Page 1

Energy Recovery Ventilator

Model ERV

• Commercial • Institutional

• 400 to 12,000 cfm

• 1.5 in. wg external

static pressure

June

2010

Page 2

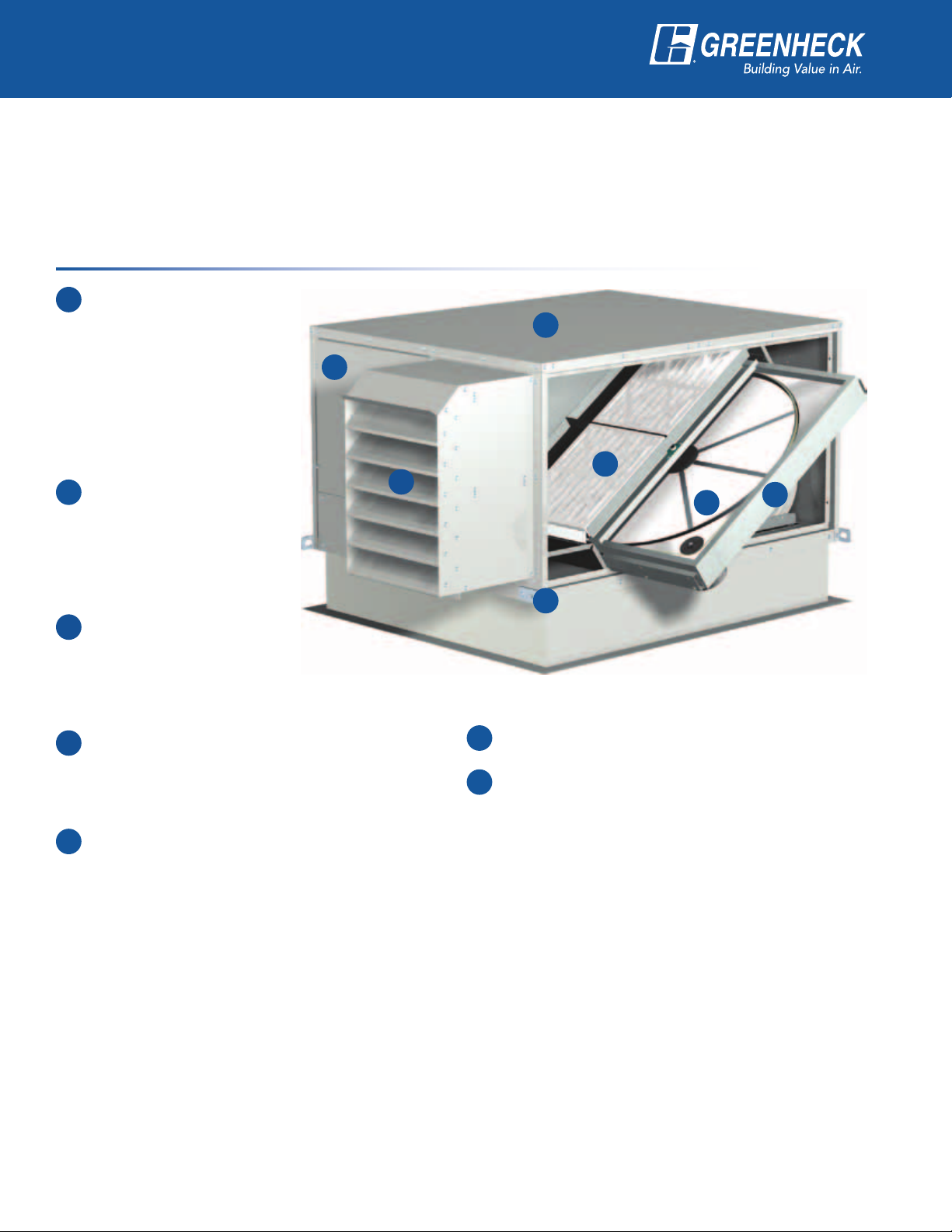

Model ERV

Greenheck’s model ERV provides fresh outdoor air to your building and is designed for operation in all climates.

This unit incorporates innovative design features with options in energy wheel performance to provide a quality

constructed unit with performance flexibility. The flexibility and reliability of these units means the ERV will fit

seamlessly into your building to improve your indoor air quality while saving energy and costs.

Design Features:

Louvered intake

1

weatherhood lowers

supply air intake

velocities to prevent

rain and snow from

being pulled in to the

unit. Each hood has

washable aluminum

mesh prefilters blocking

debris or leaves.

2-inch outdoor and

2

return air filters with a

MERV 8 (30% efficiency)

rating and are set into

filter racks that permit

easy change out and

rigid support.

Pitched roof and

3

interlocked standing

seams eliminates

standing water

and provides

rigidconstruction.

18 gauge outer wall construction is available in

4

many alternate coatings. Optional double-wall

construction protects insulation from moisture

and prevents insulation fibers from entering the

airstream. Insulation is 3 lb/ft³ density.

Multiple energy wheel options allow selection of a

5

unit by what is critical in the design or application:

• Effectiveness

• Recovery Efficiency Ratio (RER)

• Low blower horsepower

4

1

6

7

3

2

5

6

Integral lifting lugs are included for easy

maneuvering and installation of the unit.

Slide out energy wheel design allows for easy

access to the energy wheel.

7

Additional Features

• Quiet running, forward-curved blowers

• Adjustable motor pulleys for final

systembalancing

• Factory provided motor starters and

disconnectswitch in a sealed control center

• Neoprene isolation on blower assembly to

minimize sound and vibration transmission

• Bolt-on door design allows for fit in tighter

spaces. Optional hinged access is available for

roof mount applications.

