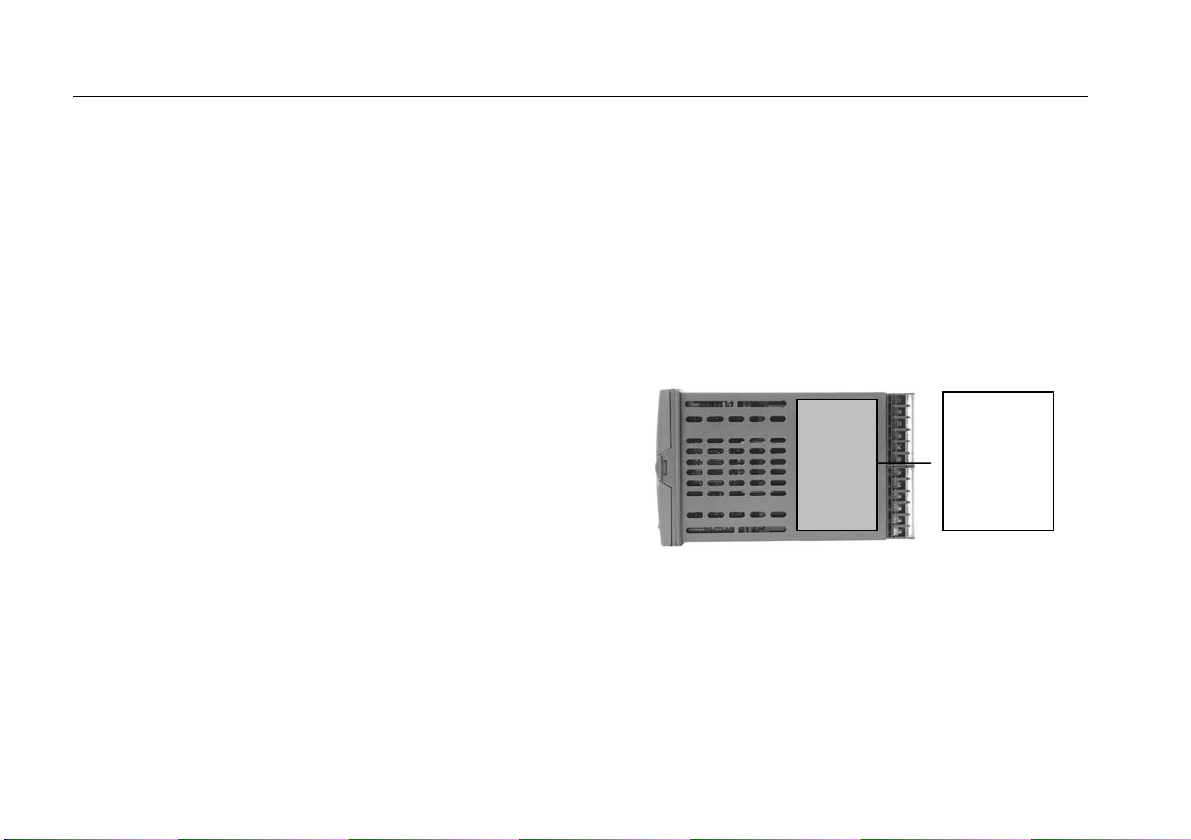

1.1.1.1 3508 or 3504 Controller Mounted in its Sleeve

The 3504 contains up to six plug-in hardware modules; the 3508 has up to three. Additionally digital communications

modules can be fitted in two positions.

The modules provide an interface to a wide range of plant devices and those fitted are identified by an ordering code

printed on a label fixed to the side of the instrument. Check this against the description of the code given in section

1.2 to ensure that you have the correct modules for your application. This code also defines the basic functionality of

the instrument which may be:-

• Controller only

• Programmer and controller

• Control type – Standard PID, valve positioner

• Digital communications type

• Options

Label

showing:-

Instrument

Order

Code

1.1.1.2 Panel Retaining Clips

Two clips are required to secure the instrument sleeve in the panel. These are supplied fitted to the sleeve.

1.1.1.3 Accessories Pack

For each input a 2.49Ω resistor is supplied for mA measurement. This will need to be fitted across the respective input

terminals

1.1.1.4 This User Guide

Issue 6 of this guide applies to instrument software versions, V2.30+, and explains:-

• How to install the controller

• Physical wiring to the plant devices

• First switch on - ‘out of the box’.

• Principle of operation using the front panel buttons

• Introduction to configuration through iTools PC software

• Ethernet adaptor if Ethernet communications has been ordered

1.1.2 Accessories

The following accessories may be ordered:-

Engineering Manual This may also be downloaded from www.eurotherm.co.uk HA027988

2.49Ω Precision resistor SUB35/ACCESS/249R.1

Configuration IR Clip ITools/None/30000IR

Configuration Clip ITools/None/30000CK

10In,10Out IO Expander 2000IO/VL/10LR/XXXX

20In,20Out IO Expander 2000IO/VL/20LR/20LR

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 5

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 6

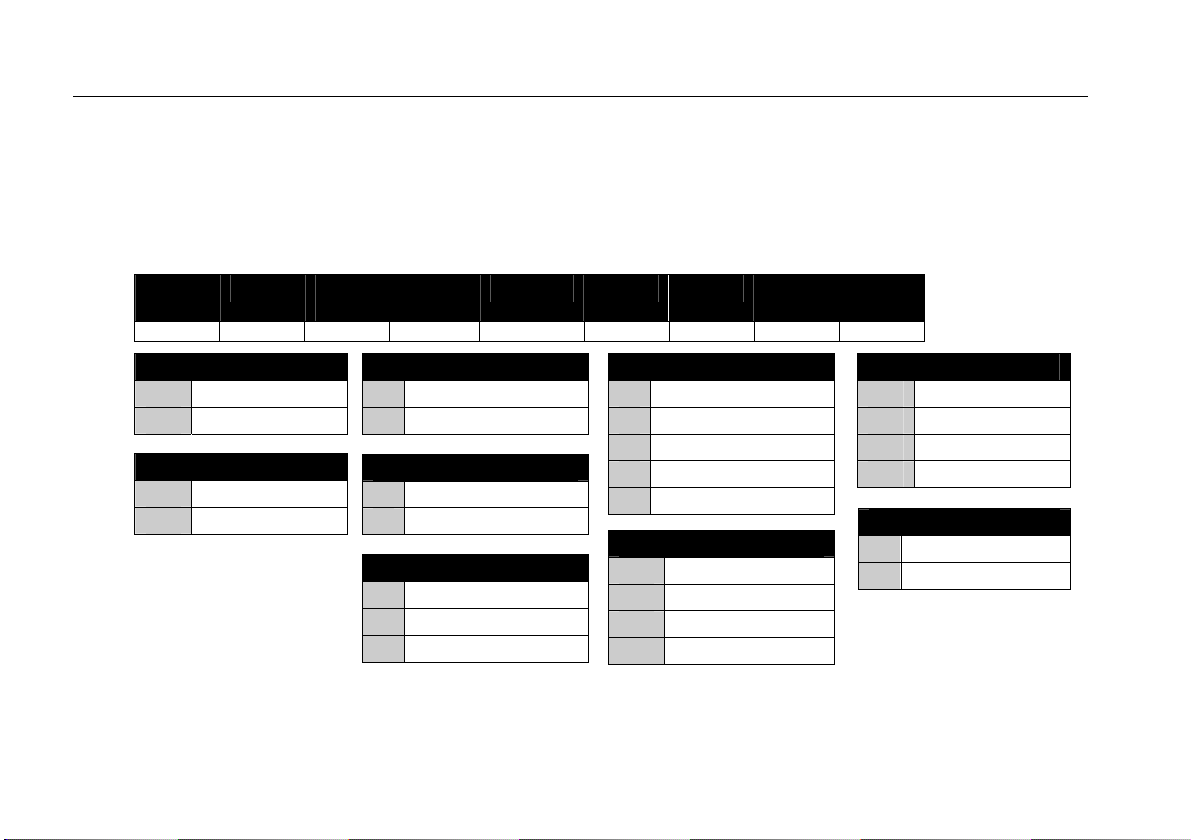

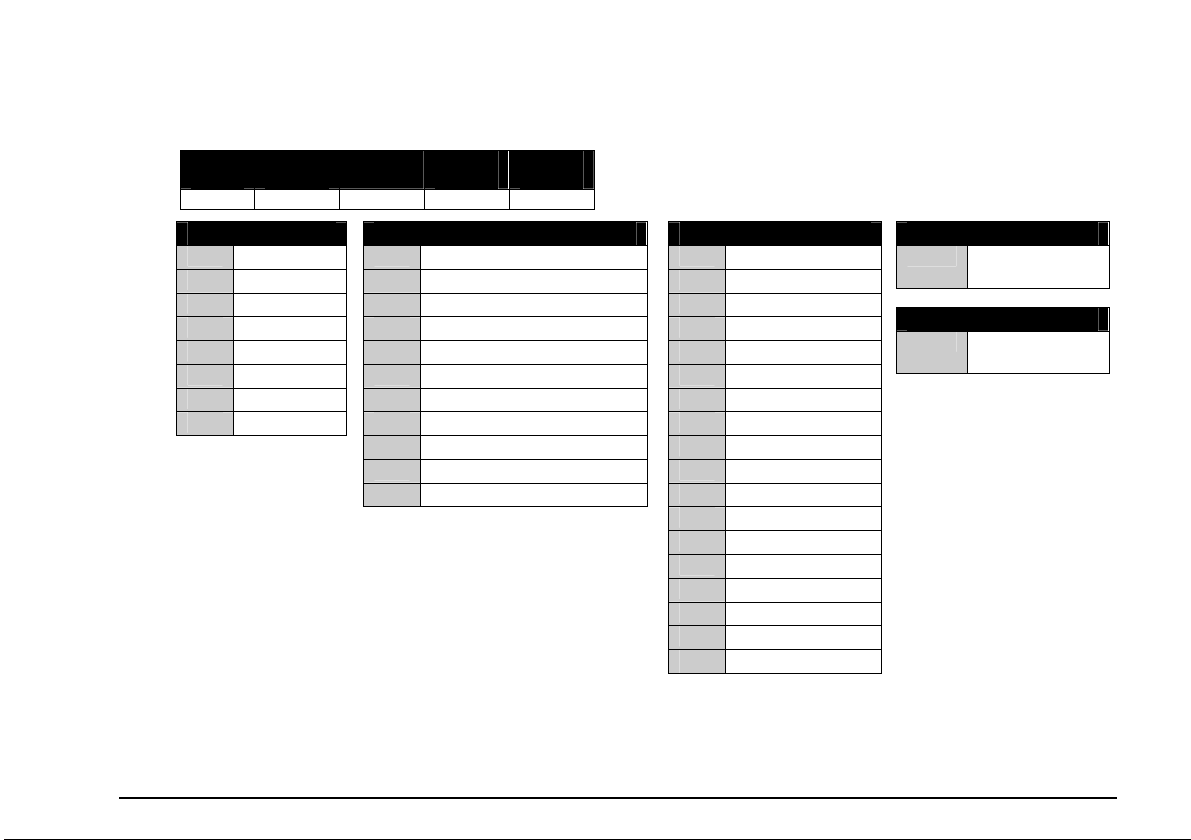

1.2 3504 and 3508 Ordering Code

The controller may have been ordered in accordance with the hardware code listed below. Alternatively, it may have

been ordered by quoting the ‘Quick Code’ listed in section 1.4. If ordered to the quick code the controller will be

configured in the factory. If it is not ordered using the quick code then it will be necessary to configure the controller

when it is first switched on. This is described in Chapter 2.

Hardware/Options Coding

Model

Number

3504 3504 Standard

3508 3508 Standard

CC Standard

F Profibus

(1) Provides Valve Position

option in Heat/Cool

applications. Single channel

VP included as standard.

Example (order code)

3504/CC/VH/2/XX/50/X/S/R2/D4/AM/XX/XX/XX/A2/XX/XX/ENG/ENG/XXXXX/XXXXX

This code describes a two loop 3504 with 50 programs. Additionalmodules for dual relay, analogue control, analogue input and EIA232

communications. English language and manuals with silver fascia.

