Grieve Corporation 2-5000 Installation Manual

Series 2-5000 Minihelic®II

Differential Pressure Gage

Specifications: Installation & Operating Instructions

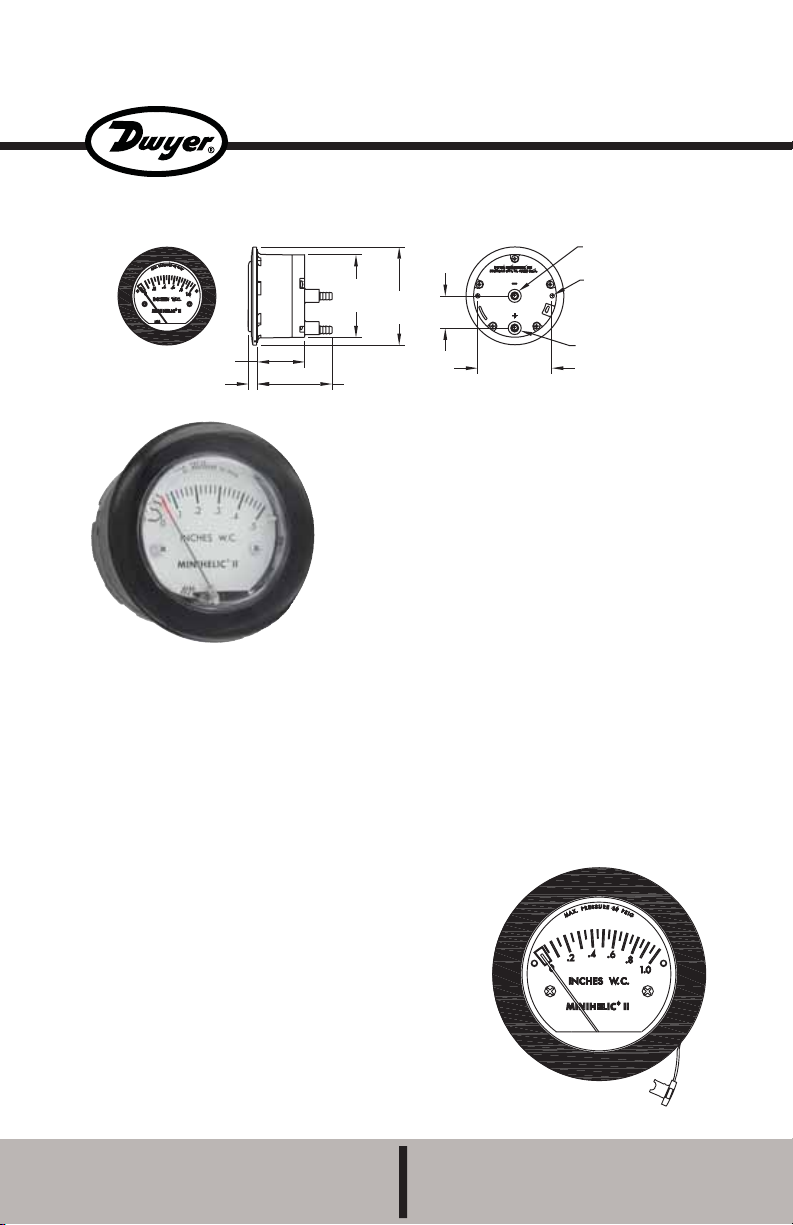

ø2-19/32

[65.88]

1-7/16 [36.51]

9/32 [7.14]

Series 2-5000 Minihelic®II Differential

Pressure Gages have clean design, small size,

low cost and sufficient accuracy for all but the most

demanding applications. With housing molded from

mineral- and glass-filled nylon and a lens molded

from polycarbonate, this gage will withstand rough

use and exposure, as well as high total pressure up

to 30 psig [2.067 bar]. Over-pressure is accommodated by a blow-out membrane molded in conjunction with the diaphragm.

INSTALLATION

1. Select a location free from excessive vibration

and where ambient temperature will be between 20

to 120°F (-6.7 to 49°C). Sensing lines may be any

length necessary without affecting accuracy.

However, long runs of tubing will dampen readings

slightly and cause a minor increase in response

time. If pulsing pressure or vibration cause excessive pointer oscillation, please contact factory for

ways to provide additional damping.