2

Page 3

-10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120

50

55

0

5

10

15

20

25

30

35

40

45

ENTHALPY - BTU PER POUND OF DRY AIR

0

10

20

25

30

35

40

45

50

55

60

65

70

75

80

0.350.300.250.20

SENSIBLE HEAT RATIO = Qs / Qt

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

15%

25%

2%

4%

6%

8% RELATIVE HUMIDITY

10% RELATIVE HUMIDITY

20%

30%

40%

50%

60%

70%

80%

90%

-5

0

0

5

5

10

10

15

15

20

20

25

25

30

30

35

35

40

40

45

45

50

50

55

55

60

60

65

65

70

70

75

75

80 WET BULB TEMPERATURE - °F

80

85

12.0

13.0

14.0 VOLUME- CU.FT. PER LB. DRY AIR

15.0

HUMIDITY RATIO - GRAINS OF MOISTURE PER POUND OF DRY AIR

Wet Bulb, Saturation Temp - °F

-10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120

DRY BULB TEMPERATURE - °F

0

5

10

15

20

25

30

35

40

45

50

50

55

55

ENTHALPY - BTU PER POUND OF DRY AIR

0

5

10

15

20

25

30

35

40

45

ENTHALPY - BTU PER POUND OF DRY AIR

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

1.10

1.15

VAPOR PRESSURE - INCHES OF MERCURY

0

10

20

25

30

35

40

45

50

55

60

65

70

75

80

DEW POINT TEMPERATURE - °F

Chart by: HANDS DOWN SOFTWARE, www.handsdownsoftware.com

1.00

0.95

0.90

0.85

0.80

0.75

0.70

0.65

0.60

0.55

0.50

0.45

0.400.350.300.250.20

SENSIBLE HEAT RATIO = Qs / Qt

SENSIBLE HEAT RATIO = Qs / Qt

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

15%

25%

2%

4%

6%

8% RELATIVE HUMIDITY

10% RELATIVE HUMIDITY

20%

30%

40%

50%

60%

70%

80%

90%

-5

0

0

5

5

10

10

15

20

25

30

35

40

45

50

50

55

55

60

60

65

65

70

70

75

75

80 WET BULB TEMPERATURE - °F

80

85

12.0

13.0

14.0 VOLUME- CU.FT. PER LB. DRY AIR

15.0

HUMIDITY RATIO - GRAINS OF MOISTURE PER POUND OF DRY AIR

Wet Bulb, Saturation Temp - °F

Chart by: HANDS DOWN SOFTWARE, www.handsdownsoftware.com

15

20

25

30

35

40

45

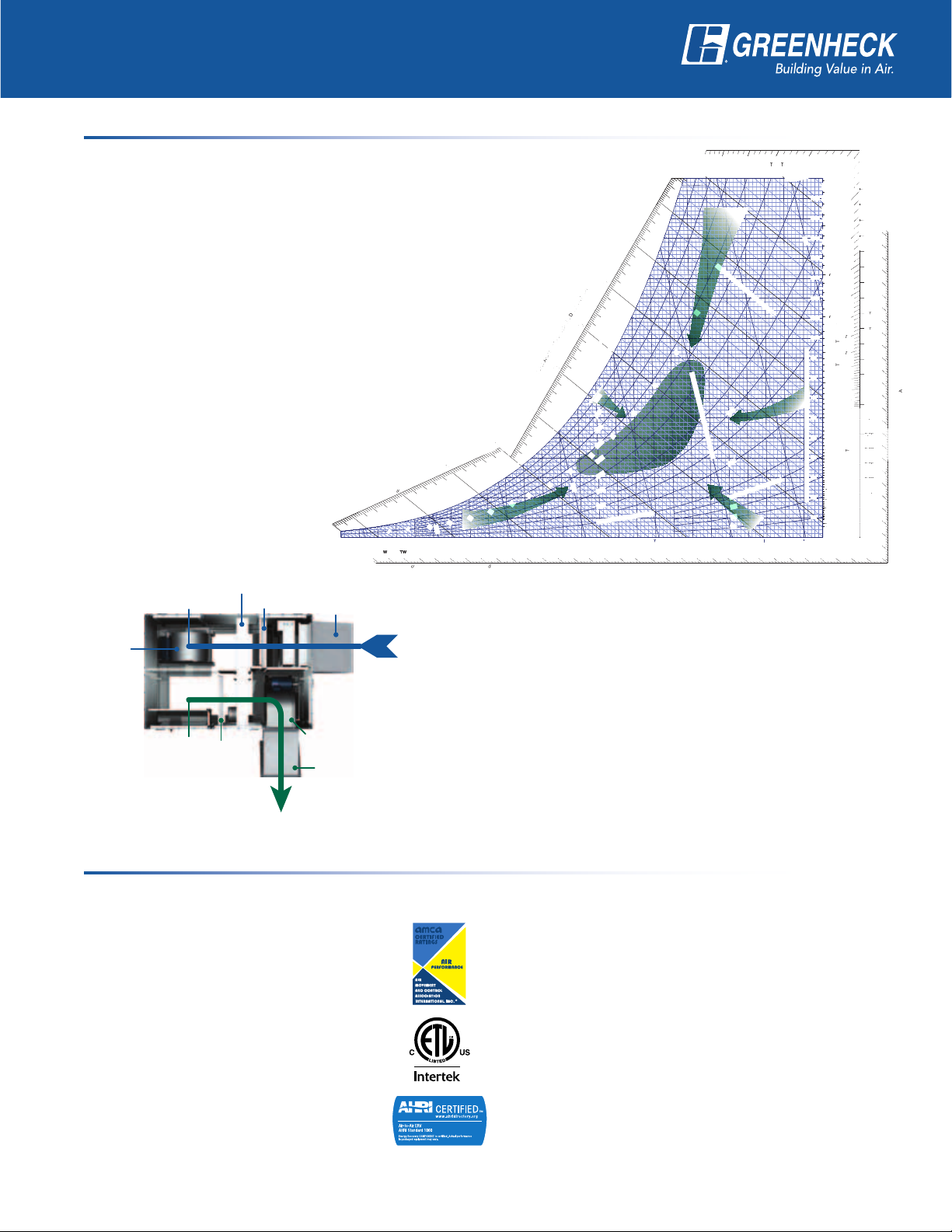

Model ERV

How does an energy recovery wheel work?

The basic objectives for providing acceptable indoor air quality (IAQ) are to

control indoor contaminates levels while maintaining desired indoor air

temperature and humidity. Compliance with the prescribed ventilation rates

in ASHRAE Standard 62 appear to satisfy the contaminant issue. However,

simply increasing outdoor air (OA) requirements with “traditional” HVAC

systems may not address the humidity issue properly and often leads to

significant energy cost increases.

The best solution for most commercial and institutional facilities

will include an enthalpy wheel product. The enthalpy wheel

transfers temperature and moisture properties from one

airstream to another. The result is capturing the cooling and

heating energy before it leaves the HVACsystem.

Moving through the unit, the return and supply airstreams

pass on opposite sides of a divider panel. The

enthalpy wheel rotates between the airstreams

transferring up to 75% of the energy

present in the exhaust airstream to

the supply.

Enthalpy Wheel

Supply Air to Building

Supply

Blower

Filters

Outdoor Air Weatherhood

Outdoor Air

Utilizing an enthalpy wheel to precondition the outdoor air,

narrows the operational range of outdoor air conditions

which the building’s HVAC equipment is designed to

temper. It is this reduction in the outdoor air range that

allows for size reduction in heating and cooling equipment

Return Air From Building

Filters

Exhaust Blower

Exhaust Weatherhood

Exhaust Air

Certifications

ERV’s construction is matched with extensive in-house testing and third-party verification of

performanceandsafety.

Licensed to bear the AMCA seal for

AirPerformance

Unit is ETL Listed — all internal electrical

components are factory wired to a single-point

power connection

ARI Standard 1060 certified energy wheel

performance assures the ERV model will function

as required in demandingenvironments

and reduced energy costs.

Greenheck certifies that the ERV models shown herein are licensed

to bear the AMCA seal. The ratings shown are based on tests and

procedures performed in accordance with AMCA Publication 211 and

comply with the requirements of the AMCA Certified RatingsProgram.

Every unit is tested at the factory before it is shipped to the job site.

Energy recovery wheels are certified by the ARI Air-to-Air Energy

Recovery Ventilation Equipment Certification Program in accordance

with ARI Standard 1060. Actual performance in packaged equipment

may vary. Certified ratings are available in the Certified Product

Directory at http://www.ahridirectory.org/ahridirectory/pages/home.

aspx

3

Page 4

What is the Benefit with

Greenheck Energy Recovery?

