Part number 464603

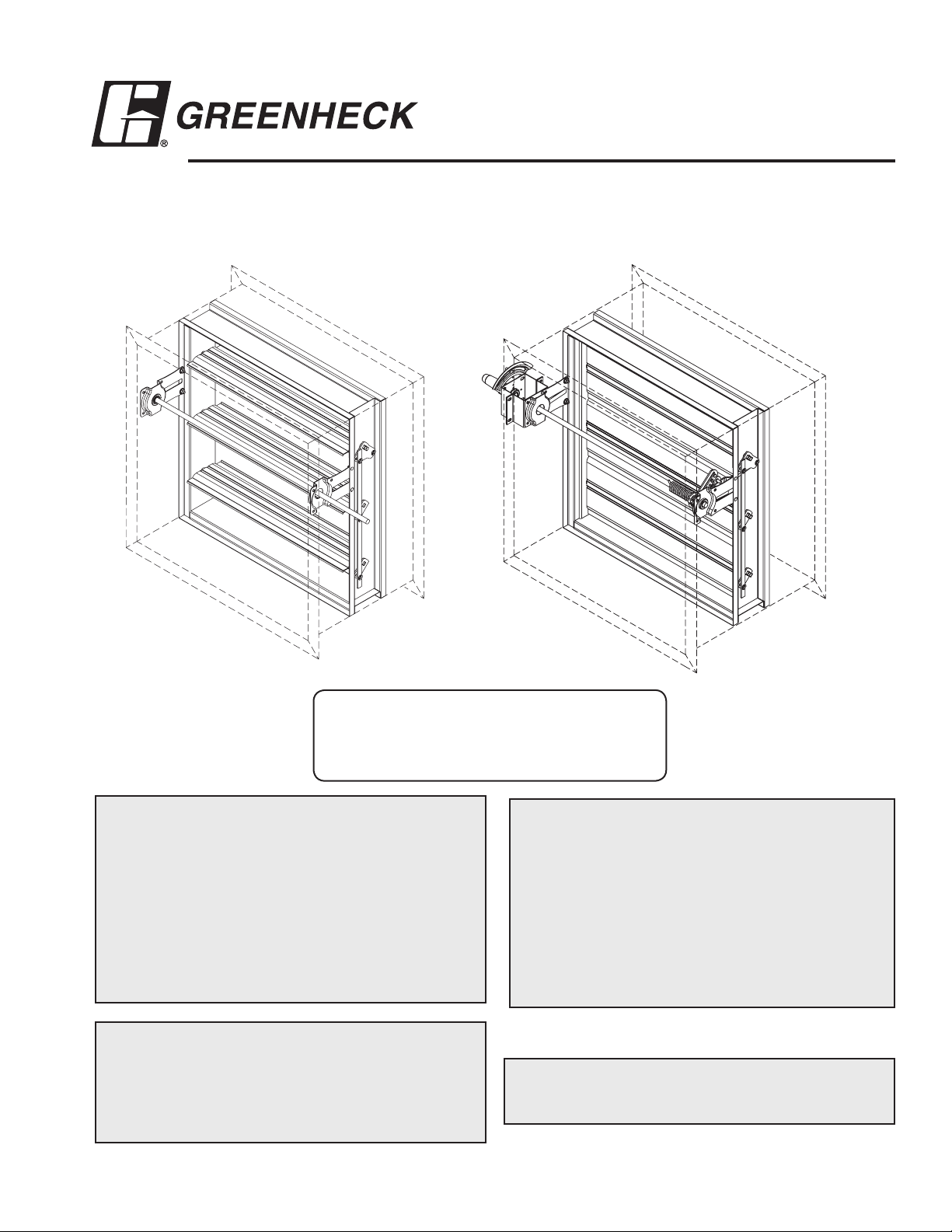

IMO-XXX & SSIMO-XXX series

Fire and Combination Fire Smoke Dampers

Vertical or Horizontal Mount

Installation, Operation and Maintenance Instructions

International Maritime Fire Test Procedure

Code

USCG Type Approved

Approval Number 164.139/0007/0

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious and

hidden damage. If damage is found, record all necessary

information on the bill of lading and file a claim with

the final carrier. Check to be sure that all parts of the

shipment, including accessories, are accounted for.

Dampers must be kept dry and clean. Indoor storage

and protection from dirt, dust and the weather is highly

recommended. Do not store at temperatures in excess of

100°F.

SAFETY WARNING:

Improper installation, adjustment, alteration,

service or maintenance can cause property damage,

injury or death. Read the installation, operating,

and maintenance instructions thoroughly before

installing or servicing this equipment.

WARRANTY

Greenheck warrants this equipment to be free from

defects in material and workmanship for a period of one

year from the purchase date. Any units or parts which

prove to be defective during the warranty period will

be repaired or replaced at our option. Greenheck shall

not be liable for damages resulting from misapplication

or misuse of its products. Greenheck will not be

responsible for any installation or removal costs.

Greenheck will not be responsible for any service work

or backcharges without prior written authorization.

This manual is the property of the owner, and is required

for future maintenance. Please leave it with the owner

when the job is complete.

