Green Machines 414RS, 424TR, 424HS User Manual

400

Home

Series

English EN

Operators Manual

To view, print or download

the latest manual, visit:

www.tennantco.com/manuals

www.greenmachines.com

YM036

Rev. 4 (5-2007)

*YM051*

This manual is furnished with each new model. It provides necessary operation and maintenance instructions.

Home

Read this manual completely and understand

the machine before operating or servicing it.

Read this manual completely and understand the machine before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the machine maintenance instructions provided.

S The machine is maintained with manufacturer supplied or equivalent parts.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

old machine components and fluids in

an environmentally safe way according

to local waste disposal regulations.

Always remember to recycle.

MACHINE DATA

Please fill out at time of installation for future reference.

Model No. -

Serial No. -

Installation Date -

Tennant UK Cleaning Solutions Ltd.

Bankside, Falkirk FK2 7XE

Scotland, United Kingdom

Phone: (+44) 1324- 611666

www.greenmachines.com

Specifications and parts are subject to change without notice.

Original Instructions, copyright E 2007 Tennant Company

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553- 8033 or (763) 513- 2850

www.tennantco.com

Table of contents

Chapter 1 How to use this manual............. 3

Chapter 2 Getting to know your machine... 5

Chapter 3 Preparing for first use.

Chapter 9 414RS model only.

Extending and stowing the seat.................29

Using the seat safely .................................31

Seat adjustments.......................................32

Setting the suction nozzle height................. 7

Fitting brushes and setting brush height ..... 8

Fitting the trash sack................................... 9

Chapter 4 Daily checklist ........................... 11

Chapter 5 Starting, stopping and driving.

Starting and stopping the engine............... 16

Setting the brush speed ............................ 17

Setting the engine speed........................... 17

Driving and stopping.................................. 18

Braking and emergency brake release...... 19

Chapter 6 The water system.

Water controls and water jets.................... 20

Water tank and disinfectants..................... 22

Chapter 7 The wander hose.

Wander hose and blanking plate............... 23

Unblocking the wander hose..................... 24

Chapter 8 Sweeping with your machine.

Sweeping in wet weather .......................... 25

Sweeping along buildings and curbs......... 25

Sweeping corners ..................................... 26

Climbing and descending curbs................ 26

Transporting your machine........................ 27

Objects to avoid when sweeping............... 28

Unblocking the suction nozzle................... 29

Chapter 10 424TR and 424HS models only.

Fitting the seat...........................................33

Adjusting the seat and footplate ................34

Selecting high speed mode (424HS only) .34

Raising and lowering the suction nozzle

(424HS only)..............................................31

Chapter 11 The Clean and Safe or Dog

Excrement Attachment option.

Preparation and use ..................................37

Chapter 12 Leaf sweeping and leaf bags..39

Chapter 13 The snowplow option.

Fitting and use ...........................................41

Chapter 14 Machine care and wash-down.

End of use wash-down ..............................44

End of week wash-down............................47

Care of filter bag........................................48

Chapter 15 Fault Finding ............................49

Chapter 16 General Specifications............59

Safety labels & graphical symbols.............60

Machine chassis plate ...............................64

Green Machine Operator Manual Page 3

Chapter 1

How to use this manual.

Please read the manual fully and follow all safety advice before using your machine.

Welcome to the Applied Sweepers Operator’s Manual. We have written this manual to help you use

your Green Machine correctly and above all, safely. Please read this manual fully before using your

Green Machine.

Throughout this manual you will see areas where particular attention must be paid to avoid death,

physical injury or damage to you or your machine. Please read these points carefully and follow

the instructions.

Your Green Machine should have been supplied with the following:

Operator’s Manual (This book).

Service Schedule

Parts Catalogue

Kubota Engine Manual

Warranty Card

If you need help, or if any of these are missing, please contact your local Green Machine

distributor listed at the front of this book.

A shop manual containing detailed repair information suitable for use by mechanics and technicians is

sold separately.

Green Machine Operator Manual Page 4

Important Safety Information

Your Green Machine is a motorized item

with moving parts. Incorrect use can lead

to death or bodily injury and/or damage

to your machine.

Always carry out the daily checks before

using the machine.

Ensure that any defects are reported to a

supervisor as soon as they are found.

Always switch the eng ine OFF when the

machine is being refueled.

Always switch the engine OF F an d

remove the machine keys if you are

leaving machine unattended.

Always switch the eng ine OFF before

opening the machine top cover.

Always switch the engine OF F an d

remove machine keys before trying to

clear a blockage.

Always be aware of your surroundings

when sweeping.

Ensure that the machine has the correct

level of maintenance in accordance with

the manufacturers recommendations.

Never try to clear a blockage with the

engine running or with the machine keys

in the ignition.

Never leave the machine unattended with

the engine running.

Never put hands, fingers, or loose

clothing near moving parts.

Never open the radiator cap when the

engine is hot.

Never run the engine with the front

suction hose removed.

Never wash the machine with the engine

running.

Do not run the engine in a confined or

poorly ventilated space.

Never stand on the Ride on Seat when

sweeping.

Never drive up or down curbs whilst

seated.

Never make non-approved modifications

or use the machine in any other way than

that shown or demonstrated by an official

representative of Applied Sweepers.

Your Green Machine incorporates Safety

Inter-Lock switches on the Suction Fan

Access Panel and on the Rear Trunking.

If either o f these items are opened or

removed, the engine will be stopped and

the engine starter will be isolated.

However, prior to opening or removing

these items, the engine should be

switched OFF and the ignition keys

removed.

Green Machine Operator Manual Page 5

Chapter 2

Getting to know your Green Machine.

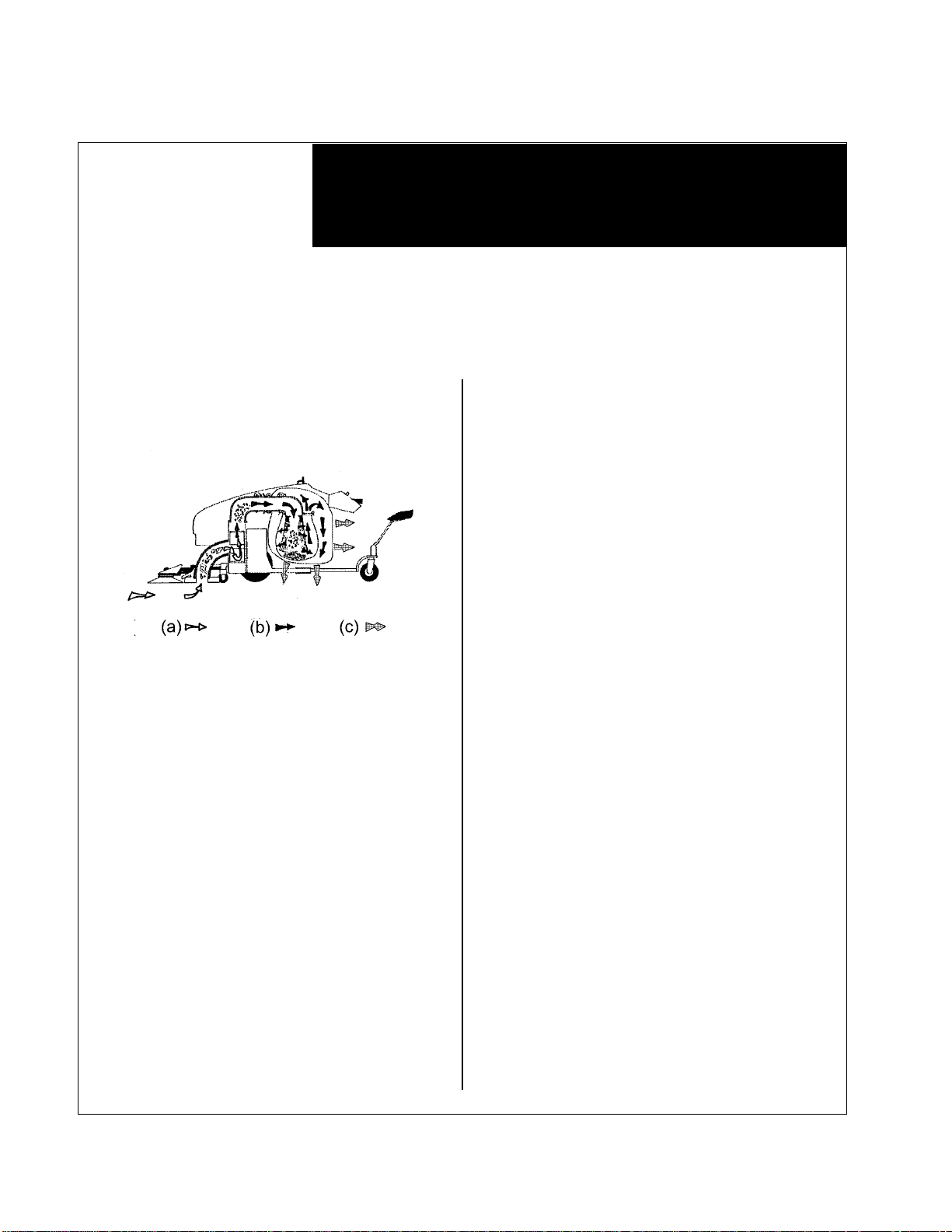

How the machine works

The Green Machine works by airflow. As long

as airflow is maintained the machine should

sweep correctl y.

