H04.0.03.6C-09 page 1 of 2

Specification:

Measuring range: -50 to +1150°C

Resolution: 1°C

Accuracy: (at nominal temperature) better than 1% ± 1 digit from -20 to +550°C and 920 to 1150°C. Better than 1,5% ± 1 digit

from 550 to 920°C. For more detailed values please refer to att. correction table.

Sensor: NiCr-Ni, acc. to ½ DIN 43710, for plug-in operation

GTF300: 2 teflon-isolated, helically winded thermoelement wires with a dia. of 0, 2mm each, length approx.

1m with miniature flat plug, free from thermo-voltage. Sensor suitable for surface and immersion

measurements. Response time in liquids 0,3sec. Measuring range: -65 to 300°C.

Display: approx. 13 mm high, 3 1/2digit LCD

Nominal temperature: 25°C

Working temperature: 0 to 45°C, please avoid quick temperature changes, if possible, otherwise a temperature

adjustment time of approx. 15 minutes has to be taken into account.

Atmospheric humidity: 0 to 80 % r.F. (not condensing)

Storage temperature: -10 to 70°C

Power supply: 9V-battery type IEC 6F22 (included)

Battery service life: approx. 700 operating hours

Low battery warning: "BAT" displayed automatically in case of low battery

Dimensions of case: approx. 106 x 67 x 30 mm (H x W x D)(sensor not included)

Weight: approx. 150g (incl. battery)

Electromagnetic compatibility: The device corresponds to the essential protection ratings established in the Directives of

the European Parliament and of the council on the approximation of the laws of the

memberstates relating to the electromagnetic compatibility (2004/108/EC).

Operating Manual for Digital Quick-Response Thermometer

GTH 1150C

Points to be observed during operation

1. As soon as „BAT“ is displayed the battery is used up and needs to be replaced immediately as too low operating voltage

may result in incorrect measurements. Unless the battery is replaced immediately the voltage will not even be enough to

display “BAT”. Therefore, make it a rule to always check the battery – even if no ‘BAT’ warning is displayed – if measuring

results are incorrect.

2. Make sure to maintain device properly and to operate it in accordance with the specification listed (do not throw, knock etc.).

3. Make sure that sensor and device are always subjected to the same temperature, i.e. try to avoid holding sensor plug in

your hand for a longer periode of time as well as subjecting device to an additional heat source as this may result in

measuring inaccuracies.

4. The length of the measuring sensor GTF300 can be reduced as desired so that it will be fully operational again after

sensor has been broken. To do so, please strip both wire ends for approx. 10mm and twist well. Measurements are not

possible as long as wire ends are exposed.

5. The battery has to be taken out, when storing device above 50°C.

It is recommended to take the battery out, when storing device for a longer period of time

General:

The GTH1150C are digital pocket thermometers for quick response temperature measurements.

Depending on the used measuring probe measurements on surfaces, in liquids, soft media, air/gases, at smallest objekts,

etc. are possible.

D - 93128 Regenstauf, Hans-Sachs-Straße 26

Fon: 0049 9402 / 9883-0

Fax: 0049 9402 / 9383-33

GREISINGER electronic GmbH

H04.0.03.6C-09 page 2 of 2

Safety Advices

This device has been designed, assembled and tested in accordance with the safety regulations for electronic measurement

devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special

safety advices will be adhered to when using the device.

1. Trouble-free operation and reliability of the device can only be guaranteed if the device is not subjected to any other

climatic conditions than those stated under "Specification".

2. Moving the device from a cold to a warm environment may lead to malfunctions due to condensation. In such a case we

recommend waiting to allow device temperature to adjust to the ambient temperature before re-starting.

3. If there is any risk whatsoever involved in running it, the device has to be switched off immediately and to be marked

accordingly to avoid re-starting.

Operator safety may be a risk, if :

- there is visible damage done to the device.

- the device is not working as specified.

- the device has been stored under unsuitable conditions for a longer time.

In case of doubt, please return device to manufacturer for repair or maintenance

Temperature Display

-50 -45.8

-40 -36.9

-30 -27.9

-20 -18.6

-10 -9.3

0 0.3

10 10.0

20 19.8

30 29.6

40 39.6

50 49.6

60 59.7

70 69.8

80 80.0

90 90.0

100 100.1

110 110.2

120 120.2

130 130.2

140 140.1

150 149.9

Temperature Display

160 159.7

170 169.5

180 179.2

190 188.9

200 198.7

210 208

220 218

230 228

240 238

250 248

260 258

270 268

280 278

290 288

300 298

310 308

320 318

330 328

340 339

350 349

360 359

Temperature Display

370 369

380 379

390 390

400 400

410 410

420 421

430 431

440 441

450 452

460 462

470 472

480 483

490 493

500 504

510 514

520 524

530 535

540 545

550 556

560 566

570 576

Temperature Display

580 587

590 597

600 607

610 618

620 628

630 639

640 649

650 659

660 670

670 680

680 690

690 700

700 711

710 721

720 731

730 741

740 751

750 762

760 772

770 782

780 792

Temperature Display

790 802

800 812

810 822

820 832

830 842

840 852

850 862

860 871

870 881

880 891

890 901

900 911

910 920

920 930

930 940

940 949

950 959

960 969

970 978

980 988

990 997

Temperature Display

1000 1007

1010 1016

1020 1026

1030 1035

1040 1045

1050 1054

1060 1063

1070 1073

1080 1082

1090 1091

1100 1100

1110 1110

1120 1119

1130 1128

1140 1137

1150 1146

1160 1155

1170 1164

1180 1173

Correction table

Recalibration:

The measuring device will be calibrated before leaving our works. A recalibration is, therefore, not necessary. If you want to

calibrate the device for an existing sensor, please proceed as follows: (calibrate 0°C before scale as otherwise correct

adjustment cannot be guaranteed)

Normally sensor adjustment by means of 0° C potentiometer is sufficent. We do not recommend a scale compensation in

order to maintain the specified accuracy of the device. If an accurate reference temperature is available, choose highest

temperature possible to calibrate the device.

