Green Machines 636 User Manual

636

Home

Find...

Go To..

Air Sweeper

Operator Manual

CloudMaker®Technology

Vari- tracktTechnology

Global

www.greenmachines.com

9006280

Rev. 04 (10-2011)

*9006280*

This manual is furnished with each new model. It provides necessary operation and maintenance instructions.

Home

Find...

Go To..

Read this manual completely and understand

the machine before operating or servicing it.

Read this manual completely and understand the machine before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the machine maintenance instructions provided.

S The machine is maintained with manufacturer supplied or equivalent parts.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

old machine components such as

batteries, hazardous fluids, including

antifreeze and oil, in an environmentally

safe way according to local waste

disposal regulations.

Always remember to recycle.

MACHINE DAT A

Please fill out at time of installation for future reference.

Model No. --

Serial No. --

Machine Options --

Sales Rep. --

Sales Rep. phone no. --

Customer Number --

Installation Date --

Green Machines

Bankside, Falkirk FK2 7XE

Scotland, United Kingdom

Phone: (+44) 1324--611666

www.greenmachines.com

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553--8033 or (763) 513--2850

www.tennantco.com

The following publications are included with this

machine:

Operators Manual

Service Schedule

Parts Catalog

Kubota Engine Manual

The following optional publications can be purchased

separately:

Kubota Engine Workshop Manual

Kubota Engine Parts Catalog

Please contact a local Green Machines distributor to

order additional publications.

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Vari--track Technology is a US registered and unregistered trademark of Green Machines Company.

Specifications and parts are subject to change without notice.

Copyright E 2009, 2010, 2011 Green Machines Company, Printed in U.S.A.

CONTENTS

Home

Find...

Go To..

CONTENTS

Safety Precautions 3.......................

Operation 7...............................

Machine Components 7..................

Controls And Instruments 8...............

Symbol Definitions 10.....................

Operation Of Controls 1 1..................

Drive Lever

(Forward / Neutral / Reverse) 11......

Brush Levers 1 1.......................

Fuel Gauge 1 1........................

Tachometer 11........................

Hour Meter 11........................

Engine T emperature Gauge 12..........

Parking Brake Indicator (Red) 12........

Turn Signal / 4--Way Warning Light

Indicator (Green) 12................

Charging System Malfunction

Indicator (Amber) 12................

Engine Oil Indicator (Red) 12...........

Headlight High Beam Indicator 12.......

Glow Plug Indicator (Amber) 13.........

Hopper Drain Switch 13................

Transit / Work Modes Switch 14.........

Brush Speed Knob 14..................

Vacuum Fan Speed Knob 15............

Vacuum Fan Speed Boost 15...........

Windshield Defroster Switch 15.........

Master Light Switch 16.................

Overhead Work Light Switch 16.........

Rear Fog Light Switch 16...............

Cab Temperature Control Knob 16.......

Heater Fan Switch 17..................

Air Conditioner (Option) 17.............

4--Way Warning Light Switch 17.........

Warning Beacon / Audible

Alarm Switch 17....................

Water Switch (Dust Suppression) 18.....

Water Flow Control Knob 18............

Brush Pressure Adjustment Knob 19.....

Parking Brake Lever 19................

Accelerator Pedal 19...................

Brake Pedal 19.......................

Steering Wheel Height

Adjustment Handle 20...............

Headlight And Multifunctional Switch 20..

Windshield Wiper / Washer Switch 20....

Horn Button 20........................

Operator Seat 21......................

Seat Belts 21.........................

Door Locks 21........................

Brush Information 22.....................

How The Machine Works 22...............

Pre--operation Checklist 23................

Post Operation Cleaning 23................

Page

Starting The Machine 24..................

Turning Off The Machine 25...............

While Operating The Machine 25...........

Sweeping 26............................

Driving Over Curbs 27....................

Raising / Lowering The Hopper 28..........

Engaging The Hopper Safety Arm 29.......

Disengaging The Hopper Safety Arm 30.....

Using The Wander Hose 30...............

Emptying The Hopper 32..................

Cleaning The Machine 33.................

Cleaning The Vacuum Fan Assembly 37....

Checking / Filling The Water Tank 37.......

Using The Machine Display

Module (MDM) System 38..............

Adjusting The Engine Speed 38............

Using The Engine Speed Boost 39.........

Machine Display Module (MDM)

Fault Screens 40......................

Options 42..............................

Pressure Washer (Option) 42...........

Rear View Camera (Option) 43..........

Radio And Compact Disk

Player (Option) 43..................

Automatic Greasing (Option) 43.........

Filling The Automatic Greasing

System Reservoir 43.............

Winter Equipment (Option) 44...........

Snow Brush (Option) 44.............

Snow Plows (Option) 45.............

Grit (Sand / Road Salt)

Dispenser (Option) 46............

Machine Troubleshooting 47...............

Conditions Table 49.......................

Maintenance 50.............................

Maintenance Chart 50....................

Lubrication 55...........................

Lubrication Points 55...................

Hydraulics 56............................

Hydraulic Hoses 57....................

Hydraulic Fluid 57.....................

Engine 58...............................

Engine Oil 58.........................

Cooling System 58....................

Engine Belt 58........................

Air Filter 59..........................

Fuel Filters 60........................

Fuel Lines 60.........................

Priming The Fuel System 60............

Valve Clearances 60...................

Battery 61

Fuses 62................................

...............................

Replacing The Fuses 62................

Page

636 9006280 (10-- 11)

1

CONTENTS

Home

Find...

Go To..

Brushes 63..............................

Replacing The Brushes 63..............

Adjusting The Brush Angle 63...........

Brush Linkage 64......................

Dust Suppression / Vacuum 65.............

Adjusting / Replacing The Nozzle Flap 65.

Vacuum Nozzle Skid 66................

Cast Iron Skid 66......................

Spray Jets 66.........................

CloudMaker 67........................

Water Tank 67..........................

Drain Cap Filter 67....................

Water Tank Door Retainer Chain 67......

Water Level Sensor 67.................

Hopper 68...............................

Hopper Door, Hopper Inlet, And

Vacuum Fan Access Door Seals 68...

Hopper Drain Seal 68..................

Hopper Cyclones Screens 68...........

Hopper Drain Screen 68................

Hopper External Drain Tube 69..........

Hopper Door Screen 69................

Hopper Raised Safety Switch 69........

Vacuum Fan Door Safety Switch 69......

Vacuum Fan Access Door 69...........

Cab 70..................................

Windshield Wiper Blades 70............

Rear View Camera (Option) 70..........

