Page 1

Innovative Combustion Solutions Worldwide

Locktite Manual Reset

• UL listed, FM & CGA approved.

• Snap-acting solenoid for fast closing.

• Two visual indicators of valve position.

• Raintight construction.

• Soft seat disc for positive shut-off.

• Two built-in auxilliary switches.

• Ball bearing trip mechanism reduces wear.

• Lever with extension chains available for

remote mounting.

• 100% factory tested before shipment.

Eclipse 200 LT valves are manually opening valves that automatically shut off the gas

supply to a combustion system when any interlocking limit switch opens. The valve

handle cannot be reset until the condition

causing the open switch is corrected and all

limit switches are closed. Typical limit

switches include air pressure, gas pressure,

temperature limit, and flame monitoring contacts. In the event of a power failure, the

valve immediately closes.

Gas Shut-Off Valves

Series 200 LT

U.S. Patent No. 3,259,357

Canadian Patent No. 764,833

LISTED 326R CGA 3.9

®

Series 200 LT valves include two visual indicators of “open” or “closed” position: a red

“flag” visible in the plastic dome on top of the

valve; and the reset handle position as indicated by cast markings on the operator

case. These valves also include two SPDT

micro-switches that can be used for auxiliary

circuits. Two contacts are made when the

valve opens, and two are made when the

valve is closed.

1” Thru 4”

Flanged

1” Thru 2”

Threaded

Page 2

200 LT Specifications

Temperature Limits +125° to –20° F (+52° to -29° C) fluid and ambient . Below 32° F (0° C) the gas

must be free of water vapor which could condense and freeze within the valve.

Maximum Inlet & 1" thru 2" 30 psig

Differential Pressure 2-1/2" thru 4" 20 psig

Gases UL listed for air, natural gas, LP gas and hydrogen.

FM approved for natural, LP and manufactured gases.

CGA approved for natural and LP gases.

Contact Eclipse for other gases. For corrosive or wet gases such as coke oven or

digester gas, corrosion-resistant valve trim must be installed at Eclipse.

Electrical Volts/Cycles 115/120 volt 50/60 hz standard.

220/50 or 240/60 available.

Holding Current 35 VA at 120 volt

Auxiliary Switches (2) 8 amp, 1/3 hp, 120 or 240 volts A.C.

Approvals UL listed, FM & CGA approved.

