Page 1

T02.0.3X.6C-05 Page 1 of 6

WEEE-Reg.-Nr. DE93889386

GREISINGER electronic GmbH

D - 93128 Regenstauf, Hans-Sachs-Straße 26

+49 (0) 9402 / 9383-0 +49 (0) 9402 / 9383-33 info@greisinger.de

Operating Manual

for Dissolved Oxygen-Measuring transducer

OXY 3610 MP

Specification:

Measuring range: 0.00 to 25.00 mg/l dissolved oxygen

Output signal: refer to type plate

Accuracy: (at nominal temperature)

Display ±1.5% of measured value ±0.2 mg/l

Output signal: ±0.2 % FS

Connection: 4 - 20 mA (2-wire)

Voltage (3- resp. 4-wire)

Electric isolation: input electrically isolated

Auxiliary energy: (supply voltage) Uv = 12 - 30 V DC (4-20mA)

Uv = 18 - 30 V DC (0-10V)

or refer to type plate

Reverse voltage protection: 50V permanent

Perm. impedance (at 4-20mA): RA(Ohm) < ( (Uv - 12V) / 0.02A )

Example: for Uv = 18V: RA < (18V - 12V) / 0.02A => RA < 300 Ohm

Permissible load (at 0-...V): RL(Ohm) > 3000 Ohm

Electrode: Special oxygen electrode GWO3600MU (in scope of supply!)

Electrode type: active diaphragm type, with integrated NTC resistor

Response time: 95% in 10 sec., depending on temperature

Operation life: 3 years er more, depending on proper maintenance

Operating pressure: max. 3 bar.

Mounting diameter: Ø 12,0 ±0,2 mm (also suitable for ½" glanding)

Length: approx. 220 mm (incl. anti-buckling glanding), Mounting length: approx. 110 mm

Weight approx. 180 g

Electrode connection: 5 pole screwable socket

Temperature compensation: automatic, 0 ... 50 °C

Calibration: via keypress at ambient air

Display: approx. 10 mm high, 4-digit LCD-display

Nominal temperature: 20 °C

Operating temperature: 0 to 50 °C (electrode 0 to 40 °C)

Relative humidity: 0 to 95 %RH (non-condensing)

Storage temperature: -20 to 70 °C (electrode 0 to 60 °C)

Housing: ABS (IP65 - with the exception of electrode and temperature probe connection sockets)

Dimensions: 82 x 80 x 55 mm (without elbow-type plug and sensor sockets)

Mounting: With fixing holes for wall mounting (in housing - accessible after cover has been

removed).

Mounting distance: 50 x 70 mm, max. shaft diameter of mounting screws is 4 mm.

Electric connection: elbow-type plug conforming to DIN 43650 (IP65),

max. wire cross section: 1.5 mm², wire/cable diameter from 4.5 to 7 mm

EMC: The

device corresponds to the essential protection ratings established in the Regulations of the

Council for the Approximation of Legislation for the member countries regarding electromagnetic

compatibility (2004/108/EG).

