Greenheck Fan ERV User Manual

Energy Recovery Ventilator

Model ERV

• Commercial • Institutional

•400 to 12,000 cfm

•1.5 in. wg external static pressure

June

2010

Model ERV

Greenheck’s model ERV provides fresh outdoor air to your building and is designed for operation in all climates. This unit incorporates innovative design features with options in energy wheel performance to provide a quality constructed unit with performance flexibility. The flexibility and reliability of these units means the ERV will fit seamlessly into your building to improve your indoor air quality while saving energy and costs.

Design Features:

1 Louvered intake weatherhood lowers supply air intake velocities to prevent

rain and snow from |

4 |

being pulled in to the |

|

unit. Each hood has |

|

washable aluminum |

|

mesh prefilters blocking |

|

debris or leaves. |

1 |

2-inch outdoor and |

2

return air filters with a MERV 8 (30% efficiency) rating and are set into filter racks that permit easy change out and rigid support.

3Pitched roof and interlocked standing seams eliminates standing water

and provides rigid construction.

418 gauge outer wall construction is available in many alternate coatings. Optional double-wall construction protects insulation from moisture and prevents insulation fibers from entering the airstream. Insulation is 3 lb/ft³ density.

5Multiple energy wheel options allow selection of a unit by what is critical in the design or application:

•Effectiveness

•Recovery Efficiency Ratio (RER)

•Low blower horsepower

3

2

5 7

6

6Integral lifting lugs are included for easy maneuvering and installation of the unit.

7Slide out energy wheel design allows for easy access to the energy wheel.

Additional Features

•Quiet running, forward-curved blowers

•Adjustable motor pulleys for final system balancing

•Factory provided motor starters and disconnect switch in a sealed control center

•Neoprene isolation on blower assembly to minimize sound and vibration transmission

•Bolt-on door design allows for fit in tighter spaces. Optional hinged access is available for roof mount applications.

2

Model ERV

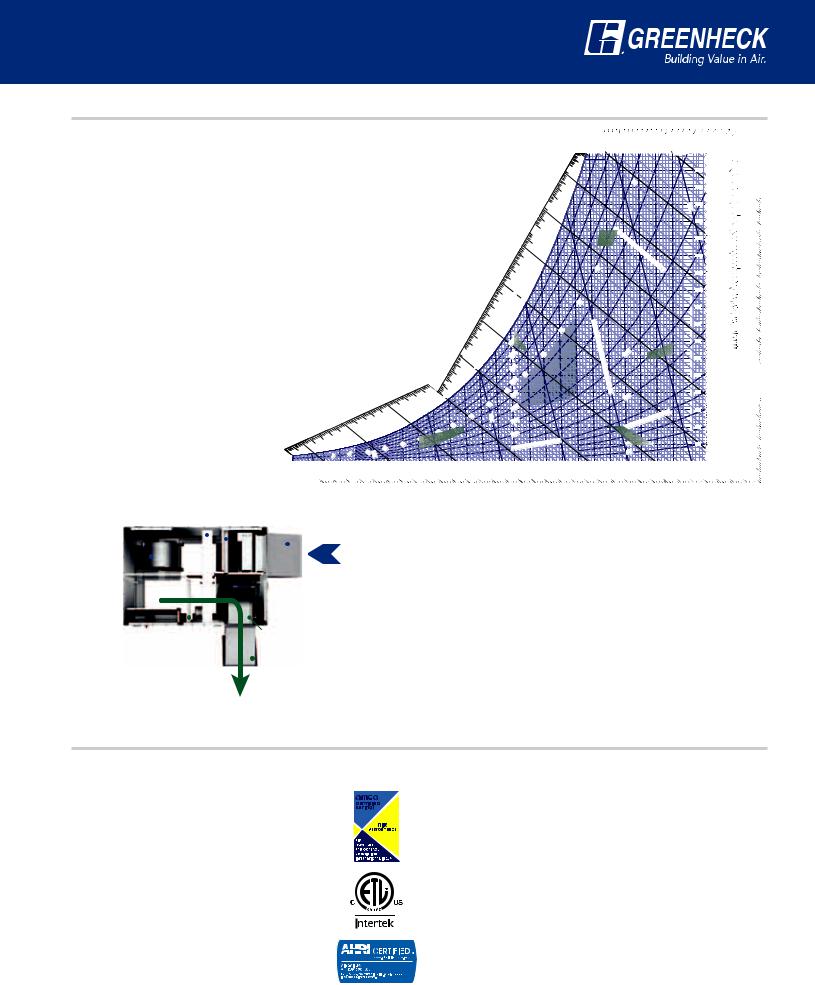

How does an energy recovery wheel work?

