Page 1

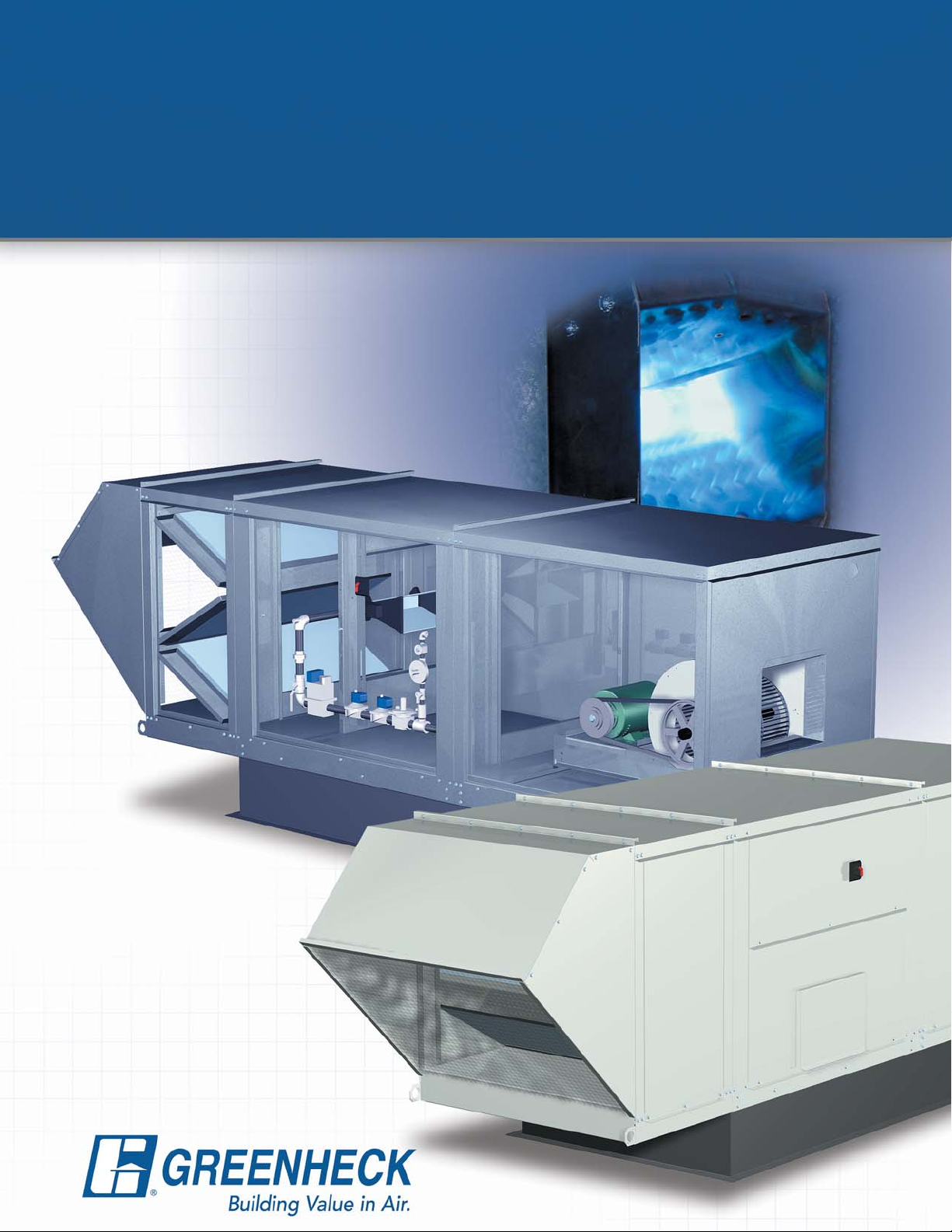

Modular Make-Up Air Unit

Model DGX

• Direct Gas-Fired Heating

• Evaporative • Chilled Water • DX Cooling

March

2007

Page 2

PRODUCT FEATURES

Model DGX

Module 1, Option 2 Module 2, Option 2

Direct Gas-Fired

Make-Up Air Unit

The Greenheck model DGX is

a 100% efficient direct gasfired heating and ventilating

unit. Chilled water, DX, and

evaporative cooling options

are also available for

combination heating and

cooling requirements.