Function Supply

Model Number

Function

Voltage

Number of

Loops

Supply Voltage

VH 100-240Vac

VL 20-29Vac/dc

Loops

1 One loop

2 Two loops

Application

XX Standard

ZC Zirconia

VP Dual Valve Position (1)

Application Programs Recipes Toolkits Fascia

Programs

X No programs

1 1 prog 20 segments

10 10 prog 500 segments

25 25 prog 500 segments

50 50 prog 500 segments

X No recipe

1 1 recipe

4 4 recipes

8 8 recipes

Recipes

XXX Std 30 wires

60 60 wires

120 120 wires

250 250 wires

G Eurotherm green

S Silver

Toolkit Wires

Fascia

Input and Output Modules

I/O Slot 1 I/O Slot 2 I/O Slot 3 I/O Slot 4

IO Slots 1, 2, 3, 4 (2), 5 (2), 6 (2)

XX None fitted

R4 Change over relay

R2 2 pin relay

RR Dual relay

T2 Triac

TT Dual triac

D4 DC control

DO Dual DC output 4-20mA

OP/24Vdc. Slots 1, 2 and 4 only

AM Analogue input (not slot 2 or 5)

D6 DC retransmission

TL Triple logic input

TK Triple contact input

TP Triple logic output

VU Potentiometer input

MS 24Vdc transmitter PSU

G3 Transducer PSU 5 or 10Vdc

LO Isolated single logic output

(2). I/O slots 4, 5 and 6 are only available on the 3504

(3). Only available with the Profibus Controller

(2)

I/O Slot 5

XX Not Fitted

A2 232 Modbus

Y2 2-wire 485 Modbus

F2 4-wire 485 Modbus

AE 232 EI-Bisynch

YE 2-wire 485 EI-Bisynch

FE 4-wire 485 EI-Bisynch

ET Ethernet 10base

PB Profibus (3)

PD Profibus with D type

DN Devicenet

XX Not Fitted

A2 232 Modbus

Y2 2-wire 485 Modbus

F2 4-wire 485 Modbus

EX IO Expander

(2)

I/O Slot

6 (2)

H Comms Slot

connector (3)

J Comms Slot

H Comms

Slot

J Comms

Slot

XX None

IT Standard iTools (CD

ENG English

FRA French

GER German

SPA Spanish

ITA Italian

ENG English

FRA French

GER German

SPA Spanish

ITA Italian

XXX None

Config

Tools

Config Tools

only)

Product Language

Manuals Language

Product

Language

Manuals

Language

XXXXX Standard

WL005 Extended 5 year

XXXXX None

CERT1 Cert of conformity

CERT2 Factory input

Warranty Calibration

Certificate

Warranty

Calibration Certificate

calibration per

input

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 7

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 8

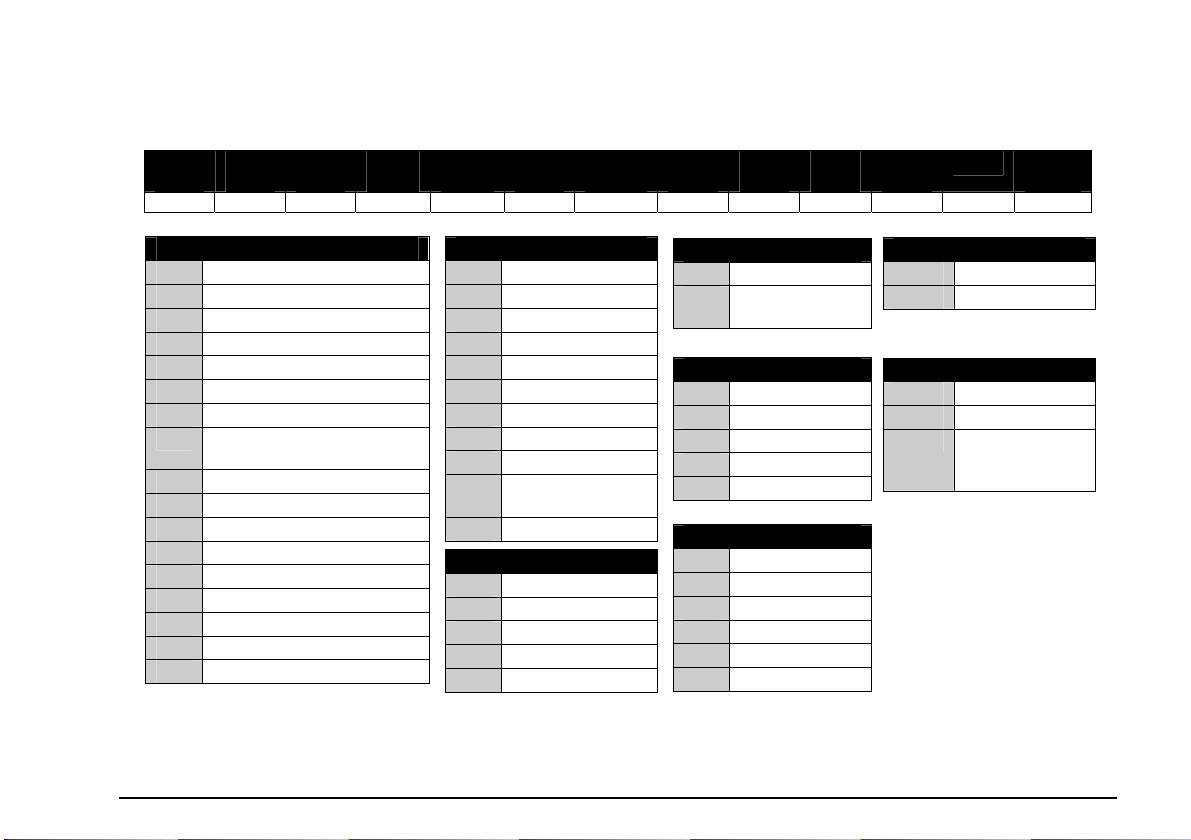

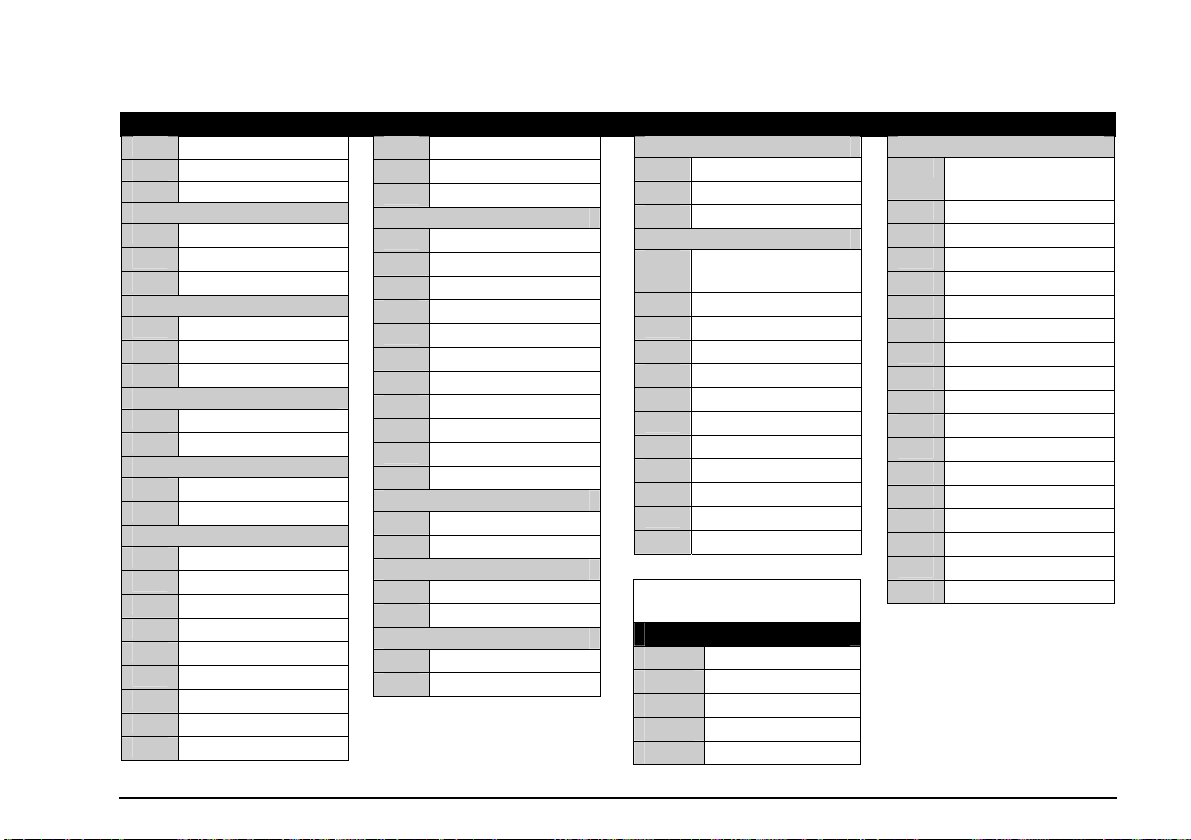

1.3 Configuration Code (Quick Start Code)

Loop 1

Config Loop 1

STD Standard

CFG Factory

Loop 1 units

C Centigrade

F

% Percent

H %RH

P PSI

B Bar

M mBar

X None

Units

Config

config (1)

configured

Fahrenheit

1. If standard config is selected an instrument without

configuration will be supplied.

Loop 1

Function

PX

FX

VX

NX

PP

PN

FF

VV

PF

PV

Loop 1 PV Loop 1

Range Lo

Loop 1 Function

Single Chan. PID

Single Chan. VP with Feedback

Single Chan. VP without Feedback

Single Chan. On/Off

Dual Chan. PID

Dual Chan. PID/OnOff

Dual Chan. VP with Feedback

Dual Chan. VP without Feedback

Dual Chan. PID/VP with Feedback

Dual Chan. PID/VP without

Loop 1

Range Hi

X

J

K

T

L

N

R

S

B

P

C

Z

A

Y

W

G

V

Q

Loop 1 PV

Unconfigured

J Thermocouple

K Thermocouple

T Thermocouple

L Thermocouple

N Thermocouple

R Thermocouple

S Thermocouple

B Thermocouple

Platinell II

C Thermocouple

Pt 100

4-20mA Linear

0-20mA Linear

0-5Vdc Linear

1-5Vdc Linear

0-10Vdc Linear

Custom Curve

Loop 1 Range Low

XXXXX

Loop 1 Range High

XXXXX

Enter value with

decimal point

Enter value with

decimal point

Loop 2

Loop 2

Units

C

F

%

H

P

B

M

X

(2). If C or F units are selected they must be the same for both loops.

