Page 1

®

Part #462888

®

Modular Small Cabinet Fan

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

Model MSCF-BI

Model MSCF-FC

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

1. Follow all local electrical and safety codes, as

well as the National Electrical Code (NEC), the

National Fire Protection Agency (NFPA), where

applicable. Follow the Canadian Electric Code

(CEC) in Canada.

DANGER

Always disconnect power before working on or

near a unit. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

2. The rotation of the wheel is critical. It must be

free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately

grounded.

4. Do not spin fan wheel faster than the maximum

cataloged fan rpm. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked

to make sure it is not exceeding the motor

nameplate amps.

5. Do not allow the power cable to kink or come

in contact with oil, grease, hot surfaces,

or chemicals. Replace cord immediately if

damaged.

6. Verify that the power source is compatible with

the equipment.

7. Never open blower access doors while the fan is

running.

When servicing the unit, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

Model MSCF Modular Small Cabinet Fan

1

Page 2

®

Receiving

Upon receiving the product, check to make sure

all items are accounted for by referencing the bill

of lading to ensure all items were received. Inspect

each crate for shipping damage before accepting

delivery. Notify the carrier if any damage is noticed.

The carrier will make notification on the delivery

receipt acknowledging any damage to the product.

All damage should be noted on all the copies of the

bill of lading which is countersigned by the delivering

carrier. A Carrier Inspection Report should be filled

out by the carrier upon arrival and reported to the

Traffic Department. If damaged upon arrival, file claim

with carrier. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited to

only items on the bill of lading.

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration

of the unit during storage. The user assumes

responsibility of the unit and accessories while in

storage. The manufacturer will not be responsible

for damage during storage. These suggestions are

provided solely as a convenience to the user.

INDOOR — The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages

use a portable electric heater to get rid of any

moisture build up. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off

the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every

three months, the fan motor should be energized. If

paint deterioration begins, consideration should be

given to touch-up or repainting. Fans with special

coatings may require special techniques for touch-up

or repair.

Machined parts coated with rust preventive should

be restored to good condition promptly if signs of

rust occur. Immediately remove the original rust

preventive coating with petroleum solvent and clean

with lint-free cloths. Polish any remaining rust from

surface with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe

thoroughly clean with Tectyl® 506 (Ashland Inc.) or

the equivalent. For hard to reach internal surfaces or

for occasional use, consider using Tectyl® 511M Rust

Preventive or WD-40® or the equivalent.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location,

they should be protected and maintained in a similar

fashion, until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners, set screws on the fan,

wheel, bearings, drive, motor base, and

accessories for tightness.

2. Rotate the fan wheel(s) by hand and assure no

parts are rubbing.

Service Clearance

Units require service clearance for:

• lterreplacement

• coilanddrainpaninspection,cleaningand

replacement

• motoranddriveinspection,maintenanceand

replacement

Access panels are provided for inspection and

cleaning of unit components. Allow service clearance

of 26 inches for removal of filters. Allow a service

clearance equal to the unit width for removal of coils

and drain pan.

Model MSCF Modular Small Cabinet Fan

2

Page 3

®

Table of Contents

Installation

Unit Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting / Hanging Instructions . . . . . . . . . . . . . 4

Mounting Dimensions ...................... 5

Dimensions / Weights ...................... 6

Filter Sizes / Quantity . . . . . . . . . . . . . . . . . . . . . . 6

Coil Dimensions . . . . . . . . . . . . . . . . . . . . . . . . .7-9

Start-Up

System Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting

Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Motor Overamps ......................... 10