For the Building Owner

• Improved Indoor Air Quality (IAQ)

Introducing fresh, outdoor air to a building is a key component to sustaining excellent indoor air quality.

Outdoor air can be very expensive to heat and cool, but the ERV unit can provide an economical approach to

delivering outdoor air into a building.

• Energy Savings = Quick Payback

The energy recovery unit provides energy savings throughout the year. In the summer, the energy recovery

unit removes heat and moisture out of the outdoor air, but in the winter, heat and moisture are added back into

the fresh airstream. When you combine the energy savings from summer and winter operation, they lead to a

very fast payback period. In most parts of the United States, the payback is less than 2 years!

Equipment Reduction Using Energy Recovery on 3000 cfm Outdoor Air

Cooling

Gas Price* Electric Cost**

Boston, MA 1.68 0.1495 8.72 226 161 4544 0.78

Minneapolis, MN 1.14 0.0712 9.55 161 217 3261 0.88

St. Louis, MO 1.34 0.0558 12.1 356 173 3088 0.35

Raleigh, NC 1.48 0.073 11.3 424 138 2790 0.57

Houston, TX 1.10 0.1011 13.0 1701 111 1089 0.22

Tampa, FL 1.59 0.0974 13.1 1779 89 988 0.21

Portland, OR 1.21 0.071 4.17 2 123 2930 2.34

Phoenix AZ 1.13 0.0766 9.40 271 161 1478 1.95

* Average gas price (dollars per therm) per region in the first six months of 2007 (source: Energy Information Administration)

** Average electricity cost (dollars per kWh) in March of 2007 (source: Energy Information Administration)

*** Assumptions: $3/cfm energy recovery cost; $650/ton avoided cooling equipment cost; 75.6% effective energy wheel; 12 hrs/day 5 days/week operation

Equipment

Reduction

(tons)

Annual

Summer

Cooling

Savings

Heating

Equipment

Reduction

(MBH)

Annual Winter

Heating

Savings

Approximate

Payback

(Years)***

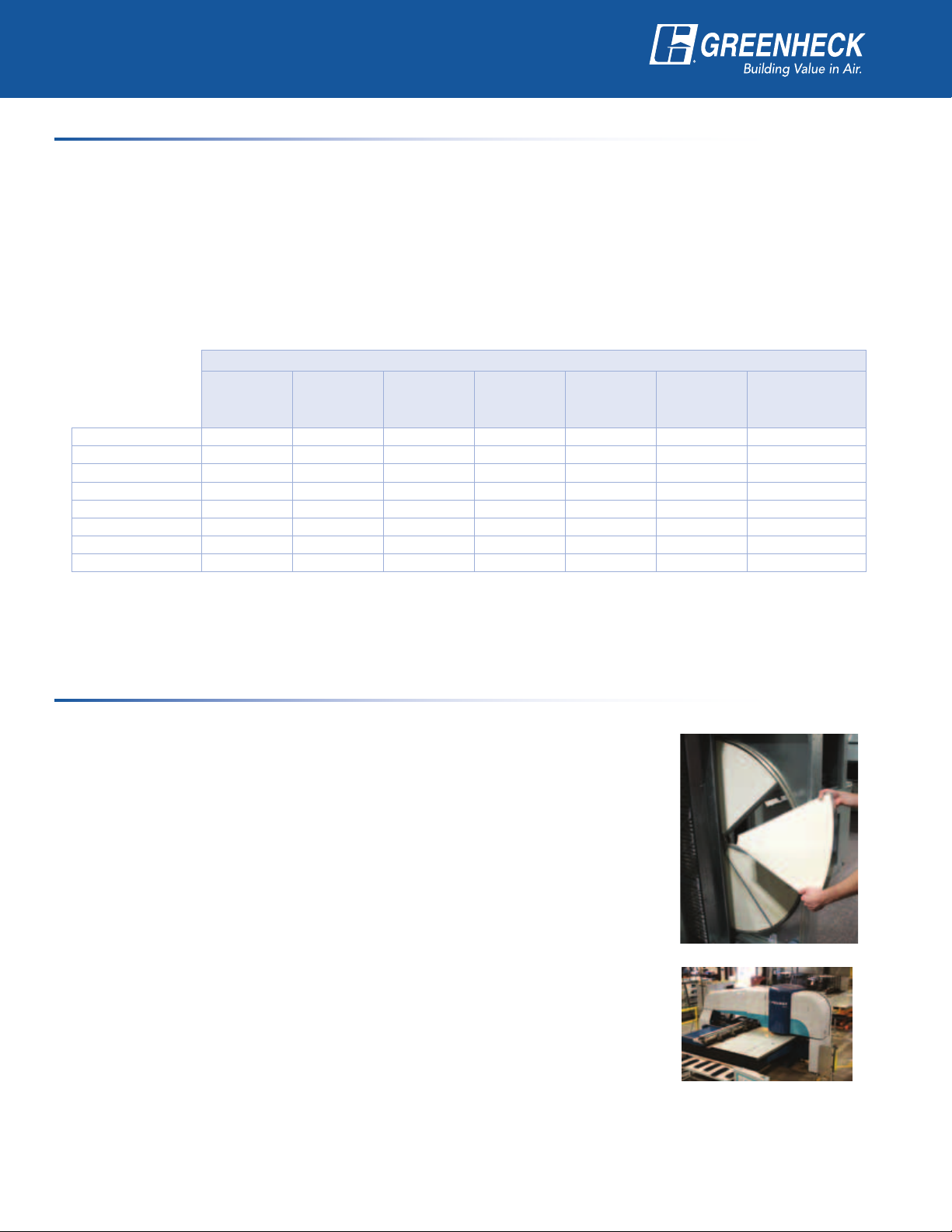

For the Maintenance Personnel

• Low Maintenance Equipment

Energy Wheel: The most important component in the ERV is the energy wheel.

This device should be inspected and cleaned as necessary, which will vary by

application and environment. Any cleaning that is required is simplified by the

easy accessible wheel with removable segments. Cleaning requires no special

equipment (light detergent and water) and can be performed in a location that is

convenient to you.

Fans: The blowers that are used in the ERV are centrifugal, forward-curved- type

fans. These fans come with easily adjustable pulleys, belt tension bolts and

permanently sealed bearings.

Filters: The 2-inch, 30% efficient MERV 8 filters that are included with the unit are

designed for easy access and removal.

• Quality Construction

Greenheck has focused on the manufacturing and unit designs to create well-

constructed equipment. Investments in automated manufacturing processes

provide accurate and repeatable results, giving excellent part fit and unit strength.

Incorporation of innovative designs add to the quality, while keeping maintenance

work simple to perform.

• Long-Lasting Equipment

Because of our high-quality construction, the equipment that goes to the field is made to last. As reassurance

to the customer, each ERV unit carries a 1-year warranty from the ship date and the wheel components

(segments, cassette, belt, and pulleys) carry a 5-year warranty.

4

Page 5

What is the Benefit with

Greenheck Energy Recovery?