If C or F are not selected for Loop 1 they cannot be selected for Loop 2

Loop 2

Function

Loop 2 Units

Centigrade (2)

Fahrenheit (2)

Percent

%RH

PSI

Bar

mBar

None

Loop 2 PV Loop 2

XX

Single Loop Only

PX

Single Chan. PID

FX

Single Chan. VP with Feedback

VX

Single Chan. VP without Feedback

NX

Single Chan. On/Off

PP

Dual Chan. PID

PN

Dual Chan. PID/OnOff

FF

Dual Chan. VP with Feedback

VV

Dual Chan. VP without Feedback

PF

Dual Chan. PID/VP with Feedback

PV

Dual Chan. PID/VP without

Range Lo

Loop 2 Function

Loop 2

Range Hi

Loop 2 PV

X

Unconfigured

J

J Thermocouple

K

K Thermocouple

T

T Thermocouple

L

L Thermocouple

N

N Thermocouple

R

R Thermocouple

S

S Thermocouple

B

B Thermocouple

P

Platinell II

C

C Thermocouple

Z

Pt 100

A

4-20mA Linear

Y

0-20mA Linear

W

0-5Vdc Linear

G

1-5Vdc Linear

V

0-10Vdc Linear

Q Custom Curve

Loop 2 Range Low

XXXXX

Loop 2 Range High

XXXXX

Enter value with

decimal point

Enter value with

decimal point

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 9

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 10

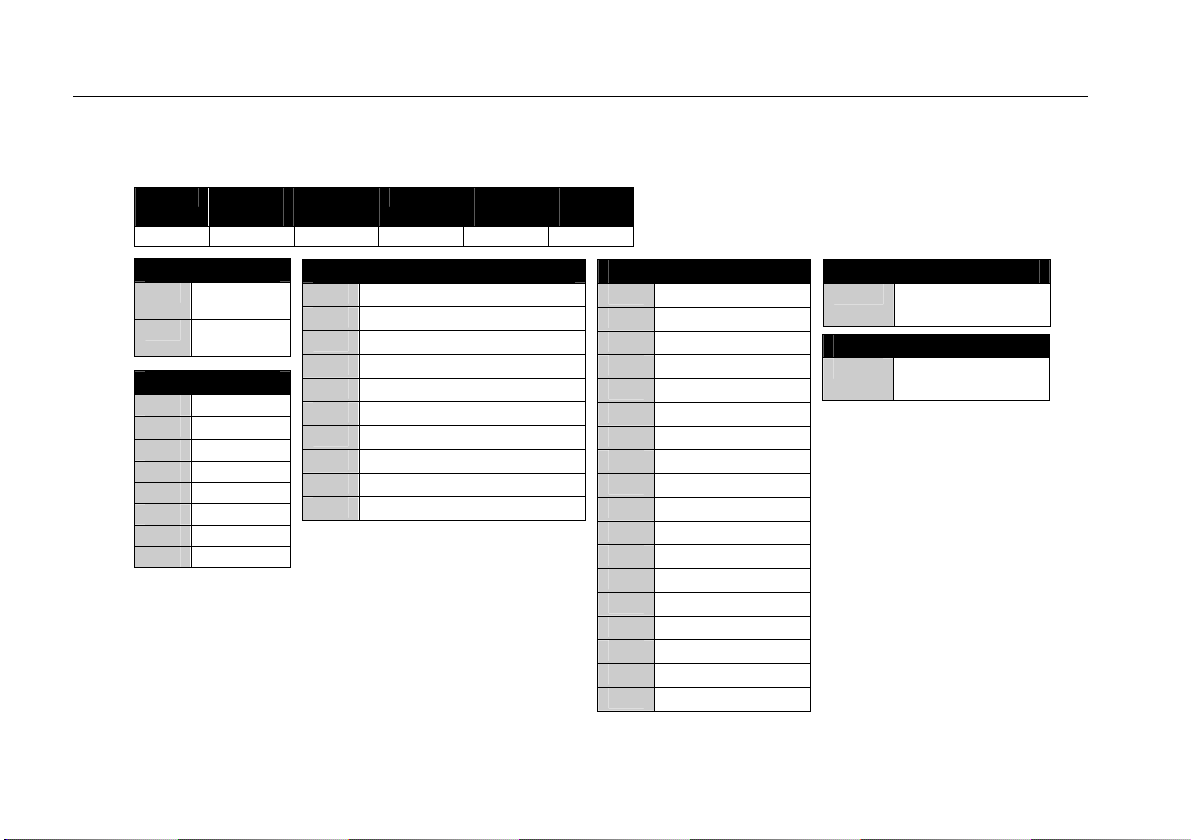

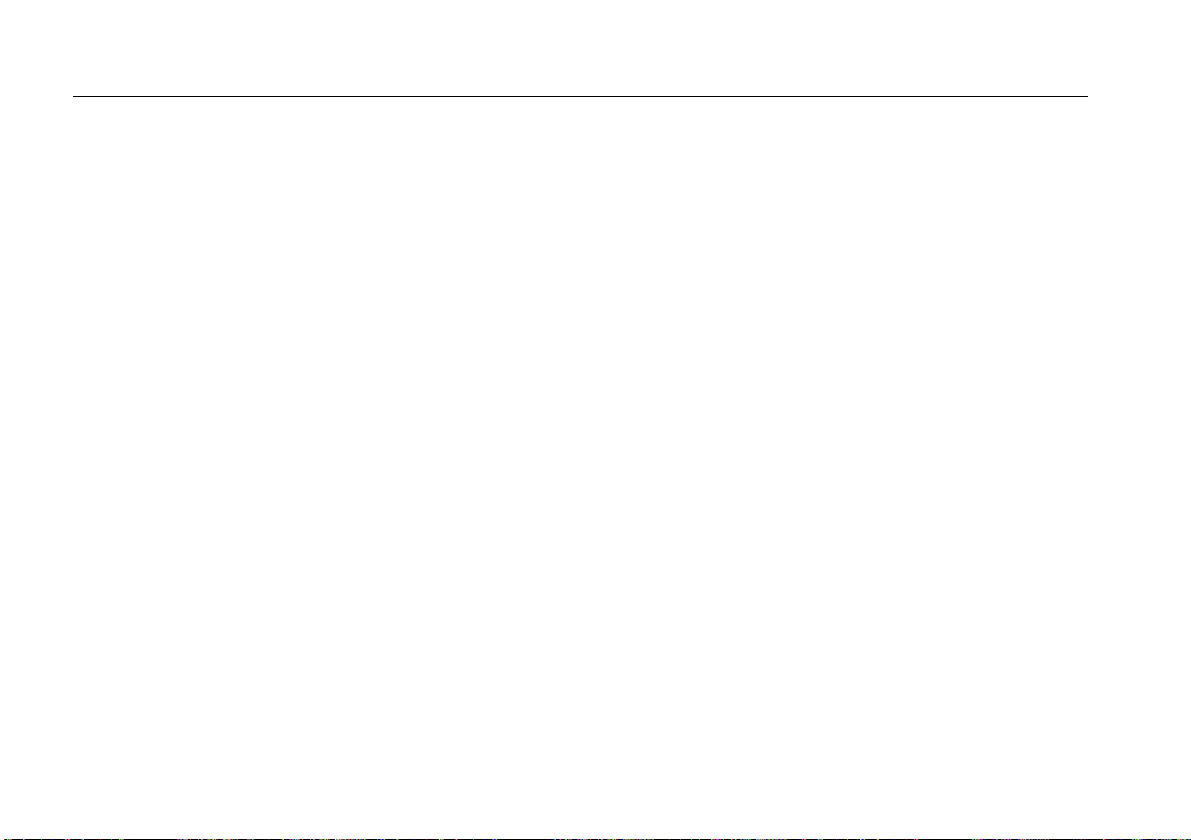

Alarms and Input/Outputs

Alarm 1 Alarm 2 Alarm 3 Alarm 4 Logic

Alarm 1

XXX

1_ _ Loop 1

2_ _ Loop 2

_FH

_FL

_DH

_DL

_DB

Alarm 2

XXX

1_ _ Loop 1

2_ _ Loop 2

_FH

_FL

_DH

_DL

_DB

Unconfigured

Full scale high

Full scale low

Deviation high

Deviation low

Deviation band

Unconfigured

Full scale high

Full scale low

Deviation high

Deviation low

Deviation band

Alarm 3

XXX

Unconfigured

1_ _ Loop 1

2_ _ Loop 2

_FH

Full scale high

_FL

Full scale low

_DH

Deviation high

_DL

Deviation low

_DB

Deviation band

Alarm 4

XXX

Unconfigured

1_ _ Loop 1

2_ _ Loop 2

_FH

Full scale high

_FL

Full scale low

_DH

Deviation high

_DL

Deviation low

_DB

Deviation band

LA

Logic

LB

Logic LA

XX

1_ Loop 1

2_ Loop 2

_B

_M

_H

_C

_R

_S

A_ Alarm

_A

_1

_2

P_ Programmer

_R

_H

_A

_1

_2

Relay

AA

Unconfigured

Sensor Break

Manual Select

Control Ch1 OP

Control Ch2 OP

Remote SP

Setpoint 2 Enable

Acknowledge All Alarms

Alarm 1 OP

Alarm 2 OP

Run

Hold

Reset

Prg Ch1 Event 1

Prg Ch1 Event 2

I/O Slot 1 I/O Slot 2 I/O Slot 3 I/O Slot

Logic LB

XX

Unconfigured

1_ Loop 1

2_ Loop 2

_B

Sensor Break

_M

Manual Select

_H

Ch1 OP

_C

Ch2 OP

_R

Remote SP

_S

Setpoint 2 Enable

A_ Alarm

_A

Acknowledge All Alarms

_1

Alarm 1 OP

_2

Alarm 2 OP

P_ Programmer

_R

Run

_H

Hold

_A

Reset

_1

Prg Event 1

_2

Prg Event 2

4 (3)

I/O Slot

5 (3)

Relay AA

XX

Unconfigured

1_ Loop 1

2_ Loop 2

_H

Control Ch1 OP

_C

Control Ch2 OP

_B

Sensor Break

SB

Sensor Break

(any loop)

A_ Alarm

_A

Any Alarm Active

_N

New Alarm

Active

_1

Alarm 1 OP

_2

Alarm 2 OP

P_ Programmer

_1

Prg Event 1

_2

Prg Event 2

I/O Slot

6 (3)

(3). I/O slots 4, 5 and 6 are only available on the 3504.

XXX

Unconfigured

1_ _ Loop 1

2_ _ Loop 2

Changeover Relay

_HX

Control Ch1 OP

_CX

Control Ch2 OP

_BX

Sensor Break

2-Pin Relay

_HX

Control Ch1 OP

_CX

Control Ch2 OP

_BX

Sensor Break

Single Logic

_HX

Control Ch1 OP

_CX

Control Ch2 OP

Single Triac

_HX

Control Ch1 OP

_CX

Control Ch2 OP

Dual Relay

_HC

Ch1 OP & Ch2

_VT

VP Ch1

_VR

VP Ch2

P12

Prg Event 1 & 2

P34

Prg Event 3 & 3

P56

Prg Event 5 & 6

P78

Prg Event 7 & 8

A12

Alarm 1 & 2 OP

A34

Alarm 3 & 4 OP

Slot Functions 1 – 6 CH1 = Heat, CH2 = Cool

HHX

Ch1 OP for loops 1 & 2

CCX

Ch2 OP for loops 1 & 2

SBR

Sensor Break both loops

Dual Triac

_HC

Ch1 OP & Ch2

_VT

VP Ch1

_VR

VP Ch2

P12

Prg Ch1 Event 1 & 2

P34

Prg Ch1 Event 3 & 3

P56

Prg Ch1 Event 5 & 6

P78

Prg Ch1 Event 7 & 8

A12

Alarm 1 & 2 OP

A34

Alarm 3 & 4 OP

HHX

Ch1 OP for loops 1 & 2

CCX

Ch2 OP for loops 1 & 2

DC Control

_H_

Ch1 OP

_C_

Ch2 OP

DC Retransmission *

_T_

PV Retransmission

_S_

SP Retransmission

Analogue Input *

2PV

Loop 2 PV

_R_

Remote SP

Potentiometer Input *

_RS

Remote SP

_VF

VP Feedback Ch1

_VG

VP Feedback Ch2

Triple Logic Input

_ _ _

Select function below

for each channel

X

Unconfigured

M

Loop 1 Manual

N

Loop 2 Manual

Q

Loop 1 Remote SP

V

Loop 2 Remote SP

S

Loop 1 Setpoint 2

T

Loop 2 Setpoint 2

E

Acknowledge All Alarms

P

Program Run

R

Program Reset

H

Program Hold

* For range, select from Table A

below

Table 1

A 4-20mA Linear

Y 0-20mA Linear

W 0-5Vdc Linear

G 1-5Vdc Linear

V 0-10Vdc Linear

Triple Logic OP

_ _ _

Select function below

for each channel

X

Unconfigured

F

Loop 1 Ch1 OP

G

Loop 1 Ch2 OP

K

Loop 2 Ch1 OP

L

Loop 2 Control Ch2 OP

A

Alarm 1 OP

B

Alarm 2 OP

C

Alarm 3 OP

D

Alarm 4 OP

1

Program Event 1

2

Program Event 2

3

Program Event 3

4

Program Event 4

5

Program Event 5

6

Program Event 6

7

Program Event 7

8

Program Event 8

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 11

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 12

1.4 How to Install the Controller

This instrument is intended for permanent installation, for indoor use only, and to be enclosed in an electrical panel.