Calibration point 0°C: Put ice cubes in a glass and pour cold water till ice cubes are

almost covered. Put sensor into glass, wait approx. 15 minutes, then stirr water with

a spoonhandle. Wait for stable value to be displayed, then turn zero point

potentiometer (NP, Potentiometer next to sensor connection) by means of a

screw driver till display shows "000".

Calibration point scale: To set the pitch (Scale) a fixed reference temperature is

required (the higher the better). Subject sensor to this temperature and set respective

display value according to correction table value (e.g. reference temperature 700°C

-> value to be set: 711) by means of pitch potentiometer (outer potentiometer).

Please note that boiling water should not be used as a temperature reference as the boiling temperature is dependent on the

atmospheric pressure. (If using a reference thermometer stating the precise temperature you may, however even use boiling water.)

Please note : During the waiting time the device should have assumed ambient temperature (we recommend a temperature

of 20 to 25°C). Please avoid holding device in your hand as well as subjecting it to an additional heat source (e.g. radiator,

lamp, sun).

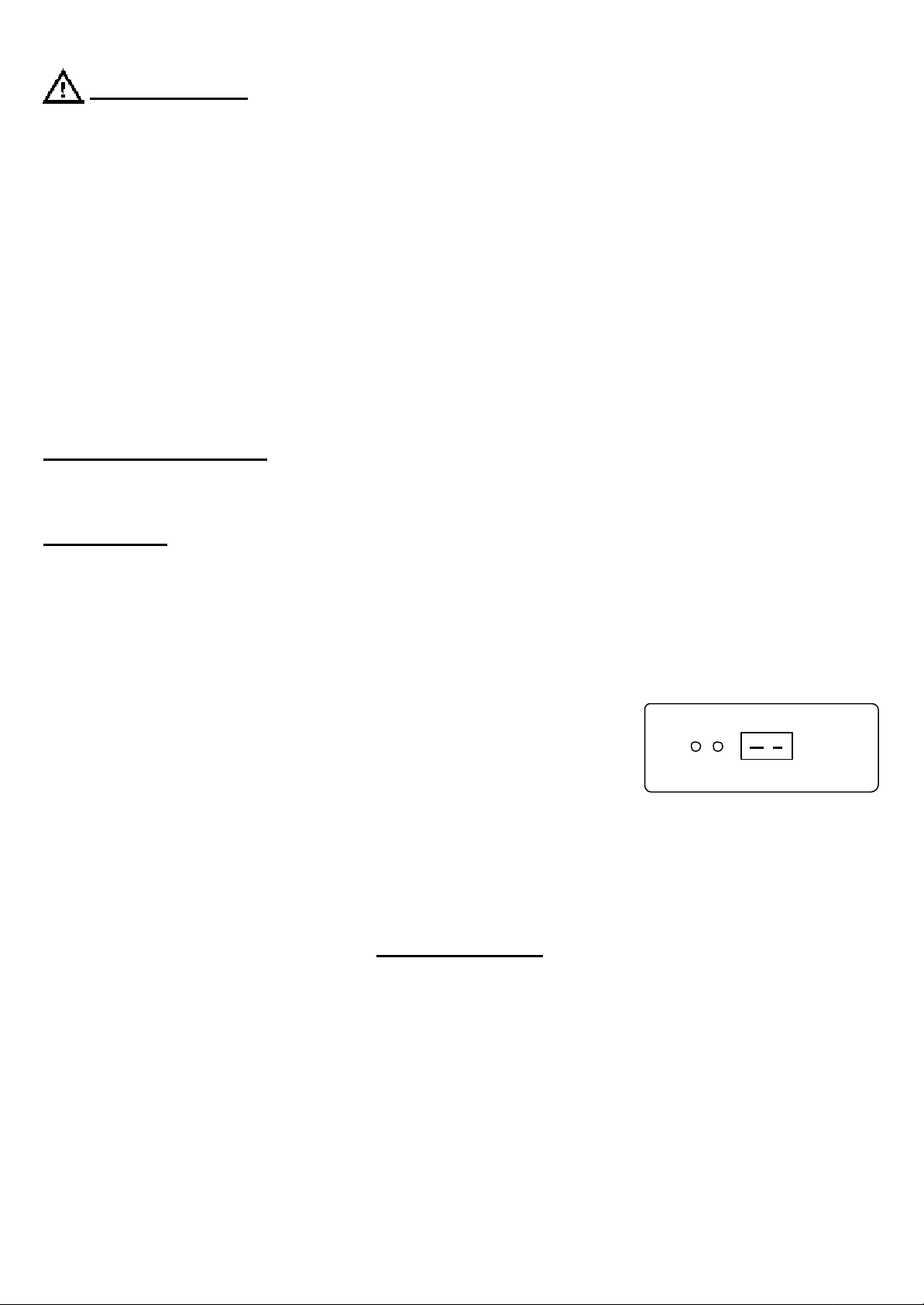

Sensor Socket

View of frontplate

Scale

NP

Disposal instruction:

The device must not be disposed in the unsorted municipal waste! Send the device directly to us (sufficiently stamped), if it

should be disposed. We will dispose the device appropriate and environmentally sound.

Loading...

Loading...