Insufficient / Too Much Airflow .............. 10

Excessive Noise or Vibration . . . . . . . . . . . . . . . 10

Start-Up

Coil Module ...........................12-13

Drain Pan / Drain Trap . . . . . . . . . . . . . . . . . . . . 13

Installation

Electric Heater ........................... 14

Operation

Electric Heater ........................... 15

Maintenance

Fan .................................... 16

Coil .................................... 16

Drain Pan ............................... 16

Reference

Start-Up Documentation ................... 17

Maintenance Log . . . . . . . . . . . . . . . . . . . . . .18-19

Warranty . . . . . . . . . . . . . . . . . . . . . . . . .Backcover

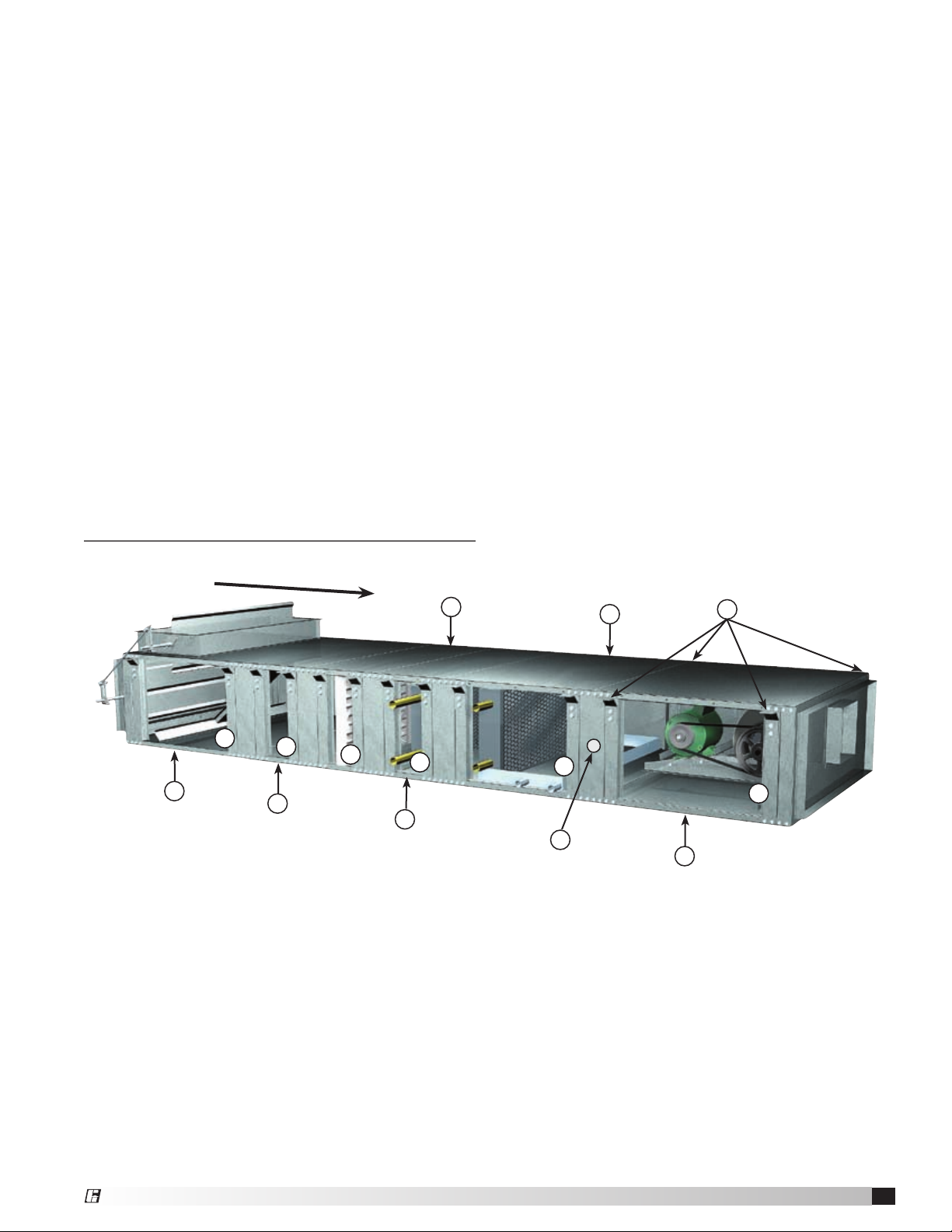

Unit Layout

Airflow

8

6

1. Fan and Cabinet Section

2. Cooling Section

• ChilledWater

• DXCoils

3. Heating Section

• HotWater

• SteamCoils

4. Filter Section

Filter may be mounted in Mixing Box Section

5. Plenum Section

8

5

8

4

8

3

9

6. Mixing Box Section

7. Lifting Lugs

Four (4) lifting lugs for each section

8. Side Access Panels

Right and left access to each section

(image shows panels removed)

9. 7/8-inch knockout is provided for the

recommended electrical wiring penetration or

disconnect switch.

2

8

7

8

1

Model MSCF Modular Small Cabinet Fan

3

Page 4

®

Hanging Bracket

Part No. 710774

Drawing No. 85537

Bridge Bracket

Part No. 711779

Drawing No. 89814

One required per assembly

3/4 inch Flat Washer

One per assembly as needed

3/8-16x3/4 Spinlock Bolt

Two required per assembly

3/8-16 Spinlock Nut

Two required per assembly

HANGING ASSEMBLY

Hanging Bracket

Part No. 710774

Drawing No. 85537

Hanging Bracket

Part No. 710774

Drawing No. 85537

Bridge Bracket

Part No. 711779

Drawing No. 89814

One required per assembly

Bridge Bracket

Part No. 711779

Drawing No. 89814

One required per assembly

3/4 inch Flat Washer

One required per assembly

3/4 inch Flat Washer

One per assembly as needed

3/8-16x3/4 Spinlock Bolt

Two required per assembly

3/8-16x3/4 Spinlock Bolt

Two required per assembly

3.0 inch

3/8-16 Spinlock Nut

Two required per assembly

3/8-16 Spinlock Nut

Two required per assembly

HANGING ASSEMBLY

BASE ASSEMBLY

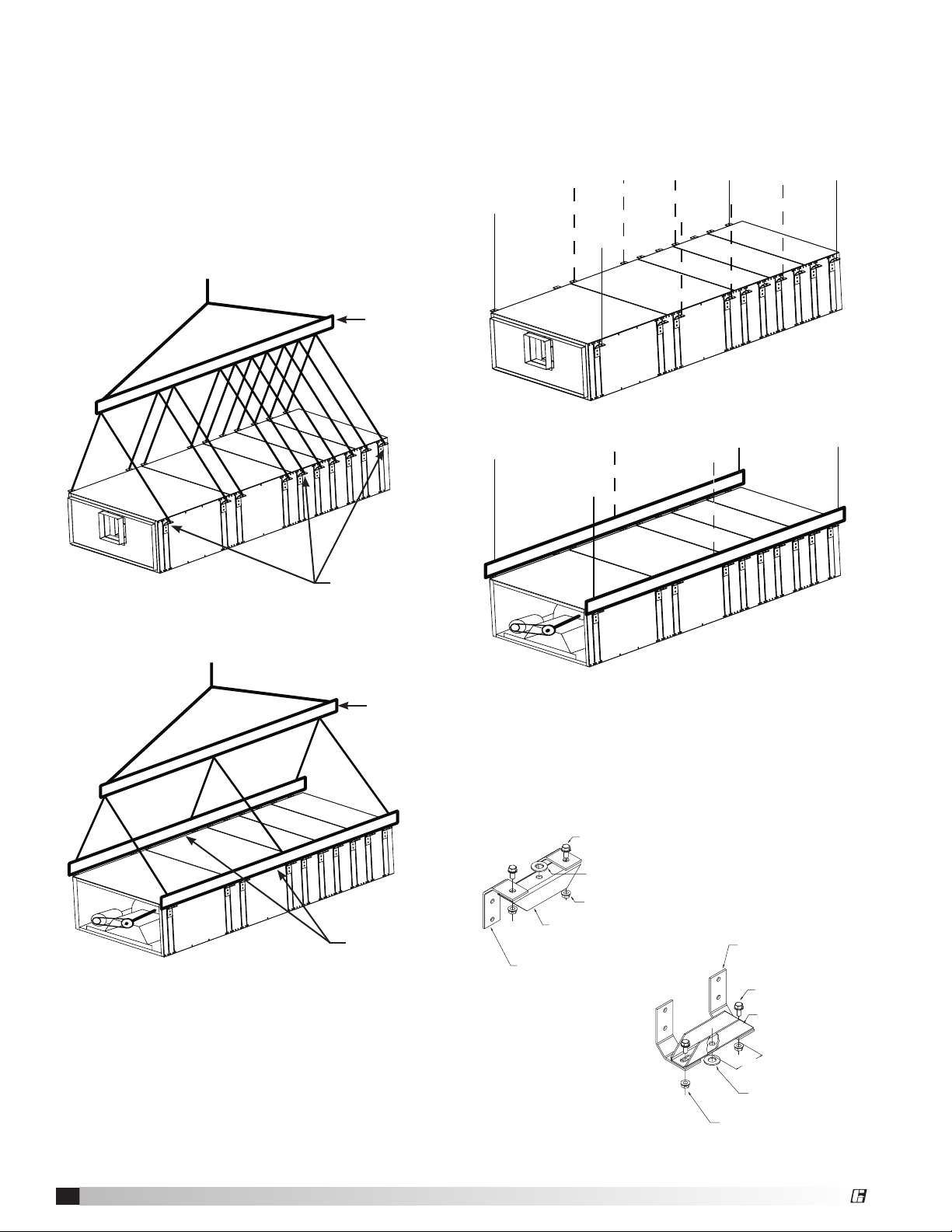

Mounting Instructions

Greenheck’s Modular Small Cabinet Fan (MSCF)

should be lifted by the factory supplied lifting lugs

(see Figure 1) or frame rails and a spreader bar

(see Figure 2) to prevent damage from occurring to

the equipment. Avoid twisting or uneven lifting of

equipment. Do not lift equipment by coil connections

or headers. The unit must remain upright during lifting.

All access doors and panels must be closed during

lifting to avoid damage.

Spreader Bar

Hanging Instructions

The MSCF should be hung by the factory supplied

lifting lugs or field supplied frame rails as shown

respectively in Figures 3 and 4. The number of

hanging brackets used will be determined by the

number of fan modules.

Figure 3

4

Figure 1

Figure 2

Model MSCF Modular Small Cabinet Fan

Lifting lugs

Figure 4

Spreader Bar

External Mounting Isolation

The MSCF is available with external neoprene or

spring isolation options. When external isolation is

selected, a bridge bracket will be provided to reduce

installation time (see Figure 5).