Additional error: <1%

Page 2

T02.0.3X.6C-05 Page 2 of 6

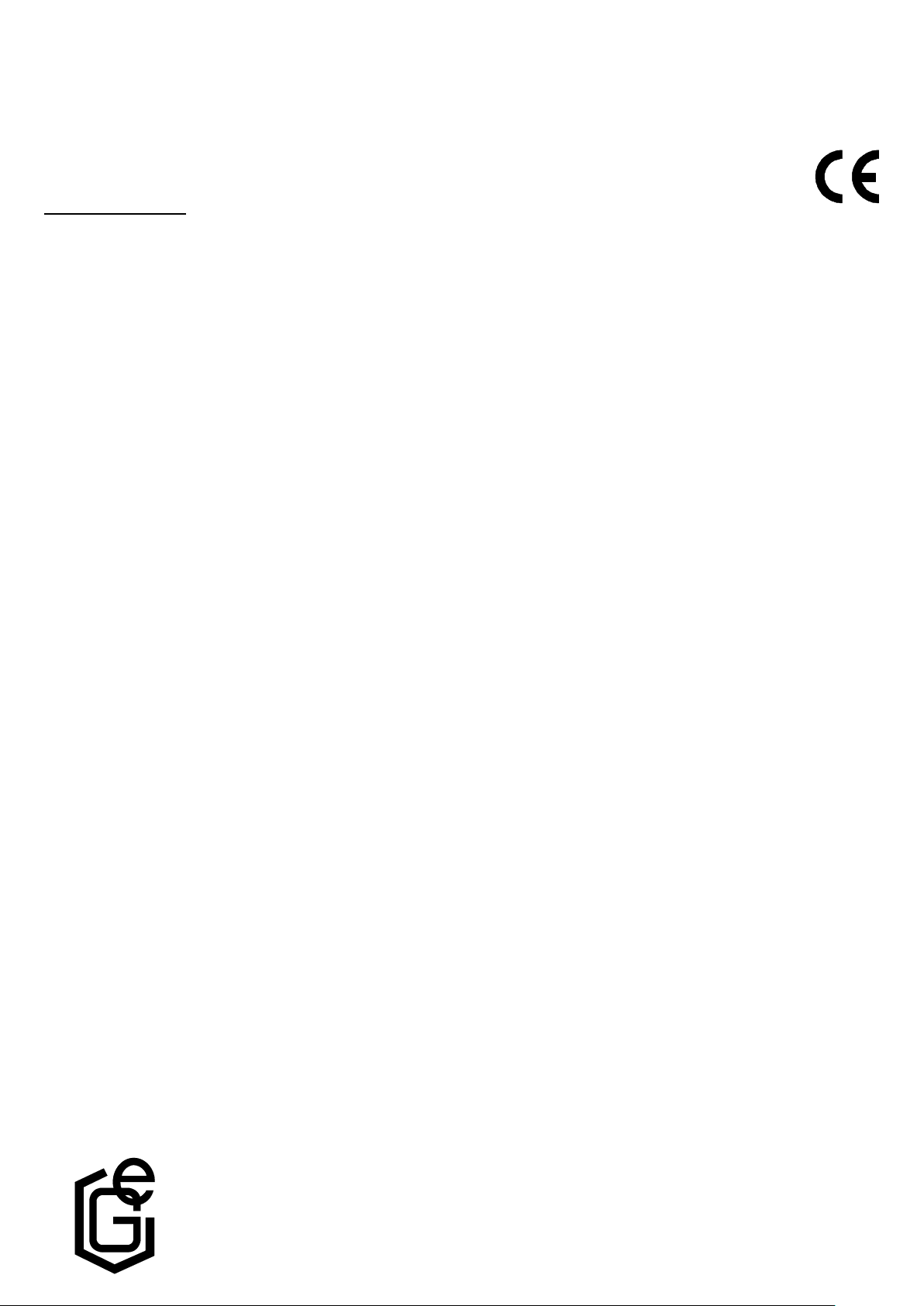

Assignment of elbow-type plug:

2-wire connection (4-20mA) 3-wire connection (voltage) 4- wire connection (voltage)

1 = supply voltage +Vs 1 = signal + 1 = signal +

2 = GND / signal 3 = supply voltage +Vs 2 = signal -

(4) = supply voltage -Vs 3 = supply voltage +Vs

signal - (4) = supply voltage -Vs

General installation instructions:

To mount the connection cable (2-, 3-, or 4-wire depending on type of device) the elbow-type plug screw has to be

loosened and the coupling insert has to be removed by means of a screw driver at the position indicated (arrow).

Pull out connection cable through PG glanding and connect to the loose coupling insert as described in the wiring

diagram. Replace loose coupling insert onto the pins at the transducer housing and turn cover cap with PG glanding in

the direction desired till it snaps on (4 different starting positions at 90° intervals). Re-tighten the screw at the angle plug.