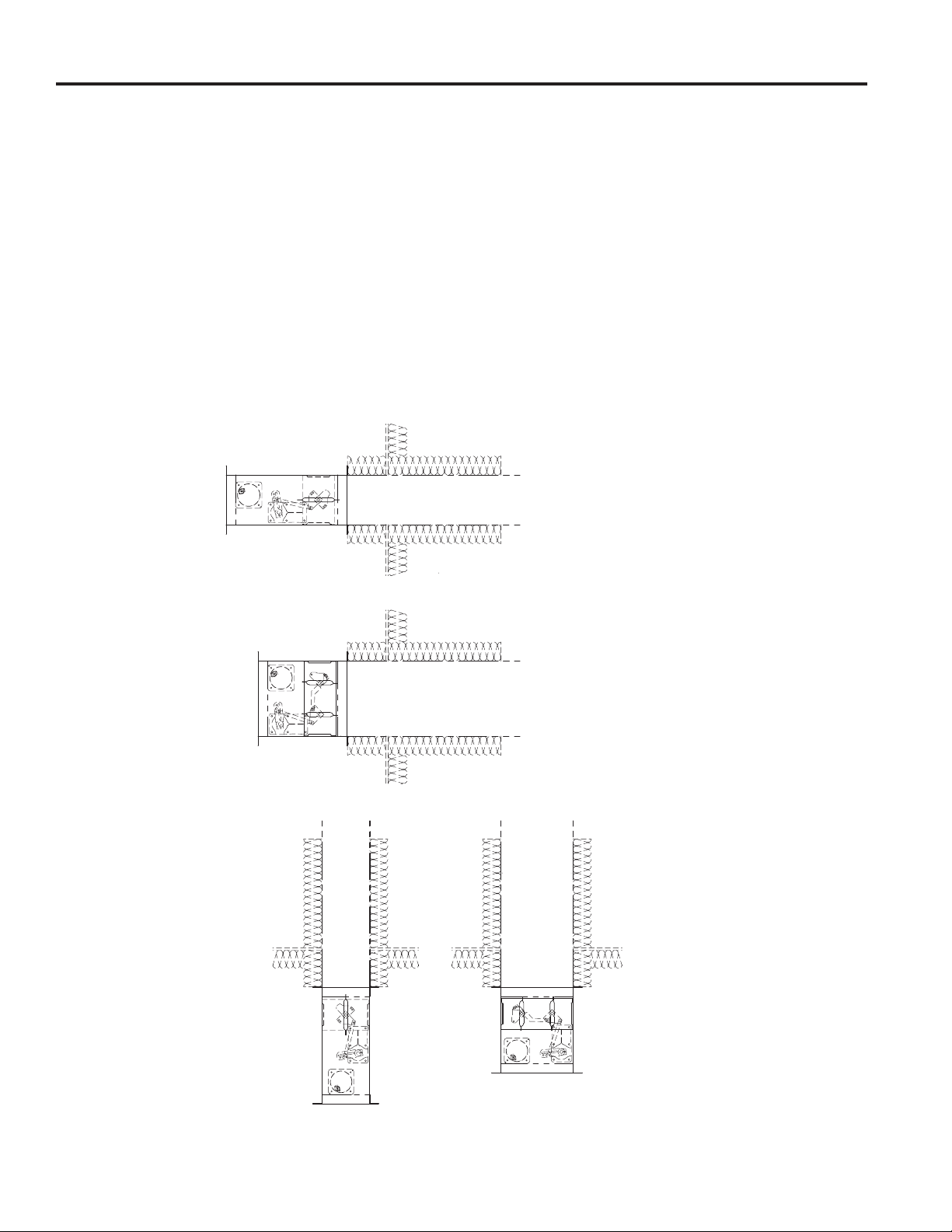

IF HEIGHT <=11.00 in. (279mm)

IF HEIGHT >11.00 (279mm)

6 in. (152mm)

18 in. (457mm)

6 in. (152mm)

18 in. (457mm)

6 in. (152mm)

6 in. (152mm)

18 in. (457mm)

18 in. (457mm)

Installation Instructions

Greenheck’s IMO dampers were tested per the International Maritime Organization’s Fire Test Procedure (FTP) code in a

Class A bulkhead and in a Class A deck for 60 minutes. The FTP code requires that the ductwork (coaming) be insulated

and that the damper be bolted or welded to the duct.

1. Insulating the Duct

The ductwork must be insulated a minimum of 6 in. (152mm) on the damper side and 18 in. (457mm) on the non-damper

side (see figures 1-4). Any US Coast Guard type approved insulation with an A60 rating can be used. The insulation is to be

installed on the duct with 0.106 in. (2.7mm) steel pins and 1.12 in. x 1.24 in. x 0.4 in. (28mm x 31mm x 10mm) steel clips.

2. Attaching Damper to Duct

The damper can be installed to the duct using either bolts or welding. If bolts are used , they are to be a minimum of 0.375

in. (9.5mm) diameter and 1 in. (25mm) long. The fasteners should be spaced 6 in. (152mm) OC and a maximum of 2 in.