Windshield Washer Fluid 70...............

Steering And Suspension 71...............

Brakes And Tires 72......................

Service Brakes 72.....................

Parking Brakes 72.....................

Tires 72..............................

Wheel Torque 72......................

Wander Hose 73.........................

Pressure Washer (Option) 73..............

Tilting / Lowering The Cab 74..............

Tilting The Cab 74.....................

Lowering The Cab 74..................

Tilting / Lowering The Hopper Manually 75...

Tilting The Hopper Manually 75..........

Lowering The Hopper Manually 76.......

Towing / Transporting The Machine 77......

Towing The Machine 77................

Transporting The Machine 77...........

Machine Jacking 79......................

Storage And Freeze Protection 80..........

Storing The Machine 80................

Freeze Protection 80...................

Specifications 81............................

General Machine Dimensions/Capacities 81.

General Machine Performance 81..........

Hydraulic System 82......................

Steering 82..............................

Power Type 82...........................

Tires 82.................................

Machine Dimensions 83...................

Page

2

636 9006280 (10-- 11)

SAFETY PRECAUTIONS

Home

Find...

Go To..

SAFETY PRECAUTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

CAUTION: To warn of unsafe practices

that could result in minor or moderate

personal injury.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

The machine is suited to sweep disposable

debris. Do not use the machine other than

described in this Operator Manual.

The following information signals potentially

dangerous conditions to the operator or

equipment:

WARNING: Moving belt and fan. Keep

away.

WARNING: Machine emits toxic gases.

Serious injury or death can result.

Provide adequate ventilation.

WARNING: Raised hopper may fall.

Engage hopper support arm.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

WARNING: Flammable materials can

cause explosion or fire. Do not use

flammable materials in tank. Only use

water.

WARNING: Do not spray people or

animals. Severe personal injury can

result. Wear eye protection. Hold

sprayer with two hands.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- Unless mentally and physically

capable of following machine

instructions.

-- If it is not in proper operating

condition.

-- In flammable or explosive areas.

2. Before starting machine:

-- Check for fuel, oil, and liquid leaks.

-- Keep sparks and open flame away

from refueling area.

-- Make sure all safety devices are in

place and operate properly.

-- Check brakes and steering for proper

operation.

-- Adjust seat and fasten seat belt.

3. When starting machine:

-- Keep foot on brake and place

directional lever in neutral.

4. When using machine:

-- Do not pick up burning or smoking

debris, such as cigarettes, matches or

hot ashes

-- Use brakes to stop machine.

-- Go slow on inclines and slippery

surfaces.

-- Use care when reversing machine.

-- Move machine with care when hopper

is raised.

-- Make sure adequate clearance is

available before raising hopper.

-- Do not make adjustments on Machine

Display Module (MDM) System while

the machine is moving. Always stop

machine before making adjustments.

-- Do not carry passengers on machine.

-- Always follow safety and traffic rules.

-- Report machine damage or faulty

operation immediately.

636 9006280 (10-- 11)

5. Before leaving or servicing machine:

-- Stop on level surface.

-- Place the drive lever in neutral.

-- Set parking brake.

-- Turn off machine.

-- Remove key from ignition.

3

SAFETY PRECAUTIONS

Home

Find...

Go To..

6. When servicing machine:

-- Avoid moving parts. Do not wear loose

clothing or jewelry.

-- Block machine tires before jacking

machine up.

-- Jack machine up at designated

locations only. Support machine with

jack stands.

-- Use hoist or jack that will support the

weight of the machine.

-- Wear eye and ear protection when

using pressurized air or water.

-- Disconnect battery connections before

working on machine.

-- Avoid contact with battery acid.

-- Avoid contact with hot engine coolant.

-- Do not remove cap from radiator when

engine is hot.

-- Allow engine to cool.

-- Keep flames and sparks away from

fuel system service area. Keep area

well ventilated.

-- Use cardboard to locate leaking

hydraulic fluid under pressure.

-- Use Tennant supplied or approved

replacement parts.

7. When loading/unloading machine

onto/off truck or trailer:

-- Turn off machine.

-- Use truck or trailer that will support

the weight of the machine.

-- Use winch. Do not drive the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

-- Set parking brake after machine is

loaded.

-- Block machine tires.

-- Tie machine down to truck or trailer.

4

636 9006280 (2-- 08)