The DGX is designed for

providing make-up air to

commercial and industrial

facilities. Airflow volumes

range from 800 to 48,000 cfm

with heating output capacities

up to 4,800,000 Btu/hr.

Direct Gas-

Fired Heat

Durable Construction

Designed for maximum weather resistance, DGX

housings are constructed of heavy gauge G90

galvanized steel. Lifting lugs are standard.

Direct Gas-Fired System

• High quality cast aluminum burners with

stainless steel mixing plates

• Maxitrol electronic

modulation burner

control

• Flame safeguard

with digital fault

indicator capability

(over 400,000 Btu/hr)

• 25:1 turn down ratio

Control Center

The control center includes the following standard

components:

• 24 volt control voltage

• Magnetic motor

starter with solid

state overload

protection

• Control

transformer

• Disconnect switch

• Distribution terminal strip

Premium grade control components are selected for

reliable operation. All electrical components are UL

Listed, recognized, or classified, and factory prewired

for single point power connection.

DGX shown with optional birdscreen

weatherhood, V-bank filter section

and horizontal fan discharge.

Module 4, Option 1

Module 5, Option 2

Vibration Isolators

The entire fan and motor

assembly is mounted on

neoprene vibration isolators to

minimize noise transmission

into the building. Spring

vibration isolators are

available in lieu of neoprene

isolators.

Reliable Fan Performance

Air performance ratings

from Greenheck’s

accredited test chamber

ensure accurate data.

Double width, double

inlet forward curved

wheels for high efficiency

and low sound levels are

constructed of heavy

gauge steel. Wheels are balanced to ensure vibration

free operation.

Access Panels

Large access panels are provided for easy inspection

and maintenance of motors, drives, fan wheels, filters,

and heater controls.

Factory Wired and Tested

All units are tested

prior to shipment to

ensure proper

operation of the gas

train, electrical

components, and

airflow controls.