Two front brushes sweep any debris towards

the center of the machine.

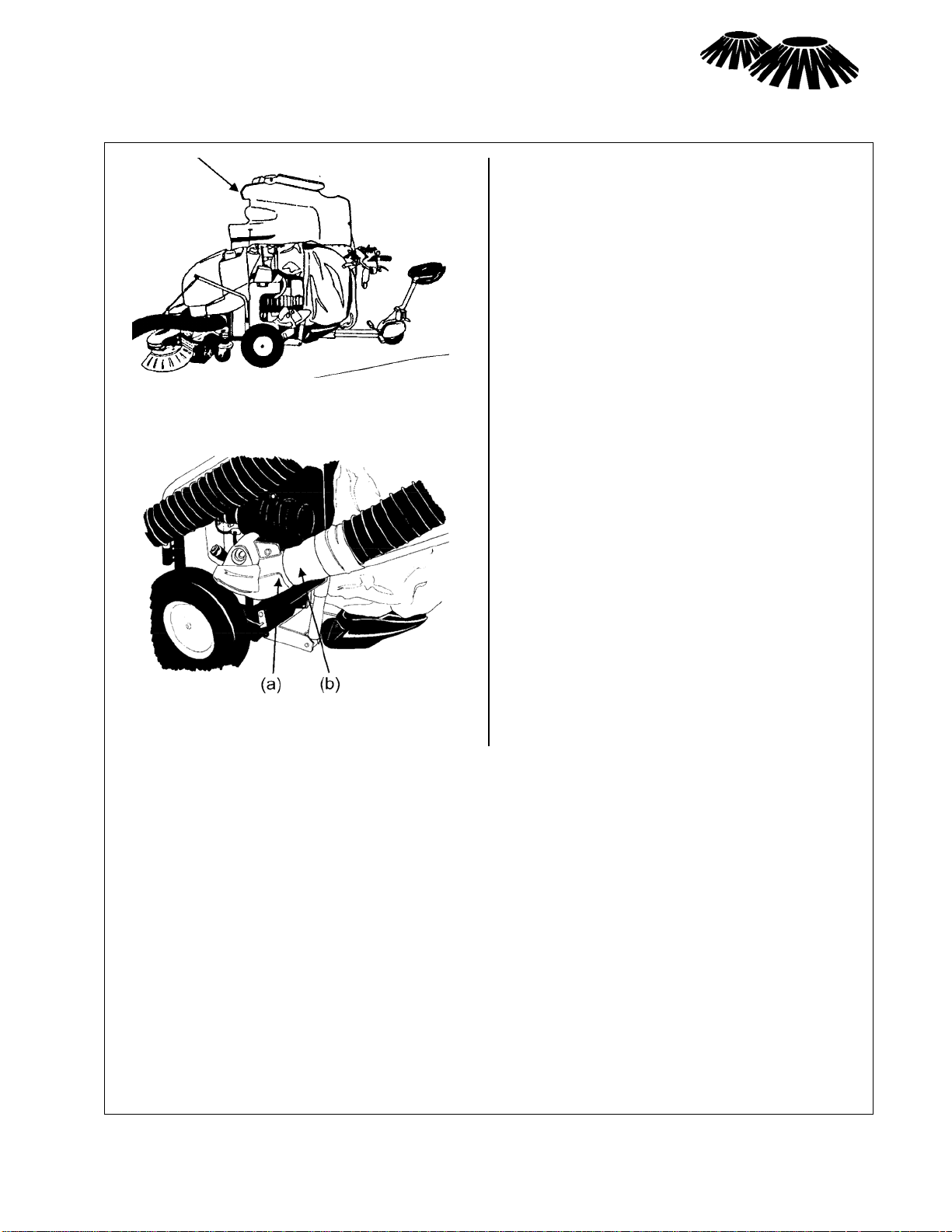

The debris is then picked up by the flow of air

through the vacuum hose (a).

A powerful impeller fan not only creates the

vacuum, but also mulches the debris as it

passes through.

The impeller fan is very strong and robust.

Broken glass or bottles which pass through

the fan come out looking like rock salt with

no sharp edges for you to cut yourself upon.

The air and mulched debris is next blown up

through the back trunking (b).

A water spray jet inside the back trunking

dampens the dust-laden debris down as it

passes through.

The debris and air are then blown downwards

through a nylon filter screen that filters out

the debris and collects the debris in a

regular plastic trash bag.

The air escapes through the filter screen and is

finally blown out through a special fabric

filter bag that screens out any remaining

dust.

As this air escapes, then the suction hose

vacuums up more new air and debris.

The Green Machine is easy to drive. Simple

hand controls allow you to vary the speed in

forward and reverse, and there are

automatic brakes.

A powerful and quiet diesel engine provides

power not only for the impeller fan, but also

for the hydraulic system that runs both the

brushes and drive.

Depending on your model, you can either ride-

behind or walk behind your Green Machine

as you work.

The machines are equipped with lights, a

beacon and a horn or voice warning

message so that you may work safely

among pedestrians or motor vehicles.

All in all, you will quickly learn that your

machine saves a lot of time and physical

labor when sweeping compared to pushing

a broom.

We’ll next look at identifying the major

features of your Green Machine.

Green Machine Operator Manual Page 6

Your Green Machine incorpor ate s Safe ty Inte r -Loc k switches on the Suction Fan Front Access Panel and on the Rear

Trunking. If either of these items are opened or removed, the engine will be stopped and the engine starter will be

isolated. However, prior to opening or removing these items, the engine should be switched OFF and the ignition

keys removed.

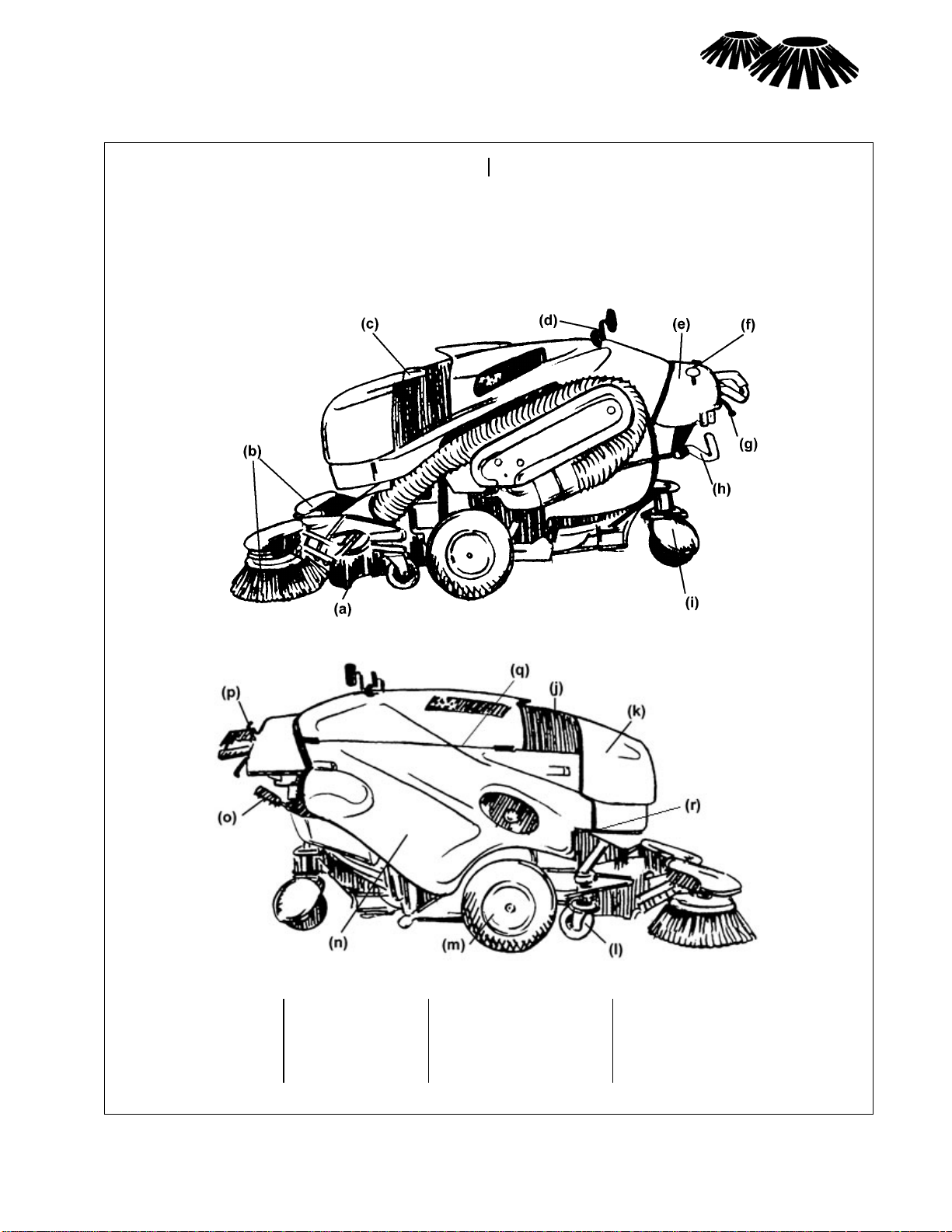

Note in this manual left and right are described as if you are standing behind the handles

looking forward.