The basic objectives for providing acceptable indoor air quality (IAQ) are to control indoor contaminates levels while maintaining desired indoor air temperature and humidity. Compliance with the prescribed ventilation rates in ASHRAE Standard 62 appear to satisfy the contaminant issue. However, simply increasing outdoor air (OA) requirements with “traditional” HVAC systems may not address the humidity issue properly and often leads to significant energy cost increases.

45

80

40

75

|

|

|

|

|

|

|

|

|

|

35 |

|

|

|

The best solution for most commercial and institutional facilities |

|

|

|

|

|

DRY |

AIR |

|

|

|

|

|

|

|

|

|

|

OF |

|

|

|

|

|

|

|||

will include an enthalpy wheel product. The enthalpy wheel |

|

|

|

|

POUND |

|

|

|

|

|

|

70 |

|

|

|

|

PER |

|

30 |

|

Temp |

-- |

°F°F |

|

|||

transfers temperature and moisture properties from one |

|

|

|

|

|

|

|

|

|

|

|||

|

|

BTU |

|

|

|

|

Saturationrti |

|

|

|

|||

ENTHALPY |

- |

|

|

|

|

|

|

|

65 |

70 |

|||

airstream to another. The result is capturing the cooling and |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

Bulb,, |

|

|

|

|

||

heating energy before it leaves the HVAC system. |

|

25 |

|

|

Wet |

|

|

|

|

|

|||

|

|

|

|

|

|

|

60 |

|

|

|

65 |

||

Moving through the unit, the return and supply airstreams pass on opposite sides of a divider panel. The