Safety instructions:

This device has been designed and tested in accordance with the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special

safety advises given in this manual will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected to any other

climatic conditions than those stated under "Specification". If the device is transported from a cold to a warm

environment condensation may cause in a failure of the function. In such a case make sure the device temperature

has adjusted to the ambient temperature before trying a new start-up.

2. General instructions and safety regulations for electric, light and heavy current plants, including domestic safety

regulations (e.g. VDE), have to be observed.

3. If device is to be connected to other devices (e.g. via PC) the circuitry has to be designed most carefully. Internal

connection in third party devices (e.g. connection GND and earth) may result in not-permissible voltages impairing or

destroying the device or another device connected.

4. If there is a risk whatsoever involved in running it, the device has to be switched off immediately and to be marked

accordingly to avoid re-starting.

Operator safety may be a risk if:

- there is visible damage to the device

- the device is not working as specified

- the device has been stored under unsuitable conditions for a longer time.

In case of doubt, please return device to manufacturer for repair or maintenance.

5. Warning:

Do not use these product as safety or emergency stop devices, or in any other application where failure of the product

could result in personal injury or material damage.

Failure to comply with these instructions could result in death or serious injury and material damage.

6. Caution, acid! The electrode contains KOH. KOH can cause severe chemical burns!

If leaking, avoid contact!

If there was contact:

• to skin: Flush contacted area with large amounts of water for several minutes.

• to clothing: remove contaminated clothing.

• to eyes: Flush with large amounts of water for several minutes,

obtain medical treatment.

After swallowing:

• give large volumes of water. DO NOT induce vomiting!

• Obtain medical treatment.

Page 3

T02.0.3X.6C-05 Page 3 of 6

Display

Meaning

Possible fault causes

Remedy

CFE.1

Temperature out of

allowed range

Temperature has to be within 5 to 40°C

Calibrate again at correct temperature

electrode error

Temperature sensing defective

Check cable, connection, replace

electrode if necessary

CFE.3

Wrong signal: to low

Membrane dried out/electrode used up

Electrode maintenance / replace

CFE.4

Wrong signal: to high

Calibration surrounding not valid

Check Calibration surrounding

CFE.6

Instable signal

Calibration surrounding not valid

Check Calibration surrounding

Display functions:

During normal operation the oxygen content is displayed in the unit [mg/l]. By pressing the Key 2 (down) the

temperature at the electrode can be shown, pressing key 3 (up) shows the state of the electrode in [%]. The state is

calculated and stored during the calibration (see below). The displays of the state and the temperature of the electrode

are marked by small arrows at the upper end of the display. After 5 seconds the transducer display switches

automatically back to the oxygen value.

display dissolved oxygen display electrode temperature display state of electrode

Calibration of the electrode:

Expose electrode to the ambient air, wait until the temperature has adopted to the ambient conditions.

Press key "SET" for 5 sec., The display shows "CAL".

After approx. 10 sec’s the transducer is calibrated or a referring error message will be shown:

Important!! Oxygen electrodes are sensitive components. Please read the referring manual prior to use.

During calibration the state of the electrode is evaluated: 100% means perfect state, 40 % means e.g. electrode has a

weak output signal and needs to be regenerated or replaced soon (p.r.t. electrode manual). The state of the electrode can

be displayed with key 3 (up).

Configuration of the device

For the correct function of the device in its application, it has to be configured to meaningful settings.

For doing this the cover has to be removed. Then the jumper J1 right above of key 2 has to be set.

Then use following configuration procedure:

1. Press key one more than 5 sec’s until OFFS appears in

the display. Now OFFS and the referring setting are shown alternating

I.) OFFSET of the measuring „OFFS“ :

The offset is entered in mg/l. It can be used to compensate different effects, e.g. special

approaching flow conditions of the application. Please refer to Appendix A

2. Enter the desired value by using keys 2 (down) and 3 (up).

Input range: -1.00...+0.00 mg/l

3. Acknowledge the value with key 1 (set): The display shows „PAbS“

Page 4

T02.0.3X.6C-05 Page 4 of 6

Display

Description

Possible fault cause

Remedy

FE 1

measuring range exceeded

Calibration is wrong

Wrong signal

Recalibrate the transducer.