For the Design Engineer

• Adhering to ASHRAE Guidelines

ASHRAE Standard 90.1 provides design guidelines regarding when it is most beneficial to use energy

recovery. Depending upon your geographic location and the percentage of outdoor air in the application,

ASHRAE recommends when to use energy recovery. An important part of this guideline is that when energy

recovery is recommended, the device should be a minimum of 50% total (sensible and latent) effectiveness

according to ARI 1060 testing procedure.

ASHRAE Standard 189.1 provides high performing building design guidelines. This requires even higher energy

recovery device performance than Standard 90.1. When energy recovery is recommended, the device shall be

a minimum 60% total (sensible and latent) effectiveness according to ARI 1060 testing procedure.

• LEED Certification Credits

For Green Building designs, the ERV offers an excellent way to acquire credits in both

Energy and Atmosphere (EA) and Indoor Environmental Quality (EQ) categories towards a

LEED certification.

• CAPS Program

CAPS is Greenheck’s comprehensive product selection program. The CAPS program was

developed with ease of use and fast selections in mind. There is also useful information

available for making selections and educating people who are new to energy recovery

technology. CAPS also provides submittals which includes unit overview, electrical

information, fan charts, arrangements, engineering drawings, payback information, and

psychrometric processes.

• CSI Specifications

After a unit has been selected in CAPS, an accurate unit specification is available for use in the job

specification. These specifications have been recently updated to the CSI format.

• Industry Certification

To ensure performance on the job site, Greenheck emphasizes the need for the 3 major industry certifications

for energy recovery units: AMCA Licensed for Air Performance, ETL Listed for safety, and ARI Certification on

the energy recovery wheel.

Prepared to Support

Green Building Efforts

For the Contractor

• Easy Installation

- Lifting Lugs

- Single-Point Power

- Bolt-doors for limited clearance applications

These are just a few of the built-in features to make the installation process quick and easy. Our

comprehensive Installation, Operation, and Maintenance Manuals are also available online, so the information

you need is quick and easy to obtain.

• Product Approval

Form, fit and function, the ERV was designed to operate in commercial and institutional applications. With over

a decade of installations specific to the energy recovery market, Greenheck’s energy recovery product line is

well known and accepted throughout the industry.

• 1 — 5-Year Warranty

Our 1-year unit warranty and 5-year energy recovery wheel warranty lets you to rest easy knowing that we

stand behind our product.

Lifting Lugs

5

Page 6

Accessories

Low-Leakage Dampers — Internally mounted for

both supply and exhaust

Where code requires low-leakage

dampers they can be provided to keep

the cold weather out in the winter,

or hot and humid weather out during

the summer. Since the dampers are

wired to a single-point power source,

a simple run command sent to the

unit powers the dampers open. When your unit is off

during unoccupied hours, the dampers close to keep

the outdoor air out.

Filters

Standard size 2-inch pleated, medium efficiency filters

and filter racks are available for supply and/or exhaust

airstreams.

Model Filter Size Quantity

ERV-251 16 x 25 1

ERV-361 16 x 20 2

ERV-521 16 x 25 3

ERV-581 16 x 20 6

ERV-522 16 x 25 7

All dimensions shown in inches.

Roof Curbs

For a cohesive fit between

the ERV and your building,

Greenheck offers a preengineered curb design. They

are available with duct adaptors

to simplify field duct installation

and get the unit up and running morequickly.

Double Wall Construction

The supply and exhaust side are internally lined with

20 gauge galvanized steel.

Weatherhoods

A louvered intake hood with 2-inch aluminum mesh

filters and exhaust hood with an integral backdraft

damper are available.

Hinged Access Doors

Panel side doors are a standard feature on all

units. Hinged access doors are available on models

ERV-361, -521, -581, -522, and -582. Access doors

are removable hinge type with lift and turn latches for

access to internal components.

Air Filtration — High-Efficiency Filters

Unit is standard with 2-inch, MERV 8,

30% efficient filters. Optional MERV 13,

85% efficient filters are available to help

meet additional LEED requirements or

simply improve indoor air quality.

Painted Exterior

For added aesthetics and a

long-lasting finish, Greenheck

offers many different paint

DESERT

SAND

PERMATECTOR™

options. Pre painted coatings

in either Gray or Desert Sand

offer economical options in customizing your unit. If

a more specific color is desired, we also offer a wide

variety of colors to meet your specific needs.

Remote Panel

With the optional remote panel you have control and

the information you want. Monitoring lights, on/off

time-clock control, or on/off/auto switch are a few of

the available options. So whether you want to control

the unit operation via a 7-day time clock or simply

want to monitor unit performance, the remote panel is

the option that you’ll need.

6

Page 7

Accessories

Dirty Filter Sensors

Filters require scheduled maintenance to improve

air quality and system efficiency. A dirty filter sensor

allows you to minimize maintenance frequency to only

when it is needed. The dirty filter kit senses when

the filters are dirty and sends a signal to our built-in

control center. Greenheck offers an optional remote

control panel and a “clogged filter” light to tie the

signal into.

Rotation Sensor

Adding a wheel rotation sensor to the unit assures

you that the energy wheel is operating properly. The

sensor sends a signal to the control center of the

unit in the rare event that the wheel stops rotating.

Greenheck offers an optional remote control panel and

a “wheel rotation” light to tie the signal into.

Factory Mounted Sensors

Amp Draw, Pressure, Temperature: Greenheck offers

factory mounted sensors that are wired back to the

control center, so you can get the information you

need to know, exactly where you need to measure

it. These sensors can be used to simply monitor unit

operation or to actively control the unit with controls

by others.

Amp Monitor

Blower amp draw can be monitored

through the use of an amperage

sensor. These sensors allow for

either an analog or digital output

based on your system needs.

CO2 Sensor

A good indicator for building health is

carbon dioxide (CO2). Greenheck offers a

CO2 sensor, that can be used to engage

the unit based on CO2 levels, or it can

increase or decrease airflows through

the use of a variable frequency drive

(VFD) on the blowers. The CO

can be unit mounted or space mounted

depending on your application.

Service Outlet

While performing minimal maintenance on your ERV, a

service outlet can provide power when and where it’s

needed. Shipped loose, the outlet can be mounted in

the correct location for your building.

Vapor-Tight Lights

Access doors provide natural lighting during the day,

but there may be times when more light is needed

to see properly inside the unit. To increase bulb life

and to also protect the bulb, Greenheck offers a

vapor-tight light.

Blower VFD’s

Variable frequency drives are a great

tool to control airflow to the space

or to maintain duct pressures. With

this optional feature, two VFD’s are

utilized, one per fan for independent

andflexiblecontrol.

sensor

2

Wheel Pressure Sensors

In each airstream, a pressure

sensor is available to monitor

wheel operation. Wheel pressure

can be used to indicate a buildup

of frost during the cold winter

months or can be used as a CFM

gauge as the energy wheel is a

laminar flow device (i.e. a specific

pressure equals a specificCFM).

Temperature Sensors

Wheel performance can be

determined with factory mounted

temperature sensors. Every

compartment can be monitored to

know how your unit is operating.