Select a location where minimum vibrations are present and the ambient temperature is within 0 and 50

122oF).

The instrument can be mounted on a panel up to 15mm thick.

To assure IP65 and NEMA 4 front protection, use a panel with smooth surface texture.

Please read the safety information, at the end of this guide, before proceeding and refer to the EMC Booklet part

number HA025464 for further information. This and other relevant manuals may be downloaded from

www.eurotherm.co.uk.

o

C (32 and

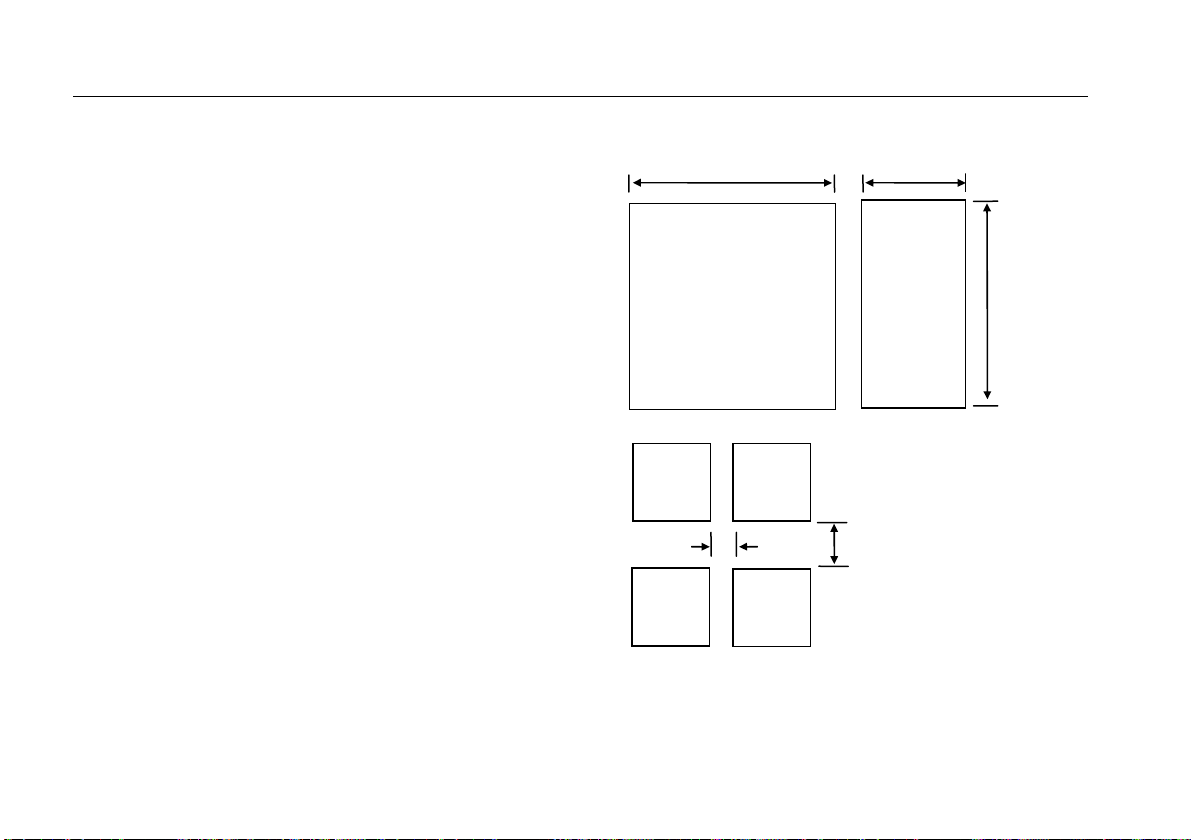

1.4.1 Dimensions

96mm

(3.78in)

48mm

(1.89in)

Latching ears

96mm

(3.78in)

150mm (5.91in)

Panel

retaining clips

Panel

retaining clips

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 13

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 14

1.4.2 To Install the Controller

1.4.2.1 Panel Cut-out

1. Prepare the panel cut-out to the size shown in the

diagram

2. Insert the controller through the cut-out.

3. Spring the panel retaining clips into place. Secure the

controller in position by holding it level and pushing

both retaining clips forward.

4. Peel off the protective cover from the display

1.4.2.2 Recommended Minimum Spacing

5. The recommended minimum spacing between

controllers shown here should not be reduced to allow

sufficient natural air flow

1.4.3 Unplugging the Controller

The controller can be unplugged from its sleeve by easing the latching ears outwards and pulling it forward out of the

sleeve. When plugging it back into its sleeve, ensure that the latching ears click back into place to maintain the IP65

sealing.

92 mm - 0.0 + 0.8

3.62 in -0.00, +0.03

3504

10mm

(0.4 in)

45 mm - 0.0 + 0.6

1.77 in -0.00, +0.02

3508

38mm

(1.5 in)

(Not to scale)

92 mm -

0.0 + 0.8

3.62 in -

0.00, +0.03

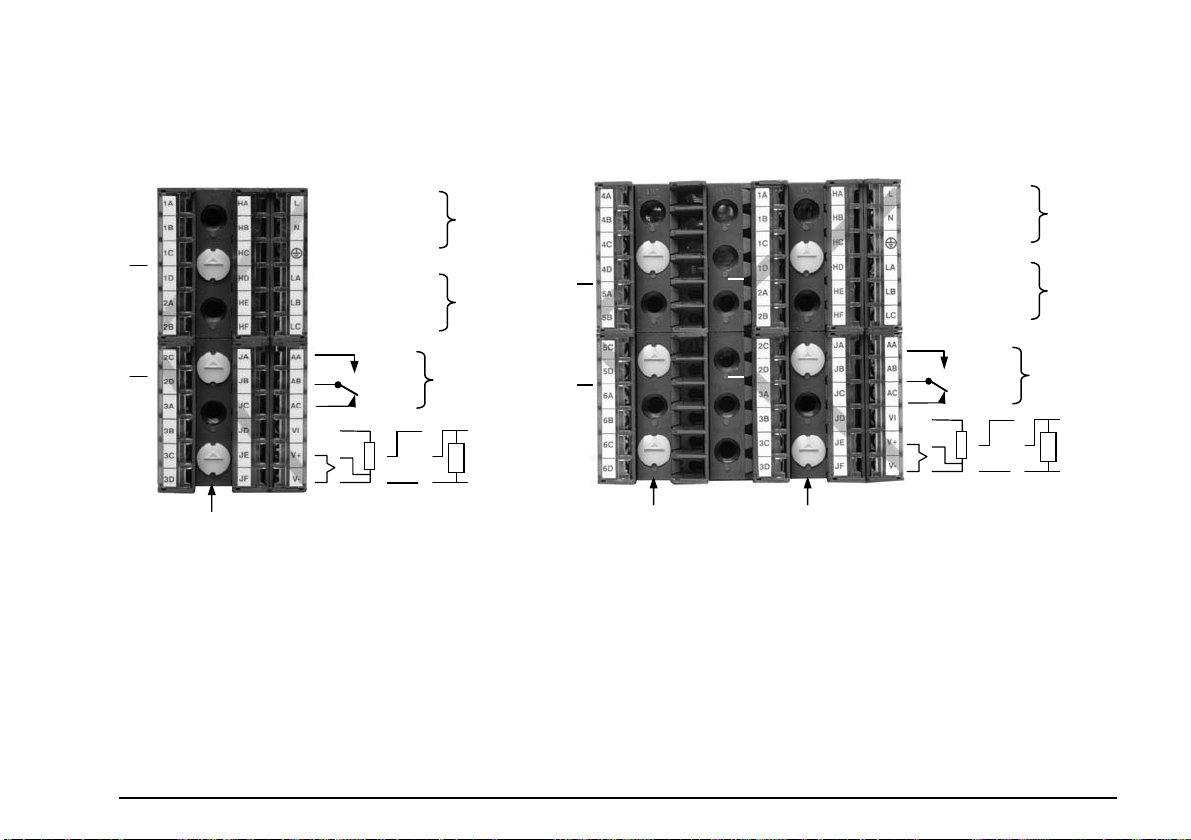

1.5 Electrical Connections

3508

Live or 24V

Neutral or 24V

MODULE 1 MODULE 2 MODULE 3

Polarising Keys (1)

One per module

(1) Polarising keys are intended to prevent modules which are not supported in this controller from being fitted into

the controller. An example might be an unisolated module (coloured red) from a 2400 controller series. When

pointing towards the top, as shown, the key prevents a controller, fitted with an unsupported module, from being

plugged into a sleeve which has been previously wired for isolated modules. If an unisolated module is to be fitted, it

is the users responsibility to ensure that it is safe to install the controller in the particular application. When this has

been verified the polarising key may be adjusted with a screwdriver to point in the down direction.

(2) High or low voltage versions are orderable. Ensure you have the correct version

Ground

Logic I/O A

Logic I/O B

COMMS MODULE 1 COMMS MODULE 1

Logic I/O Com

T/C RTD mV mA

(2)

PV Input

Power

Supply

(2)

Digital

Inputs/

Outputs

Fixed Relay

(form C)

3504

PV Input

(2)

(2)

Power

Supply

Digital

Input/

Outputs

Fixed Relay

(form C)

Live or 24V

Neutral or 24V

COMMS MODULE H COMMS MODULE J

Ground

Logic I/O A

Logic I/O B

Logic I/O Com

MODULE 4 MODULE 5 MODULE 6

MODULE 1 MODULE 2

MODULE 3

Polarising Keys (1)

One per module

T/C RTD mV mA

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 15

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 16

1.5.1 Wire Sizes

The screw terminals accept wire sizes from 0.5 to 1.5 mm (16 to 22AWG). Hinged covers prevent hands or metal

making accidental contact with live wires. The rear terminal screws should be tightened to 0.4Nm (3.5lb in).

1.6 Standard Connections

These are connections which are common to all instruments in the range.