enthalpy wheel rotates between the airstreams |

|

|

15 |

||||

|

|

|

|||||

transferring up to 75% of the energy |

|

|

|

|

|

10 |

|

present in the exhaust airstream to |

|

|

|

|

|

|

35 |

|

|

|

|

|

|

25 |

|

|

|

|

|

5 |

|

|

30 |

the supply. |

0 |

|

|

10 |

|

20 |

25 |

|

|

|

|

|

15 |

|

|

|

|

|

|

5 |

|

15 |

20 |

|

|

0 |

|

10 . |

|

||

|

-5 |

|

5 |

|

|||

|

|

|

|

|

12 |

|

|

|

|

|

0 |

|

0 |

|

|

30

20

45 40

45 40

40

40

35

50

55 |

|

90% |

|

|

|

80% |

|

|

|

|

|

60 |

||

|

|

70% |

55 |

|

|

|

|

|

|

|

|

60% |

|

|

|

50 |

50% |

|

|

|

|

|

|

|

45 |

|

40% |

|

|

|

|

|

|

|

13 |

|

|

|

|

. |

|

30% |

|

|

0 |

|

|

|

|

|

|

20% |

|

|

|

|

|

RELATIVE |

HUMIDITY |

|

|

10% |

|

|

|

|

|

|

|

-10 |

-5 |

0 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

Chart by: HANDS DOWN SOFTWARE, www.handsdownsoftware.com |

|

|

|

|

|

DRY BULB TEMPERATURE - °F |

|

|

||||||||||

0.20 |

0.25 |

0.30 |

0.35 |

0.40 |

|

|

|

SENSIBLE HEAT RATIO = Qs / Qt |

|

|

|

||

50 |

|

55 |

|

|

|

|

|

|

|

|

|

|

1.15 |

|

|

|

|

170 |

0.45 |

|

|

|

|

|

|

1.10 |

|

|

|

|

|

|

|

|

|

85 |

|

|

|

|

|

|

|

|

|

160 |

|

1.05 |

|

|

|

|

|

|

|

|

|

|

|

|

80 |

|

|

|

|

15 |

150 |

0.50 |

1.00 |

|

|

|

. |

|

||

|

|

|

0 |

|

|

|

|

|

|

|

|

|

0.95 |

|

|

|

|

140 |

|

|

80 |

|

|

|

|

WET |

BULB |

|

|

|

TEMPERATURE- |

|

75 |

|

|

|

|

|

°F |

|

14 |

|

|

|

. |

|

|

|

0 |

|

|

|

VOLUME |

|

|

|

- |

|

|

|

CU |

25% |

|

|

. |

|

||

. |

|

|

|

FT |

|

|

|

PER |

|

|

|

LB |

|

|

|

. |

|

|

|

DRY |

|

|

|

AIR |

|

|

|

|

15% |

|

|

|

|

|

HUMIDITY |

|

|

RELATIVE |

|

|

|

8% |

|

|

|

6% |

|

HUMIDITY RATIO - GRAINS OF MOISTURE PER POUND OF DRY AIR

HUMIDITY RATIO - GRAINS OF MOISTURE PER POUND OF DRY AIR

|

|

|

0.55 |

0.90 |

|

75 |

|

|

|

130 |

|

|

|

|

|

|

|

0.85 |

|

|

|

|

|

|

120 |

|

|

0.60 |

0.80 |

|

|

|

||

110 |

70 |

|

0.65 |

0.75 |

- °F |

|

|||

|

|

|

0.70 |

|

|

|

TEMPERATURE |

|

|

100 |

|

0.70 |

|

|

|

|

|

|

0.65 |

90 |

65 |

|

0.75 |

|

|

|

|

0.60 |

|

80 |

|

POINT |

0.80 |

|

|

0.85 |

0.55 |

||

|

60 |

DEW |

|

|

|

|

0.90 |

0.50 |

|

70 |

|

|

0.95 |

|

|

|

|

0.45 |

|

|

55 |

|

1.00 |

|

|

|

|

||

60 |

|

|

/ Qt |

0.40 |

|

50 |

|

= Qs |

0.35 |

50 |

|

|

RATIO |

|

|

|

|

||

|

45 |

|

HEAT |

0.30 |

40 |

|

|

|

|

|

40 |

|

SENSIBLE |

0.25 |

30 |

35 |

|

0.20 |

|

|

30 |

|

|

0.15 |

20 |

|

|

|

|

25 |

|

|

|

|

|

|

|

|

|

|

20 |

|

|

0.10 |

|

|

4% |

|

|

|

|

10 |

10 |

|

|

|

|

|

|

|

|

|

0.05 |

|

|

|

2% |

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

||

85 |

90 |

95 |

100 |

105 |

110 |

115 |

|

120 |

|

VAPOR PRESSURE - INCHES OF MERCURY

55

55

50

50

45

45

40

40

35

35

ENTHALPY - BTU PER POUND OF DRY AIR

0 |

5 |

10 |

15 |

20 |

25 |

30 |

|

|

|

|

Enthalpy Wheel |

|

|

|

|

|||

Supply Air to Building |

|

|

Filters |

|

Outdoor Air Weatherhood |

||||||

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|||

Supply |

|

|

|

|

|

|

|

|

|

|

Outdoor Air |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

Blower |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Exhaust Blower |

|||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

Return Air From Building |

Filters |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Exhaust Weatherhood |

||

|

|

|

|

|

|

|

|

|

|||

Exhaust Air

Certifications

Utilizing an enthalpy wheel to precondition the outdoor air, narrows the operational range of outdoor air conditions which the building’s HVAC equipment is designed to temper. It is this reduction in the outdoor air range that allows for size reduction in heating and cooling equipment and reduced energy costs.

ERV’s construction is matched with extensive in-house testing and third-party verification of performance and safety.

Licensed to bear the AMCA seal for

Air Performance

Unit is ETL Listed — all internal electrical components are factory wired to a single-point power connection

ARI Standard 1060 certified energy wheel performance assures the ERV model will function as required in demanding environments

Greenheck certifies that the ERV models shown herein are licensed to bear the AMCA seal. The ratings shown are based on tests and procedures performed in accordance with AMCA Publication 211 and comply with the requirements of the AMCA Certified Ratings Program.

Every unit is tested at the factory before it is shipped to the job site.

Energy recovery wheels are certified by the ARI Air-to-Air Energy Recovery Ventilation Equipment Certification Program in accordance with ARI Standard 1060. Actual performance in packaged equipment may vary. Certified ratings are available in the Certified Product Directory at http://www.ahridirectory.org/ahridirectory/pages/home. aspx

3

What is the Benefit with

Greenheck Energy Recovery?