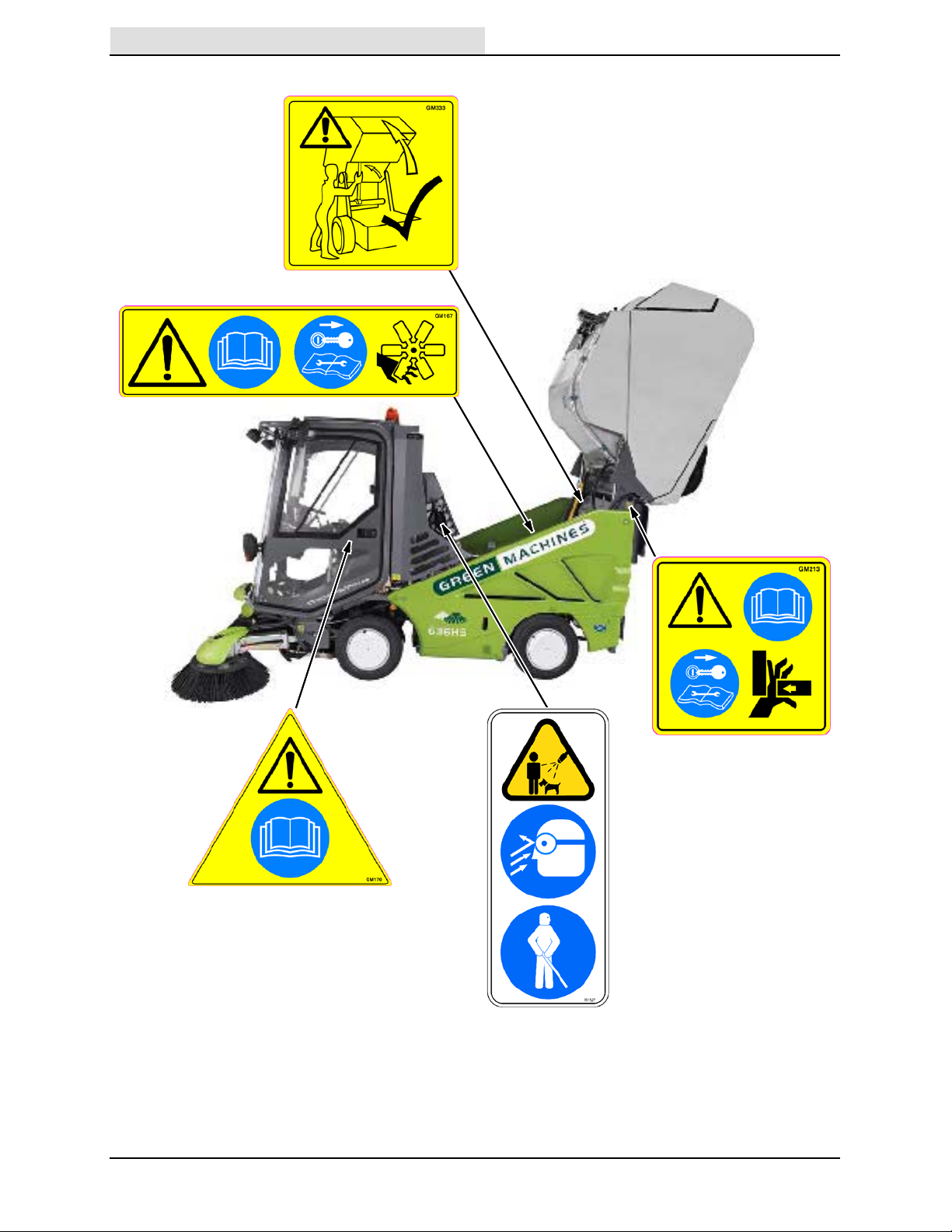

The following safety labels are mounted on the

Home

Find...

Go To..

machine in the locations indicated. If any label

becomes damaged or illegible, install a new label

in its place.

SAFETY PRECAUTIONS

636 9006280 (2-- 08)

5

SAFETY PRECAUTIONS

Home

Find...

Go To..

6

636 9006280 (2-- 08)

MACHINE COMPONENT S

Home

Find...

Go To..

OPERATION

OPERAT ION

17

3

4

5

9

8

10

11

18

1

6

7

2

21

1. Wander hose

2. Hopper

3. Warning beacon

4. Overhead work lights

5. Headlights / Turn signals

6. Right access door

7. Vacuum fan access door

8. Right brush

9. CloudMaker (dust suppression)

10. Spray jets (dust suppression)

11. Rear view camera (Optional)

20

13

19

12. Rear fog light

13. Water tank

14. Taillights / Turn signals

15. Water tank level tube

16. Water tank door

17. Left access door

18. Wander hose access door

19. Hydraulic fluid level indicator

20. Engine compartment

21. Left brush

14

15

16

12

636 9006280 (2-- 09)

7

OPERATION

Home

Find...

Go To..

CONTROLS AND INSTRUM ENTS

9

8

10

17

14

15

7

6

13

5

4

3

1

11

12

2

16

19

21

23

25

27

29

18

20

22

24

26

28

30

1. Left Brush Lever

2. Right Brush Lever

3. Drive Lever

(Forward / Neutral / Reverse)

4. Glow Plug Indicator (Amber)

5. Engine Temperature Gauge

6. Engine Oil Indicator (Red)

7. Charging System Malfunction

Indicator (Amber)

8. Turn Signal / 4--Way Warning Light

Indicator (Green)

9. Parking Brake Indicator (Red)

10. Fuel Gauge

11. Headlight High Beam Indicator

12. Tachometer

13. Hour Meter

14. Wander Hose Switch

8

15. Pressure Washer Switch (Optional)

16. Machine Display Module (MDM)

17. Hopper Drain Switch

18. Hopper Raise / Lower Switch

19. Transit / Work Modes Switch

20. Brush Speed Knob

21. Vacuum Fan Speed Knob

22. Windshield Defroster Switch

23. Overhead Work Light Switch

24. Rear Fog Light Switch

25. Master Light Switch

26. Air Conditioner Switch (Optional)

27. Heater Fan Switch

28. Warning Beacon / Audible Alarm Switch

29. 4--Way Warning Light Switch

30. Water Control Knob (Dust Suppression)

636 9006280 (2-- 09)

OPERATION

Home

Find...

Go To..

5

2

6

1

4

7

11

10

1. Parking Brake Lever

2. Cab Temperature Control Knob

3. Brush Pressure Adjustment Knob

4. Water Flow Control Knob

5. Accelerator Pedal

6. Brake Pedal

9

3

8

7. Steering Wheel

8. Steering Wheel Height Adjustment

Handle

9. Headlight and Multifunctional Switch

10. Windshield Wiper / Washer Switch

11. Horn Button

636 9006280 (2-- 09)

9

OPERATION

Home

Find...

Go To..

SYMBOL DEFINITIONS

These symbols are used on the machine to

identify controls, displays, and features.

Transit / Work Mode Hazard Lights

Brush Speed Signal Light / 4--Way Hazard Light

Brush Pressure Glow Plug (Preheat)

Vacuum Fan Speed Voltmeter

Horn Air Conditioner (Option)

Warning Beacon Parking Brake

Operating Lights Bright Headlights

Windshield Defroster Overhead Lights

Oil Pressure Dust Suppression 0

Master Lights Dust Suppression 1

Heater Fan Dust Suppression 2

Rear Fog Lights Water Flow Control

10

Raise / Lower Hopper Wander Hose (Option)

Hopper Drain Pressure Washer (Option)

636 9006280 (2-- 09)

OPERATION OF CONTROLS

Home

Find...

Go To..