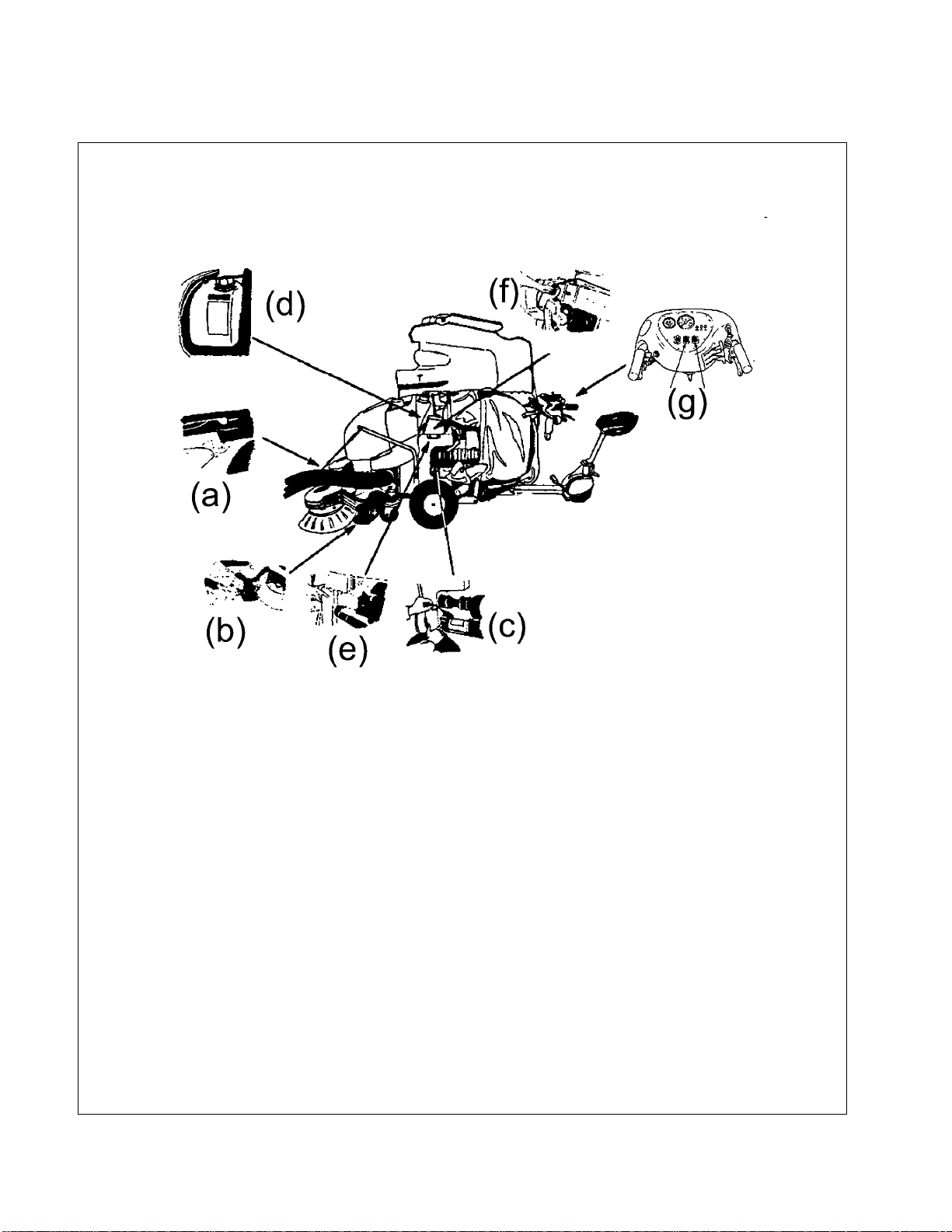

(a)Suction Nozzle

(b)Front Brushes

(c)Flashing Beacon

(d)Rear View Mirrors

(e)Operator Console

(f)Cup Holder

(g)Drive Lever

(h)Wander Hose

(i)Rear Wheel

(j)Water Tank

Left Side

Right Side

(k)Front Storage Box

(l)Front Castor Wheel

(m)Main Road Wheel

(n)Side Access Panel

(o)Parking Brake

(p)Throttle, brush and flap controls.

(q) Safety switch ( under top cover)

(r) Safety switch( on fan access

panel )

Green Machine Operator Manual Page 7

Chapter 3

Preparing for your first use.

This chapter will guide you through the adjustments needed to optimize your Green

Machine for its first use.

Setting the suction nozzle

height.

It is important to check that the suction nozzle

height is correctly set.

If the suction nozzle is too high off the

ground, then suction performance will be

reduced.

If the suction nozzle is too low to the

ground, then the suction nozzle will

make contact with uneven surfaces and

the horseshoe-shaped skid underneath

the suction nozzle will get worn down

and will need to be replaced.

Always set height with machine on level ground.

Remove the castor locking pins (one on each

side).

It helps to move the wander hose to the side to

allow access to the left-side locking pin.

rotating the castor caps on each side.

Turn the caps clockwise to raise the nozzle, or

anti-clockwise to lower the nozzle.

You should adjust both sides to leave just

enough space for your fingers to fit between

the horseshoe-shaped skid and the ground about ¾ “ (20mm) at each side is good.

If the surface that you are sweeping is very

uneven, then you may wish to raise the

nozzle a little more.

You will have to check and readjust the

nozzle height from time to time. This is

because the castor wheels that hold the

suction nozzle off the ground will wear

down as you use your machine. Failure

to periodically check the nozzle height

can mean expensive repairs if your front

nozzle wears down.

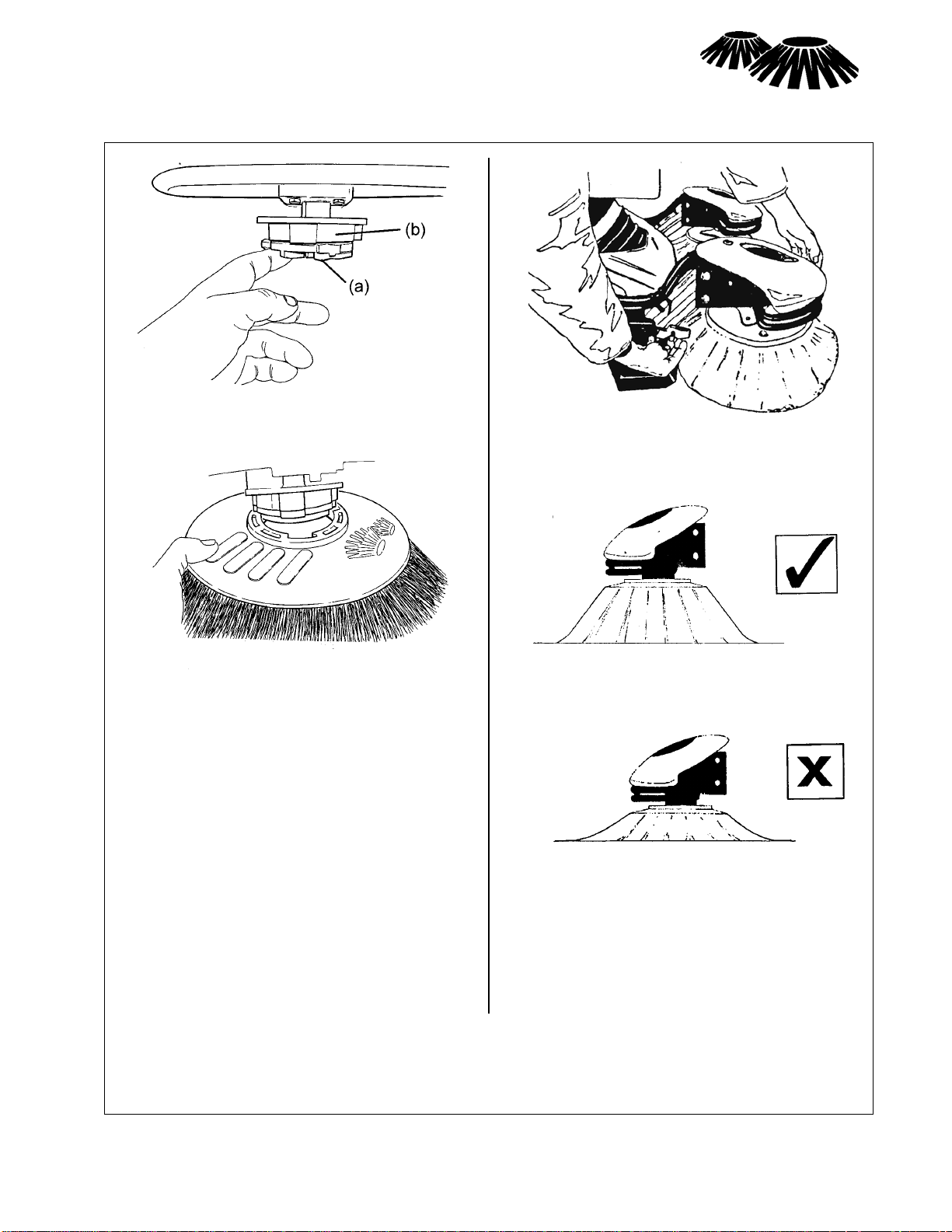

Fitting the brushes.