1.6.1 PV Input (Measuring Input)

Notes:

1. Do not run input wires together with power cables

2. When shielded cable is used, it should be grounded at one point only

3. Any external components (such as zener barriers, etc) connected between sensor and input terminals may cause

errors in measurement due to excessive and/or un-balanced line resistance or possible leakage currents

4. Not isolated from logic I/O A and logic I/O B

1.6.1.1 Thermocouple or Pyrometer Input

VI

V+

V-

Use the correct type of thermocouple compensating cable, preferably shielded, to extend wiring

T/C

1.6.1.2 RTD Input

VI

V+

V-

RTD

For 2-wire

this is a

local link

The resistance of the three wires must be the same

The line resistance may cause errors if it is greater than 22Ω

Note: the RTD wiring is not the same as 2400 series instruments. It is the same as 26/2700 series

1.6.1.3 Linear Input V, mV and High Impedance V

VI

V+

V-

+80mV

0 – 2V

0 – 10V

mV range +40mV or +80mV

High level range 0 – 10V

High Impedance mid level range 0 – 2V

A line resistance for voltage inputs may cause measurement errors

1.6.1.4 Linear Input mA

VI

V+

V-

0 – 20mA

4- 20mA

Connect the supplied load resistor equal to 2.49Ω for mA input

The resistor supplied is 1% accuracy 50ppm

A resistor 0.1% accuracy 15ppm resistor can be ordered as a separate item

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 17

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 18

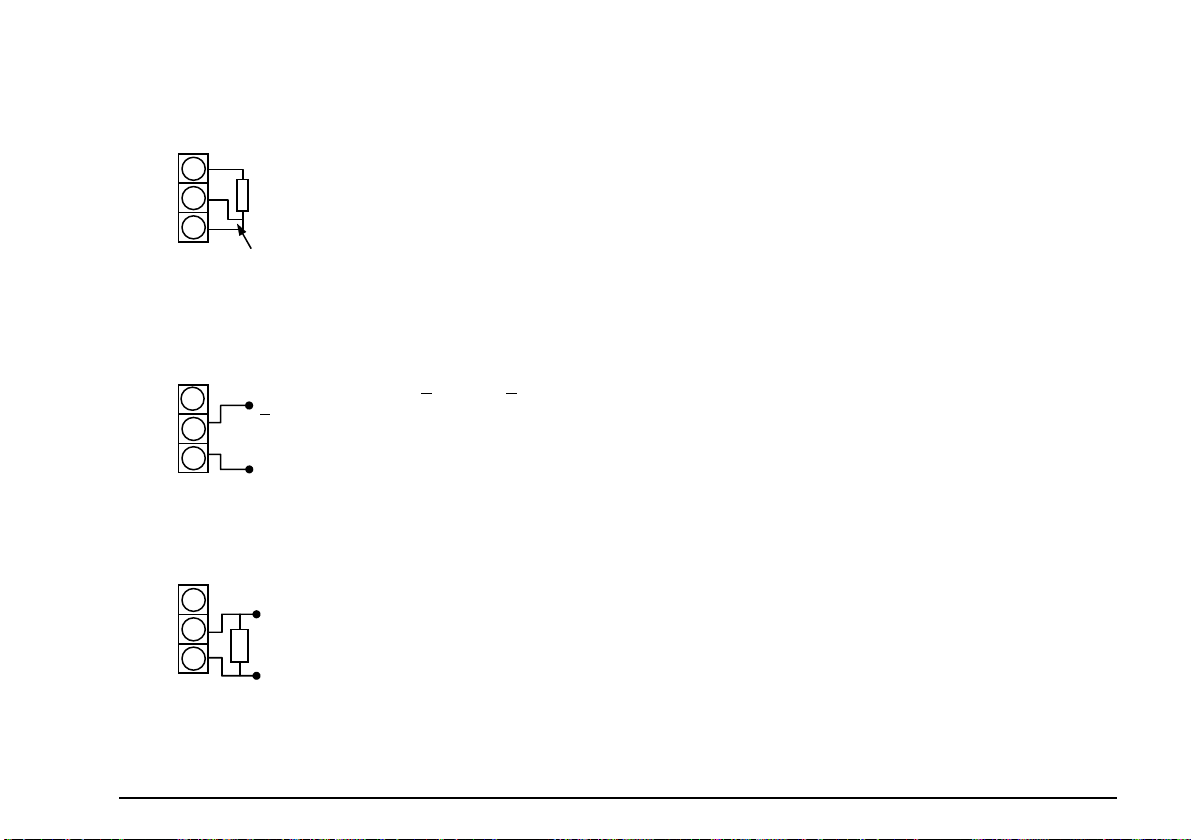

1.6.2 Digital I/O

These terminals may be configured as logic inputs, contact inputs or logic outputs in any combination. It is possible

to have one input and one output on either channel.

!

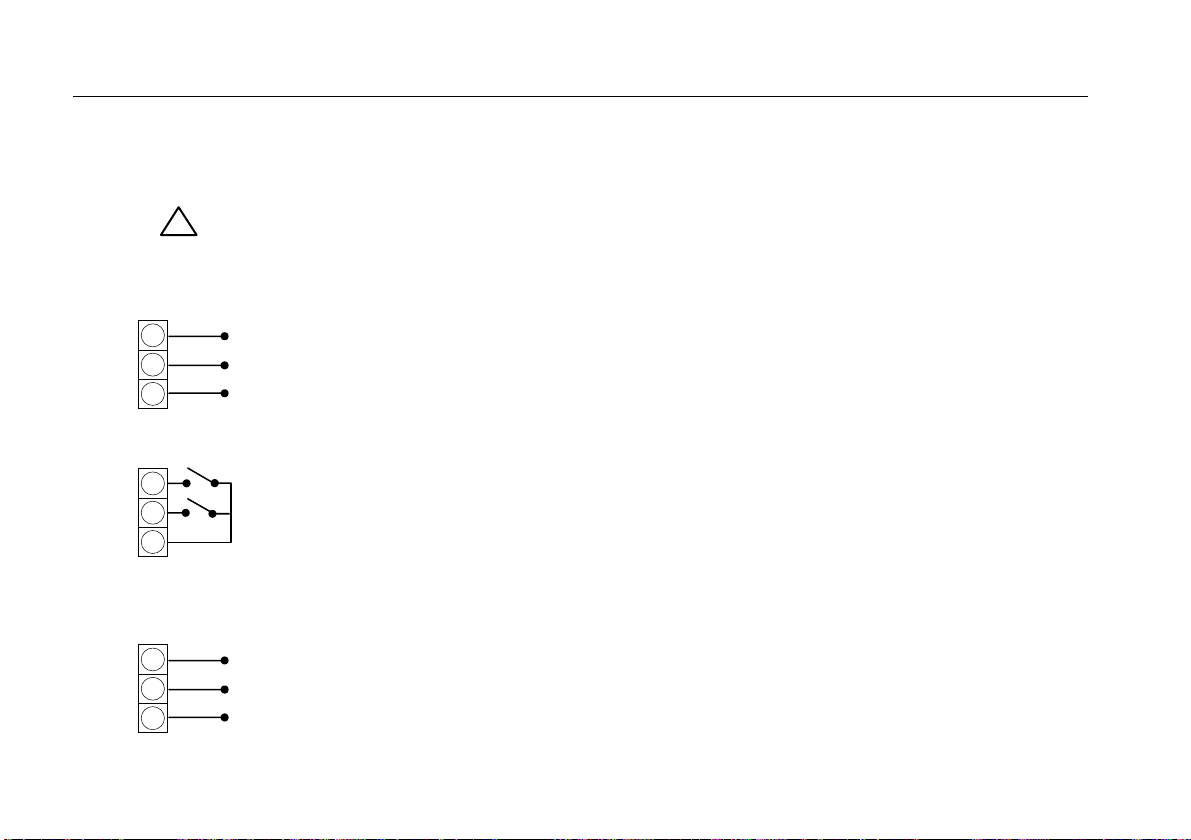

1.6.2.1 Logic Inputs

The Digital IO is not isolated from the PV input

LA

LB

LC

Input 1

Input 2

Common

Voltage level logic inputs, 12V, 5-40mA

Active > 10.8V

Inactive < 7.3V

1.6.2.2 Contact Closure Inputs

LA

LB

LC

Input 1

Input 2

Common

Contact open > 1200Ω

Contact closed < 480Ω

1.6.3 Digital (Logic) Outputs

LA

LB

LC

Output 1

Output 2

Common

The logic outputs are capable of driving SSR or thyristors up to 9mA, 18V

It is possible to parallel the two outputs to supply 18mA, 18V.

Note : The Digital IO terminals are not isolated from the PV.

The fixed digital logic outputs may be used to power remote 2 wire transmitters. The fixed digital I/O are, however,

not isolated from the PV input circuit, so this does not allow the use of 3 or 4 wire transmitters. An isolated module

must be used for the 3 and 4 wire types.

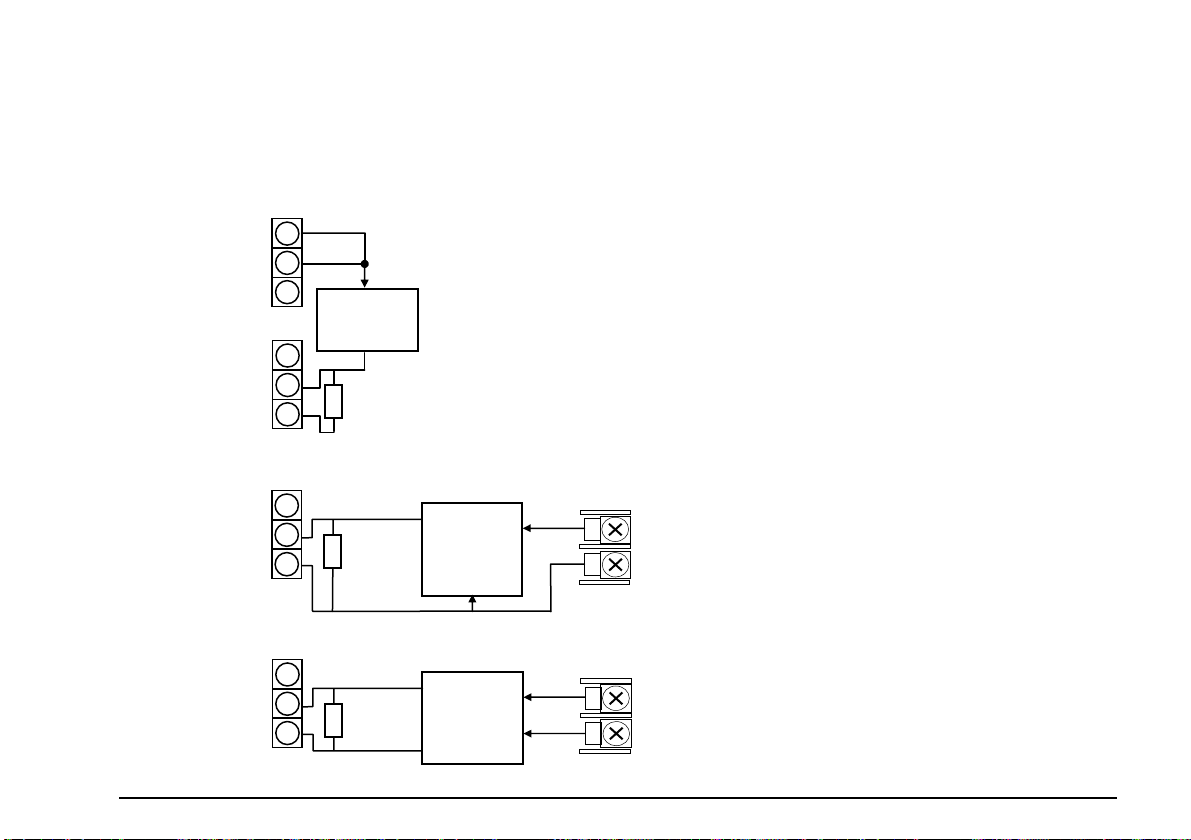

1.6.4 Digital (Logic) Outputs used to power a remote 2 wire transmitter.

Output 1

Output 2

4- 20mA

LA

LB

LC

VI

V+

V-

2 Wire

Transmitter

2.49Ω

The parallel logic outputs supply >20mA, 18V.

Note : The Digital IO terminals are not isolated from the PV.