7

Page 8

Accessories

Economizer Control (Free Cooling)

Take advantage of cool outdoor air to handle space loads. A call for cool air is sent to the unit’s control center

which triggers one of a few different options to bring in fresh cool air:

Energy Wheel On/Off

The wheel cycles off when it’s in the free cooling range (temperature or enthalpy), and

cycles on when outdoor air is too warm or too cold. This option is recommended when the

air is being supplied to an air handling unit or duct heater, and not directly to the space.

Energy Wheel Modulation

The wheel speed modulates to maintain a 55°F discharge temperature. Above 55°F,

the wheel is off up to a high-limit temperature setting (typically 70°F). This option is

recommended when the air is supplied directly to the space from the ERV or when more

precise temperature control is needed.

Frost Protection

Cold climates, in combination with higher indoor humidity levels, may cause frost to form on the energy wheel

during normal operation. To protect against frost, we measure the outdoor temperature and the energy wheel

pressure drop. When it’s cold enough and the wheel pressure is increasing, the wheel is frosting. Only then will

the frost methods described below engage. See the “Frost Control Strategy Recommendations” chart on this

page for which of the three Greenheck frost methods we recommend for your building.

Timed Exhaust Frost Control

The supply blower cycles on and off based on a

factory provided timer. With the supply blower

off, the warm exhaust air melts the frost. Once the

wheel pressure decreases, the supply blower turns

Winter Outside Air

backon.

Modulating Wheel Frost Control

A factory installed variable frequency drive (VFD)

≥ 10°F (-12.2°C) ≤ 50% RH None

≥ -5°F (-20.6°C) <

slows the wheel down making it less effective.

In other words, the slow rotating wheel spends

enough time in the warm exhaust airstream to melt

≥ 10°F (-12.2°C) ≤ 50% RH

≥ -5°F (-20.6°C) <

the frost. Once the wheel pressure decreases,

it returns to full speed. Both blowers operate

continuously during this frost mode. Modulating

wheel frost control is available on all sizes except

the ERV-251.

Preheat Frost Control

An electric preheater is built into the ERV outdoor air intake. When frost occurs, the heater engages, and

increases the outdoor air temperature above the frost threshold to melt the wheel. Once the pressure

decreases, the heater shuts off.

Frost Control Strategy Recommendations

Winter Indoor Air

Design

10°F (-12.2°C)

10°F (-12.2°C)

≥ -5°F (-20.6°C) Any RH

Design

≤ 35% RH Timed Exhaust

≤ 35% RH

Recommended

Frost Control

Strategy

Electric Preheat

The map at left indicates the frost control

options, if any, that are appropriate based

on climactic conditions during typical

16hour per day operation.

Preheat Frost Control Recommended*

Timed Exhaust Frost Control Recommended*

No Frost Control Needed

*Modulating Wheel Frost Control can also be used in these areas.

8

Page 9

Arrangements

Top View

Supply Air

Exhaust Air

Interior

This compact design is ideal for the space limitations

that routinely complicate interior installations.

Arrangement A

Specify Arrangement A for interior mounting. All ERV

sizes are available in this arrangement. Fig.1 is typical

for ERV-251, -361, -521, and -581.

Exterior

Where roof mount or pad mount installations are

preferred, Greenheck offers three arrangements to

provide the flexibility to simplify system design and

installation. Louvered intake hood and an exhaust hood

are standard on Arrangements B, C and D. The housing

and hood design minimize re-entrainment of exhaust

air.

Top View

Supply Air

Exhaust Air

Fig. 1

Arrangement A - Interior Mounted

Top View

Arrangement B

Ideal for roof mount installations where both exhaust and

supply ducts penetrate the roof deck and attach to the

bottom of the energy recovery ventilator. Fig. 2 is typical

for ERV-251, -361, -521, and -581.

Arrangement C

Ideal for roof mount installations where the supply

airstream is to be routed directly into a rooftop HVAC

unit. Exhaust air enters the ERV from below.

Arrangement D

Suited for pad mounting, where both the exhaust and

supply ducts connect to the end of the ERV.

Supply

Air

Fig. 2

Exhaust

Hood

Exhaust Air

Intake Hood

Arrangement B - Roof Mounted

9

Page 10

Dimensions

Arrangement A Arrangement B

ERV-251, ERV-361, ERV-521, ERV-581

Model

ERV-251 46 34 27 12 8 10 16 6

ERV-361 62 51 34 18 15 18 18 8

ERV-521 67 67 44 16 15 24 24 10

ERV-581 75 70 67 16 22 22 27 16 18

Exterior Dimensions Duct Dimensions

A B C D E F G K L Q P

3

⁄4 7 10 16 340

3

⁄8 111⁄2 19 18 860

3

⁄4 131⁄2 26 26 1290

3

⁄4 28 48 1470

All dimensions shown are in inches. Weight assumes outdoor unit with filters, weatherhoods, and supply damper.

Outdoor Air Discharge

Exhaust Air Inlet

F x G

Arrangement A

L x K

Outdoor Air Inlet

Q x P

Outdoor Air Discharge

L x K

C

C

Arrangement B

B

A

E

Exhaust Air Inlet

F x G

Exhaust Hood

Intake Hood

Exhaust Air Discharge

L x K

A

B

Weight

(lbs.)

D

Arrangement C Arrangement D

Outdoor Air Discharge

L x K

C

Exhaust Air Inlet

F x G

B

E

Exhaust Hood

A

D

Intake Hood

Service Clearance

Installation must allow clearance for access to the energy

recovery wheel on the supply side. Minimum clearances

are shown in the table at right. Page 4 shows the side

panel that enables wheel access.

Outdoor Air Discharge

L x K

B

C

Exhaust Air Inlet

F x G

Exhaust Hood

Model

Supply Side

ERV-251

ERV-361

ERV-521

ERV-581

All dimensions shown are in inches.

E

32

44

60

65

A

D

Intake Hood

Exhaust Side

30

30

40

40

10

Page 11

Dimensions

Arrangement C

Arrangement D

Arrangement A

Arrangement B

ERV-522 and ERV-582

Model

Exterior Dimensions Duct Dimensions

A B C D E F G H J K L Q P

ERV-522S 124 84 64 16 19 48 25 26 36 16 18

5

⁄8 60 25 3230

Weight

(lbs.)

ERV-522H 124 84 64 16 19 48 25 26 36 19 22 60 25 3230

1

ERV-582H 146 97 77 17

⁄2 263⁄4

All dimensions shown are in inches. Weight assumes outdoor unit with filters, weatherhoods, and supply damper.

Arrangement A

Outdoor Air Discharge

Outdoor Air Inlet

Q x P

C

Exhaust Air Discharge

L x K

B

A

60 28 31 38 23 25 70 30 3700

Arrangement B

L x K

Exhaust Air Inlet

F x G

C

Intake Hood

Exhaust Air Inlet

H x J

B

E

D

A

Exhaust Hood

Outdoor Air Discharge

L x K

Arrangement C Arrangement D

Outdoor Air Discharge

E

A

Exhaust Hood

L x K

C

Intake Hood

Exhaust Air Inlet

H x J

B

D

Service Clearance

The installation must allow clearance for access to

the energy recovery wheels and servicing. Minimum

clearances are shown in the table at right. Model ERV522 and ERV-582 energy wheels are mounted in an

upright position, side by side. For servicing, the energy

wheels slide out of the ventilator at opposite corners.