Adjust the nozzle to the correct height by

Green Machine Operator Manual Page 8

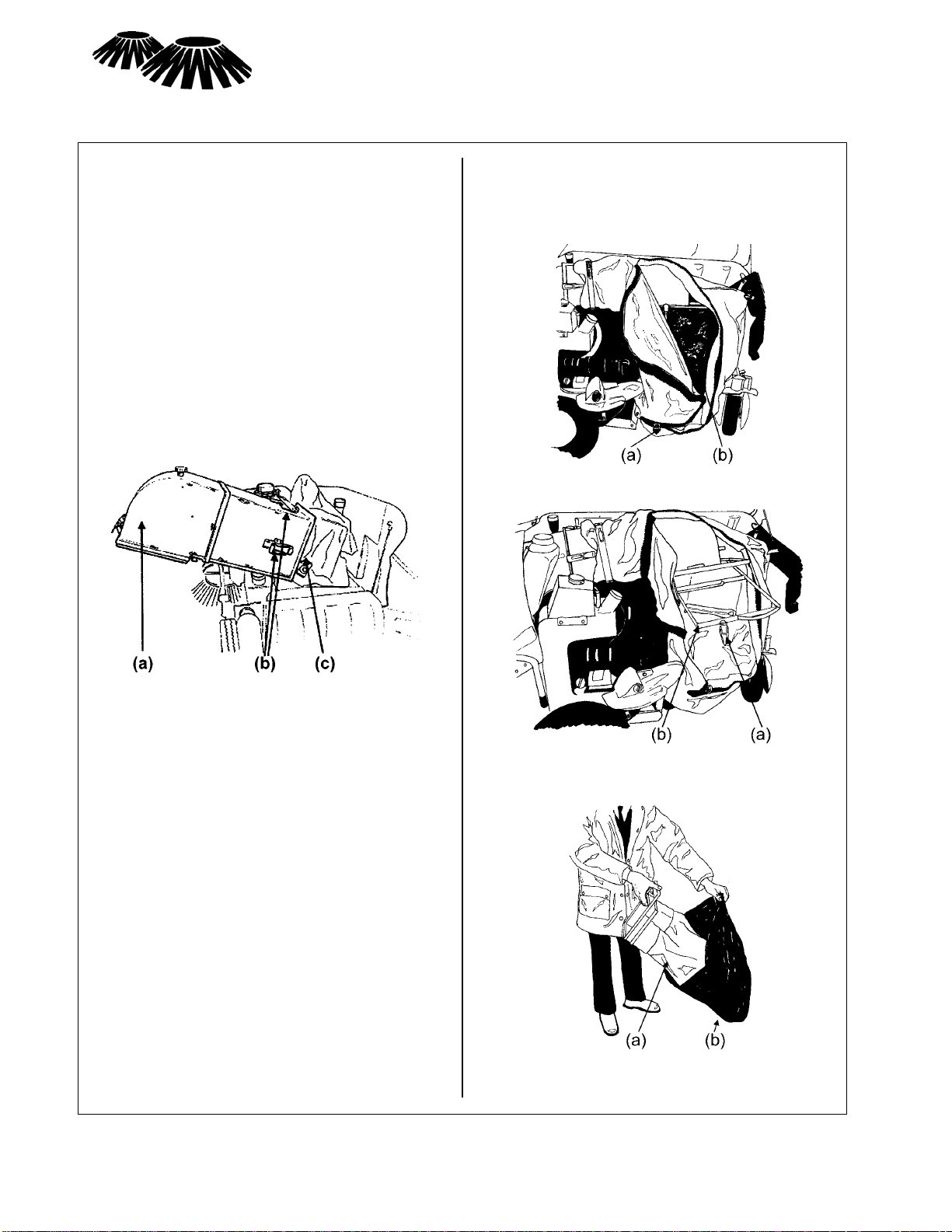

Tilt the machine rearward to gain easier access

to the front of the machine.

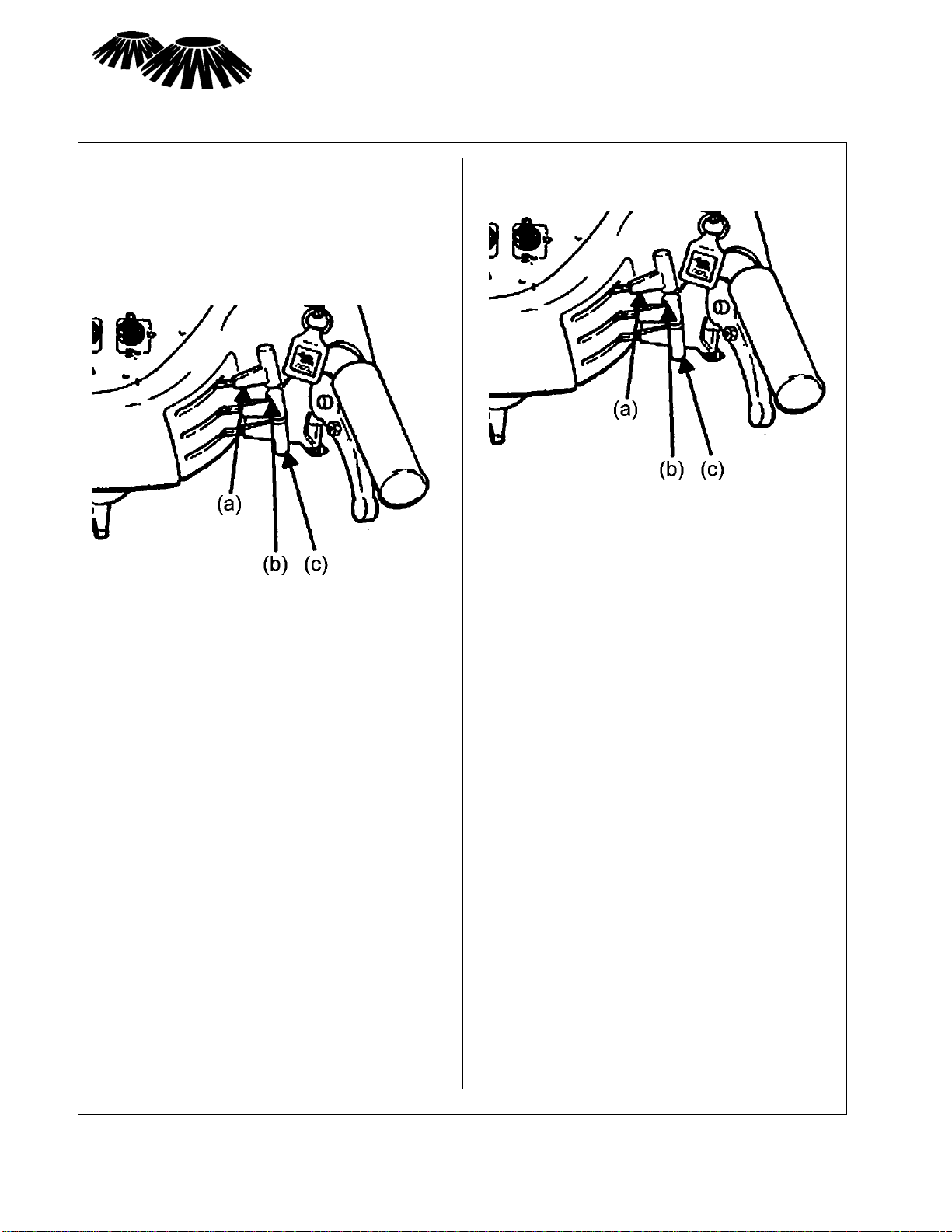

Turn the plastic locking cam (a) so that the lugs

on the cam line up with the lugs on the

metal drive hub (b).

Unhook the brush.

Push down on the brush assembly until you feel

the brush can move down no further.

Fit the new brushes and turn the locking cam

until you feel a solid click. This click means

that the brushes are now in the fully locked

position.

The cam on the left side of the machine locks in

the opposite way to the cam on the right

side. This is so that both cams are selftightening when the brushes are turning.

Setting the brush height.

Always check the suction nozzle height is

correct before adjusting the brush height.

The correct brush height is when the tips of the

brush bend slightly as shown.

If when you push down, the brush spreads out

too far then the brushes are set too low.

This will not improve the quality of

sweeping, but your brushes will wear out

much faster.