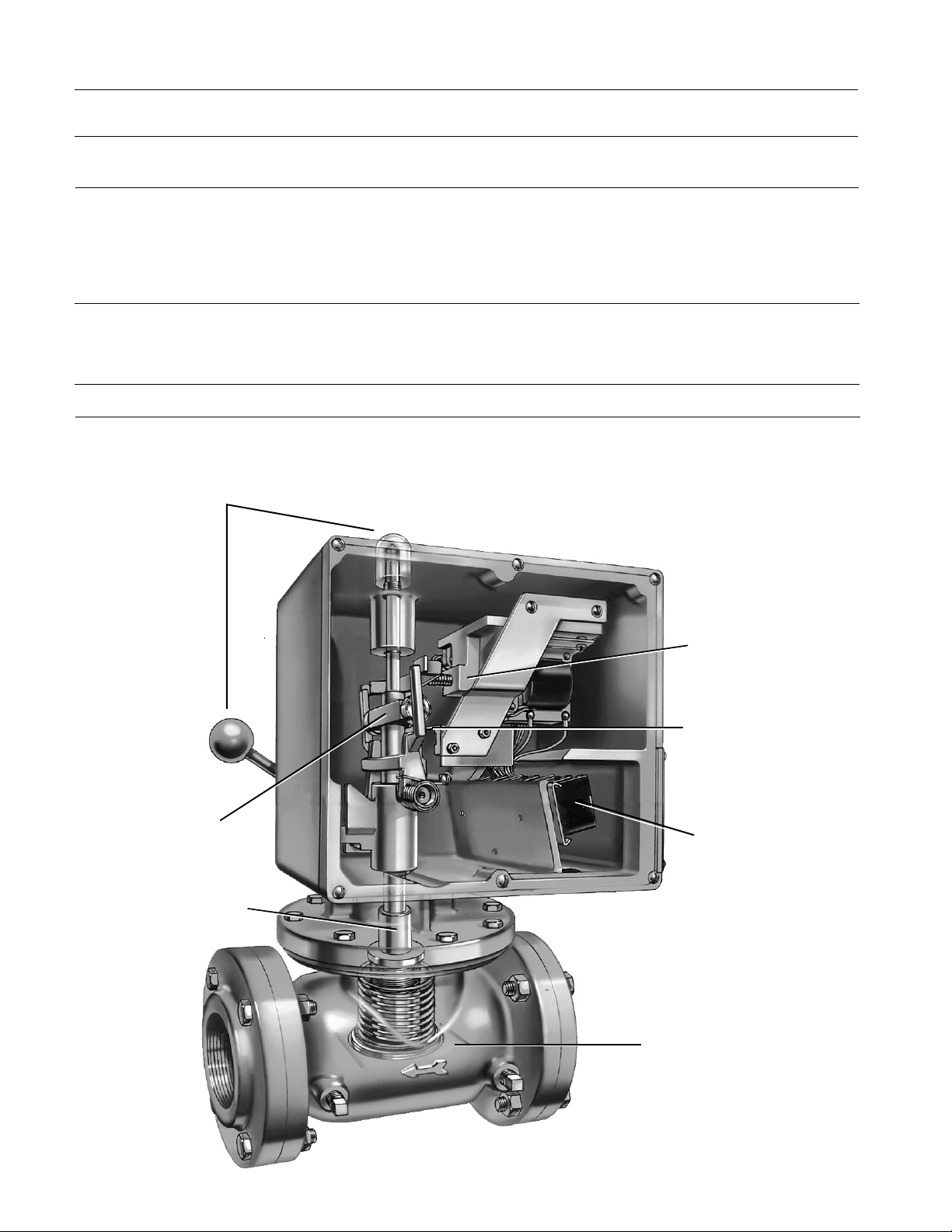

Design Features

Two separate visual checks of

valve's open / closed position

Ball bearing tripping & locking

mechanism minimizes friction

& reduces wear

Precision machined and ground

main shaft prevents binding

Snap action, spring

loaded pusher arm

solenoid assembly

designed to provide

quick closure when

electrical signal

is interrupted

Built in microswitch to

make or break other

electrical circuits

Internal terminal strip

accomadates most electric

interlocking protection devices

Valve closes with line pressure,

not against it. Synthetic valve seat

compounded for use with all

commercially available gases

2

Page 3

Capacities*

T

T

210 LT

208 LT

206 L

204 LT

30

20

10

6

4

2

P, "w.c.

1

.6

.4

.2

.1

.1 .2 .4 .6 1 2 4 6 10 20 40 60 100

Capacity, SCFH in 1000's

205 L

212 LT

216 LT

*For natural gas (.6 s.g.) with

an inlet pressure no higher

than 1.1 psig. For other

gases, multiply capacty by:

Butane (2.0 s.g.) .548

Propane (1.5 s.g.) .628

Air (1.0 s.g.) .775

Allowable Mounting Positions

Factory Supplied

Operator Position #1 (Standard) #2 #3 #4

Valve Mounted

With

Operator

Straight

Up or Down

Valve Mounted

With

Wiring Box

Cover

Facing Up

200 LT valves can be supplied with the operator rotated in any of four positions with respect to the valve body, #1, #2, #3, and #4. Position #1

is supplied standard unless otherwise specificed. The sketches above show the allowable mounting orientations for each of the four factorysupplied operator positions. The operator must not be mounted in a position other than those shown.