Frame Rails

(by others)

Figure 5

Page 5

®

24

PLENUM

12

PLENUM

CHILLED

WATER

COIL

HEATING

COIL

VERTICAL

FILTER

FAN

MIXING BOX

w/DAMPER

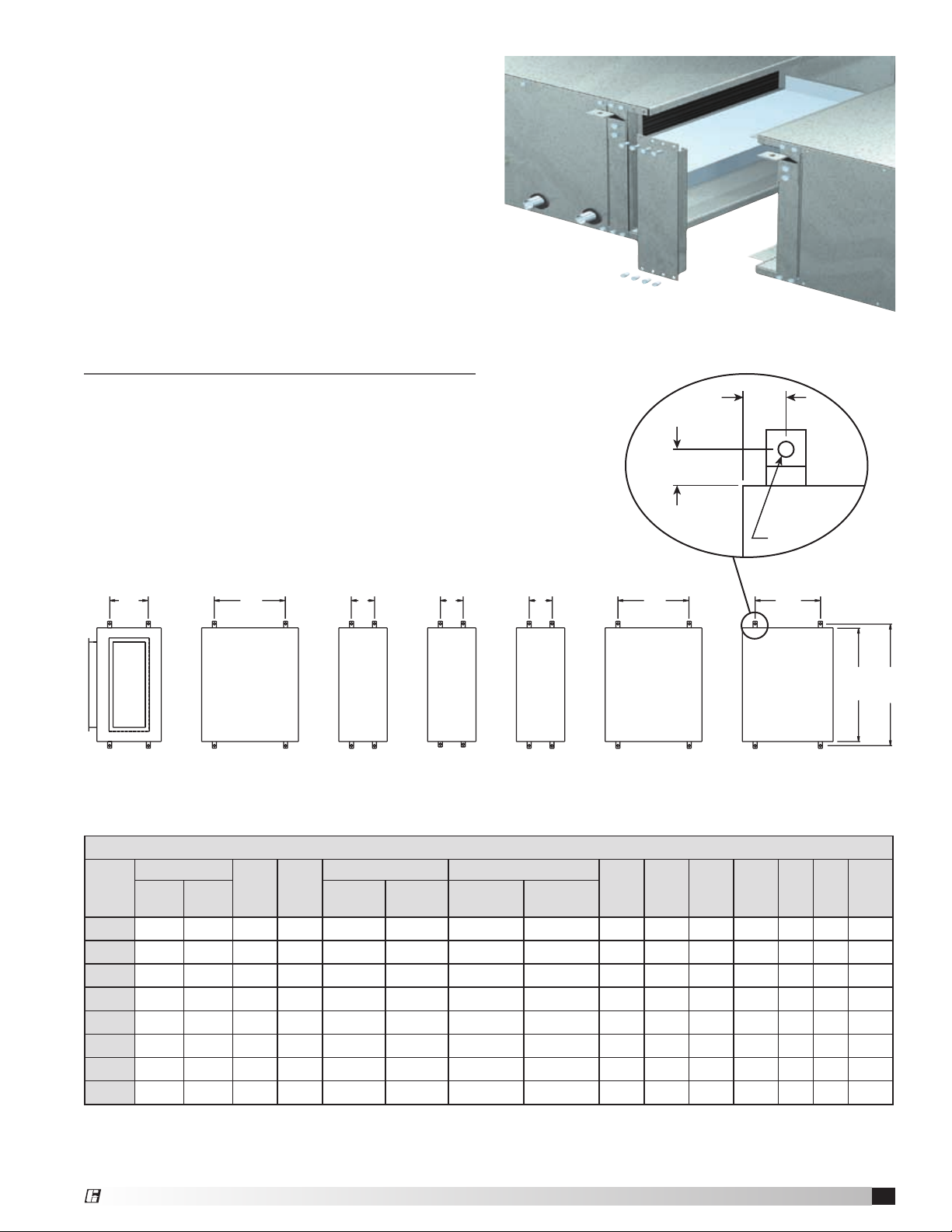

Modular Construction

The MSCF is designed to be modular so it can be

mounted as an assembly or as individual sections

when the appropriate lifting equipment is not

available.

MSCF Mounting Dimensions

K

J

L

A

B C D E

F

G

Mixing 24 in. 12 in. Filter *Heating Cooling / Combo Fan

Box Plenum Plenum Coil

Horizontal Hanging

Unit

Size

w/o

Filter

A

w/

Filter

B C

Vertical Sloped

D E

Hot Water

1 & 2 Row

15 6.75 18.5 18.5 6.75 6.75 18.5 6.75 9.5 18.5 19 38 2.5 3 .5 43

20 6.75 18.5 18.5 6.75 6.75 18.5 6.75 9.5 18.5 19 38 2.5 3 .5 43

25 6.75 21 18.5 6.75 6.75 21 6.75 9.5 18.5 23 38 2.5 3 .5 43

30 6.75 25 18.5 6.75 6.75 25 6.75 9.5 18.5 26 38 2.5 3 .5 43

45 6.75 26 18.5 6.75 6.75 26 6.75 9.5 18.5 26 50 2.5 3 .5 55

50 6.75 26 18.5 6.75 6.75 26 6.75 9.5 18.5 32 50 2.5 3 .5 55

65 6.75 32 18.5 6.75 6.75 28 6.75 9.5 18.5 36 50 2.5 3 .5 55

85 6.75 32 18.5 6.75 6.75 28 6.75 9.5 18.5 36 62 2.5 3 .5 67

*See CAPS for electric heating dimensions.

All dimensions are in inches.