As you use the machine and the brushes

wear down, you will have to re-adjust the

brush height from time to time.

Green Machine Operator Manual Page 9

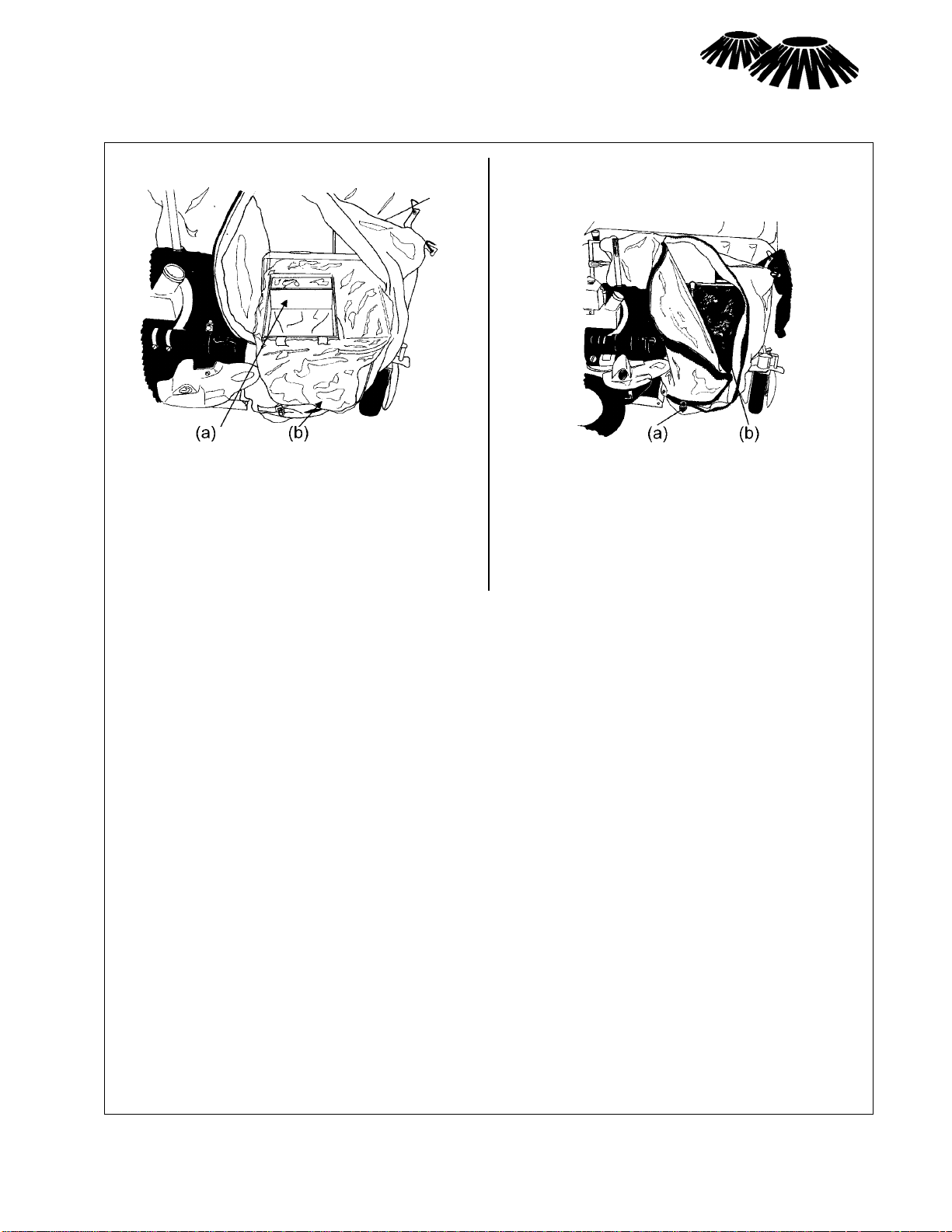

Removing the protective

plastic sheet.

Your Green Machine is often shipped with a

protective plastic sheet fitted inside the back

trunking that must be removed prior to first

use.

First ensure you remove the ignition

keys so that the machine will not start

accidentally.

Never start the machine with the back

trunking open.

Fitting the plastic trash

sack.

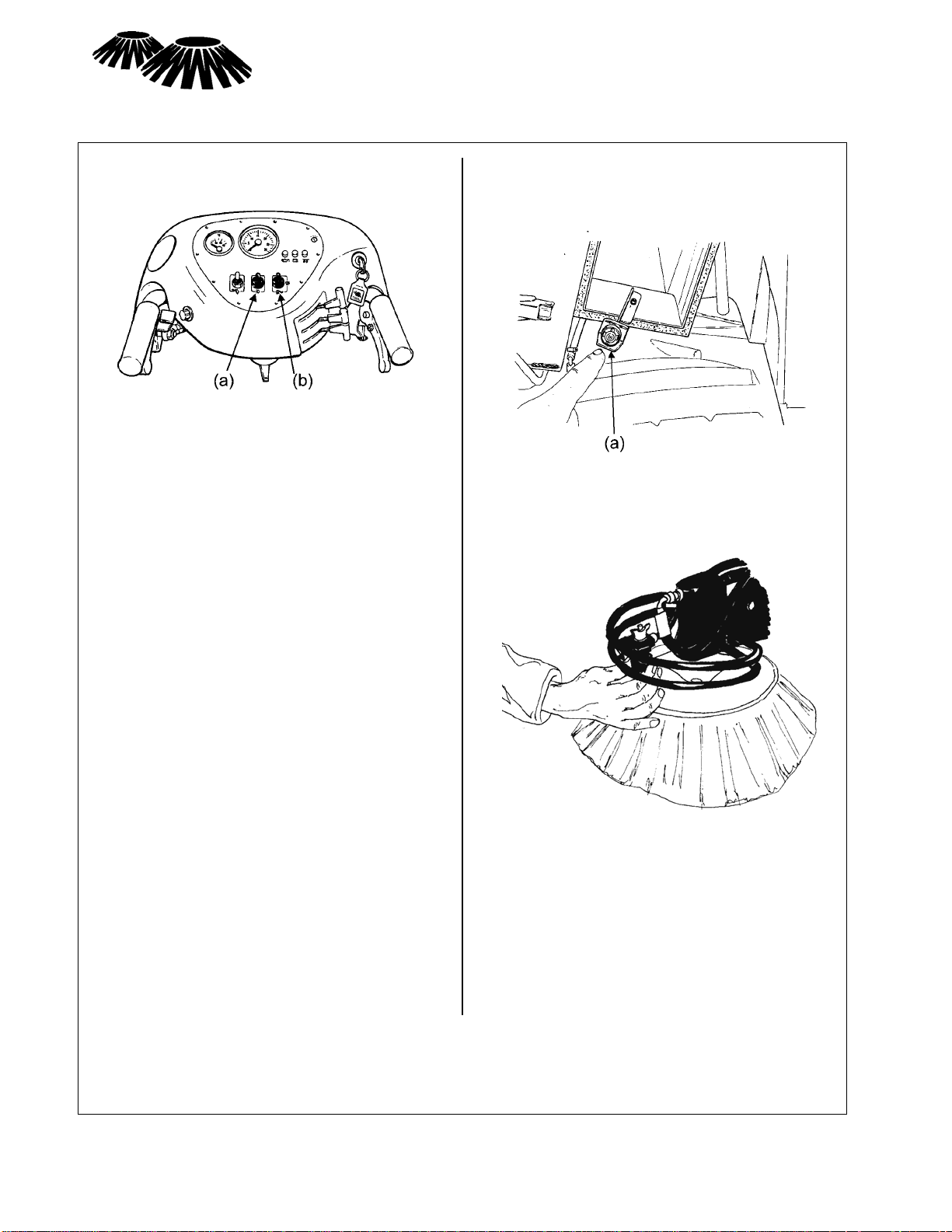

Open the zipper (a) on the filter bag (b).

Undo the two toggle clamps (b) and swing out

the back trunking (a).

Remove the protective plastic (c).

Close the back trunking by first lifting the hinge

lock pin and then swinging the back trunking

closed.

Re-fasten the toggle clamps.

Un-fasten the toggle clamp (a) and pull out the

sliding frame (b) towards you.

Remove the plastic screen and holder (a) and

insert the screen inside a regular 30 gallon

Page 10 Green Machine Operator Manual

(70 Litre) plastic trash sack.

Now insert the plastic sack and screen back

into the sliding frame.

Please make sure that the plastic sack

edges are folded around the outer sliding

frame, and not around the inside screen

holder (a).

If you fit the plastic sack in the wrong way,

your machine will not pick up properly.

Close the sliding frame and refasten the toggle

clamp.

Zip up the filter bag and close the top cover.

Now you are ready to go to the next chapter

– daily operator checks.

Green Machine Operator Manual Page 11

Chapter 4

Daily checklist.