11

C

Intake Hood

Model

B

D

Supply Side

ERV-522

ERV-582

All dimensions shown are in inches.

38

42

Outdoor Air Discharge

L x K

E

A

Exhaust Hood

Exhaust Side

38

42

Exhaust Air Inlet

F x G

Page 12

NOTES:

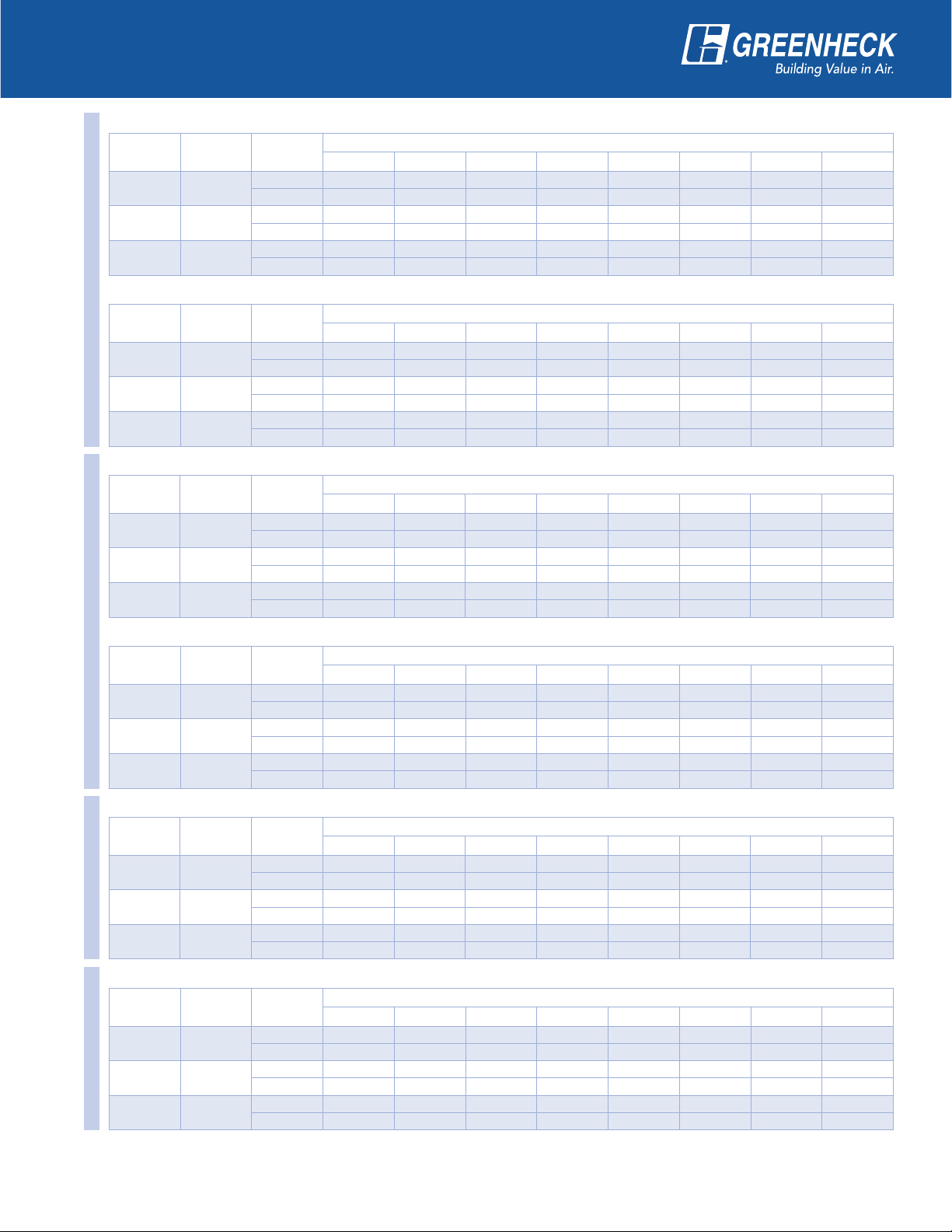

1. Performance tables show EXTERNAL

static pressure capabilities.

2. Bhp, watt and amp values shown are for

one blower motor only.

Performance

Supply and Exhaust - Belt and Direct Drive

The airflow performance data shown

applies to arrangement A and is licensed to

bear the AMCA Seal for Air Performance.

Performance data for other arrangements

may differslightly.

For specific performance for all arrangements,

use Greenheck’s Computer Aided Product

Selection (CAPS) program.

All models are available in A, B, C, and

Darrangements.

ERV-251S (Standard Airflow)

Nominal

RPM

950 3.0/1.5 300 563 536 498 450 378

1150 5.3/2.7 530 700 680 658 634 597 513

1350 8.6/4.3 855 834 818 801 783 762 711 642

ERV-251H (High Airflow)

Nominal

RPM

1150 5.0/2.5 500 802 777 742 706 667

1340 8.1/4.1 810 958 937 915 887 857 792

Model ERV-251 / Direct Drive

1520 11.5/5.8 1150 1089 1070 1051 1032 1008 954 895

Max Amps

115/230

Max Amps

115/230

Max. Watts

(input)

CFM

Max. Watts

(input)

CFM

Greenheck Fan Corporation certifies that the

ERV models shown herein are licensed to bear

the Air Performance AMCA seal. The ratings

shown are based on tests and procedures

performed in accordance with AMCA Publication

211 and comply with the requirements of the

AMCA Certified Ratings Program.

EXTERNAL STATIC PRESSURE (in. wg)

0.25 0.375 0.50 0.625 0.75 1.00 1.25

EXTERNAL STATIC PRESSURE (in. wg)

0.25 0.375 0.50 0.625 0.75 1.00 1.25

ERV-361S (Standard Airflow)

CFM OV

1000 1495

1200 1794

1400 2093

1600 2392

ERV-361H (High Airflow)

CFM OV

1600 2392

Model ERV-361 / Belt Drive

1800 2691

2000 2990

2200 3289

Gross supply air performance ratings (airflow, pressure, and power) are at port 2 with port 1, port 3 and port 4 at 0.0 in. wg. Gross exhaust air

performance ratings (airflow, pressure, and power) are to port 3 with port 1, port 2 and port 4 at 0.0 in. wg. Power rating (Bhp) does not include drive

losses. Performance ratings do not include the effects of appurtenances in the airstream.