2. This gage is calibrated and zeroed in the vertical

position at the factory. If the gage is used in any

other position, it must be re-zeroed each time the

position is changed. Gages with ranges under 5˝

w.c.(1.24 kPa), or the equivalent, should be used

only in the vertical position unless special calibration

was specified when ordering.

2-3/8 [60.33]

Bulletin A-36-A

LOW PRESSURE PORT

ø7/16 [11.11] HOLE IN

PANEL FOR SURFACE MOUNT

(2) ø5/32 HOLES

IN PANEL FOR SURFACE

ø3-1/16

[77.79]

1-[25.40]

2.330 [59.18]

SURFACE MOUNT

HOLES

SPECIFICATIONS

Service: Air and compatible gases.

Wetted Materials: Consult factory.

Housing: Glass filled nylon; polycarbonate lens.

Accuracy: ±5% of full scale at 70°F (21.1°C).

Pressure Limits: 30 psig (2.067 bar) continuous

to either pressure connection.

Temperature Limits: 20 to 120°F (-6.67 to

48.9°C).

Size: 2-1/16˝ (52.39 mm) diameter dial face.

Mounting Orientation: Diaphragm in vertical

position. Consult factory for other position orientations.

Process Connections: Barbed, for 3/16˝ I.D.

tubing (standard); 1/8˝ male NPT (optional).

Weight: 6 oz (170.1g).

CAUTION: FOR USE ONLY WITH AIR OR

COMPATIBLE GASES.