Connect the supplied load resistor equal to 2.49Ω for mA input

1.6.5 Digital (Logic) Outputs used to power a remote 3 wire transmitter.

2.49Ω

3 Wire

Transmitter

A

-

Isolated Transmitter Option

module +24V >20mA

B

4- 20mA

VI

V+

V-

1.6.6 Digital (Logic) Outputs used to power a remote 4 wire transmitter.

2.49Ω

4 Wire

Transmitter

A

-

Isolated Transmitter Option

module +24V >20mA

B

VI

4- 20mA

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 19

V+

V-

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 20

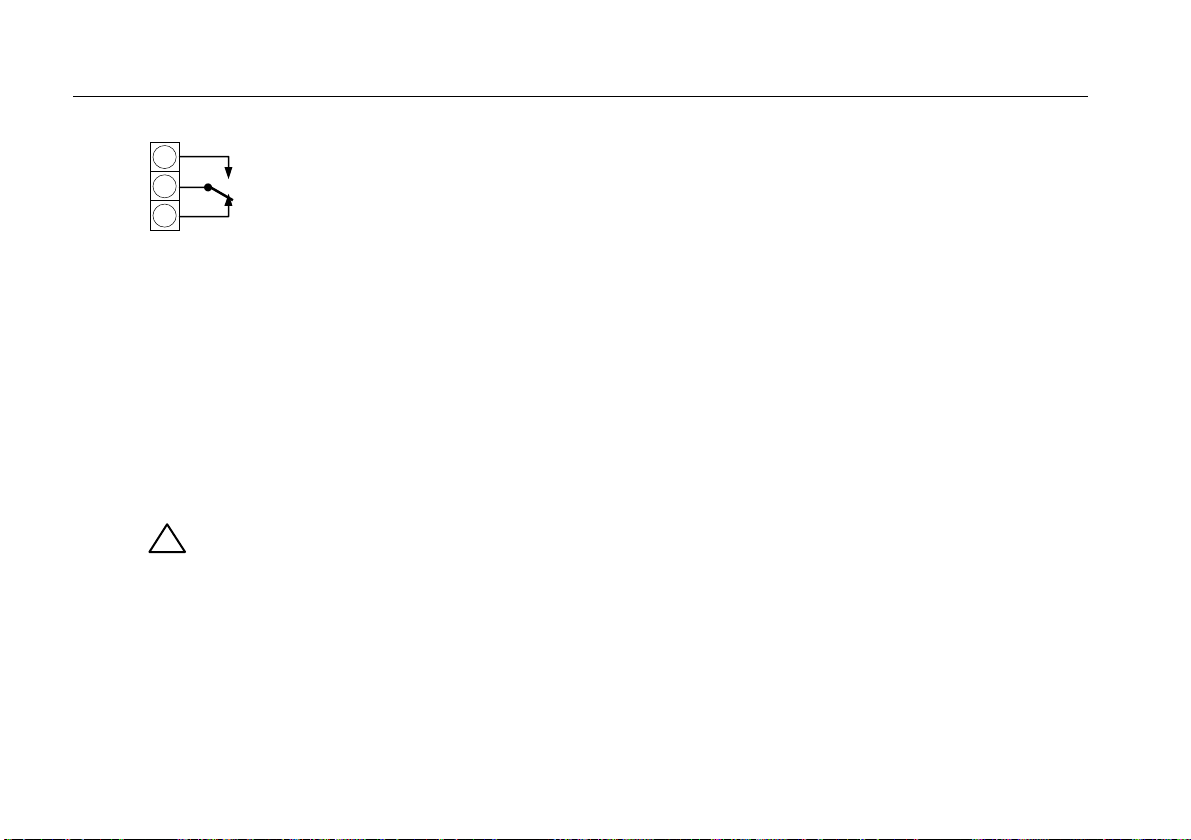

1.6.7 Relay Output

AA

AB

AC

Relay rating, min: 1V, 1mAdc. Max: 264Vac 2A resistive

Relay shown in de-energised state

Isolated output 240Vac CATII

1.6.7.1 General Note About Inductive Loads

High voltage transients may occur when switching inductive loads such as some contactors or solenoid valves.

For this type of load it is recommended that a ‘snubber’ is connected across the contact of the relay switching the

load. The snubber typically consists of a 15nF capacitor connected in series with a 100Ω resistor and will also prolong

the life of the relay contacts.

!

When the relay contact is open and it is connected to a load, the snubber passes a current (typically 0.6mA

at 110Vac and 1.2mA at 240Vac. It is the responsibility of the installer to ensure that this current does not hold on the

power to an electrical load. If the load is of this type the snubber should not be connected.

See also section 1.7.9.

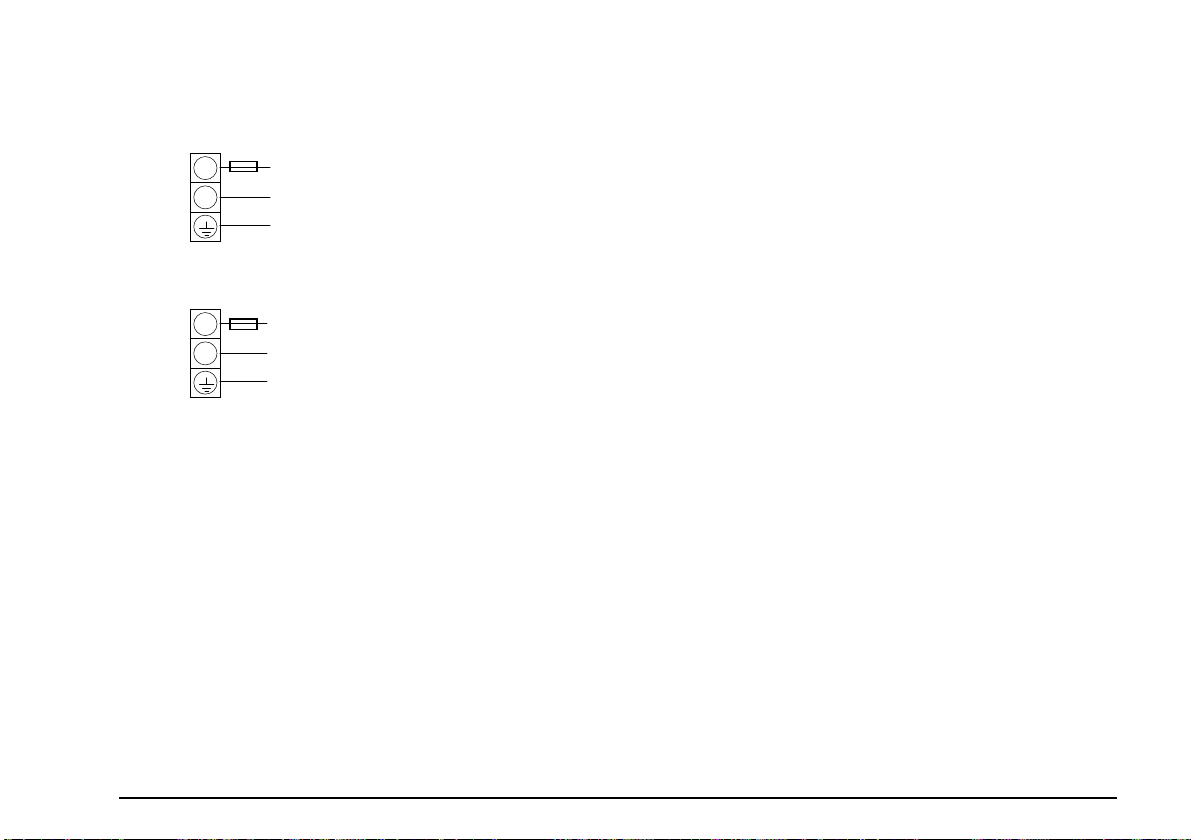

1.6.8 Power Supply Connections

L

N

100 to

240Vac

50/60Hz

1. Before connecting the instrument to the power line, make sure that the line voltage

corresponds to the description on the identification label

2. For supply connections use 16AWG or larger wires rated for at least 75

3. Use copper conductors only

4. For 24V the polarity is not important

5. It is the Users responsibility to provide an external fuse or circuit breaker.

24

24

24V ac

or dc

For 24 V ac/dc fuse type T rated 4A 250V

For 100/240Vac fuse type T rated 1A 250V

Safety requirements for permanently connected equipment state:

• a switch or circuit breaker shall be included in the building installation

• it shall be in close proximity to the equipment and within easy reach of the operator

• it shall be marked as the disconnecting device for the equipment

Note: a single switch or circuit breaker can supply more than one instrument

o

C

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 21

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 22

1.7 Plug in I/O Module Connections

Plug in I/O modules can be fitted in three positions in the 3508 and six positions in 3504. The positions are marked

Module 1, 2, 3, 4, 5, 6. With the exception of the Analogue Input module, any other module listed in this section, can

be fitted in any of these positions. To find out which modules are fitted check the ordering code printed on a label on

the side of the instrument. If modules have been added, removed or changed it is recommended that this is recorded

on the instrument code label.

The function of the connections varies depending on the type of module fitted in each position and this is shown

below. All modules are isolated.