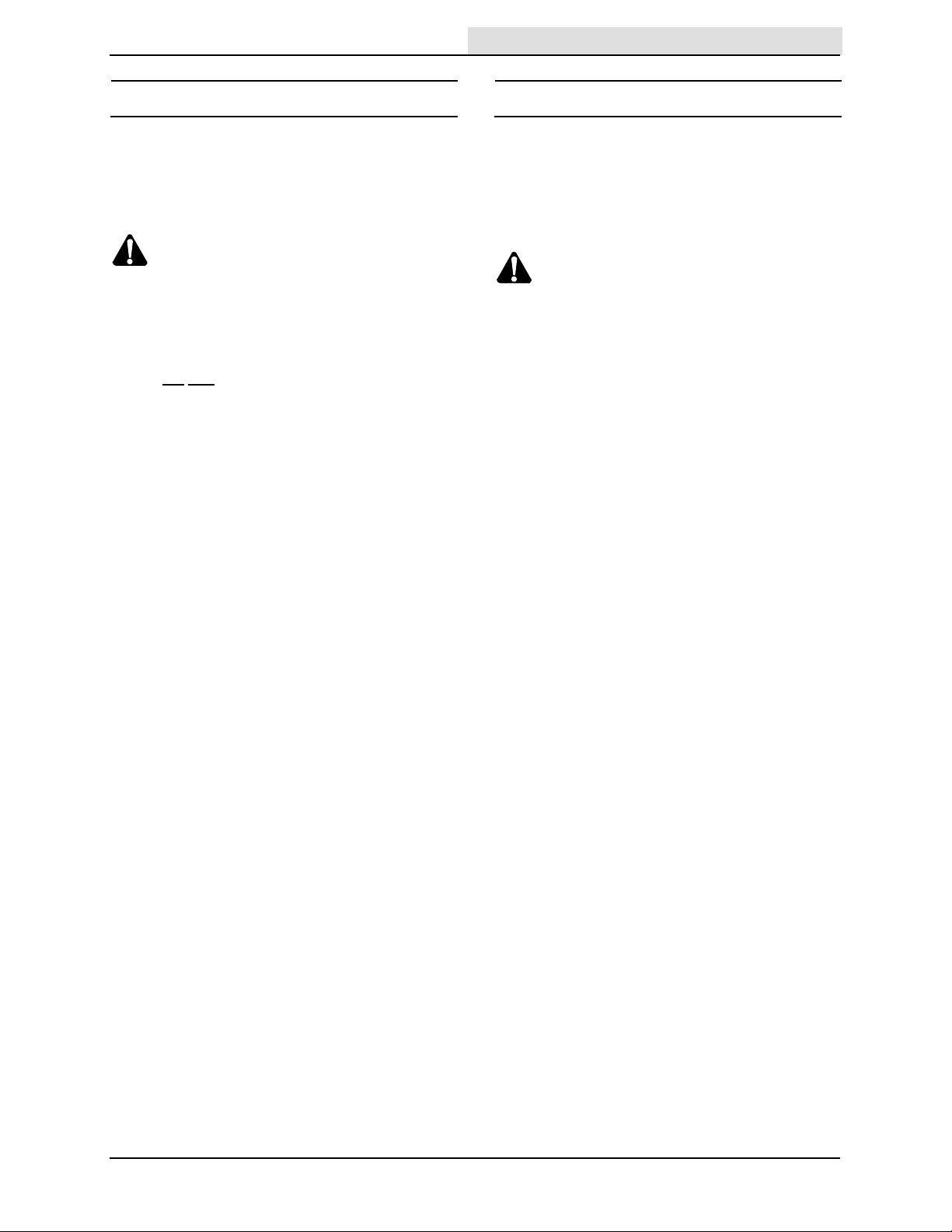

DRIVE LEVER

(FORWARD / NEUTRAL / REVERSE)

NOTE: Lift the lock toward the ball handle before

moving the drive lever to the desired position.

Forward: Place the Drive lever into the forward

position and press the accelerator pedal.

Neutral: Place the Drive lever into the middle

position.

Reverse: Place the Drive lever into the reverse

position and press the accelerator pedal.

OPERATION

FUEL GAUG E

The Fuel gauge displays the amount of fuel in the

tank. Use diesel fuel only.

TACHOMETER

The Tachometer displays the engine speed in

rotations per minute (rpm).

BRUSH LEVERS

Use the Brush levers to adjust the brush path

width and edge sweep.

HOUR METER

The Hour meter displays the number of hours the

machine was operated. Use this information to

determine machine service intervals.

636 9006280 (2-- 09)

11

OPERATION

Home

Find...

Go To..

ENGINE TEMPERATURE GAUGE

The Engine temperature gauge indicates the

engine temperature.

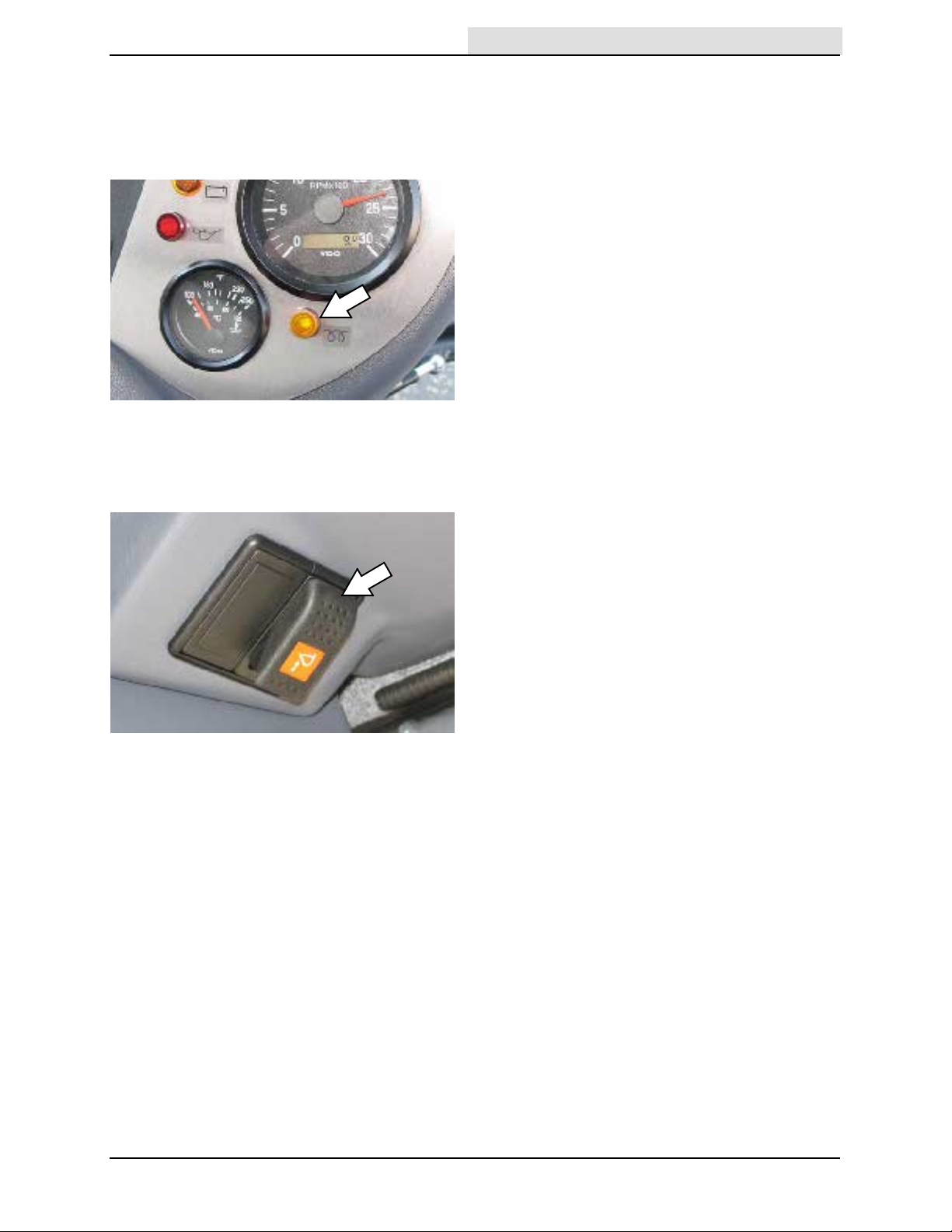

PARKING BRAKE INDICATOR (RED)

The Parking brake indicator illuminates when the

parking brake is engaged.