FRPM 777 863 941 1015 1147 1277 1397 1515

BHP 0.21 0.25 0.29 0.33 0.41 0.49 0.58 0.69

FRPM 899 974 1043 1109 1232 1343 1453 1557

BHP 0.34 0.39 0.43 0.48 0.58 0.68 0.78 0.87

FRPM 1023 1091 1153 1212 1324 1429 1527 1618

BHP 0.52 0.58 0.64 0.68 0.80 0.92 1.03 1.14

FRPM 1149 1212 1269 1323 1424 1520 1613 1701

BHP 0.75 0.82 0.89 0.95 1.07 1.20 1.34 1.47

FRPM 1006 1065 1122 1175 1275 1367 1457 1542

BHP 0.58 0.64 0.69 0.74 0.86 0.96 1.07 1.19

FRPM 1119 1172 1223 1272 1365 1452 1533 1613

BHP 0.82 0.88 0.93 0.99 1.12 1.25 1.36 1.49

FRPM 1232 1279 1326 1372 1458 1541 1618 1692

BHP 1.11 1.17 1.23 1.30 1.43 1.58 1.72 1.85

FRPM 1347 1389 1433 1474 1555 1633

BHP 1.46 1.53 1.60 1.67 1.81 1.97

0.125 0.250 0.375 0.50 0.75 1.00 1.25 1.50

0.125 0.250 0.375 0.50 0.75 1.00 1.25 1.50

EXTERNAL STATIC PRESSURE (in. wg)

EXTERNAL STATIC PRESSURE (in. wg)

12

Page 13

Performance

Supply and Exhaust - Belt Drive

ERV-521S (Standard Airflow)

CFM OV

2,200 2,183

2,700 2,679

3,200 3,175

ERV-521H (High Airflow)

CFM OV

Model ERV-521

3,100 3,076

3,700 3,671

4,300 4,267

ERV-522S (Standard Airflow)

CFM OV

5,000 2,416

5,750 2,779

6,500 3,141

FRPM 830 881 933 981 1072 1155 1238 1315

BHP 0.72 0.80 0.87 0.95 1.09 1.25 1.41 1.57

FRPM 998 1040 1081 1124 1203 1278 1350 1416

BHP 1.29 1.38 1.47 1.57 1.75 1.93 2.12 2.30

FRPM 1168 1203 1240 1274 1345 1412 1477

BHP 2.11 2.21 2.32 2.43 2.65 2.86 3.08

FRPM 980 1017 1054 1089 1159 1226 1290 1355

BHP 1.57 1.65 1.73 1.82 1.99 2.18 2.36 2.54

FRPM 1156 1187 1219 1249 1309 1367 1425 1480

BHP 2.62 2.72 2.83 2.92 3.12 3.33 3.55 3.77

FRPM 1334 1361 1388 1415 1467 1519 1569

BHP 4.08 4.20 4.31 4.43 4.65 4.89 5.13

FRPM 754 794 831 869 943 1011 1072 1134

BHP 2.20 2.39 2.57 2.76 3.15 3.54 3.89 4.30

FRPM 855 892 924 957 1022 1087 1146 1201

BHP 3.28 3.49 3.70 3.92 4.33 4.81 5.26 5.67

FRPM 956 991 1021 1049 1108 1164 1222 1276

BHP 4.67 4.90 5.15 5.39 5.88 6.33 6.89 7.41

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

EXTERNAL STATIC PRESSURE (in. wg)

EXTERNAL STATIC PRESSURE (in. wg)

EXTERNAL STATIC PRESSURE (in. wg)

ERV-522H (High Airflow)

CFM OV

Model ERV-522

6,000 2,067

7,500 2,584

9,000 3,100

ERV-581H (High Airflow)

CFM OV

4,300 2,064

5,050 2,424

Model ERV-581

5,800 2,784

ERV-582H (High Airflow)

CFM OV

9,000 2,254

10,500 2,630

Model ERV-582

12,000 3,005

Gross supply air performance ratings (airflow, pressure, and power) are at port 2 with port 1, port 3 and port 4 at 0.0 in. wg. Gross exhaust air

performance ratings (airflow, pressure, and power) are to port 3 with port 1, port 2 and port 4 at 0.0 in. wg. Power rating (Bhp) does not include drive

losses. Performance ratings do not include the effects of appurtenances in the airstream.

FRPM 535 581 619 660 731 797 857 913

BHP 1.57 1.79 1.96 2.16 2.55 2.94 3.33 3.72

FRPM 646 686 722 753 818 877 930 983

BHP 2.90 3.20 3.46 3.68 4.17 4.66 5.12 5.62

FRPM 763 794 827 857 910 964 1016 1063

BHP 4.90 5.20 5.57 5.89 6.42 7.01 7.60 8.18

FRPM 637 687 733 772 850 923 988 1055

BHP 1.20 1.35 1.49 1.61 1.88 2.16 2.42 2.73

FRPM 731 774 817 855 922 989 1053 1111

BHP 1.89 2.05 2.23 2.39 2.68 3.00 3.33 3.65

FRPM 826 866 903 939 1004 1061 1120 1177

BHP 2.79 2.99 3.18 3.38 3.74 4.07 4.44 4.83

FRPM 595 629 661 692 746 797 843 888

BHP 3.61 3.95 4.26 4.54 5.25 5.89 6.48 7.09

FRPM 685 713 741 769 820 867 911 952

BHP 5.60 5.99 6.38 6.74 7.44 8.27 9.03 9.74

FRPM 776 800 825 849 897 941 982

BHP 8.24 8.66 9.12 9.56 10.36 11.19 12.13

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

0.125 0.25 0.375 0.50 0.75 1.00 1.25 1.50

EXTERNAL STATIC PRESSURE (in. wg)

EXTERNAL STATIC PRESSURE (in. wg)

EXTERNAL STATIC PRESSURE (in. wg)

13

Page 14

Selection Guidelines

Motor Specifications

Blower motor information

must be specified to select

unit. The horsepower,

voltage, phase and enclosure

availability is presented

in the table on the right. If

exhaust and supply blower

horsepower are different,

consult the CAPS program.

Model

ERV-251S*

ERV-251H*

115/1 230/1 230/460/3 230/1 230/460/3 230/1 230/460/3

1

⁄4

1

⁄2

ERV-361* -

ERV-521* ERV-581* - - 1 - 5 - 1 - 5 - 1 - 3

ERV-522* - 1

Open TE Two Speed Open

1

⁄4 - - - - -

1

⁄2 - - - - -

1

⁄4 - 2

1

⁄2 - 3

1

⁄2 - 3 11⁄2 - 15 11⁄2 1 - 15 - 1 - 71⁄2

1

⁄4 - 2

1

⁄2 - 51⁄2 - 11⁄21⁄2 - 5

1

⁄4 - 2

1

⁄4 - 2

1

⁄2 - 11⁄2 - 11⁄2

1

⁄2 - 1

1

⁄2 - 3

ERV-582* - - 11⁄2 - 15 - 1 - 15 - 1 - 71⁄2

UL Listing is available on most open drip proof motors.

*Energy wheel drive motor is only available with open drip proof motors

.