4 Row HW

& Steam

F G H J K L M

H

M

Model MSCF Modular Small Cabinet Fan

5

Page 6

®

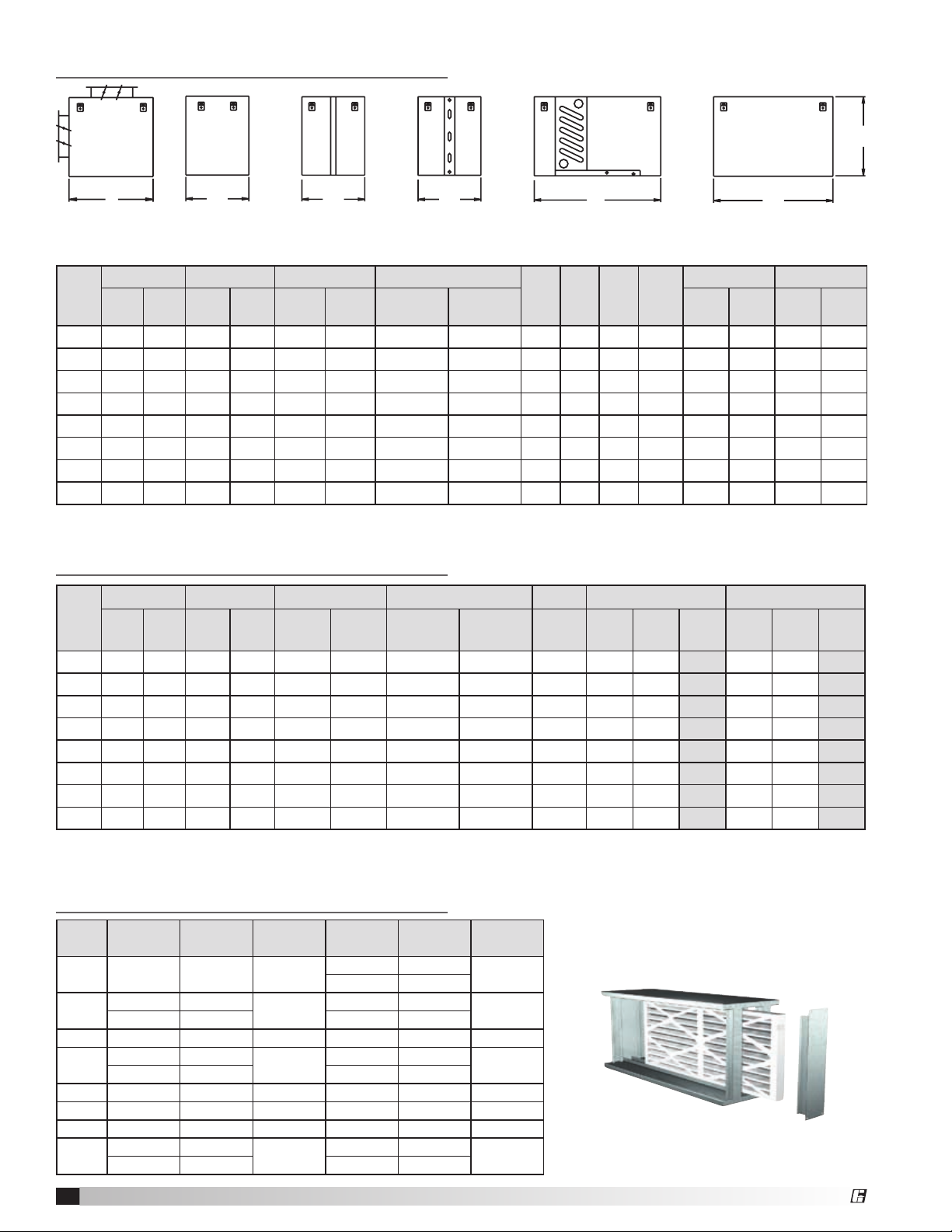

Dimensional Data

24

PLENUM

12

PLENUM

CHILLED

WATER

COIL

HEATING

COIL

VERTICAL

FILTER

FAN

MIXING BOX

w/DAMPER

12

PLENUM

CHILLED

WATER

COIL

HEATING

COIL

VERTICAL

FILTER

FAN

G

A

B C D E

Mixing Plenum Filter *Heating Cooling / Combo Fan

Box Coil

Unit

Size

15 11 24.5 12.75 24.5 12.75 24.5 12.75 15.5 24.5 25 11 38 9 36 4 6.75

20 14 24.5 12.75 24.5 12.75 24.5 12.75 15.5 24.5 25 14 38 12 36 6.5 6.75

25 16 27 12.75 24.5 12.75 27 12.75 15.5 24.5 29 16 38 14 36 8 8.5

30 18.5 31 12.75 24.5 12.75 31 12.75 15.5 24.5 32 18.5 38 16.5 36 9 9

45 18.5 32 12.75 24.5 12.75 32 12.75 15.5 24.5 32 18.5 50 16.5 48 9 10

50 21 32 12.75 24.5 12.75 32 12.75 15.5 24.5 38 21 50 19 48 10.25 10

65 26 38 12.75 24.5 12.75 38 12.75 15.5 24.5 42 26 50 24 48 12 12.75

85 26 38 12.75 24.5 12.75 38 12.75 15.5 24.5 42 26 62 24 60 12 15

*See CAPS for electric heating dimensions.

All dimensions are in inches.

A B C D

w/o

w/

Filter

12 in. 24 in. Vertical Sloped

Filter

Hot Water

1 & 2 Row

4 Row HW

& Steam

E F G

Unit

Width

Height Width Height Width

Weights

Unit

Size

15 80 107 31 57 34 61 61 86 145 94 50 144 - - -

20 95 126 36 68 41 72 72 101 171 111 50 161 - - -

25 105 140 40 75 45 80 80 112 190 130 60 190 168 60 228

30 118 157 45 84 50 90 88 123 209 150 75 225 182 75 257

45 132 176 50 94 55 100 99 138 234 194 75 269 239 100 339

50 151 202 58 108 64 115 113 159 269 253 100 353 279 100 379

65 197 263 75 141 77 150 136 190 323 328 125 453 333 100 433

85 226 302 85 170 90 175 140 196 350 360 140 500 375 100 475

All weights are approximated. Motor weights may very depending on enclosure type and horsepower.

**Weightinformationforhotwater,steam,chilledwaterandDXcoilsiswetweight.

*See CAPS for electric heat dimensions.

A B C **D **E F (FC) F (BI)

w/o

Filter

Filter

w/

12 in. 24 in. Vertical Sloped

Hot Water

1 & 2 Row

4 Row HW

& Steam

CW/DX Fan

Max

Motor

Total Fan

F

Inlet Outlet

Max

Motor

Total

Filter Sizes and Quantity

Unit

Size

6

Vertical Quantity

15 9x18 2 1.8

20

25 14x18 2 3.0 16x20 2 3.8

30

45 16x24 2 4.8 24x24 2 7.2

50 18x24 2 5.4 24x24 2 7.2

65 24x24 2 7.2 24x24 4 14.4

85

12x12 1

12x24 1 16x20 1

16x16 1

16x20 1 24x24 1

12x24 1

24x24 2 24x24 4

Model MSCF Modular Small Cabinet Fan

Face

Area

2.5

3.4

8.9

Sloped Quantity

12x12 1

12x24 1

16x16 1

12x24 1

12x24 2

Face

Area

2.5

3.4

5.3

17.8

Page 7

®

Coil Dimensions

Inlet

Outlet

Outlet

Inlet

Outlet

Inlet

Hot Water • 1 and 2 Row

A

Hot Water • 4 Row

A

Unit

Size

Face

Area

A B C D E F

15 1.6 38 12.75 11.0 3.0 0.75 .5

20 2.2 38 12.75 14.0 4.5 0.75 .5

3

E

C

F

D

25 2.7 38 12.75 16.0 4.0 0.88 .5

30 3.2 38 12.75 18.5 4.0 0.88 .5

45 4.5 50 12.75 18.5 4.0 0.88 .5

50

5.2 50 12.75 21.0 4.0 1.13 .5

65 6.7 50 12.75 26.0 4.0 1.38 .5

85 8.6 62 12.75 26.0 4.0 1.38 .5

All dimensions are in inches.

NOTE

6

B

G

F

D

E

C

B

Fluid enters the coil from the bottom connection

(Inlet) and exits from the top (Outlet).

Unit

Size

All dimensions are in inches.

Face

Area

A B C D E F G

15 1.6 38 15.50 9.38 3.188 0.750 4.0 11.0

20 2.2 38 15.50 9.38 3.188 0.750 4.5 14.0

25 2.7 38 15.50 9.38 3.188 0.875 4.0 16.0

30 3.2 38 15.50 9.38 3.188 0.875 4.0 18.8

45 4.5 50 15.50 9.38 3.188 1.375 4.0 21.0

50 5.2 50 15.50 9.38 3.188 1.375 4.0 26.0

65 6.7 50 15.50 9.38 3.188 1.375 4.0 26.0

85 8.6 62 12.75 9.38 3.188 1.375 4.0 26.0

NOTE

With airflow from left to right, the fluid enters the coil

from the bottom connection (Inlet) and exits from the

top (Outlet). The other two coil connections should

be capped off (Cap).