CHARGING SYSTEM MALF UNCT IO N

INDICATOR (AMBE R)

The Charging system malfunction indicator

illuminates when the alternator is not charging the

battery.

ENGINE OIL INDI CATOR (RED)

The Engine oil indicator illuminates when the oil

pressure is low.

TURN SIGNAL / 4--WAY WARNING L IG HT

INDICATOR (GREEN)

The Turn signal /4--way warning light indicator

illuminates when the turn signals or 4--way

warning lights are activated.

12

HEADLIGHT HIG H BEAM INDICATOR

The Headlight high beam indicator illuminates

when the headlight high beams are on.

636 9006280 (2-- 09)

GLOW PLUG INDICATOR (AMBER)

Home

Find...

Go To..

The Glow plug indicator illuminates when the

ignition switch is turned clockwise far enough to

activate light, but not far enough to start the

engine.

HOPPER DRAI N SWITCH

Use the Hopper drain switch to drain excess

water from the hopper.

OPERATION

636 9006280 (2-- 09)

13

OPERATION

Home

Find...

Go To..

TRANSIT / WORK MODES SWITCH

Transit Mode (top position) is for moving between

job sites. The machine can reach speeds up to 40

km/h (25 mph) when in this mode. The front

wheels automatically track out to provide more

stability when the machine exceeds 5 km/h

(approximately 3 mph). The brushes raise and

stop rotating, the vacuum head raises, and the

vacuum fan stops operating.

Work Mode 1 (middle position) is for sweeping.

The machine can reach speeds up to 12 km/h

(8 mph) when in this mode. If the front wheels are

in the out position, they will automatically track in

when the machine exceeds 5 km/h (approximately

3 mph). The brushes lower and begin rotating, the

vacuum head lowers, and the vacuum fan begins

operating.

Work Mode 2 (bottom position) is for moving short

distances between work areas and driving over

curbs or speed bumps. The machine can reach

speeds up to16 km/h (9 mph) when in this mode.

The brushes raise and stop rotating, the vacuum

head raises, and the vacuum fan stops operating.

The machine automatically provides increased

traction.

BRUSH SPEED KNOB

Turn the Brush speed knob clockwise to increase

the speed of both brushes and counterclockwise

to decrease the speed of both brushes.

14

636 9006280 (2-- 09)

OPERATION

Home

Find...

Go To..

VACUUM FAN SPEED KNOB

Turn the Vacuum fan speed knob clockwise t o

increase the vacuum and counterclockwise to

decrease the vacuum.

NOTE: For normal operating conditions the

vacuum fan speed should be set to below 2400

rpm.

VACUUM FAN SPEED BOOST

The vacuum fan speed can be set to above 2400

rpm (boost) for a short time (5 minutes). A

countdown bar appears on the MDM display.

Reduce the vacuum fan speed to less than 2400

rpm before the countdown bar expires. It must be

reduced for at least 30 seconds or the machine

must be stopped and the drive lever placed in

neutral for five seconds before returning to

vacuum fan speed boost. If not, an audible alarm

will sound at the end of the five minutes, the fan

will shut off, and a warning message will appear

on the MDM display.

To reset the vacuum fan speed boost limiting

system, stop the machine and place the drive

lever in neutral. Restart the machine and turn the

vacuum speed to below 2400 rpm.

This vacuum fan speed boost is available for only

five 5--minute intervals per hour. After five boost

periods, the vacuum fan speed will be limited to

2300 rpm for the rest of the hour

WINDSHIELD DEFROSTER SWITCH

Use the Windshield defroster switch to defrost the

windshield.

636 9006280 (9-- 09)

15

OPERATION

Home

Find...

Go To..