MOUNT

HIGH PRESSURE PORT

ø7/16 [11.11] HOLE IN

PANEL FOR SURFACE MOUNT

Figure A

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057

Phone: 219/879-8000 www.dwyer-inst.com

e-mail: info@dwyer-inst.com

Bulletin A-36-A

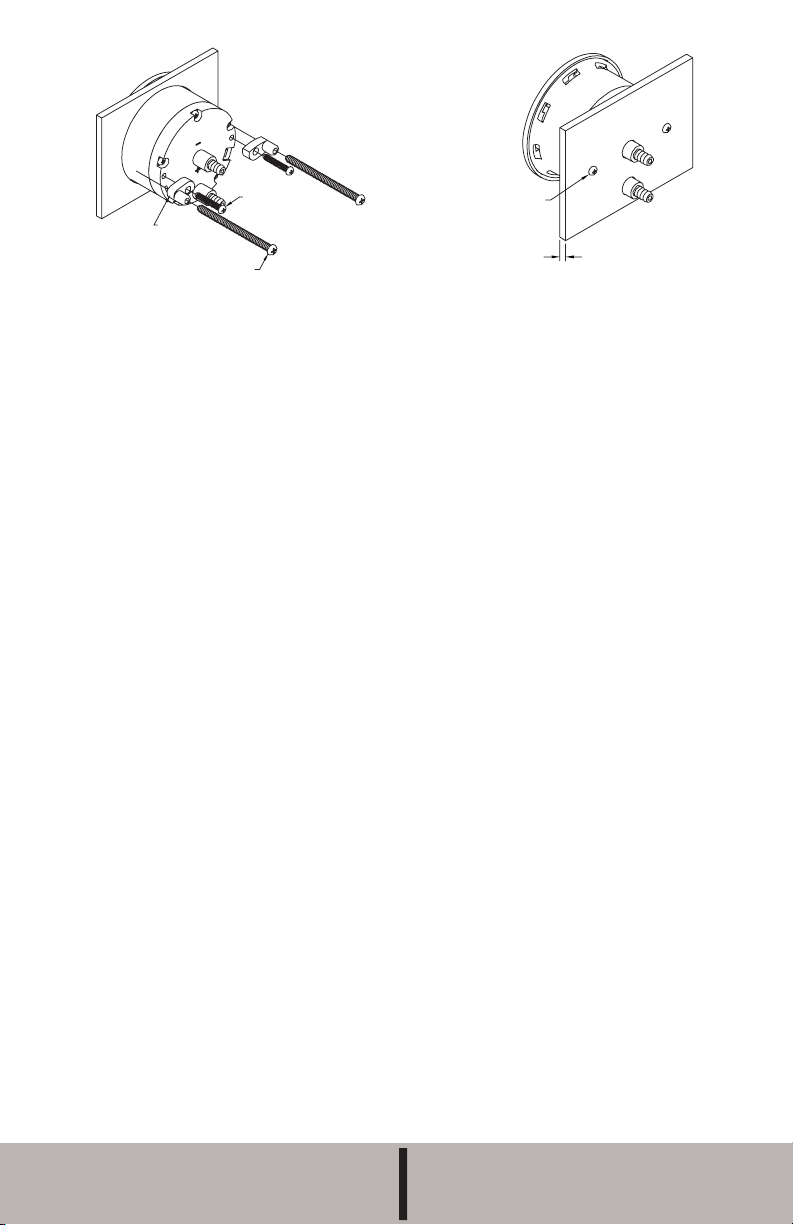

#4 MOUNTING

#6 MOUNTING

SCREW

SCREW

MOUNTING

LUG

PANEL MOUNTED

PANEL MOUNTED INSTALLATION

3. To surface-mount the gage in a 3/16 (4.78

mm) max panel thickness, drill two 5/32˝ (3.97

mm) holes on a horizontal line, 2.330˝ (59.18

mm) apart for mounting screws. Next, drill two

7/16˝ (11.11 mm) holes 1.000˝ (25.4 mm) apart

on a vertical line for pressure connections.

Secure the gage with two #4 mounting screws.

Be careful not to block the slotted hole near the

right-hand mounting hole, this provides a path

for pressure relief in the event of over-pressurization.

4. To panel-mount the gage, cut a 2-5/8˝ (66.68

mm) diameter hole. Install mounting lugs to the

back of the gage with two #4 mounting screws,

thread two #6 mounting screws through mounting lugs and tighten.

®

5. Before installation, the Minihelic

Pressure Gage may need to be zeroed before

placing into operation. If zeroing is required, you

must first remove the locking clip located near

the bottom face of the gage (refer to Fig A). Use

a small blade screwdriver or the allen wrench

supplied with the Minihelic

Pressure Gage to remove the clip. The clip is

attached with a hinge design so it will not get

lost after removal. After removing the clip, firmly

hold the case with one hand and rotate the front

cover in the counterclockwise direction with the

palm of the other hand. The Minihelic

Differential Pressure Gage utilizes a bayonet

locking design. The cover will rotate approximately 9 degrees then stop and can be

removed. Caution: When removing the cover

be careful to slowly pull the cover straight off the

gage housing. Damage can occur to the scale if

the cover is pulled off on an angle. If difficult to

loosen cover, place a small sheet of rubber

between the cover and the palm of the hand.

The zero adjust screw is located below the

scale at the “zero” label near the base of the

pointer. Use the hex allen wrench supplied and

II Differential

®

II Differential

®

II

#4 MOUNTING

SCREW

3/16 (4.78) MAX

PANEL THICKNESS

SURFACE MOUNTED

6. To measure positive pressure, connect

tubing to port marked “HI” and vent “LO” port

to atmosphere. For negative pressure (vacuum), connect to port marked “LO” and vent

“HI” port to atmosphere. For differential pressure, connect higher pressure to port marked

“HI” and lower to “LO” port. If gage is supplied with 1/8˝ NPT connections, be careful

not to over-tighten fittings to avoid damage to

the gage.

CALIBRATION CHECK

Select a second gage or manometer of

known accuracy and in an appropriate range.

Use short lengths of rubber or vinyl tubing to

connect the high-pressure side of the gage

and the test gage to two legs of a tee. Very

slowly, apply pressure through the third leg.

Allow enough time for pressure to equalize

throughout the system and for fluid to drain. if

a manometer is being used. Compare readings. If the gage being tested exceeds rated

accuracy, it should be returned to the factory

for recalibration.

MAINTENANCE

No lubrication or periodic servicing is

required. Keep case exterior and cover clean.

Occasionally, disconnect pressure lines to

vent both sides of the gage to atmosphere

and re-zero per installation paragraph 5.

Upon final installation of the Series 2-5000

®

Minihelic

II Differential Pressure Gage, no

routine maintenance is required. A periodic

check of the system calibration is recommended. The Series 2-5000 is not field serviceable and should be returned if repair is

needed (field repair should not be attempted

and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes. Contact customer

service to receive a return goods authorization number before shipping.

adjust until the pointer is on zero. This must be

done with both pressure connections vented to

atmosphere and the gage oriented in the final

mounting position. Replace cover.

©Copyright 2007 Dwyer Instruments, Inc Printed in U.S.A. 2/07 FR# 14-440434-10 Rev.4

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, IN 46361, U.S.A. Fax: 219/872-9057

Phone: 219/879-8000 www.dwyer-inst.com

e-mail: info@dwyer-inst.com

Loading...

Loading...