For the Building Owner

•Improved Indoor Air Quality (IAQ)

Introducing fresh, outdoor air to a building is a key component to sustaining excellent indoor air quality. Outdoor air can be very expensive to heat and cool, but the ERV unit can provide an economical approach to delivering outdoor air into a building.

•Energy Savings = Quick Payback

The energy recovery unit provides energy savings throughout the year. In the summer, the energy recovery unit removes heat and moisture out of the outdoor air, but in the winter, heat and moisture are added back into the fresh airstream. When you combine the energy savings from summer and winter operation, they lead to a very fast payback period. In most parts of the United States, the payback is less than 2 years!

|

|

Equipment Reduction Using Energy Recovery on 3000 cfm Outdoor Air |

|

||||

|

|

|

|

|

|

|

|

|

|

|

Cooling |

Annual |

Heating |

Annual Winter |

Approximate |

|

|

|

Equipment |

Summer |

Equipment |

||

|

Gas Price* |

Electric Cost** |

Heating |

Payback |

|||

|

Reduction |

Cooling |

Reduction |

||||

|

|

|

Savings |

(Years)*** |

|||

|

|

|

(tons) |

Savings |

(MBH) |

||

|

|

|

|

|

|||

Boston, MA |

1.68 |

0.1495 |

8.72 |

226 |

161 |

4544 |

0.78 |

Minneapolis, MN |

1.14 |

0.0712 |

9.55 |

161 |

217 |

3261 |

0.88 |

St. Louis, MO |

1.34 |

0.0558 |

12.1 |

356 |

173 |

3088 |

0.35 |

Raleigh, NC |

1.48 |

0.073 |

11.3 |

424 |

138 |

2790 |

0.57 |

Houston, TX |

1.10 |

0.1011 |

13.0 |

1701 |

111 |

1089 |

0.22 |

Tampa, FL |

1.59 |

0.0974 |

13.1 |

1779 |

89 |

988 |

0.21 |

Portland, OR |

1.21 |

0.071 |

4.17 |

2 |

123 |

2930 |

2.34 |

Phoenix AZ |

1.13 |

0.0766 |

9.40 |

271 |

161 |

1478 |

1.95 |

*Average gas price (dollars per therm) per region in the first six months of 2007 (source: Energy Information Administration)

**Average electricity cost (dollars per kWh) in March of 2007 (source: Energy Information Administration)

***Assumptions: $3/cfm energy recovery cost; $650/ton avoided cooling equipment cost; 75.6% effective energy wheel; 12 hrs/day 5 days/week operation