FE 2

Measuring values below

measuring range

Wrong signal

Check the connections, cable and electrode.

FE 7

System fault

Error in device

Disconnect from supply and reconnect. If error

remains: return to manufacturer

FE 9

Input signal is not valid

Sensor not connected or

cable defective

Check sensor, cable and connections

8.8.8.8

Segment test

The transducer performs a display test for 2 seconds after power up. After

that it will change to the display of the measuring.

Input signal is not valid

Permissible input range is

exceeded

Check if not a wrong electrode is connected.

Replace electrode.

-0,6

-0,4

-0,2

0

0,3 0,5 0,7 0,9 1,1 1,3 1,5 1,7 1,9

v [m/s]

Offset [mg/l]

II.) Average ambient absolute pressure „PAbS“ (function of the altitude above sea level):

Necessary for a correct evaluation of the state of the electrode. If the application works for example at an altitude of

350 m above sea level, 980mbar is a correct setting. Please refer to Appendix B

4. Enter the desired value by using keys 2 (down) and 3 (up).

Input range: 500...2000 mbar

5. Acknowledge the value with key 1 (set): The display shows „FilLt“

III.) Display damping „FiLt“:

By this factor the ‘speed’ of the display can be adopted to the application. This is intended to reduce instabilities in the

measured value as they appear in some specialised applications

6. Enter the desired value by using keys 2 (down) and 3 (up).

Input range: 0...15 (0: fast display, 15: slow display. Setting ex works: 10)

7. Acknowledge the value with key 1 (set).

8. The settings are stored. The unit starts up again. (8888 in display)

Attention: Bring back the jumper j1 to the ‚parking position‘ after configuration (one contact connected, the

second contact ‚on air‘)!

Then the device can be calibrated by key 1 and the configuration data is protected.

Error and System Messages

Appendix A: Offset settings for different applications

The Offset setting is supposed to correct measuring deviations caused by different flow speed (v) around the electrode:

For activated sludge basins and at flow speeds > 1m/s a offset setting

of ca –0,6 should be entered.

In between 0,3 and 1m/s the offset can be read from the diagram.

0,3m/s correspond to the speed that is achieved by stirring by hand.

Flow speeds below 0,3 m/s are not sufficient to get a correct and

reproducible measuring.

Page 5

T02.0.3X.6C-05 Page 5 of 6

Altitude [m]

Pabs[mbar)

Altitude[m]

Pabs[mbar)

-100

1025

900

909 0 1013

1000

898

100

1001

1200

877

200

989 1400

856

300

977 1600

835

400

966 1800

814

500

954 2000

794

600

943 2500

746

700

932 3000

701

800

920 4000

616

Replenishing hole

Electrode shaft

O-ring

Diaphragm head

Appendix B: abs. ambient pressure as a function of the altitude above sea level

Values between are to be interpolated

Appendix C: the oxygen electrode:

The oxygen electrode is an active electrode consisting of a silver cathode and a lead

anode using potassium hydroxide (KOH) as an electrolyte. In case of oxygen being

present it will be reduced at the silver cathode and the electrode produces electric

current. In case of no oxygen being present not current will be produced. Both the

silver cathode and the lead anode will be used up during oxygen measuring. The

electrode ages. We, therefore, recommend regular maintenance of the electrode at

monthly intervals (p.r.t. ‘Electrode maintenance’).

Electrode design:

The electrode housing is made of PVC. With the exception of the electrode shaft all

parts need to be maintained regularly and be replaced if necessary.

o Protective flask: The protective flask is used to moisten the diaphragm. The service

life of the electrode will be prolonged. The protective flask contains water.

Attention! Use water only; never use potassium chloride (KCI); this is only required for

storage of pH-electrode.

o Diaphragm head: the diaphragm head is covered with a teflon diaphragm. It will be

filled with KOH electrolyte and screwed onto the electrode shaft (no air bubbles).