Note: Incorrect rotation of the operator can result in damage to the microswitch. Please contact your Eclipse representative if rotation

n

of the operator after shipment is required.

3

Page 4

200 LT Dimensions

6-7/8"

175 mm

“D”

O.D.

“A”

N.P.T.

Pipe size

Wiring

Box

Cover

(2) Conduit

Connections

1/2" N.P.T.

6-1/2"

165 mm

7-7/16"

189 mm

F

“C”

Threaded

9-1/2"

241 mm

OPEN

G

“E” Threaded

“E” Flanged

CLOSED

RESET

4-5/16"

110 mm

B

“C”

Flanged

English Units

Catalog C

Number 120 V. 240 V. Open A B C D E F G Lbs.

Assembly Number

V

Threaded Iron Body

204 LT-IS 571604 571604-1 23.4 1 12-1/16 1-1/2 5-1/2 7-1/4 3-11/16 --- 26

205 LT-IS 571605 571605-1 29.8 1-1/4 12-1/16 1-1/2 5-1/2 7-1/4 3-11/16 --- 26

206 LT-IS 571606 571606-1 50.4 1-1/2 12-5/8 2-1/16 5-1/2 9 4-5/16 --- 32

208 LT-IS 571608 571608-1 58.5 2 12-5/8 2-1/16 5-1/2 9 4-5/16 --- 30

Flanged Aluminum Body

204 LT-AF 560604 560604-1 23.4 1 12-3/16 1-3/4 5-7/8 7-1/16 3-13/16 5-7/8 23

205 LT-AF 560605 560605-1 29.8 1-1/4 12-3/16 1-3/4 5-7/8 7-1/16 3-13/16 5-7/8 23

206 LT-AF 560606 560606-1 50.4 1-1/2 12-3/4 2-1/2 5-7/8 9 4-13/16 7 28

208 LT-AF 560608 560608-1 58.5 2 12-3/4 2-1/2 5-7/8 9 4-13/16 7 27

216 LT-AF 560616 560616-1 234.0 4 16-3/16 4 7-15/16 15-5/8 7-13/16 13 60

Flanged Iron Body

210 LT-IF 560611 560611-1 116.0 2-1/2 14-1/8 3-1/16 7-7/8 12-5/8 5-3/4 9-3/4 52

212 LT-IF 560613 560613-1 126.0 3 14-1/8 3-1/16 7-7/8 12-1/4 5-3/4 9-3/4 52

Dimensions In Inches

Net

Catalog C

Number 120 V. 240 V. Open A B C D E F G Kgs.

204 LT-IS 571604 571604-1 23.4 1" 306 38 140 184 94 --- 11.8

205 LT-IS 571605 571605-1 29.8 1-1/4" 306 38 140 184 94 --- 11.8

206 LT-IS 571606 571606-1 50.4 1-1/2" 321 52 140 229 110 --- 14.5

208 LT-IS 571608 571608-1 58.5 2" 321 52 140 229 110 --- 13.6

204 LT-AF 560604 560604-1 23.4 1" 310 44 149 195 97 149 10.4

205 LT-AF 560605 560605-1 29.8 1-1/4" 310 44 149 195 97 149 10.4

206 LT-AF 560606 560606-1 50.4 1-1/2" 324 64 149 229 122 178 12.7

208 LT-AF 560608 560608-1 58.5 2" 324 64 149 229 122 178 12.2

216 LT-AF 560616 560616-1 234.0 4" 411 102 202 397 198 330 27.2

210 LT-IF 560611 560611-1 116.0 2-1/2" 359 78 200 321 146 248 23.5

212 LT-IF 560613 560613-1 126.0 3" 359 78 200 321 146 248 23.5

Bulletin 750 7/01

Metric Units

Assembly Number Dimensions In Millimeters

V

Threaded Iron Body

Flanged Aluminum Body

Flanged Iron Body

Net

Loading...

Loading...