These checks must be done daily before starting

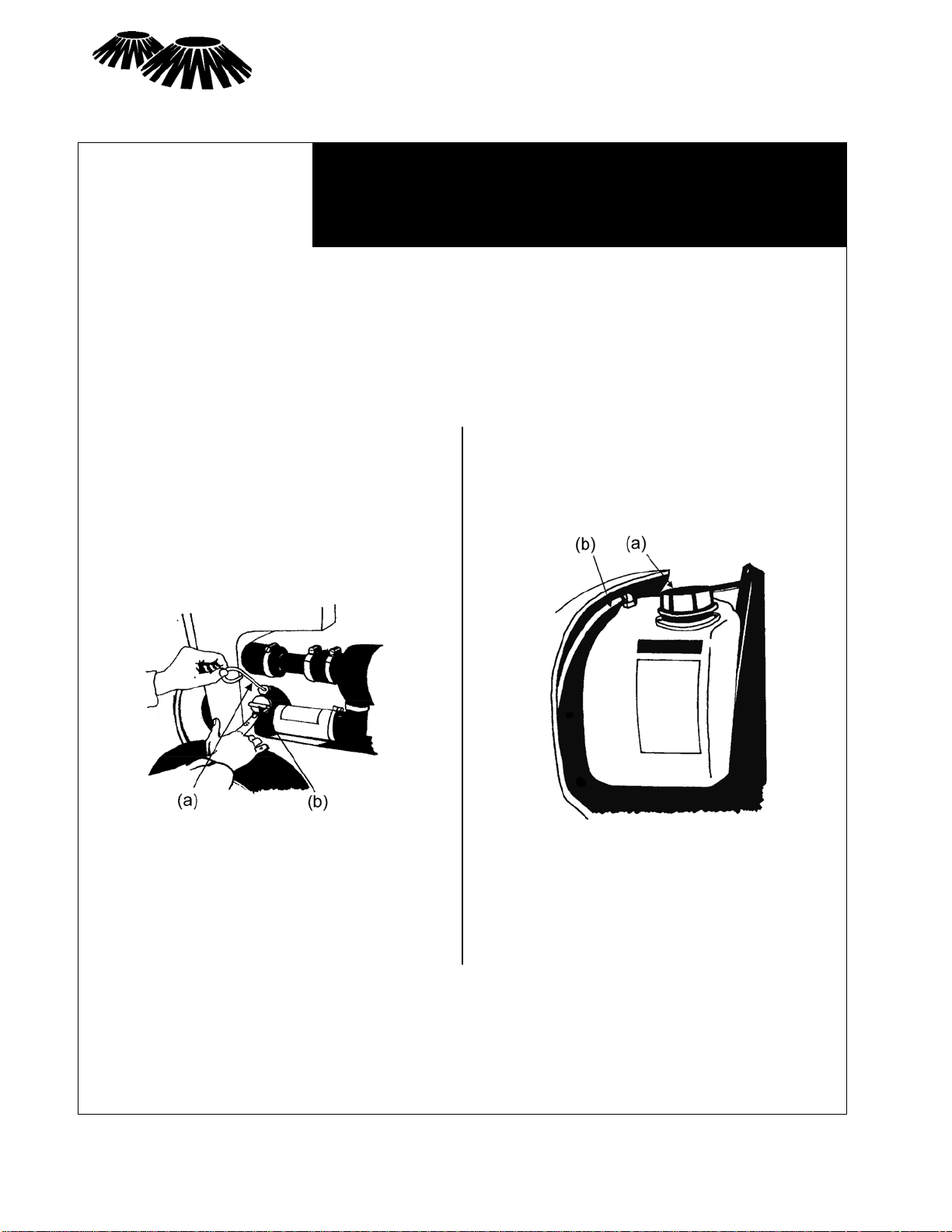

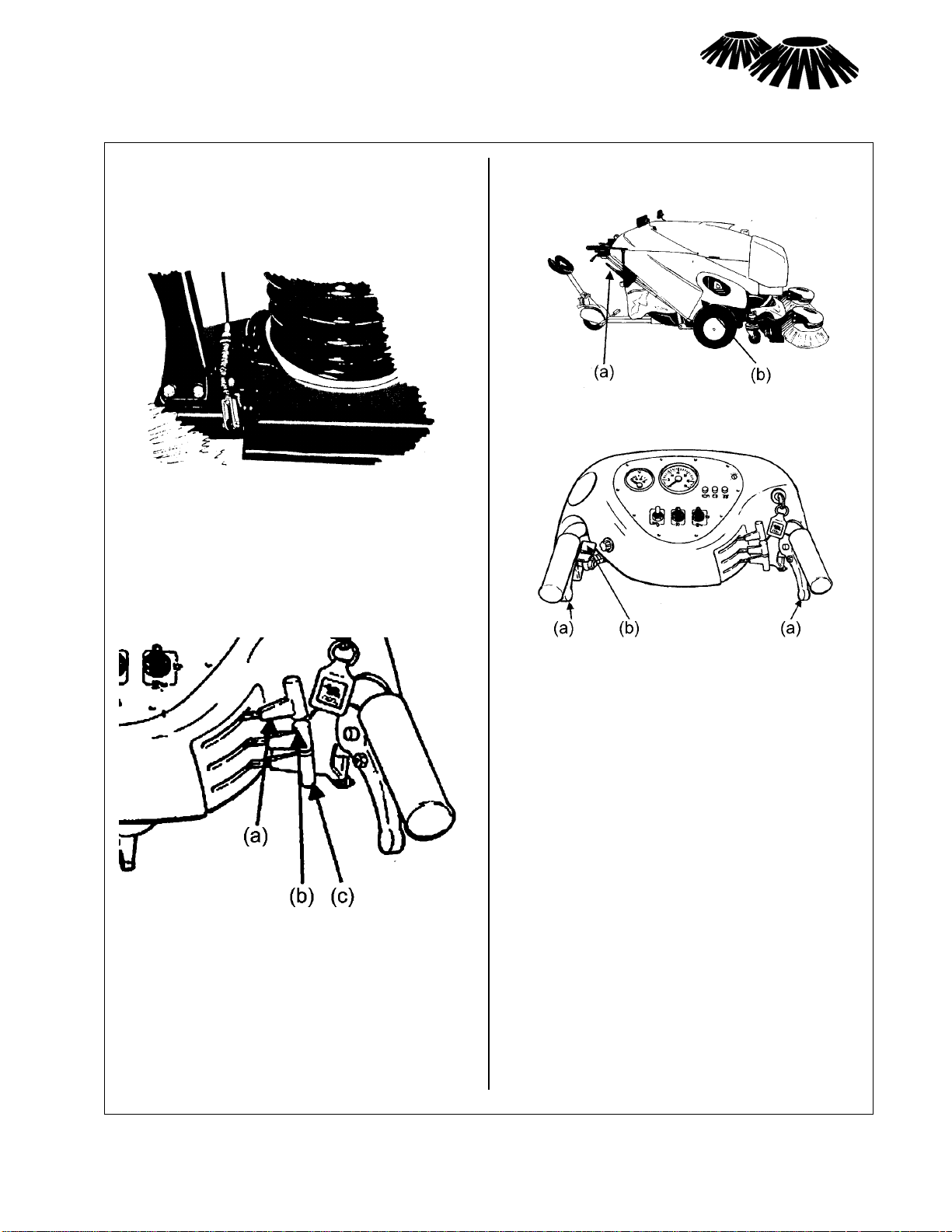

Check the engine oil level.

Ensure that the engine oil level is between the

minimum and maximum marks on the

dipstick (a). Top up as required.

Use regular motor oil – 10W40 grade is

recommended.

If you need to top-up the oil, you can do so

through the filler cap (b) that is located just

below the dipstick.

Add a small quantity of oil at a time and recheck

the level frequently. Take care not to overfill.

Check the water tank

level.

Fill up the water tank with cold water by opening

the red filler cap (a).

You can see the water level in the tank using

the clear plastic sight tube (b).

You may wish to add a disinfectant to the water

system. Please see Chapter 6 for more

details.