Damages in the diaphragm, large air bubbles or air bubble rings in the diaphragm head

will result in erroneous measurements. This may also be the reason for errors in the

calibration. The diaphragm head is a spare part and can be ordered individually.

o Filling hole: If the electrode is used at high temperatures or if it has been stored

without its protective flask for a longer period of time, some electrolyte will be lost due

to evaporation. If necessary unscrew diaphragm head, remove locking screws and top

up electrolyte using a syringe. Replace and tighten locking screws. Normally some

electrolyte can be observed penetrating at the silver cathode.

When is electrode maintenance required:

• Unless it is used the electrode is to be stored in the protective flask filled with water or directly in a vessel filled with

dechlorinated water.

• Residues of bacteria, fungi or algae must be removed prior to measuring using a soft paper towel.

• If a calibration can no longer be carried out or if the membrane is damaged the electrode needs maintenance.

• In the course of the time air bubbles may accumulated underneath the membrane. As long as they are small and do not

affect the silver cathode the measurements will not be influenced. If, however, there is a large ring of air bubbles

underneath the membrane covering the silver cathode, the electrode needs maintenance.

! Attention during maintenance is required as the electrolyte is highly corrosive !

Use disposable gloves during maintenance, if available, or rinse hands thoroughly with water.

Page 6

T02.0.3X.6C-05 Page 6 of 6

Electrode maintenance:

1. Prepare liquid absorbing paper towel.

2. Remove membrane head and wipe off electrolyte solution with paper cloth.

Do not touch electrolyte. If your skin has come into contact with electrolyte, rinse thoroughly with clear water.

3. Clean silver cathode using sand paper (grain size 240). Do not shine silver cathode as its surface needs to be rough

so that the electrolyte can be dispersed evenly. Remove any dust from grinding.

4. If necessary take out replenishing screw and top up with electrolyte till it is spilling out (e.g. using a disposable

syringe). Put back replenishing screw. (normally not necessary)

5. Put new membrane head on the paper towel and fill up with electrolyte making sure there are no air bubbles.

6. Put electrode into head vertically from above till the thread catches. Then take up head with paper towel and screw

onto electrode from underneath. Electrolyte will be displaced from the membrane head, flowing over.

7. Mop up excess electrolyte using paper towel.

8. Turn electrode around and check for air bubbles. If there are no air bubbles or only tiny ones the maintenance has

been completed. If there are large air bubbles the process has to be repeated.

If O-ring has been damaged, it has to be replaced.

Please note: Prior to its being calibrated again the electrode needs to be lying on a table for at least 3 hours.

If electrode can no longer be calibrated although it has been properly maintained, the electrode needs to be returned to

manufacturer for check up and may have to be replaced.

How to Operate:

a.) Store the oxygen electrode always in water, either in the protective flask, or directly in a vessel filled with

dechlorinated water. For storage in the protective flask first push the cap oh the electrode second the o-ring and

thereafter put the electrode in the flask and screw the cap down the flask.

If the diaphragm has dried up the electrode must be soaked in water for approx. 2 h prior to measuring start-up. Then

a calibration can be carried out without any problems.

b.) The electrode are only suitable for the devices OXY3610MP. Unsuitable devices may lead to the destruction of the

measuring device and the oxygen electrode.

c.) For measuring remove the protective flask of the electrode

d.) Please note: the electrode measurement is sensitive against shocks!

By stirring of the electrode in the measured liquid be careful that the electrode does not hit the container. A vibration of

the electrode has a effect to the measured value.

Disposal instructions

The electrode contains lead and caustic electrolyte. Dispose as special waste.

According to the ElektroG (law for bringing into market, the return and the environmentally friendly disposal of

electronic equipment) we accept the return of the electrode and the device.

Send the device or electrode directly to us (sufficiently stamped), if it should be disposed. We will dispose it

appropriately and environmentally friendly.

Loading...

Loading...