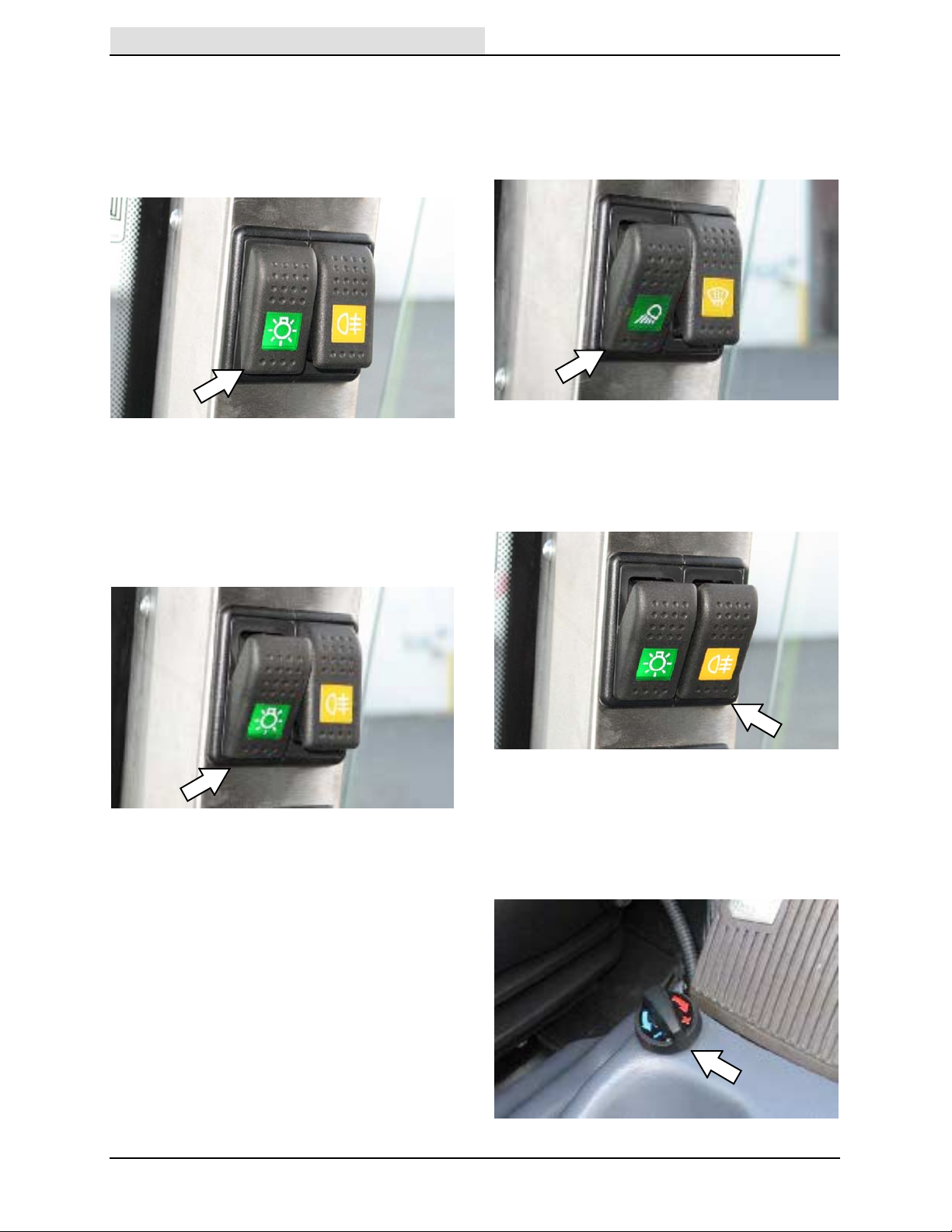

MASTER LIGHT SWITCH

Use the 3--position Master light switch to control

the headlights, overhead work lights, and rear fog

lights. Push the switch to the second position to

operate only the headlights. Push the switch back

to the first position to turn off all lights.

Push the switch to the third position to operate the

headlights and allow use of the overhead work

lights and rear fog lights.

NOTE: The rear fog light and overhead work light

switches must be in the on position for the lights

to function.

OVERHEAD WO RK L I G HT S W I T CH

Use the Overhead work light switch to operate the

overhead work lights. The Master light switch

must be in the third position to operate the

overhead work lights.

REAR F OG LI GHT SWI TCH

Use the Rear fog light switch to operate the rear

fog lights. The Master light switch must be in the

third position to operate the rear fog lights.

16

CAB T EMPERATURE CO NTRO L KNOB

Turn the Cab temperature control knob clockwise

to increase the temperature and counterclockwise

to decrease the temperature inside the cab when

the heater is on.

636 9006280 (2-- 09)

OPERATION

Home

Find...

Go To..

HEATER FAN SWITCH

Use the 2--speed Heater fan speed switch to

operate / adjust the heater fan.

AIR CONDITIONER (OPTION)

Use the 2--speed Air conditioner fan speed switch

to operate / adjust the air conditioner fan.

WARNING BEACON / AUDIBL E AL ARM

SWITCH

Use the 3--position Warning beacon / audible

alarm switch to activate the warning beacon and

audible alarm. Push the switch to the second

(middle) position to operate only the warning

beacon.

Push the switch to the third (lower) position to

operate both the warning beacon and audible

alarm. Push the switch back to the first position to

turn off the warning beacon and audible alarm.

4--WAY WARNING LI GHT SW ITCH

Use the 4--way warning light switch to operate the

4--way warning lights.

636 9006280 (2-- 09)

The warning beacon can be swung back behind

the cab to allow for lower clearances.

17

OPERATION

Home

Find...

Go To..