For the Maintenance Personnel

•Low Maintenance Equipment

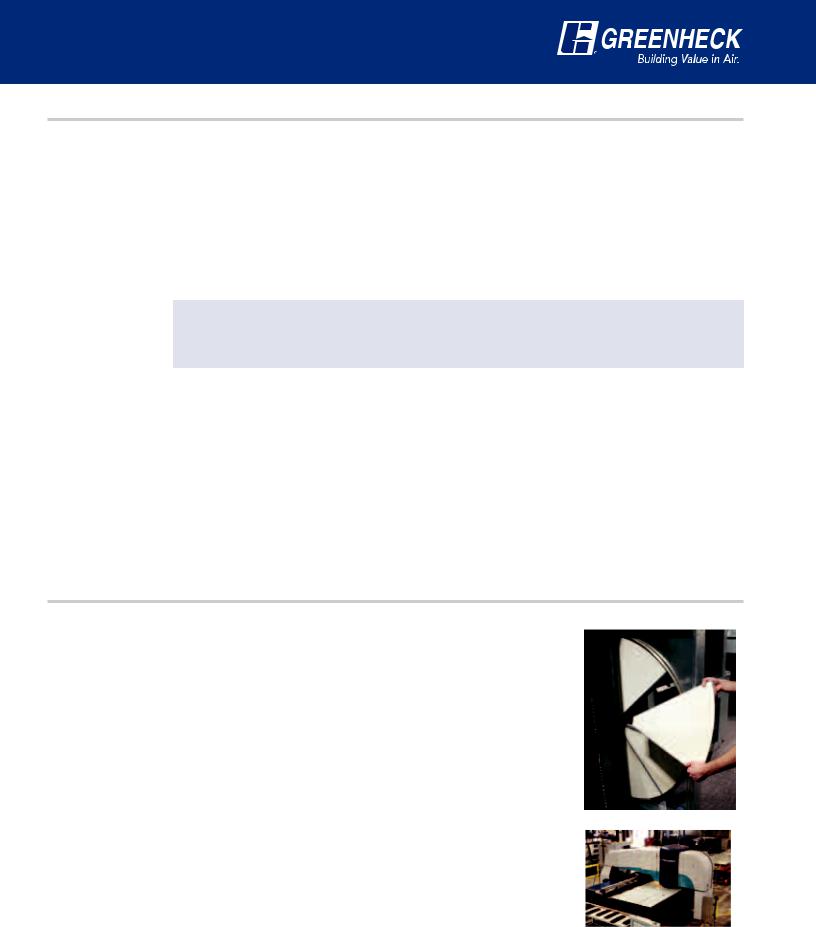

Energy Wheel: The most important component in the ERV is the energy wheel. This device should be inspected and cleaned as necessary, which will vary by application and environment. Any cleaning that is required is simplified by the easy accessible wheel with removable segments. Cleaning requires no special equipment (light detergent and water) and can be performed in a location that is convenient to you.

Fans: The blowers that are used in the ERV are centrifugal, forward-curved- type fans. These fans come with easily adjustable pulleys, belt tension bolts and permanently sealed bearings.

Filters: The 2-inch, 30% efficient MERV 8 filters that are included with the unit are designed for easy access and removal.

•Quality Construction

Greenheck has focused on the manufacturing and unit designs to create wellconstructed equipment. Investments in automated manufacturing processes provide accurate and repeatable results, giving excellent part fit and unit strength. Incorporation of innovative designs add to the quality, while keeping maintenance work simple to perform.

•Long-Lasting Equipment

Because of our high-quality construction, the equipment that goes to the field is made to last. As reassurance to the customer, each ERV unit carries a 1-year warranty from the ship date and the wheel components (segments, cassette, belt, and pulleys) carry a 5-year warranty.

4

What is the Benefit with

Greenheck Energy Recovery?

For the Design Engineer

•Adhering to ASHRAE Guidelines

ASHRAE Standard 90.1 provides design guidelines regarding when it is most beneficial to use energy recovery. Depending upon your geographic location and the percentage of outdoor air in the application, ASHRAE recommends when to use energy recovery. An important part of this guideline is that when energy recovery is recommended, the device should be a minimum of 50% total (sensible and latent) effectiveness according to ARI 1060 testing procedure.

ASHRAE Standard 189.1 provides high performing building design guidelines. This requires even higher energy recovery device performance than Standard 90.1. When energy recovery is recommended, the device shall be a minimum 60% total (sensible and latent) effectiveness according to ARI 1060 testing procedure.

•LEED Certification Credits

For Green Building designs, the ERV offers an excellent way to acquire credits in both Energy and Atmosphere (EA) and Indoor Environmental Quality (EQ) categories towards a LEED certification.

• CAPS Program

Prepared to Support Green Building Efforts

CAPS is Greenheck’s comprehensive product selection program. The CAPS program was developed with ease of use and fast selections in mind. There is also useful information available for making selections and educating people who are new to energy recovery technology. CAPS also provides submittals which includes unit overview, electrical information, fan charts, arrangements, engineering drawings, payback information, and psychrometric processes.

•CSI Specifications

After a unit has been selected in CAPS, an accurate unit specification is available for use in the job specification. These specifications have been recently updated to the CSI format.

•Industry Certification

To ensure performance on the job site, Greenheck emphasizes the need for the 3 major industry certifications for energy recovery units: AMCA Licensed for Air Performance, ETL Listed for safety, and ARI Certification on the energy recovery wheel.

For the Contractor

•Easy Installation

-Lifting Lugs

-Single-Point Power

-Bolt-doors for limited clearance applications

Lifting Lugs

Lifting Lugs

These are just a few of the built-in features to make the installation process quick and easy. Our comprehensive Installation, Operation, and Maintenance Manuals are also available online, so the information you need is quick and easy to obtain.

•Product Approval

Form, fit and function, the ERV was designed to operate in commercial and institutional applications. With over a decade of installations specific to the energy recovery market, Greenheck’s energy recovery product line is well known and accepted throughout the industry.

•1 — 5-Year Warranty

Our 1-year unit warranty and 5-year energy recovery wheel warranty lets you to rest easy knowing that we stand behind our product.

5

Loading...

Loading...