Steam • 1 and 2 Row

Unit

Size

Face

Area

A B C D E F G

15 1.6 38 15.50 7.75 3.31 1.5 5.18 11.0

20 2.2 38 15.50 7.75 3.00 1.5 6.50 14.0

25 2.7 38 15.50 7.75 3.31 2.5 7.69 16.0

30 3.2 38 15.50 7.75 3.00 2.5 9.00 18.5

45 4.5 50 15.50 7.75 3.00 2.5 9.00 18.5

G

50 5.2 50 15.50 7.75 4.31 2.5 10.18 21.0

65 6.7 50 15.50 7.75 3.00 2.5 12.50 26.0

F

A

C

Electric Heat • See our Computer Aided Product Selection (CAPS) Software Program for dimensional data.

B

D

E

85 8.6 62 15.50 7.75 3.00 2.5 12.50 26.0

All dimensions are in inches.

NOTE

Steam enters the coil from the center connection

(Inlet) and exits from the bottom (Outlet).

Model MSCF Modular Small Cabinet Fan

7

Page 8

®

Coil Dimensions - continued

Chilled Water • 4, 6 or 8 Row

3

With airflow from left to right, the fluid enters the coil

1

C

from the bottom connection (Inlet) and exits from the

top (Outlet). The other two coil connections should

be capped off (cap).

A

B

Unit

Size

Face

Area

A B C

4 Row 6 Row 8 Row 4 & 6 Row 6 Row

15 1.6 38 24.5 11.0 10 12 14 0.75 1.38

20 2.2 38 24.5 14.0 10 12 14 0.75 1.38

25 2.7 38 24.5 16.0 10 12 14 0.88 1.38

30 3.2 38 24.5 18.5 10 12 14 0.88 1.38

45 4.5 50 24.5 18.5 10 12 14 0.88 1.38

50 5.2 50 24.5 21.0 10 12 14 1.38 1.63

65 6.7 50 24.5 26.0 10 12 14 1.38 1.63

85 8.6 62 24.5 26.0 10 12 14 1.38 1.63

All dimensions are in inches.

J K

Airflow

K

6.5

Outlet

(cap)

J

13.25

NOTE

(cap)

Inlet

18.5

.75

1.5

3.75

3.88

2

Direct Expansion (DX) • 4, 6 or 8 Row

(Orifice Code 18/19)

Coil connection made inside housing.

Two inch hole is provided.

3

With airflow from left to right, the fluid enters the coil

C

1

Unit

Size

A

Face

Area

A B C

B

L M N P

4 Row 6 Row 8 Row All All

15 1.6 38 24.5 11.0 8.75 10.75 12.75 5.25 0.63 0.63 1.38

20 2.2 38 24.5 14.0 8.75 10.75 12.75 7.00 0.63 0.63 1.38

25 2.7 38 24.5 16.0 8.75 10.75 12.75 8.00 0.88 1.38 1.38

30 3.2 38 24.5 18.5 8.75 10.75 12.75 9.00 0.88 1.38 1.38

45 4.5 50 24.5 18.5 8.75 10.75 12.75 9.00 0.88 1.38 1.38

50 5.2 50 24.5 21.0 8.75 10.75 12.75 10.25 0.88 1.38 1.63

65 6.7 50 24.5 26.0 8.75 10.75 12.75 13.00 1.13 1.38 1.63

85 8.6 62 24.5 26.0 8.75 10.75 12.75 13.00 1.13 1.38 1.63

All dimensions are in inches.

from the center connection (Inlet) and exits from the

bottom (Outlet). The other coil connections should

be capped off (cap).

4 & 6

Row

8 Row

NOTE

Airflow

(cap)

Outlet

N

6.5

Inlet

L

13.25

18.5

3.88

P

M

2

3.75

1.5

Model MSCF Modular Small Cabinet Fan

8

Page 9

®

Coil Dimensions - continued

Direct Expansion (DXI) • 4, 6 or 8 Row

Dual Circuit with 50/50 Face Interlaced Construction

Coil connection made inside housing.

Two inch hole is provided.

3

C

1

NOTE

The first suction header on the entering air side

of the coil is circuited to the top distributor. With

airflow from left to right, the fluid enters the coil

from the center connection (Inlet) and exits from the

bottom (Outlet). The other connections should be

capped off (cap).

A

B

Unit

Size

Face

Area

A B C

D E

4 Row

6 & 8

Row

4 Row 6 Row 8 Row

F G

30 3.2 38 24.5 18.5 9.25 11.0 7.88 8.50 8.5 7.00 12.0

45 4.5 50 24.5 18.5 9.25 11.0 7.88 8.50 8.5 7.00 12.5

50 5.2 50 24.5 21.0 9.25 11.0 7.50 8.50 8.75 7.75 13.5

65 6.7 50 24.5 26.0 9.25 11.0 8.12 8.75 8.75 9.50 17.0

85 8.6 62 24.5 26.0 9.25 11.0 8.12 8.75 8.75 9.50 17.0

All dimensions are in inches.

Airflow

Outlet 1

6.5

(cap) (cap)

Outlet 2

3.75

E

D

13.25

18.5

Inlet 1

Inlet 2

F

G

1.5

2

Model MSCF Modular Small Cabinet Fan

9

Page 10

®

Backward

Inclined

Airfoil

Forward

Curved

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

R

o

t

a

t

i

o

n

Forward

Curved

R

o

t

a

t

i

o

n

C

l

o

c

k

w

i

s

e

G

System Start-Up

For proper unit function and safety, follow everything

in this start-up procedure in the order presented.

This is to be done after the electrical connections are

complete.

PRE-START CHECK LIST

1. Disconnect and lock-out all power switches to fan.

2. Check all fasteners, set screws and locking

collars on the fan, bearings, drive, motor base and

accessories for tightness.

3. Rotate the fan wheel by hand and assure no parts

are rubbing.

4. Check the V-belt drive for proper alignment and

tension.

Unit Size G

25 - 50 1/4 inch

65 - 85 3/8 inch

Wheel Overlap Dimensions

SPECIAL TOOLS REQUIRED

•VoltageMeter

•Tachometer

•AmperageMeter

1. Check Voltage

Before starting the unit, compare the supplied voltage

with the unit’s nameplate voltage and the motor

voltage. Units are not provided with thermal overload

protection unless a control center has been ordered

with the unit or the motor has been selected with

thermal overload protection.

2. Check Blower Rotation

A common problem is wheel rotation in the wrong

direction. For centrifugal fans, incorrect wheel rotation

will provide poor air performance, motor overloading

and possible burnout. Rotation should be checked

while the fan is coasting to a stop. Proper wheel

rotation is shown.

any two supply power connections will reverse the

direction of rotation.

To reverse the rotation, turn the power off and use the

following procedure:

• Forsinglephaseunits,rewirethemotorperthe

instructions on the motor.