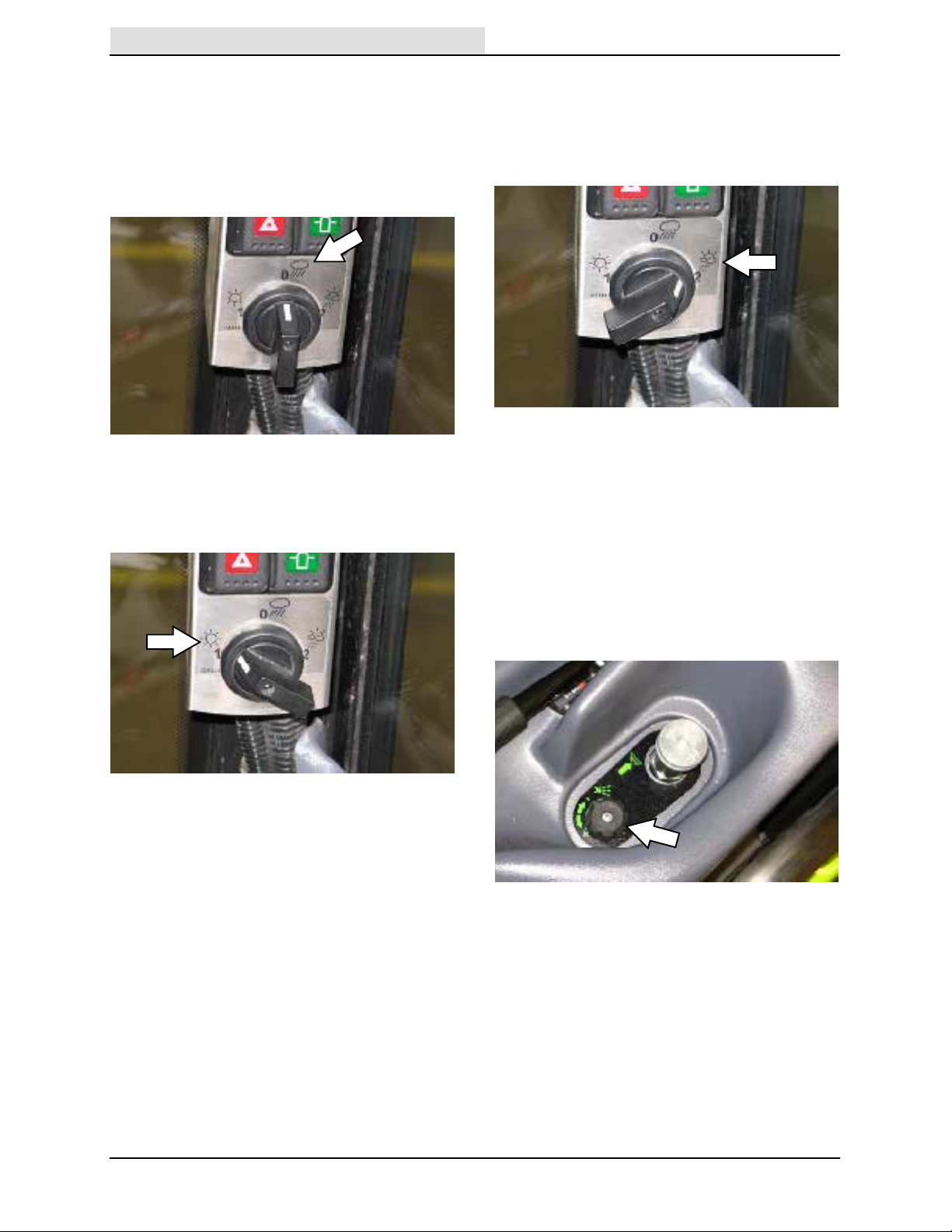

WATER SWITCH (DUST SUPPRESSION)

Turn the water switch to position 0 in areas where

dust suppression is not necessary. Neither the

brush head spray jets nor the vacuum tube spray

jets operate in this mode. The CloudMaker nozzle

continues to rotate to keep the spray head clean,

but does not use water.

Turn the water switch to position 1 for dry areas

where full dust suppression is necessary. The

CloudMaker nozzle, brush head spray jets, and

vacuum tube spray jet operate in this mode.

Turn the water switch to position 2 in areas where

some dust suppression (wet sweeping) is

necessary. Only the brush head spray jets and

vacuum tube spray jets operate in this mode. The

CloudMaker nozzle continues to rotate to keep

the spray head clean, but does not use water.

WATER FLOW CONTROL KNOB

Turn the Water flow control knob clockwise to

decrease the amount of water supplied to the

brush jets and counterclockwise to increase the

amount of water to the brush jets.

NOTE: T o operate only the CloudMaker and

conserve water, turn the water switch to position 1

and the water flow control knob to the minimum

flow setting to turn off the water to the brush

spray jets.

18

636 9006280 (2-- 09)

OPERATION

Home

Find...

Go To..

BRUSH PRESSURE ADJUSTMENT KNOB

To adjust the brush pressure, loosen the lock ring

under the Brush pressure adjustment knob.Turn

the knob counterclockwise to decrease the brush

pressure and clockwise to increase the brush

pressure. Retighten the lock ring.

PARKING BRAKE LEVER

Pull the Parking brake lever to engage the parking

brake. Slightly lift the Parking brake lever, press

the button, and completely lower the lever to

disengage the parking brake.

ACCELERATOR PEDAL

Press the Accelerator pedal to move the machine.

NOTE: The accelerator pedal is very responsive

to pressure. Press the pedal slowly to move the

machine. Releasing the pedal will cause the

machine to slow down.

BRAKE P EDAL

Press the Brake pedal to stop the machine.

636 9006280 (1-- 10)

19

OPERATION

Home

Find...

Go To..

STEERING WHEEL HEIGHT ADJUSTMENT

HANDLE

1. Loosen the Steering wheel height adjustment

handle and adjust the steering wheel to the

desired height.

2. Tighten the Steering wheel height adjustment

handle to secure the steering column /

steering wheel into place.

HEADLIGHT AND MULTIFUNCTIO NAL

SWITCH

WINDSHIEL D WIPER / WASHER S WIT CH

Turn the outer ring to activate the windshield

wipers. Press the outer ring to active the

windshield washer.

HORN BUTTON

Push the horn button located at the end of the

switch to sound the horn.

Parking and Headlights On: Rotate the knob

clockwise.

Parking Lights On: Rotate the knob to the first

click.

Headlights On: Rotate the knob to the second

click.

Bright Headlights On: Push the lever down.

Bright Headlights Off: Pull the lever up.

Flash Bright Headlights: Pull the lever up, then

release.

Signals: Push the lever forward for the right

signal. Pull the lever back for the left signal.

20

636 9006280 (2-- 09)

OPERATION

Home

Find...

Go To..

OPERATOR SEAT

The operator seat has four adjustments: backrest

angle, seat tilt, operator weight, and front to back.

The front--to--back adjustment lever adjusts the

seat position.

The backrest and seat tilt adjustment knobs

adjust the angle of the backrest and seat.

SEAT BELTS

FOR SAFETY: Before starting machine, adjust

seat and fasten seat belt.

DOOR LOCKS

The cab doors can be locked from either inside or

outside the cab.

Outside cab: Use the key to lock and unlock the

door.

The weight adjustment knob controls the firmness

of the operator seat.

636 9006280 (9-- 09)

Inside cab: Move the lever up to lock the door.

Move the lever down to unlock the door.

NOTE: Doors locked from the inside cannot be

unlocked from the outside using a key. Ensure

that the door(s) are unlocked before closing the

cab door.

21

OPERATION

Home

Find...

Go To..

BRUSH I NFO RMATION

For best results, use the correct brush type for the

cleaning application.

NOTE: The amount and type of soilage play an

important role in determining the type of brushes

to use. Contact an authorized service

representative for specific recommendations.

Polypropylene Brush -- Best overall general

cleaning brush. The bristles fan out and dig into

cracks to remove debris.

Polypropylene and Wire Brush -Recommended for moving heavy debris. Best

bristle mix for moving large quantities of sand and

heavier debris. The bristles fan out similar to the

polypropylene brush. The wire bristles provide the

ability to move heavier material.

PET (Polyethylene Terephthalate) Heavy Duty

Brush -- Recommended for areas where there is

a heavy build up of debris. The stiffer / thicker

bristles provide more aggressive digging action to

remove compacted debris from along buildings,

curbs, and in corners.

HOW THE MACHI NE WORKS

The two front brushes move debris to the center

of the machine and the vacuum pulls the debris

into the hopper. The airflow must be maintained

through the machine to keep it functioning

properly.

The air and debris swirl in a cyclonic rotation

inside the hopper. The dust and debris drops to

the bottom of the hopper and the air exits through

vents at the rear of the machine. Screens located

in the hopper prevent light debris (leaves, paper,

etc...) from exiting the hopper and the cyclone

assemblies located at the top of the hopper

prevent dust particles from exiting the hopper.

22

636 9006280 (10-- 11)

OPERATION

Home

Find...

Go To..

PRE--OPERATION CHECKLIST

Raise the hopper and engage the hopper safety

arm before performing the pre--operation checks.

See the RAISING / LOWERING THE HOPPER

section of this manual.