Minimum Circuit Amps (MCA) Calculations for ERV Units

Wheel drive, 24 volt internal control amp and standard electric preheat kW. Single or three phase ERV units

Wheel Drive Amps

Model

115 208/230 460 115/1 208/1 230/1 208/3 230/3 460/3

ERV-251 0.6 0.6 NA 0.5 2.5 2.1, 4.1 2.5, 5 NA NA NA

ERV-361 NA 1.2 0.6 1 NA NA NA 4.1, 8.2, 12.3 5, 10, 15 5, 10, 15

ERV-521 NA 2.8 1.4 1 NA NA NA

24v

Control

Amps

Standard Electric Preheat kW

8.2, 12.3,

15.5

10, 15, 19 10, 15, 20, 25, 30

ERV-581 NA 1.6 0.8 1 NA NA NA 12.3, 15.5 15, 19 15, 20, 25, 30, 38

ERV-522 NA 5.6 2.8 1 NA NA NA 15.5 19 20, 25, 30, 45

ERV-582 NA 3.2 1.6 1 NA NA NA 15.5, 24.5 19, 30 20, 38, 50

NA = not available

MCA Example Calculation

Greenheck ERV selected: ERV-361S-B, 2 hp

supply motor, 11⁄2 hp exhaust motor, 15kW

preheater operating at 460 volt, three phase.

Step 1: Consult NEC table (not shown) for 2 hp

Model CFM

supply motor amps = 3.4 A

Step 2: Consult NEC table (not shown) for 11⁄2 hp

exhaust motor amps = 2.6 A

Step 3: Calculate 15kW preheater amp draw =

15,000W/ [460 * 3 ] = 18.8 A

ERV-251

ERV-361

If no preheater is used skip step 3

Step 4: Wheel drive amps for ERV-361 from

table above = 0.6 A

Step 5: 24v Control Amps for ERV-361 from

table above = 1.0 A

ERV-521

ERV-581

ERV-522

Step 6: MCA = Amperage total from steps

1 thru 5 x 1.25

ERV-582

MCA = (3.4 + 2.6 + 18.8 + 0.6 + 1.0)

1.25 = 33 A

Note: Calculations are approximate, use our Computer Aided Product Selection (CAPS) program for exact

MCA calculations.

Filter Pressure Drop

Intake Hood

with 2-inch

aluminum

filters

Pleated

2-inch

filters

500 0.09 0.09

1,000 0.32 0.19

1,000 0.09 0.10

2,200 0.45 0.28

2,500 0.13 0.14

4,500 0.45 0.32

4,500 0.17 0.15

5,500 0.30 0.24

6,000 0.15 0.14

9,000 0.40 0.25

9,000 0.13 0.16

12,000 0.45 0.27

14

Page 15

Typical Applications

The ERV unit can add to the benefit of a building design anywhere that outdoor air is required and the exhaust

air is considered “clean” (ASHRAE class 1 or class 2 air ratings). Some examples of commercial and institutional

applications where energy recovery units have been utilized are given below.

Animal Shelters Bars and Clubs Churches Dormitories

Locker Rooms Nursing Homes Office Buildings Printing Shops

Restaurants Schools Function Halls Casinos

Veterinary Hospitals

With Ducted Air Handlers

The ERV unit may be combined with ducted air handling units or fan coil boxes. A single energy recovery

ventilator may provide fresh outdoor air for multiple air handling units or in a one-to-one ratio where a single

energy recovery ventilator and air handler serve one space.

AIR HANDLING

UNIT (AHU)

Heating

Coil

Cooling

Coil

72°F 50% 72°F 50%

ZONE 1 ZONE 2

With Packaged Rooftop Equipment

This diagram illustrates how energy recovery

ventilators may be used in conjunction

with packaged rooftop equipment. Fresh,

outdoor air enters the energy recovery

ventilator and is pretreated before entering

the heating/cooling equipment. This

pretreating occurs because the energy

recovery wheel is transferring latent and

sensible energy between the outdoor air and

the building exhaust air.

Heating

Coil

Cooling

Coil

SUPPLY AIR

AHU

RELIEF AIR

Exhaust

Fan

RESTROOM

EXHAUST

AIR

OUTDOOR AIR UNIT (OA unit)

RESTROOM

WITH ENERGY RECOVERY

Energy

Wheel

Exhaust

Fan

EXHAUST AIR

ZONE 1

72°F

50%

AIR HANDLING

UNIT (AHU)

OUTDOOR

AIR

Energy

Wheel

ENERGY RECOVERY

VENTILATOR (ERV)

Supply

Fan

15

Heating

Coil

SUPPLY AIR

Cooling

Coil

Page 16

Greenheck’s Energy

Recovery Models

Model MiniVent - Energy Recovery Ventilator

The MiniVent-450 & 750 are energy recovery ventilators

used for commercial and institutional applications that

require 300 to 800 cfm of ventilation air. The compact

design provides an economical solution for individual

spaces, such as school classrooms and small offices.

Model ERH - Energy Recovery with Heating

With the ERH, you save money with the total energy wheel

and get the convenience of supplemental heating. The ERH

provides preconditioned air in the summer and space neutral

air in the winter, which is ideal if your climate has prominent

summer and winter seasons. The heating section further

tempers cold outdoor air to desired conditions. Four housing

sizes available with airflow capacities up to 10,000 cfm and

external static pressures up to 1.5 in. wg.

Model ERCH - Energy Recovery with Cooling and Heating

The model ERCH combines the benefits of the total energy wheel with

supplemental cooling and heating. The result is a product that is specifically

designed to process 100% outdoor air to desired supply conditions. Four housing

sizes provide airflow capacities from 1,000 to 10,000 cfm with external static

pressures up to 1.5 in. wg. A variety of tempering options are available. The coil

section of the ERCH accommodates a cooling coil, a heating coil, or both.

Model VER - Versatile Energy Recovery (VersiVent)

The Model VER is a fully featured, versatile energy recovery unit with a wide

range heating and cooling options available. The unit includes an

energy wheel to pre temper the outdoor air which reduces the heating

and cooling equipment needed, while also lowering operational costs.

In addition to the standard heating and cooling options, the VersiVent

has options such as environmentally friendly R410 refrigerant, a wraparound heat pipe for additional dehumidification and reheat capacity,

and a quiet, efficient, plenum supply fan. Capacities range from 2,000 to

10,000 cfm with external static pressures up to 3.0 in. wg.

Model APEX - Affordable, Practical, Energy Exchanger

The model APEX combines high airflow capacities with cost saving energy

recovery ventilation by providing centralized outdoor air distribution and

reducing the need for multiple unit installations. Fresh outdoor air is

preconditioned by the total enthalpy wheel, which recovers a majority of

the energy from the exhaust air. It saves 3-4 tons of cooling per 1,000 cfm

and saves 50-60 MBH of heating per 1,000 cfm. Easy to install and operate

with airflow capacities from 10,000 to 20,000 cfm and external static

pressures up to 2.5 in. wg.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one

year from the shipment date. The energy recovery wheel is warranted to be free from defects in material

and workmanship for a period of five years from the shipment date. Any units or parts which prove defective

during the warranty period will be replaced at our option when returned to our factory, transportation

prepaid. Motors are warranted by the motor manufacturer for a period of one year. Should motors furnished

by Greenheck prove defective during this period, they should be returned to the nearest authorized motor

service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2010 Greenheck Fan Corp.

Prepared to Support

Green Building Efforts

00.TAP.1000 R7 6-2010 SN

Loading...

Loading...