Page 12 Green Machine Operator Manual

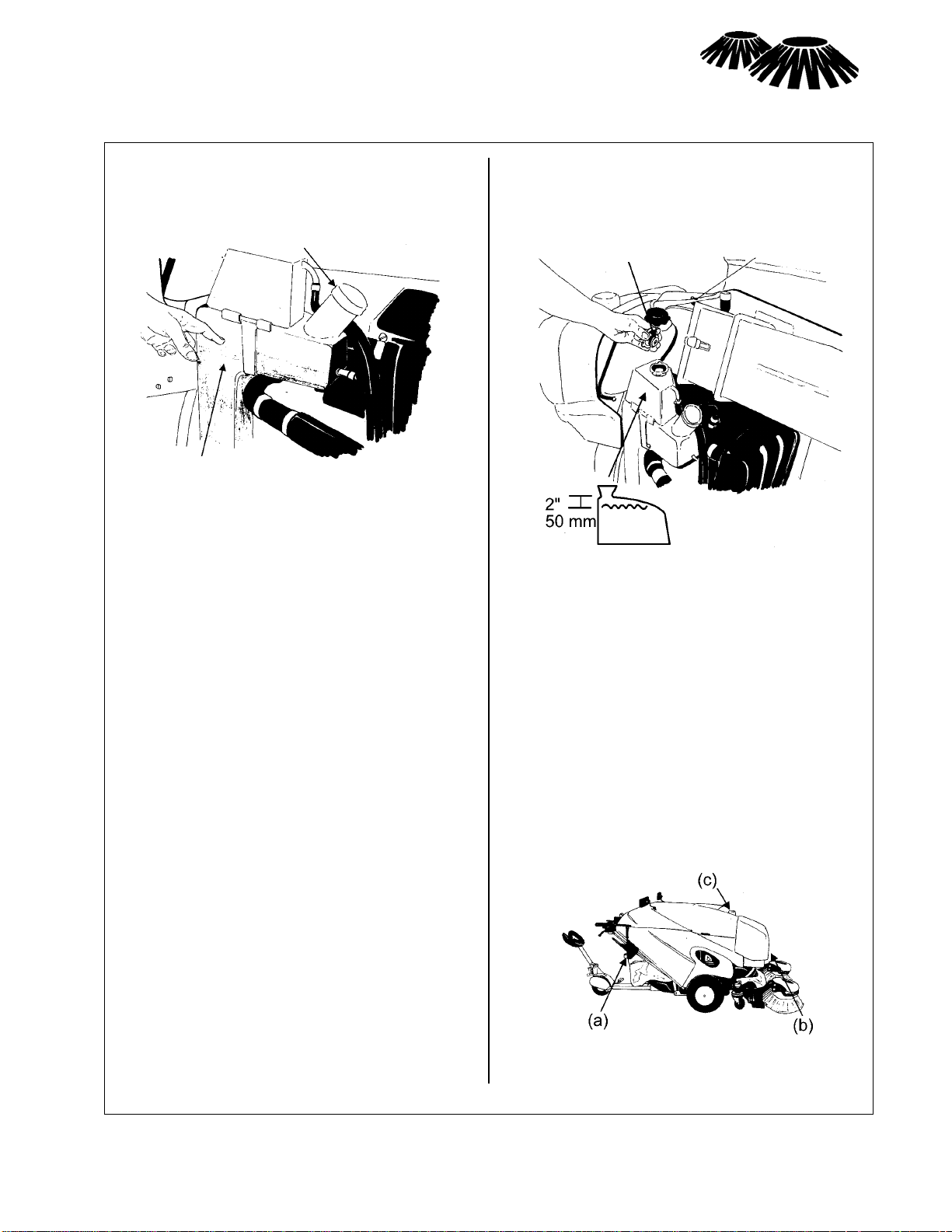

Check the diesel fuel

level.

Top up the fuel tank with regular diesel fuel if

required.

A full tank should last you about ten hours

running time.

Be careful not to spill any fuel– if you do so then

wipe off with a dry rag.

Avoid spilling diesel fuel on the air intake screen

that is located beneath the air filter housing.

If fuel spills on it, then dirt will stick to the screen

and may result in the engine starting to

smoke after some time. (Please see

Chapter 15 - Faultfinding).

Check the radiator

coolant level.

Open the radiator header tank pressure cap.

Take care when opening the pressurized

cap when the engine is hot. This is a

pressurized system with very hot liquid

inside.

The level should be 2” (50 mm) below the top of

the tank when the engine is cold.

Top up with a mixture of 50% water / 50% anti-

freeze when necessary.

Do not overfill, or else excess coolant will

escape out of the tank when the engine

heats up!

Check all electrical Items.

With the ignition key switched on to the first

position, check that the lights (a) and (b),

Green Machine Operator Manual Page 13

the beacon (c) and beeper (or optional voice

message) are all working correctly.

The switches are located on the control console

as shown.

Switch (a) operates the lights.

Switch (b) is a two-position switch.

The first position operates the beacon only.

The second position operates both the beacon

and the beeper or voice warning.

Your Green Machine incorporates Safety Inter-

Lock switches on the Suction Fan Front

Access Panel and on the Rear Trunking.

If either of these items are opened or removed,

the engine will be stopped and the engine

starter will be Isolated.

However, Prior to opening or removing these

items, the engine should be switched off

and the ignition keys removed.

To check that these switches are functioning

correctly, switch off the engine and swing

open the Rear Trunking. STANDING WELL

CLEAR of the open trunking, turn the

ignition switch to the engine start position.

The engine SHOULD NOT CRANK. If it

does, report immediately to your supervisor.

If the engine does not crank with the rear trunk

open, then the safety switches are operating

correctly.

Close the rear trunking. NOTE:- In spite of the

fact that the machine is fitted with safety

Inter-Lock switches, the engine should

always be switched off and the ignition keys

removed before opening the Suction Fan

Front Access panel or the Rear Trunking.

Check the water sprays.

Check that the water spray jet in the back

trunking is working – see Chapter 6 for more

information.

Check that the water spray jets for the brushes

are working – see Chapter 6 for more

information.

Page 14 Green Machine Operator Manual

After all checks have been completed close the

top cover, ensuring that it is correctly

secured.

Replace the wander hose (b) correctly in its

holster (a).

Green Machine Operator Manual Page 15

Daily Check Summary

Nozzle height correctly set.........................(a)

Brush Height correctly set..........................(b)

Correct engine oil level. .............................(c)

Water tank filled.........................................(d)

Diesel tank filled.........................................(e)

Correct coolant level...................................(f)

Check all electrical items working..............(g)

Green Machine Operator Manual Page 16

Chapter 5

Starting, stopping and driving

Starting the engine.

Never start the engine if the front suction

hose is removed or the back trunking is

open.

Never run the engine continuously in a

confined, or enclosed space.

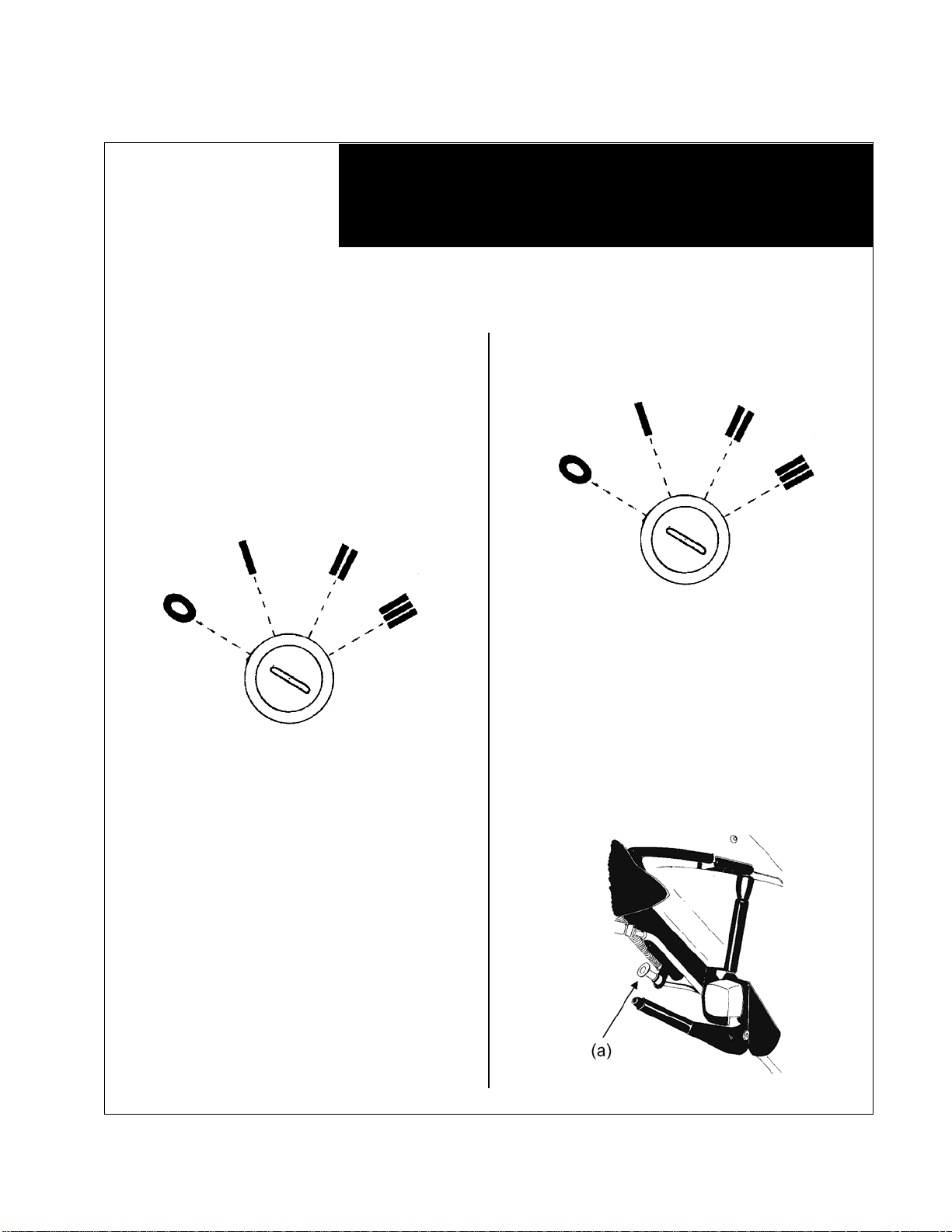

Insert the starter key into the key-switch.