WARNING: Raised hopper may fall.

Engage hopper safety arm.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, place drive

lever in neutral, set parking brake, turn off

machine, and remove key from ignition.

NOTE: Do

when raising the hopper for pre--operation checks.

- Check the engine coolant level.

- Check the windshield washer fluid level.

- Check the air filter indicator.

- Check the engine oil level.

Not unlock the hopper lid latches

POST OPERATION CLEANING

Completely clean the machine after every use.

Raise the hopper and engage the hopper safety

arm before cleaning the hopper and the engine

compartment. See the RAISING / LOWERING

THE HOPPER section of this manual.

WARNING: Raised hopper may fall.

Engage hopper safety arm.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, place drive

lever in neutral, set parking brake, turn off

machine, and remove key from ignition.

- Empty the hopper.

- Clean the interior of the hopper.

- Clean the engine compartment and around

the hydraulic components.

- Clean the area surrounding the water pump

and the bottom corners of the radiator.

- Check the hydraulic fluid level.

- Check the water tank level.

- Check the condition of the brushes. Remove

any string, banding, plastic wrap, or other

debris from the brushes.

- Check the vacuum head height and side

skids.

- Check tire pressure and condition of tires.

- Check operating lights (headlights, taillights,

work lights, rotating beacon, and hazard

warning lights).

- Check safety equipment.

- Ensure all panels are secured in place.

- Check the fuel level.

- Ensure all controls, gauges, and indicators

function properly.

- Clean the brushes and vacuum head area.

- Clean the vacuum fan assembly.

636 9006280 (10-- 11)

23

OPERATION

Home

Find...

Go To..

STARTING THE MACHINE

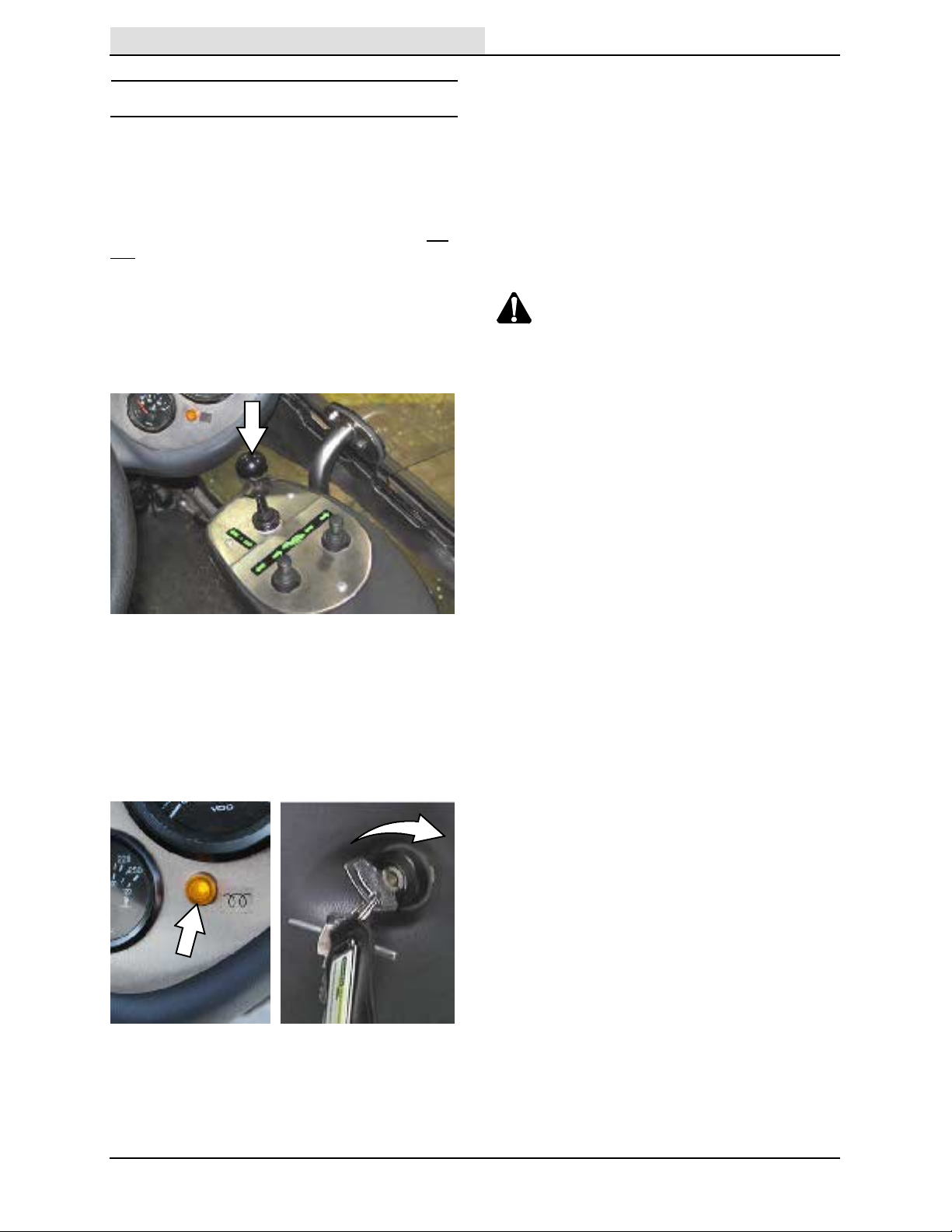

3. Turn the key further clockwise to start the

engine.

FOR SAFETY: Do not operate machine, unless

operator manual is read and understood.

NOTE: Watch / listen for visual and audible

warnings from the MDM (Machine Display

Module) system while operating the machine. Do

not operate the machine until all warnings have

been corrected. See MACHINE DISPLAY

MODULE (MDM) FAULT SCREENS section of

this manual.

1. Sit in the operator seat, press the brake pedal

or set the parking brake, and place the drive

lever into neutral.

NOTE: Do not operate the starter motor for more

than 10 seconds at a time or after the engine has

started. Allow the starter to cool 15--20 seconds

between starting attempts or damage to the

starter motor may occur.

4. Allow the engine and hydraulic system to

warm up for three to five minutes.

WARNING: Machine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory authorities for exposure

limits. Keep engine properly tuned.

FOR SAFETY: When starting machine, keep

foot on brake and drive lever in neutral.

2. Turn the key clockwise until the glow plug

indicator comes on, but not far enough to start

the engine. Hold the key in this position for 5

seconds, depending on temperature. Colder

temperatures require longer time.

24

636 9006280 (2-- 09)

Loading...

Loading...