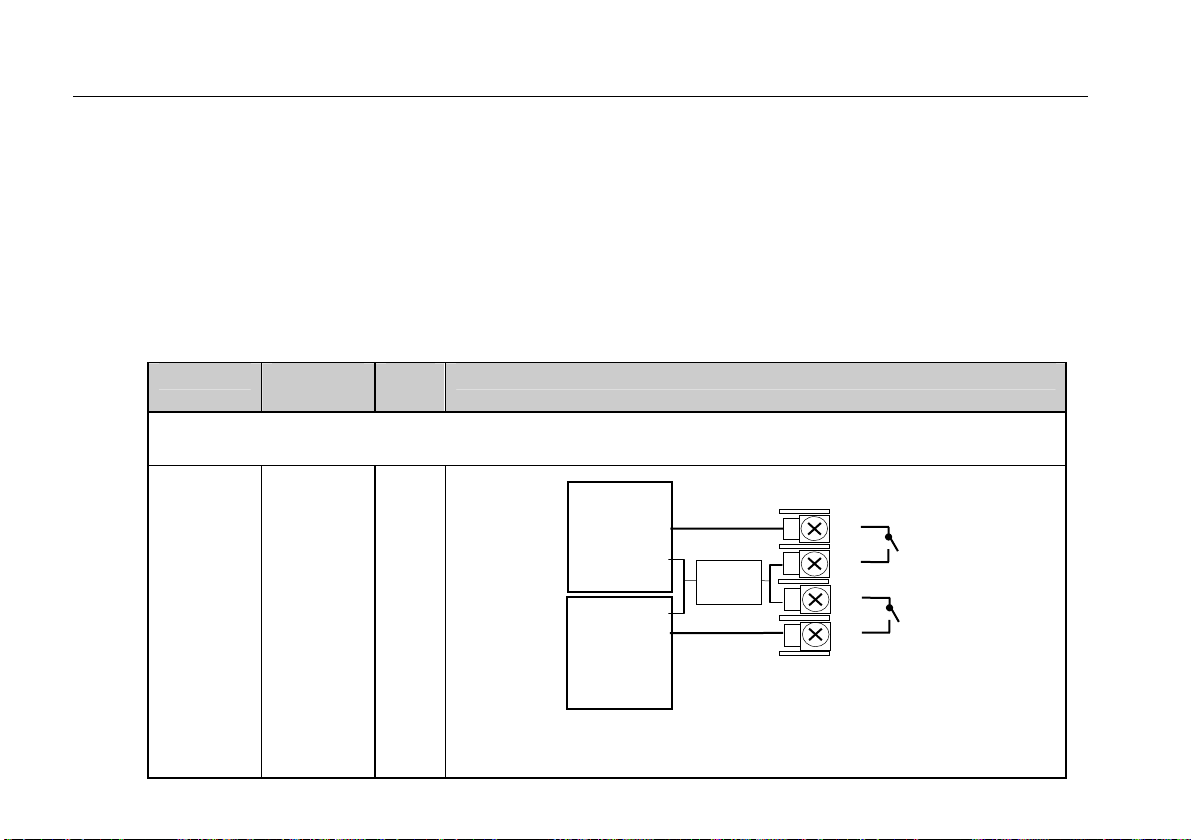

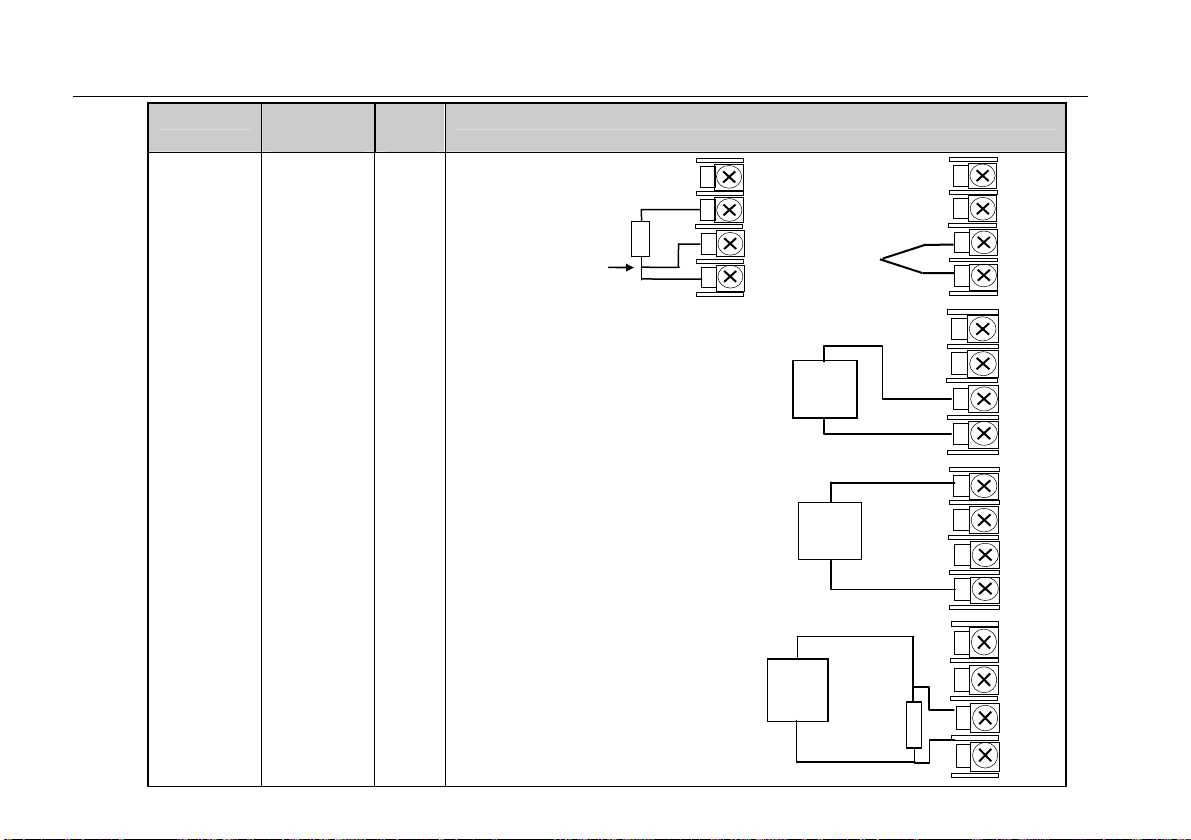

1.7.1 I/O Modules

I/O Module Typical

usage

Note: The order code and terminal number is pre-fixed by the module number.

Module 1 is connected to terminals 1A, 1B, 1C, 1D; module 2 to 2A, 2B, 2C, 2D, etc.

Relay (2 pin)

and

Dual Relay

2A, 264Vac

max

1mA 1V min

Heating,

cooling,

alarm,

program

event,

valve raise,

valve lower

H/W

Code

R2 and

RR

Connections and examples of use

Isolated output 240Vac CATII

Contactor

Relay

Panel lamp

etc

Contactor

Relay

Panel lamp

etc

Voltage

supply

First relay

A

B

C

D

Second relay

(dual relay only)

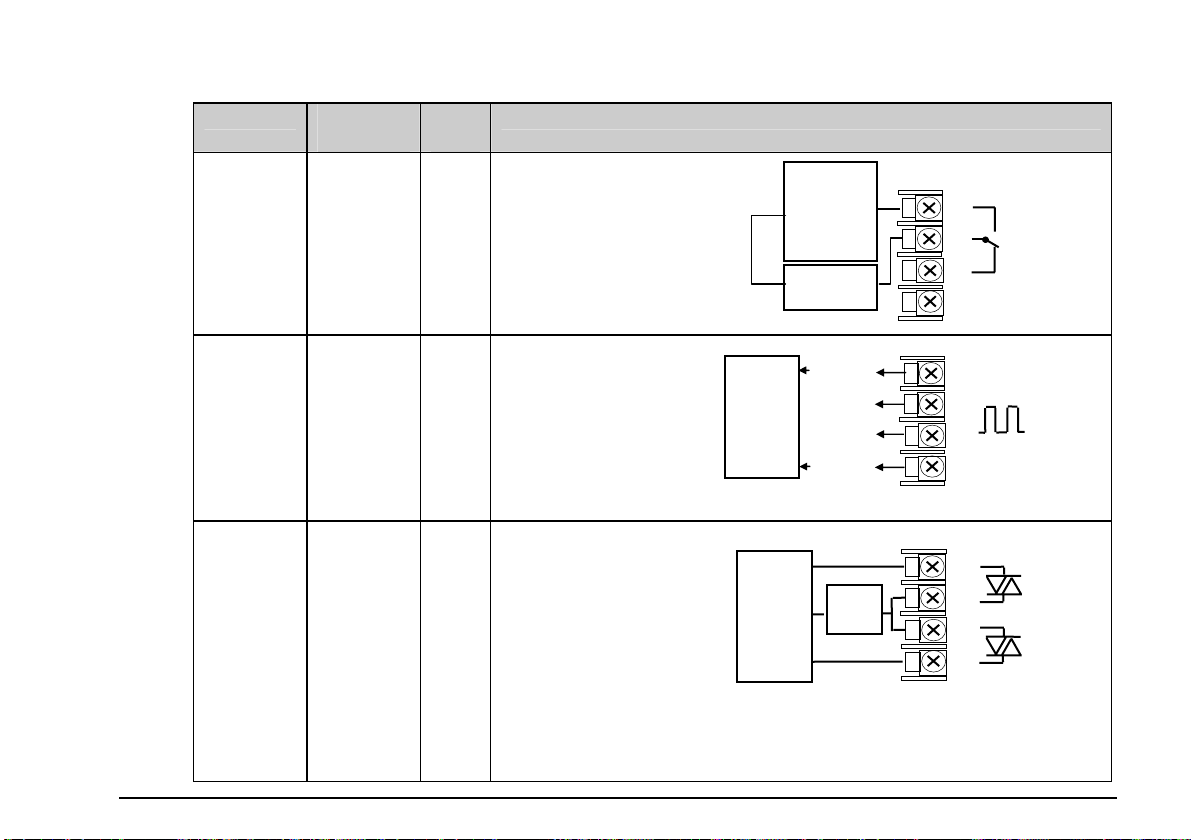

I/O Module Typical

_ _ _

usage

Change Over

Relay

(2A, 264Vac

max)

1mA 1V min

Heating,

cooling,

alarm,

program

event, valve

raise, valve

lower

Triple Logic

and

Isolated

Single Logic

Heating,

cooling,

program

events

Output

(18Vdc at

8mA max.)

Triac

and Dual

Triac

Heating,

cooling,

valve raise,

valve lower

(0.7A, 30 to

264Vac

combined

rating)

H/W

Code

R4

Isolated output 240Vac CATII

TP and

LO

Isolated output 240Vac CATII

T2

and TT

Isolated output 240Vac CATII

Note 1: Dual relay modules may be used in place of dual triac.

Note 2:- The combined current rating for the two triacs must not exceed 0.7A.

Single Logic Output

connections are:-

D – Common

A – Logic Output

Connections and examples of use

Contactor,

Relay

, Panel lamp

etc

Voltage

supply

+

+

+

Voltage

supply

SSR or

thyristor

unit

Motorised

valve

+

-

Output A

Output B

Output C

Common

Raise

Lower

A

B

C

D

A

+

B

C

D

First triac

A

B

C

D

Second triac

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 23

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 24

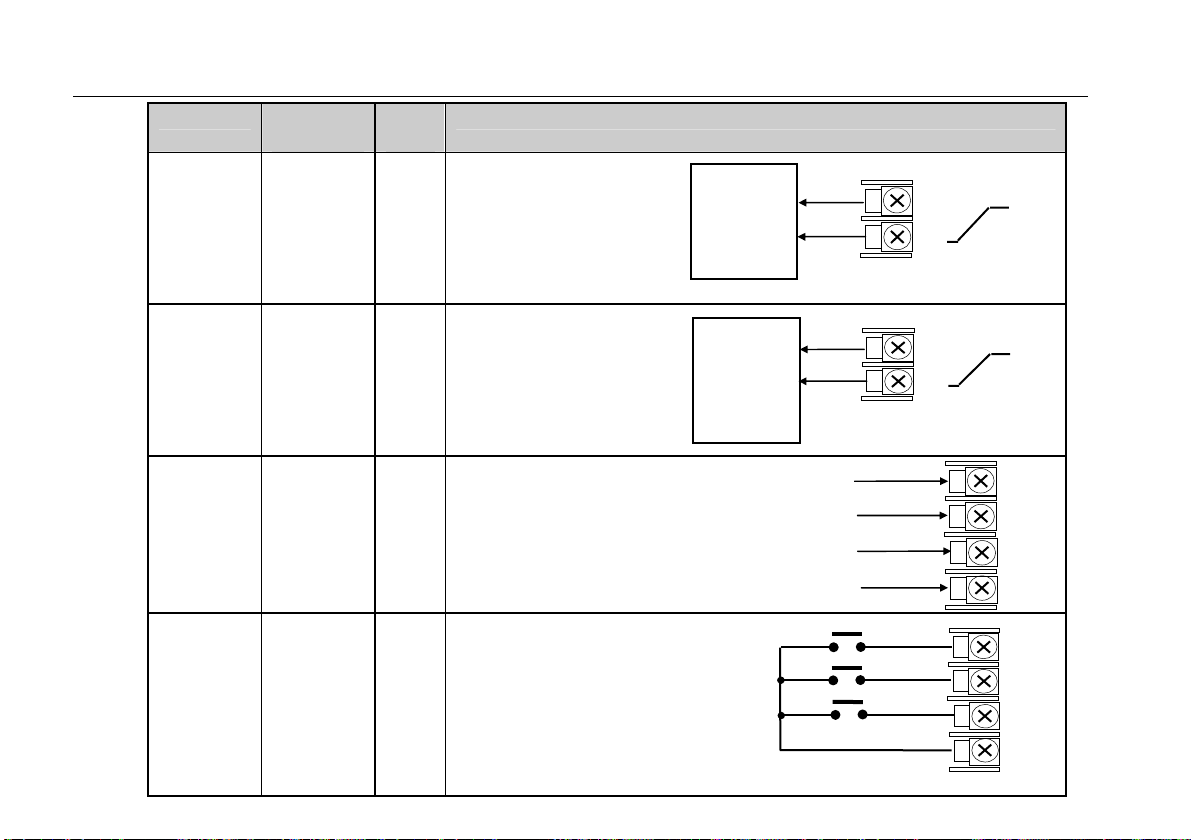

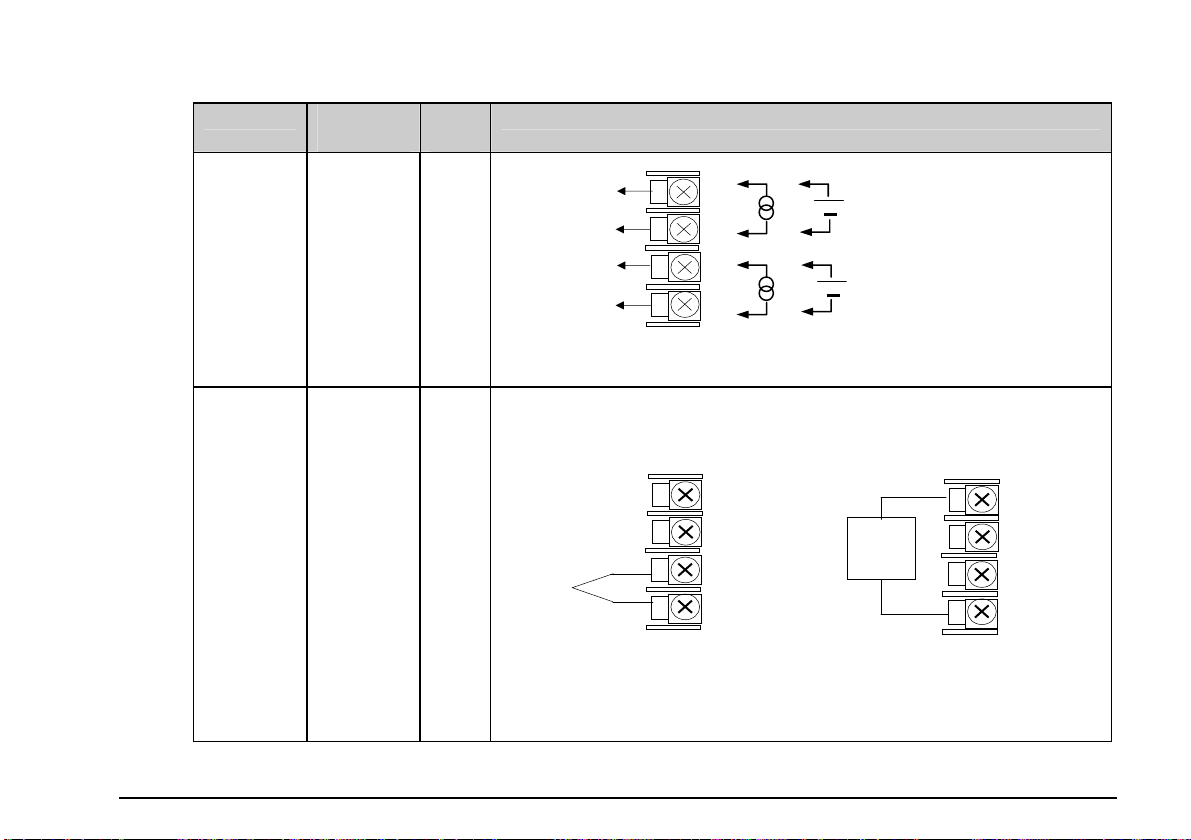

I/O Module Typical

usage

DC Control

(10Vdc,

20mA max)

