Gretsch Guitars Your GRETSCH User Guide

Introduction

Thank you for choosing a Gretsch

®

guitar. We believe this new

instrument will give you many years of pleasure.

Please take a few moments to read through this booklet. In it you

will nd answers to many of your questions and other invaluable

information about care and maintenance for your guitar.

A Memo to Guitar Enthusiasts from Fred Gretsch Jr.

Information essential to every guitarist– students, professionals

and hobbyists–is gathered together here for you. Keep it in your

guitar case accessory pocket for quick reference about the care

of your guitar, how to use it to the full extent of its capabilities,

what to demand when purchasing a guitar, and for your personal

le of phone numbers and addresses.

Your musical instrument is a very personal extension of you,

the musician. It must be worthy of your ability and possibilities.

The musician who plays a GRETSCH guitar nds themselves

producing ner tone, developing increasing speed with

less fatigue, and taking new pride in the superb beauty and

craftsmanship of their instrument.

The guitar you play is a de nite factor in the quality of the music

you produce, and a GRETSCH guitar truly glori es the talents

of the artist who commands it.

Contents

Moisture Content and Humidity

2

Protection from Temperature and Humidity

2

Cracks in the Wood

3

Finish-Checking

3

General Maintenance

3

Tuning Machines

Tuning 6-String Guitars

4

Tuning 12-String Guitars

5

Changing Strings

5

Re-Stringing Your Guitar with a Fixed Tailpiece

7

The Bigsby

®

Vibrato Tailpiece

7

Re-Stringing the Bigsby

®

Vibrato

8

Truss Rod Adjustment

8

Adjustment of Action

9

Pickup Adjustment

9

Floating Bridge Adjustment

Resolving Tuning Issues

Traveling with Your Guitar

Basic Controls Guide

®

Warranty

Personal Address and Telephone Directory

For detailed speci cations of Gretsch instruments,

please visit our website at: www.gretschguitars.com

Wood is a porous, organic material, and

is affected dimensionally by changes in the

made from solid woods, are without a doubt,

more susceptible to the effects of changes

in humidity than laminated instruments, and

therefore require ongoing attention to their

The moisture content of wood is

determined by the relative humidity and

temperature of the surrounding atmosphere.

Relative humidity is expressed as a

percentage of air’s capability to hold

moisture. For example, 30% relative

humidity means that the air is holding 30% of

the moisture it could possibly hold at a given

temperature.

The moisture content for wood and the

relative humidity for air are measured quite

differently. In wood, a 6% moisture content

is present at 30% relative humidity and 72˚ F

temperature, (about 22.2˚ C).

and Humidity

The greatest threats to a ne wood guitar,

temperature and humidity.

High humidity

can cause softening of

the glues used in the construction of the

instrument. Also, as the woods absorb

moisture from the air, it can cause the top

guitars, to expand and rise - making string

your guitar to a drier climate, (either hot or

low

wood can cause shrinkage and cracking, no

matter how long the wood may have been

previously aged. It also can cause the top and

back to shrink, making the string action low.

The collective experience of all of the

major guitar manufacturers today, has

demonstrated that the ideal temperature to

preserve the integrity of solid wood acoustic

guitars is room temperature, which is about

40% to 50%.

In the winter, the forced air systems used

to heat most homes, can drive temperatures

up and humidity levels dangerously low for

guitars. A good measure of protection against

drying out your guitar is to use a room

humidi er.

When the instrument is not in use, we

recommend that you keep it in its case and

use one of the small guitar humidi ers such

dealers. Do not leave the guitar out for long

periods near a heating vent, radiator or in

direct sunlight near a window.

Do not leave your guitar in the trunk of

Please note:

Damage caused to the guitar as the result

®

warranty.

by changes in temperature and humidity.

While a crack may initially be alarming, if

it is taken care of promptly it shouldn’t be a

be repaired without compromising structural

If the crack is in the top, near the bridge,

loosen all the strings to reduce tension,

problem), and have the crack repaired as

Please note: Cracks in

the wood, which occur as the result of

®

warranty.

Finish checking, (very small splits in

the nish), usually occurs in winter and is

typically the result of suddenly exposing

temperatures.

All of the materials that make up a

guitar expand and contract with changes

in temperature and humidity, and they do

this at different rates. Wood expands as it

warms, and it does so faster than the nish

placed over it. When this expansion occurs,

the nish does stretch somewhat, but when

it cannot stretch anymore, it will split and

Although it does not affect the tone of the

instrument, this nish checking mars its

When an instrument has been brought

into a building after it has been out in the

Please note: Finish checks,

which occur as the result of exposure to

temperature or humidity changes will not

be covered under the Gretsch warranty.

Clean the instrument after each use, making

well as any of the plated parts, i.e. machine

heads, pickups, etc. with a soft dry cloth.

For gloss nishes, use a non-silicone based

guitar polish. For satin nishes, use only a

nishes, use a soft, slightly damp cloth and

When not playing the instrument, keep it

tuned to pitch and in its case. However, if you

plan to store the instrument for long periods

tension, but do not remove them.

The natural oils in Rosewood and Ebony

ngerboards may dry out over time. Rough,

your fretboard a drink of raw linseed oil

periodically to preserve its integrity and

natural beauty. Remove the strings rst; then

into the wood, let it soak in, and then wipe to

dry any excess oil.

Be careful when using vinyl, plastic or

tubing, as these materials may react with,

Please

the use of non-FMIC-approved polishes,

be covered under the Gretsch

®

warranty.