Turn the key to position I.

When the engine is cold : turn the key to

position II and hold for five seconds. The

orange light on the control console will

indicate that the glow plug engine preheater is warming the engine.

When the engine is warm you can omit this

step.

Now turn the key to position III and the engine

will start.

After the engine starts, immediately let go of the

key and it will return to position I.

Stopping the engine.

Turn the Key to position 0 and the engine will

stop.

The emergency engine

shut-off button.

If the engine fails to stop when the key is turned

to position 0, then it is likely that there has

been an electrical problem that is preventing

the engine from shutting down correctly.

Should either of the red warning lamps

on the operator console for OIL or

CHARGING remain illuminated when the

engine is running, then the engine must

be shut down and the fault reported to

maintenance.

Green Machine Operator Manual Page 17

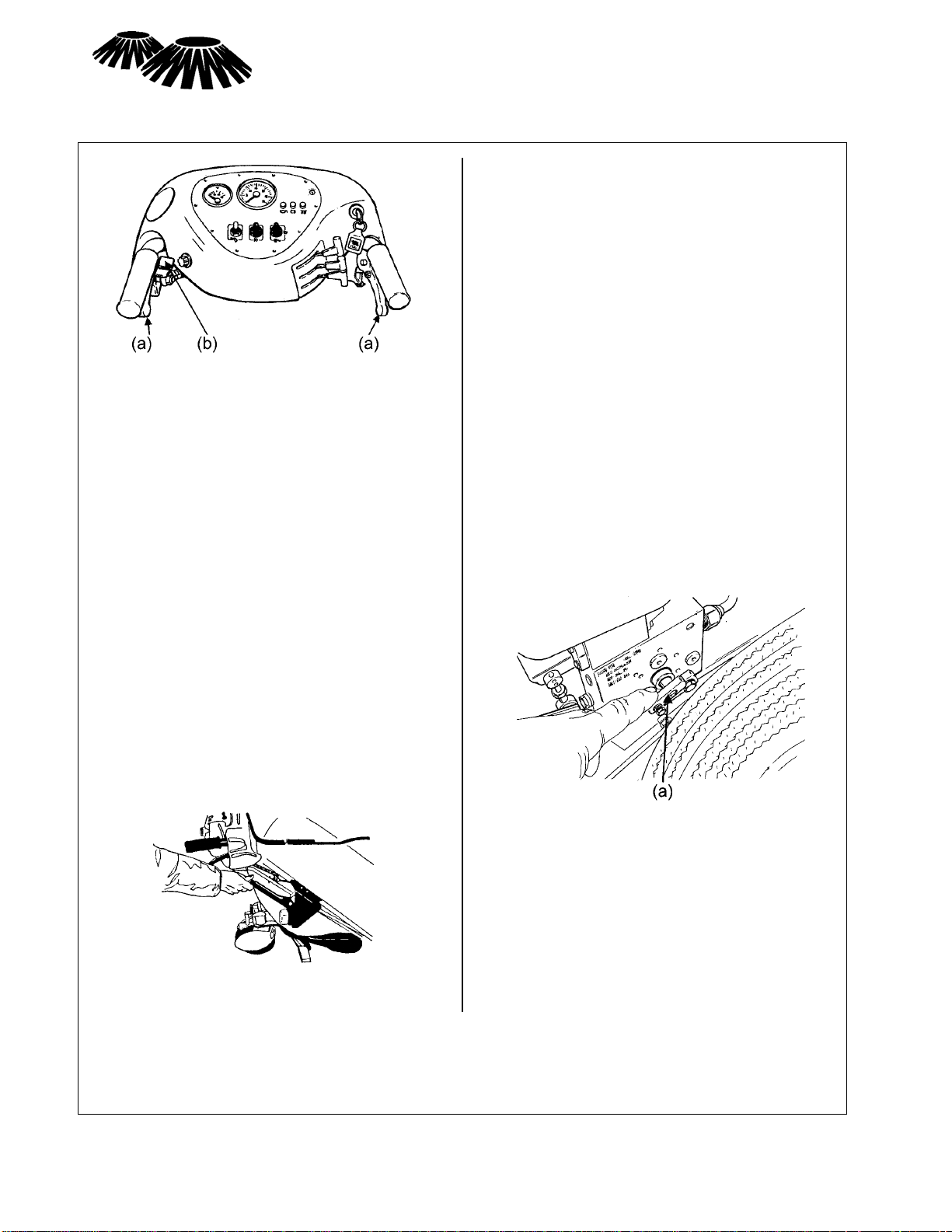

To stop the engine in this case, pull the red

button (a) located under the handlebars on

the right side of the machine.

Report the fault to your maintenance staff.

Setting the brush speed.

The brush speed lever is the bottom lever (c) on

the right hand side of the operator console

and has a black handle.

For normal sweeping set the lever at mid

position.

The brush speed can be changed for different

conditions.

For example, when sweeping a high volume of

leaves or when scrubbing you can set the

brush speed higher.

When sweeping glass, dog fouling, vomit,

spilled food etc., then slow the brushes

down.

If the brush speed is set too high, trash will be

thrown too far across the path of the

machine and the brushes will also wear

faster.

If the brush speed is set too low, then trash will

not be thrown far enough to allow pick-up,

and also the brushes will tend to bounce up

and down as you drive forward.

Setting the engine speed.

The throttle lever (b) is also on the right hand

side of the operator console and has a red

handle.

When running your machine, always use the

minimum engine revs that you need to pick

up the material being swept.

Start off with just under half power.

For machines equipped with a tachometer (rev

counter) this would be 2200 r.p.m.

The throttle speeds will need to be set

according to the nature of the debris you are

sweeping.

Use a mid position for general sweeping such

as dry litter and leaves.

You may need a three-quarter position for large

volumes of litter.

You may have to use almost full throttle when

sweeping heavy material such as thick

deposits of grit and dirt.

Wet conditions will also need a higher throttle

setting.

Try not to use too much throttle, particularly

when your filter bag is clean at the start of

your shift.

Too much throttle means too much airflow. The

dust and debris that you pick up will blow

into the plastic trash sack and will blow

straight back out again. The dust will then

be blown hard against the surfaces of the

filter bag, which results in a loss of suction

performance.

So although it seems strange at first, the lower

Page 18 Green Machine Operator Manual

the throttle setting that you use, the longer

your machine will sweep efficiently.

The Front Flap

There is a flap opening at the front of the

machine.

Opening the flap allows the pick-up of bulkier

debris such as plastic bottles, paper cups,

leaves etc.

When sweeping heavier debris such as sand or

dust, the machine works best with the flap

closed.

Check that the parking brake (a) is released.

Using the right or left hand drive lever (a),

slowly squeeze the lever until the machine

moves forwards .

The more you squeeze, the faster the machine

will drive.

Stopping.

To stop the machine in forward or reverse just

let go of the drive levers.

The machine has what is called “hydrostatic

braking” or a “dead man’s handle” so that it

The topmost lever (a) on the control console

operates the flap.

will come to a controlled stop as soon as

you let go of the drive levers.

Driving in reverse.

Driving forwards.

Always have both hands holding the handles.

Check that it is all clear around you before

moving off.

Green Machine Operator Manual Page 19

Always ensure that there is sufficient room

behind you before reversing.

Pull back on the reverse drive lever (b) using

your left thumb until the machine starts to

reverse.

To stop the machine in forward or

reverse just let go of the drive lever.

The parking brake.

The machine is driven by hydraulics. When the

drive lever is operated the machine moves

in the direction chosen. On releasing the

drive lever the hydraulic system applies a

braking force to bring the machine to a

controlled stop. (This is called “Hydrostatic

Braking”).

However hydrostatic braking systems are not

sufficient to stop the machine gently

creeping down hills or inclines when the

machine is left on unleveled ground.

Therefore there is also a parking brake fitted to

the machine that should be used when the

machine is to be parked unattended.

To release the parking brake, press the button

on the end of the parking brake lever and

then move the lever to the fully up position.

Parking brakes are not fitted as standard

on model 414S2D walk-behind models.

Therefore do not leave this model parked

on any hill or incline.

The emergency brake

release.

Because the hydrostatic braking system is

engaged automatically when the machine is

not being driven in forward or reverse, then

the machine will be unable to be moved

when the engine is not running.

If a situation occurs where the engine cannot be

started and the machine needs to be

moved, the emergency brake release can

be opened. This is located on the right side

of the machine as shown.

Open the emergency brake release (a) by

turning it anti-clockwise just like a faucet.

When done, close the brake release valve

hand-tight only.

Do not use wrenches etc. since over-

tightening can damage the valve.

Do not open the emergency brake release

To engage the parking brake (a), push the

brake lever downwards until it locks.

Page 20 Green Machine Operator Manual

if the machine is on a gradient unless the

road wheels are chocked or the parking

brake is applied.

Loading...

Loading...