• Forthreephaseunits,interchangeanytwo

power leads. This can be done at the motor

starter.

3. Check for Vibration

Check for unusual noise, vibration or overheating of

bearings. Excessive vibration may be experienced

during initial start-up. Left unchecked, excessive

vibration can cause a multitude of problems, including

structural and/or component failure. Many conditions

can be discovered by careful observation. If the

problem is wheel unbalance, in-place balancing can

be done providing there is access to the fan wheel.

Generally, fan vibration and noise is transmitted

to other parts of the building by the ductwork. To

eliminate this undesirable effect, Greenheck has

used a heavy canvas connection between the scroll

and the discharge of the fan. If noise is an issue, we

recommend using heavy canvas connections on the

inlet of the fan. Refer to the Troubleshooting section of

this manual if a problem develops.

4. Air Volume Check and Measurement

Along with the building balance, the unit’s air volume

(cfm) should be measured and compared with its

rated air volume. This unit is flexible for varying air

volume, but the actual air volume should be known for

making final adjustments. The most accurate way to

measure the air volume is by using the pitot traverse

method in the ductwork away from the blower. Other

methods can be used, but should be proven and

accurate. To adjust the air volume, change the fan rpm

or the system losses. See Troubleshooting section in

this guide.

5. Measure Motor Voltage, Amperage

and Fan RPM

All access doors must be installed. Measure and

record the input voltage and motor amperage(s).

To measure the fan RPM, the blower door will need to

be removed. Minimize measurement time because the

motor may over amp with the door removed.

Compare measured amps to the motor nameplate

full load amps and correct if over amping. See the

Troubleshooting section in this guide.

Proper Wheel Rotation

When connecting a 3-phase motor, there is a 50%

chance that the fan will run backwards. Changing

Model MSCF Modular Small Cabinet Fan

10

Page 11

®

Troubleshooting

NOTE

Before taking any corrective action, ensure unit is incapable of operation during repairs.

Symptom Possible Cause Corrective Action

Blown fuse or open circuit breaker Replace fuse or reset circuit breaker and check amps

Blower fails to

operate

Motor overamps

Insufficient airflow

Broken fan belt Replace

Defective motor or capacitor Replace

Motor starter overloaded Reset starter and check amps

Airflow too high Check airflow and adjust drives if needed

Static pressures are higher or lower

than design

If higher, ductwork should be improved

If lower, fan RPMs should be lower

Blower rotation is incorrect Check rotation and correct

Motor voltage incorrect Check motor nameplate and supplied voltage

Motor horsepower too low

See specifications and catalog for fan curves to determine

if horsepower is sufficient

Shorted windings in motor Replace motor

Mixing box damper not fully open Adjust damper linkage or replace damper motor

System static pressure too high

Improve ductwork to eliminate losses using good duct

practices

Blower speed too low Check for correct drives and RPMs with catalog data

Mixing box dampers closed Open and adjust

Dirty or clogged filters Clean or replace

Leaks in ductwork Repair

Elbows, or other obstructions may

restrict fan outlet

Correct or improve ductwork

Too much airflow

Excessive noise or

vibration

Belt slippage Adjust belt tension

Unit running backwards

Correct as shown in System Start-Up section, Step #2,

page 10

Excessive dirt buildup on wheels Clean wheel

Blower fan speed too high Check for correct fan RPM

Filter(s) not in place Install filters

Insufficient static pressure

(airflow resistance)

Wheel improperly aligned and rubbing on

housing

Induce static pressure into system ductwork

Center wheel

Loose wheel on shaft Tighten wheel setscrew

Loose motor or blower sheave Tighten sheave setscrew

Belts too loose Adjust belt tension after 24 hours of operation

Belts too tight

Loosen to maintain 3/8 inch deflection per ft. of span

between sheaves

Worn belt Replace

Motor base or blower loose Tighten mountings bolts

Worn bearings Replace

Bearing and drive alignment Realign

Motor out of balance Replace

Unbalanced wheel caused by excessive

dirt and grease buildup

Replace or rebalance

Sheaves eccentric or out-of-balance Replace or rebalance

Accumulation of material on wheel Clean wheel and housing

Foreign objects in wheel or housing Remove objects. Check for damage or unbalance.

Model MSCF Modular Small Cabinet Fan

11

Page 12

®

Start-Up of Coil Module

Steam Main

Return Main

Strainer

Gate Valve

Control Valve

Modulating Two-Position

Check Valve

Vacuum Breaker

Float & Thermostat Trap

Hot Water and Chilled Water

1. Piping should be in accordance with accepted

industry standards. Pipework should be supported

independently of the coils. Water pipes are copper

with sweat connections. USE WET TOWEL TO

AVOID BURNING COIL CONNECTION GROMMETS.

When installing coupling, do not apply undue

stress to the connection extending through the

unit. Use a back-up pipe wrench to avoid breaking

the weld between coil connection and header.

2. Connect the water supply to the bottom

connection on the air-leaving side and the water

return to the top connection on the air-entering

side. The extra bottom connection can be used for

an auxiliary manual drain connection, and the extra

top connection may be used for an automatic air

vent, or the extra connections can be capped. To

ensure proper venting, an external air vent in the

piping is recommended. Connecting the supply

and/or return in any other manner will result in very

poor performance. CAP UNUSED CONNECTIONS.

3. The air vent at the uppermost point should be

temporarily opened during system start-up to

release all of the air from the coil. To maintain heat

transfer capacity, periodically vent any air in coil.

Vent to be located behind connections side access

door.

4. Water coils are not normally recommended for

use with entering air temperatures below 40°F.

No control system can be depended on to be

100% safe against freeze-up with water coils.

Glycol solutions or brines are the only safe media

for operation of water coils with low entering air

conditions.

WARNING

Continuous water circulation through the coil at all

times is highly recommended.

5. Pipe sizes for the system must be selected on the

basis of the head (pressure) available from the

circulation pump. Piping should be in accordance

with accepted industry standards.

6. For chilled water coils, the condensate drain

pipe should be sized adequately to ensure the

condensate drains properly. See Drain Pan Traps

section and related drawing.

Direct Expansion (DX) Coils

1. Piping should be in accordance with accepted

industry standards. Pipework should be supported

independently of the coils. Undue stress should not

be applied at the connection to coil headers.

2. The condensate drain pipe should be sized

adequately to ensure the condensate drains

properly. See Drain Pan Traps and related drawing.

Model MSCF Modular Small Cabinet Fan

12

3. When connecting suction and liquid connections,

make sure the coil is free from all foreign material.

Make sure all joints are tight and free of leakage.

4. Greenheck does not supply compressor or

condensingunits,forfurtherinstructiononDXcoil

installation and operation contact your compressor

and/or condenser manufacturer.

DXI coils have dual connections and should be used

with two compressors.

WARNING

Standard unit insulation of 1.5 lbs. density has an

insulation R-value of 3.7.

For applications where the unit discharge

temperatures are below 55°F and the unit is installed

in a warm, humid environment, additional insulation

may need to be applied to the exterior of the unit to

prevent condensation.

Steam Coils

Application Recommendations

Satisfactory operation and

service life are best

ensured when coils

are installed with

proper piping,

trap and support

arrangement.