2

Page 3

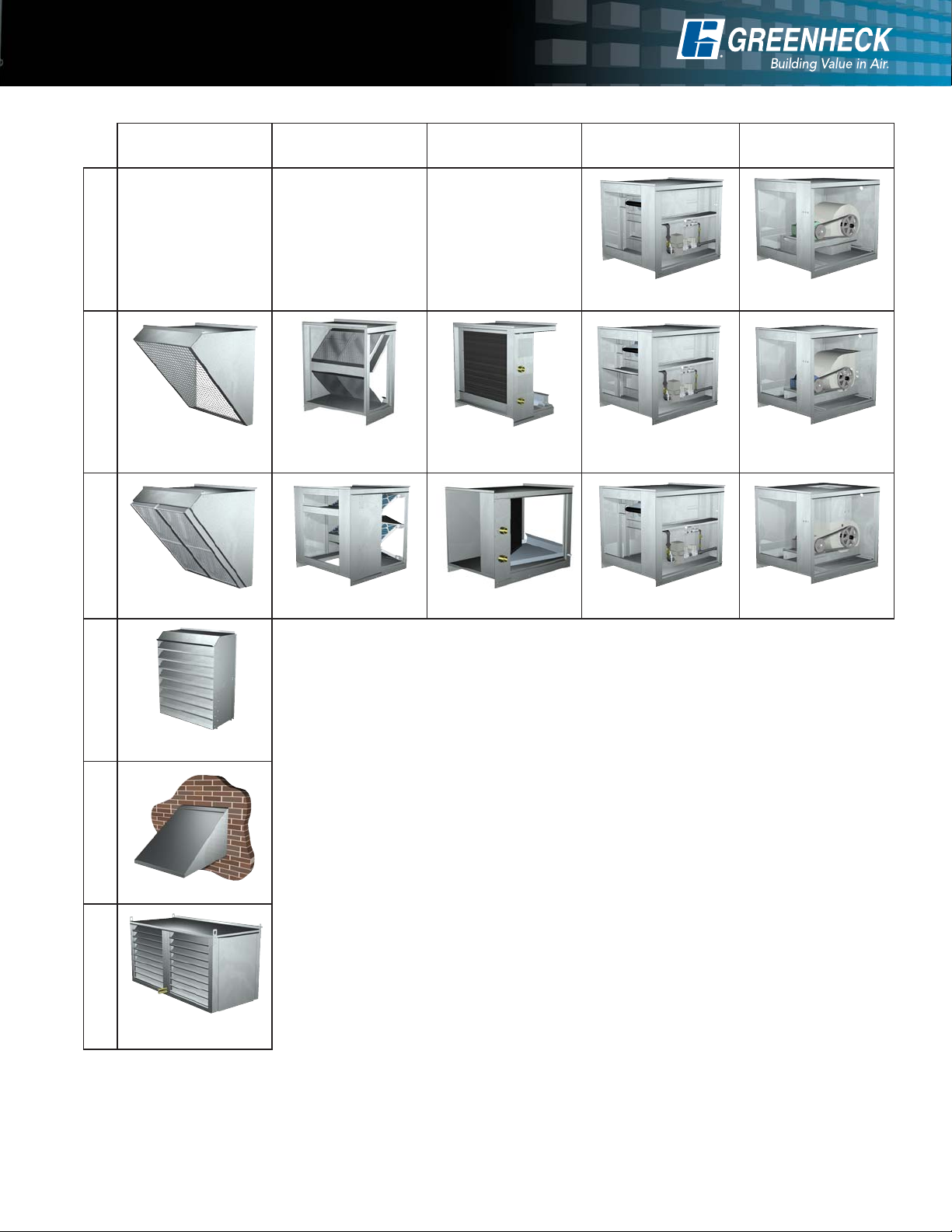

MODULE SELECTION OPTIONS

Module 1

INTAKE

None

requires

Module 2, Option 2

Option 1

Option 2

Birdscreen Weatherhood

Option 3

requires

Module 2, Option 2

Filtered

Weatherhood

Module 2

FILTER

Module 3

COOLING

None None

V-Bank Filters

Pleated or

Aluminum Mesh

80/20 Filtered

Recirculation

*Cooling Coil – CW, DX

(standard capacity)

*Cooling Coil – CW, DX

(high capacity)

Module 4

HEATING

Direct Gas Furnace

100% Outdoor Air

Direct Gas Furnace

Recirculation - requires

Module 2, Option 3

Direct Gas Furnace

Variable Air Volume

Module 5

DISCHARGE

Downblast

Discharge

Horizontal

Discharge

Upblast

Discharge

Option 4

Weatherhood

Option 5

Option 6

Louvered

Thru-Wall

Evaporative

Cooling

*Chilled water or direct expansion (DX) cooling is available with the model DGX. The cooling section

includes the cooling coil, sloped stainless steel drain pan and insulated double wall construction.

Drain and coil connections are stubbed through the wall for convenience.

For proper coil sizing, use Greenheck CAPS selection software or contact your local representative.

Four row and six row chilled water or DX coils are available with airflow capacity up to 11,000 cfm.

Cooling coil sections are installed upstream of the fan section for a draw through arrangement and

provide a streamlined transition to adjacent DGX sections. DX coils require remote condensing units.

• Module 2 is not available with the Evaporative Cooler section (Module 1, Option 6)

• Cooling Coil modules (Module 3, Option 2 & 3) are not available with Recirculation (Module 2,

Option 3)

• Optional intake dampers available on Cooling Coil section (Module 3, Option 2 & 3)

• Module 1, Option 3, 4 & 5 are not available on Housing 35 and larger

The evaporative cooling section includes a galvanized steel housing with a louvered intake, 2 inch

aluminum mesh filters and a stainless steel evaporative cooling module. The evaporative cooling

media has a depth of 12 inches for 90% cooling effectiveness.