(51mm) from the corners.

Horizontal Airflow- Vertical Damper mount

Fig. 1

Fig. 2

Vertical Airflow- Horizontal Damper mount

Fig. 3

Fig. 4

L1

DAMPER

INDICATOR

LIGHTS

L2

CLOSED POSITION OF THE DAMPER.

A BLUE MARKER INDICATE THE

THE SWITCH WIRES WRAPPED WITH

NOTE:

YELLOW

ELECTRICAL CAPACITY = 10AMP @ 120 / 240 VAC

YELLOW

YELLOW

YELLOW

NO

NO

S2

S1

BY OTHERS

L1

M

L2

ELECTRIC DAMPER

ACTUATOR OR PNEUMATIC

SOLENOID VALVE

PRIMARY TEMP

SENSOR

ELECTRICAL CAPACITY = 10 AMP @ 120 / 240 VAC

BLACK

ORANGE

P

NC

BLACK

WHITE/RED

Size Limitations

Damper model Maximum Single Maximum Overall size for

Section size Multi-section dampers

IMO-310 32 in. x 32 in. 64 in. x 32 in.

(813mm x 813mm) (1626mm x 813mm)

SSIMO-310 32 in. x 32 in. 64 in. x 32 in.

(813mm x 813mm) (1626mm x 813mm)

IMO-311 32 in. x 32 in. 64 in. x 32 in.

(813mm x 813mm) (1626mm x 813mm)

SSIMO-311 32 in. x 32 in. 64 in. x 32 in.

(813mm x 813mm) (1626mm x 813mm)

Manually operated dampers (IMO-310 & SSIMO-310)

Manually operated dampers utilize a spring and fusible link assembly to close the damper during elevated temperature

conditions. No electrical power is required for these models.

Motor operated dampers (IMO-311 & SSIMO-311)

Motor operated dampers are supplied with an electric thermal response device which cuts power to the spring return

actuator upon sensing an elevated temperatures. See below for electrical connections.

Connection and Operation of Temperature

Response Devices (RRL standard, OCI option,

RRL Wiring

and PRV option)

RRL - Dampers will be supplied with a thermostat-type

temperature response device, as a standard. The device is a RRL

(resettable link device), which only incorporates one thermostat

and therefore the damper remains closed as soon as its sensor

temperature is reached. The RRL does not contain blade

indication switches. Refer to Figure 5 for wiring of the RRL

thermostat.

If RRL is ordered with a pneumatic actuator, an EP switch is

required with an appropriate electric power circuit to allow the

electric thermostat to control the pneumatic actuator.

OCI - The OCI (open or closed indicator) option contains a single

pole, double throw switch used to indicate the damper blade

position. The switch provides a positive open or closed signal

when used in conjunction with remote indicator lights. Refer to

Fig. 7 for wiring of the OCI option.

PRV - The PRV (pneumatic relief valve) option is heat responsive

device used with pneumatic actuators. This can be used in place

of EP switch where a RRL is used. The PRV activates when

temperature in excess of the temperature of the fusible link are

detected. When the fusible link melts, air from the actuator is

exhausted to close the dampers. Pneumatic actuators are to be

piped per local code.

Fig. 5

OCI Wiring

Fig. 6

RATINGS

Integral Switch Type: Single Pole, double throw

Electrical Capacity: 10 Amps, 1/3 hp, 120 or 240 Vac

1/2 Amp, 125 Vdc; 1/4 Amp 250 Vdc

5 Amps, 120 Vac “L” (lamp load)

1.0 Amps, 24 Vac

1.5 Amps, 24 Vdc

Temperature Limit: 165° F (standard primary sensor)

212° F ( optional primary sensor )

Damper Maintenance

Dampers do not typically require maintenance as long as they are kept dry and clean. If cleaning is necessary,

use mild detergents or solvents. If lubrication is desired for components such as axle bearings, jackshaft

bearings and jamb seals, do not use oil-based lubricants or any other lubricants that attract contaminants such

as dust.

Dampers and their actuator(s) must be maintained, cycled, and tested in accordance with:

• The latest editions of NFPA 80, 90A, 92A, UL864, and local codes.

• Actuator manufacturer recommendations.

Damper Trouble Shooting

The following is a possible cause and correction list for common concerns with the dampers.

Symptom Possible Cause Corrective Action

Frame is ‘racked’ causing blades to Adjust frame such that it is square

bind on jamb seals and plumb

Actuator linkage loose Close damper, disconnect power, adjust

and tighten linkage

Damper does not

Defective motor Replace

fully open and/or

fully close

Screws in damper linkage Locate screws and remove

Actuator linkage hitting wall or floor Damper installed too far into wall. Move

out to line designated on damper label.

Contaminants on damper Clean with a non-oil-based solvent

(see Damper Maintenance)

RRL or TOR sensor

tripped

Damper does not

operate

Heat

No power supplied to the actuator

Push reset button located on backside

of RRL or TOR.

Copyright © 2007 Greenheck Fan Corporation

IMO-XXX series IOM Rev. 3 July 2007

Loading...

Loading...