Tuning Machines

Gretsch

®

uses only the nest tuning

machines. Many of these machines are pre-

lubricated, die-cast, sealed tuners, which

do not require periodic oiling for smooth

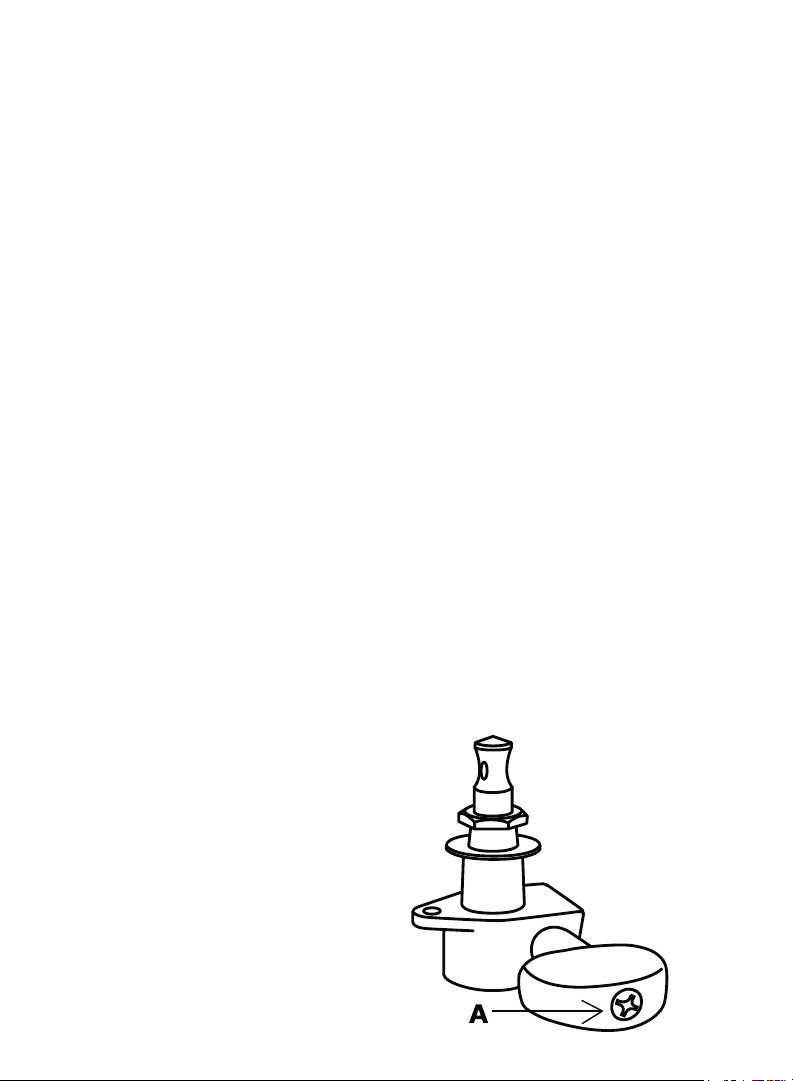

A small tension adjustment screw is located

tension is too loose, the machine may slip

the button may become very dif cult to turn.

Make sure that the adjustment is rm, but not

too tight.

Next, depress the “B” string at the 5th fret,

to produce an “E” and tune the thinnest string

to a matching “E”.

Finally, go back and play the low “E” string

“A”, matches the “A” on the adjacent string.

If using an electronic tuner on your electric

guitar, turn the volume up and tune from low

Tuning 12-String Guitars

Due to the tremendous amount of tension

In standard 12-string tuning, the second

pitches, E, A, D, G, B, E, and using the

previous page.

For the E, A, D, and G strings, the rst

its partner. For the B and E strings, the rst

the same pitch), as its partner string.

Many players nd it dif cult to press the

tension caused by the extra strings.

A remedy that some players choose is to

tune the entire guitar to a lower relative pitch,

the rst or second fret, to bring it back up to

where it plays at standard pitch.

The guitar will certainly be easier to play,

the neck over time, but bear in mind that it

will also sacri ce a bit of the tone projection

All Gretsch

®

however, a 12-string tuned at standard

pitch, should be monitored regularly for

For instruments with open gear tuners, make

lightweight oil from time to time for smooth

The Chrome and Gold plating on Gretsch

tuning machines may become degraded from

the acids and oils in nger sweat. Wipe the

machines off with a soft dry cloth after each

use to preserve their appearance and function.

Strings that have not been secured

properly to the tuning machine post may

is commonly misdiagnosed as an issue with

the tuners. Check your string installation

Tuning 6-String Guitars

There are a couple of different methods

your guitar is acoustic, electric or an

tone, you may want to purchase one. It will

dramatically simplify tuning your acoustic or

Always tune from below pitch,

up

to the

pitch. This will help eliminate string slack

possibility of slippage and tuning changes

low

(thickest)

(thinnest): E, A, D, G, B, E.

If you have an acoustic guitar use the A-

440 reference tone on your tuner, a guitar

pitch pipe, an A-440 tuning fork or other

pitch reference, and tune the second string,

“A” to pitch.

Then, depress the second, or “A” string at

the 5th fret, to produce a “D”, and tune the

“D” string to that same pitch.

Next, depress the D string at the 5th fret, to

produce a “G”, and tune the “G” string until

the pitches match.

Next, depress the “G” string at the 4th fret,

to produce a “B”, and tune the “B” string

until the two pitches match.

Loading...

Loading...