Heating,

cooling

e.g. to a

4-20mA

process

actuator

DC Retransmission

(10Vdc,

20mA max)

Logging of

PV, SP,

output

power, etc.,

(0 to 10Vdc,

0 to 20mA)

Triple Logic

Input

Triple

Contact

Input

Events

e.g. Program

Run, Reset,

Hold

Events

e.g. Program

Run, Reset,

Hold

H/W

Code

D4

D6

TL

TK

Connections and examples of use

Isolated output 240Vac CATII

Isolated output 240Vac CATII

Isolated output 240Vac CATII

Contact

inputs

<100 ON

>28K OFF

Isolated output 240Vac CATII

Actuator

0-20mA

or

0-10Vdc

To other

controllers

0-20mA

or

0-10Vdc

Logic inputs

<5V OFF

>10.8V ON

Limits:

-3V, +30V

External

Switches or

Relays

Input 1

Input 2

Input 3

Common

A

B

A

B

Input 1

Input 2

Input 3

Common

+

-

+

-

A

B

C

D

A

B

C

D

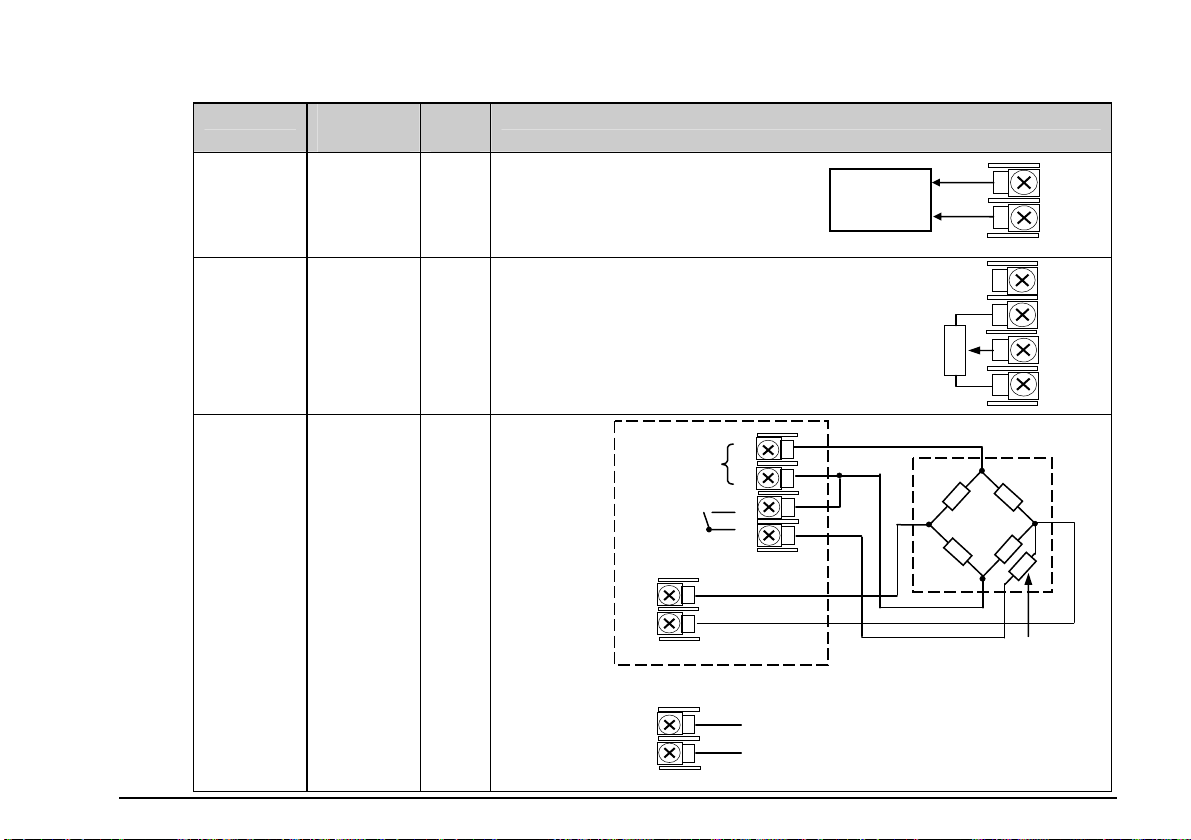

I/O Module Typical

usage

24V

Transmitter

Supply

(20mA)

Potentiometer

input

100Ω to

15KΩ

To power an

external

transmitter

Valve

position

feedback

Remote

setpoint

Transducer

G3

Power

Supply

Configurable

5V or 10Vdc

Minimum

load

resistance

300Ω

H/W

Code

MS

Isolated output 240Vac CATII

VU

Isolated output 240Vac CATII

Isolated output 240Vac CATII

Connections and examples of use

10Vdc power

supply

Internal

switch to

connect Rcal

V+

V-

C

D

A

+

B

-

C

D

Input

Controller

Input if an analogue input module is used in the appropriate slot

Transmitter

This may be fitted either in the

transducer or in the controller

-

+0.5V

0V

Transducer

A

V+

Calibration resistor Rcal

V-

B

A

B

A

B

C

D

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 25

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 26

I/O Module Typical

usage

Analogue

Input

(T/C & RTD)

Modules

1, 3, 4 & 6

only

(mV, V and

mA)

Second PV

input

Remote

setpoint

H/W

Code

AM

3-wire RTD

For 2-wire

this is a

local link

Isolated output

240Vac CATII

Connections and examples of use

mV (40mV or 80mV)

Voltage

-3 to 10V or –1.4 to 2V

Current 0 to 20mA

Or (4 to 20mA)

A

B

C

D

+

mVolt

source

-

+

Volt

source

-

+

Current

source

-

Thermocouple

2.49Ω

resistor

supplied

A

B

+

-

C

D

A

B

C

D

A

B

C

D

A

B

C

D

I/O Module Typical

usage

Dual DC

Output

(each

channel can

be 4-20mA

or 24Vdc

power

supply)

Analogue

Input

(T/C & RTD)

Modules

1, 3, 4 & 6

only

Control

output 12

bit

resolution

Can only be

fitted in slots

1, 2 and 4

Zirconia

Probe

H/W

Code

DO

AM

Connections and examples of use

Output 1

Output 2

The temperature sensor of the zirconia probe can be connected to the Fixed PV

input, terminals V+ and V-, or to an Analogue Input module, terminals C & D. The

Volt Source connected to an Analogue Input module, terminals A & D.

Fixed PV (or an Analogue Input

Isolated output 240Vac CATII

+

-

+

-

+

-

Module)

A

B

4-20mA

C

D

V+ or C

V- or D

20V – 30V

+

Zirconia

Volt

source

-

Analogue Input Module

A

B

C

D

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 27

3500 Series User Guide Part No HA027987 Issue 7.0 May-06 28

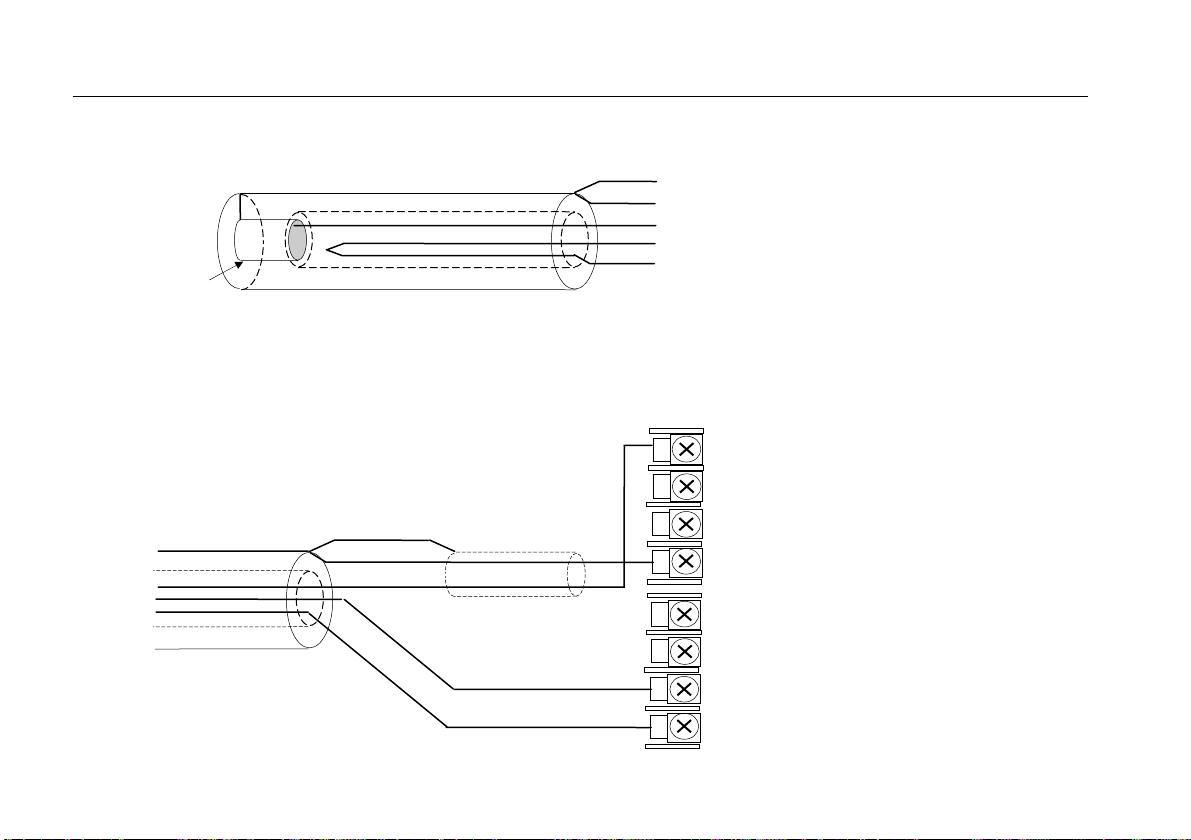

1.7.2 Zirconia Probe Construction

Hot End

Ceramic Insulator

Outer Electrode

Inner Electrode

Zirconia

Sensor

Outer metallic shell of the probe

Screen

-

Zirc. mV

+

+

Thermocouple

-

1.7.3 Zirconia Probe Screening Connections

The zirconia sensor wires should be screened and connected to the outer shell of the probe if it is situated in an area

of high interference.

+

Outer Electrode

Inner Electrode

Screen

Zirc. mV

+

T.C.

-

-

+

-

Screened Cable

+

-

A

B

C

D

A

B

C

D

Loading...

Loading...