The following

notes and

drawing are

recommended

for the coil unit

installation and

operation.

General

1. Provide

separate

supports and

hangers for the

unit and the piping.

2. Be certain that adequate piping flexibility is

provided. Stresses resulting from expansion of

closely coupled piping and coil arrangement can

cause serious damage.

3. Standard steam coils are pitched in the casings

when installed for horizontal airflow. The casing

must be level after the unit is installed for proper

condensate drainage. If condensate is not

removed, the coil will suffer from water hammering

and will have a shortened life. On vertical airflow

applications, the coils must be pitched when

installed.

4. Do not reduce pipe size at the coil return

connection. Carry return connection size through

the dirt pocket, making the reduction at the branch

leading to the trap.

Steam Coil Piping

Page 13

®

2P = minimum

2P = minimum

General - continued

5. It is recommended that vacuum breakers be

installed on all applications to prevent retaining

condensate in the coil. Generally, the vacuum

breaker is to be connected between the coil inlet

and the return main. The vacuum breaker should

be open to the atmosphere and the trap design

should allow venting of large quantities of air.

6. Do not attempt to lift condensate when using

modulating or on-off control.

7. Do not reduce the pipe size leaving the coil.

Traps

1. Size traps in accordance with the manufacturer’s

recommendations. Be certain that the required

pressure differential will always be available. DO

NOT UNDERSIZE.

2. Float and thermostatic or bucket traps are

recommended for low pressure steam. On high

pressure systems, bucket traps are normally

recommended. The thermostatic traps should be

used only for air venting.

3. Bucket traps are recommended for use with on-off

control only.

4. Locate traps at least 12 inches below the coil

return connection.

Controls

1. On high pressure installations, a two-position

steam valve with a face and bypass arrangement is

preferred where modulating control is required.

2. Modulating valves must be sized properly. DO NOT

UNDERSIZE.

Freezing Conditions (entering air below 35°F)

1. 5 PSI steam must be supplied to the coil at all times.

2. Modulating valves are not recommended. Control

should be by means of face and bypass dampers.

3. Provision should always be made to thoroughly

mix fresh air and return air before it enters the

coil on return air units. Also, temperature control

elements must be properly located to obtain true

air mixture temperatures.

4. As additional protection against freeze-up, the trap

should be installed sufficiently —far below the coil

to provide an adequate hydrostatic head to ensure

removal of condensate during an interruption in the

steam pressure. Estimate 3 feet for each 1 PSI of

trap differential required.

5. On start-up, admit steam to coil ten minutes before

admitting outdoor air.

6. Provision must be made to close fresh air dampers

if steam supply pressure falls below minimum

specified.

Drain Pan / Drain Trap

Drain lines and traps should be run full size from the

drain pan connection. Drain pans should have drain

lines and traps to permit the condensate from the

coils to drain freely. On all units with drain pans, the

trap depth and the distance between the trap outlet

and the drain pan outlet should be twice the static

pressure (P) in the drain pan section under normal

operation to assure the trap remains sealed.

Drain Pan / Drain Trap

Model MSCF Modular Small Cabinet Fan

13

Page 14

®

Installation of Electric Heater

(optional)

WARNING

Electrical Shock Hazard! Disconnect all power

sources before doing any work on the unit.

General:

The requirements and practices described below

are based on the National Electric Code (NEC) and

The Space Heating Standard of the Underwriters

Laboratories Inc. (UL). Although UL requirements

are uniform throughout the country, local electrical

codes may deviate from the National Electrical Code.

Therefore, local inspection authorities should be

consulted regarding local requirements.

Electrical Wiring Instructions:

1. Use the wiring diagram supplied with the heater

as a guide in correlating field wiring with the

heater internal wiring.

2. All field wiring to the heater must meet the

requirements of the National Electric Code and

any other applicable local or state codes.

3. Wiring to the heater must be rated for 75°C

(167°F) minimum.

4. If heater does not have a built-in disconnect

switch or main circuit breaker, install a remote

disconnect (furnished by others) in accordance

with the National Electric Code, Article 424-65.

Calculation of Line Currents (amps):

Single Phase Current =

EXAMPLE: 5 kW, 208 volt

5000 watts

208 volts

= 24 amps

Three Phase Current =

EXAMPLE: 14.4 kW, 208 volt

14400 watts

208 volts x 1.73 360

=

14400

watts

volts

watts

volts x 1.73

= 40 amps

Sizing of Supply Conductors

The required minimum size of supply conductors

is marked at the field wiring terminals within the

heater control box or reference the Supply Wire Size

table included in this section. The wire gauges are

calculated for 125% of the heater line current as

required by the National Electric Code, Article 424-3(b)

based on conductor insulation rated for 75°C (167°F).

Supply Wire Size

(Not more than six conductors in Single Conduit 1)

AWG or

MCM

14 12 0000 184

12 16 250 204

10 24 300 228

8 36 350 248

6 52 400 268

4 68 500 304

3 80 600 336

2 92 700 368

1 104 750 380

0 120 800 392

00 140 900 416

000 160 1000 436

1

For 7-24 conductors in raceway or cable, reduce allowable

heater line currents to 87½% of those shown above.

2

Based on 30°C. (86°F) ambient temperature, for higher

ambient temperature see National Electric Code table

310-16 and 310-18 Note 13.

3

Based on 80% of ratings in the National Electric Code

table 310-16 for 75°C insulation.

Max. Heater

Line Current

Copper

3

2

AWG or

MCM

Max. Heater

Line Current

Copper

3

2

Effect of Low Voltage on Wattage and

British Thermal Unit (BTU)

The heating elements may be used on voltages

lower than the design voltage of the heater, however,

the wattage and BTU output will be reduced to the

percentages listed in the table below.

De-rated Wattage for Low Voltage

% of

Heater

Voltage

Line

Voltage

Heater

Wattage

Heater

Voltage

Line

Voltage

and BTU

480

277

240

Model MSCF Modular Small Cabinet Fan

14

460 92

440 84 190 83

265 92

254 84 110 84

230 92

220 84

208 75

200 69

208

120

200 92

115 92

% of

Heater

Wattage

and BTU

Page 15

®

Sequence of Operation - Electric

Heater

1. Electric heaters are divided in to equally sized

steps. For example, a 60 kW heater with 3 steps

will have 20 kW per step. The thermostat and

step controller will control these steps.

2. 120 Volt power from the control center (when

supplied) or by others with out a control center,

is delivered to the electric heater for the step

controller. This power must be interlocked with

the supply fan, so when the fan is off, the heater

control power is off.

3. A step control with the thermostat set to

70ºF the heater will be off with a temperature

sensing above 70ºF. As the temperature varies

the steps turn on and off to hold the setpoint

discharge temperature. The colder the discharge

temperature becomes the more steps the

controller will energize.

4. With a step controller, in addition to the fan

interlock mentioned in Step 2, the heater has an

airflow switch to prove that airflow is established

before energizing the steps. The heater also

has an automatic resetting highlimit switch and

manual resetting highlimit switch set above the

automatic switch to protect from overheating.

5. For more detailed information on your specific

controller, please review the controller spec

sheet supplied with the heater.

Model MSCF Modular Small Cabinet Fan

15

Page 16

®

Fan Maintenance

Belt Span

Deflection =

Belt Span

64

C

l

o

c

k

w

i

s

e

C

l

o

c

k

w

i

s

e

G

CORRECT WRONG WRONG WRONG

Greenheck recommends these procedures to ensure

trouble-free operation of this unit. It is especially

important to maintain heater units for clean and

efficient operation. Most unit failures can be attributed

to poor setup or poor maintenance.

A record of maintenance performed on this unit

should be kept. This information will provide essential

information if problems are encountered. A section at

the back of this manual is provided for recording the

unit’s maintenance history.

CAUTION

When performing any maintenance on this unit,

be certain the power is disconnected and cannot

be accidentally turned on. The control center

disconnect can be locked in the off position.

Two Weeks after Start-Up

Belts - Belts tend to stretch after a period of

time. They should be

periodically checked

for wear and tightness.

Approximately 3/8 inch

of deflection per ft.

of span between

sheaves is standard for

belt tightness. When

replacing belts, use the

same type as supplied

with the unit. Matched

belts should always be

used on units with multi-groove pulleys.

If adjustments are made, it is very important to check

the pulleys for proper alignment. Misaligned pulleys

lead to excessive belt wear, vibration, noise and

power loss.

Belt Alignment

Replacement of belts can be accomplished by

loosening the motor to the point where the belts

can be removed by hand. Do not force belts on or

off as this may cause breakage of cords leading to

premature belt failure. Belts should be adjusted as

above.

NOTE: For motors of 1 hp or less a

smaller sliding base bracket

is used to attach to blower.

Every Three (3) Months

Filters - The filter in the unit should be inspected

at least every three (3) months. Depending on the

environment, filters could require changing or cleaning

more or less often. The filters can be slid out of the

coil connection side of the unit.

If washable filters are installed, they can be washed in

warm soapy water. An adhesive spray can be applied

to increase filter efficiency.

If disposable filters are installed, check by holding up

to a light source. If light cannot pass through the filter,

it should be replaced. Replacement filters should be

of the same manufacturer and size. When reinstalling

filters, be sure to install with the airflow in the correct

direction indicated on the filter.

Yearly

Bearings — Most bearings are permanently

lubricated and require no further lubrication under

normal use. Normal use being considered -20ºF to

120ºF and in a relatively clean environment. Some

bearings are re-lubricatable and will need to be regreased depending on fan use. Check your bearings

for grease fittings to find out what type of bearing

you have. If your fan is not being operated under

normal use, bearings should be checked monthly for

lubrication.

Motors — Motor maintenance is generally limited to

cleaning and lubrication (where applicable). Cleaning

should be limited to the exterior surfaces only.

Removing dust and grease buildup on motor housing

assures proper motor cooling. Greasing of motors

is intended only when grease fittings are provided.

Many fractional motors are permanently lubricated

and require no further lubrication. Motors supplied

with grease fittings should be greased in accordance

with manufacturer’s recommendations. When motor

temperature does not exceed 104ºF (40ºC), the grease

should be replaced after 2000 hours of running time

as a general rule.

Wheels — Wheels require very little attention when

moving clean air. Occasionally, oil and dust may

accumulate on the wheel causing imbalance. When

this occurs the wheel and housing should be cleaned

to assure smooth and safe operation. Inspect fan

impeller and housing for fatigue, corrosion or wear.

Routinely check all fasteners, set screws and locking

collars on the fan, bearing, drive, motor base and

accessories for tightness.

Model MSCF Modular Small Cabinet Fan

16

Page 17

®

Coil Maintenance Start-Up Documentation

Coils must be clean to obtain maximum performance.

Check once a year under normal operating conditions

and, if dirty, brush or vacuum clean. Soiled fins reduce

the capacity of the coil, demand more energy from the

fan, and create an environment for odor and bacteria

to grow and spread through the conditioned zone.

High pressure water (400 psi or less) may be used to

clean coils with fin thickness over 0.006 inches thick.

Test the spray pressure over a small corner of the

coil to determine if the fins will withstand the spray

pressure.

For coils with fragile fins or high fin density, foaming

chemical sprays and washes are available. Many coil

cleaners contain harsh chemicals, so they must be

used with caution by qualified personnel only. Care

must be taken not to damage the coils, including fins,

while cleaning.

CAUTION

Fin edges are sharp.

Winterizing Coils

Coil freeze-up can be caused by such things as air

stratification and failure of outdoor air dampers and/

or preheat coils. Routine draining of water cooling

coils for winter shutdown cannot be depended upon

as insurance against freeze-up. Severe coil damage

may result. It is recommended that all coils be drained

as thoroughly as possible and then treated in the

following manner.

Fill each coil independently with an antifreeze solution

using a small circulating pump and again thoroughly

drain. Check freezing point of antifreeze before

proceeding to next coil. Due to a small amount of

water always remaining in each coil, there will be

diluting effect. The small amount of antifreeze solution

remaining in the coil must always be concentrated

enough to prevent freeze-up.

NOTE: Carefully read instructions for mixing antifreeze

solution used. Some products will have a higher

freezing point in their natural state than when mixed

with water.

Job Information

Job Name _________________________________

Address _________________________________

City ________________ State ______ Zip ___________

Phone Number _________________________________

Contact Person _________________________________

Start-Up Company Information

Service Oranization _______________________________

Address _______________________________

City ________________ State ______ Zip ___________

Phone Number _______________________________

Fax Number _______________________________

Start-Up Date _______________________________

Start-Up Personnel Name __________________________

Nameplate Information

Unit Model Number _______________________________

Volts ________________ Hertz ________ Phase _______

Amps _______________ Mark _______________________

Fan rpm _____________

Unit Serial Number _______________________________

Field Start-Up Documentation

oCheck blower rotation

oCheck air volume (cfm)

_________ Design

_________ Actual

oActual motor voltage _________ Volts

oActual motor hertz _________ Hertz

oActual motor phase _________ Phase

oActual motor amps _________ Amps

Drive

oFan RPM Range

_________ Minimum

_________ Maximum

Drain Pan Maintenance

Drain pans in any air conditioning unit will have

some moisture in them, therefore, algae and other

organisms will grow due to airborne spores and

bacteria. Periodic cleaning is necessary to prevent

this buildup from plugging the drain and causing the

drain pan to overflow. Inspect twice a year to avoid

the possibility of overflow. Also, drain pans should be

kept clean to prevent the spread of disease. Cleaning

should be performed by qualified personnel.

Model MSCF Modular Small Cabinet Fan

17

Page 18

®

Maintenance Log

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Model MSCF Modular Small Cabinet Fan

18

Page 19

®

Maintenance Log

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Model MSCF Modular Small Cabinet Fan

19

Page 20

®

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

GreenheckCatalogIAHSeries(MSCF-FC•MSCF-BI•

LFC-C•VFC-FC•VFCD-FC)providesadditionalinformation

describing the equipment, fan performance, available

accessories, and specification data.

Phone:(715)359-6171•Fax:(715)355-2399•E-mail:gfcinfo@greenheck.com•Website: www.greenheck.com

462888 • MSCF Modular Small Cabinet Fan, Rev. 2, November 2005 Copyright 2005 © Greenheck Fan Corporation

20

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at www.amca.org.

Loading...

Loading...