The entire section mounts directly to the front of the DGX unit, eliminating transition or ductwork

by others. Drain and overflow are conveniently tapped through the side of the cooling section. The

supply line connection is field located where convenient. Freeze protection, automatic drain & fill, and

water economizer (Water Wizard) options are also available.

Airflow capacity for evaporative cooling is up to 46,000 cfm. The evaporative cooling section for the

housing 32 and larger ship separately.

3

Page 4

Variable Volume

Variable Volume

Recirculation

Temperature Control

VARIABLE MAKE-UP AIR OPTIONS

The variable volume option is recommended when a

building’s exhaust volume will vary. The make-up air

volume will track with the exhaust volume, providing

only the necessary amount of make-up air.

The variable volume option saves energy by reducing

both fan power and gas consumption whenever makeup air requirements are less than the maximum.

Airflow Control Strategies

Greenheck offers four methods of controlling the

make-up air volume. All four vary the fan speed for

maximum energy savings.

• Variable Frequency Drive controlled by building

pressure.

• Variable Frequency Drive controlled manually with a

remote potentiometer.

• Variable frequency drive controlled by a 2-10 VDC

or 4-20 mA signal.

Recirculation

The recirculation option is recommended when the

ventilation equipment provides the primary source of

heating for the space.

Up to 80% of the air from the space can be

recirculated and filtered and then combined with a

minimum of 20% outdoor air for a continuous source

of fresh air. Only outdoor air is used for combustion to

eliminate the possibility of contaminants from the

recirculated air crossing over the burner.

• 2 speed motor controlled manually with a remote

switch.

Burner By-Pass Damper

The Variable Volume option includes a patented

burner by-pass damper, which maintains the pressure

drop across the burner as air volumes change. This

assures that complete and proper combustion occurs.

The by-pass damper is self-adjusting, designed for

minimal maintenance, and requires no controls.

Outside Air

Supply Air

• Modulating actuator controlled manually with a

remote potentiometer.

• Modulating actuator controlled by a 2-10 VDC or

4-20 mA signal.

• Two position actuator controlled manually with a

remote switch/time clock.

20%

Airflow Control Strategies

Greenheck offers four methods of controlling the ratio

of recirculated air to outdoor air via motorized

dampers.

• Modulating actuator controlled by building pressure.

Temperature Control

There are three temperature control

options for heat: 1) Discharge Control, 2)

Space Control, and 3) DDC Interface

Control. Cooling controls are by others.

Discharge Control

A factory installed modulating system

controls the gas valve to provide the

desired temperature based on a sensor

at the fan discharge. A room override

option is available to boost the discharge

temperature when the space is too cool.

4

80-0%

Outside Air

(100-20%)

Recirculated Air

(0-80%)

Supply Air

Room Control

Specify this option when the DGX has the primary

responsibility for controlling the room temperature. A

manually adjusted room thermostat provides feedback

to the unit controls, which vary the discharge

temperature in order to maintain desired room set

point.

DDC Interface Control

Allows for an external signal (0-10 VDC or 4-20 mA)

from the building management system to modulate

the burner output to satisfy monitored conditions.

Page 5

Roof Mounted Installation

Thru-Wall Installation

INSTALLATION OPTIONS

Roof Mounted Installation

Model DGX is available for stand alone installations as shown below. Downblast (Arrangement DB), upblast

(Arrangement UB), or horizontal (Arrangement HZ) discharge may be specified.

Upblast Discharge - Arrangement UB

The Greenheck combination package

simplifies installation and reduces field labor

costs. The pre-engineered design ensures that

the supply fan, exhaust fan, curb, and

combination extension components interface

properly for kitchen ventilation applications.

Equally important, Greenheck combination

packages are specifically designed to comply

with NFPA 96.

NFPA 96 states:

• Exhaust duct must terminate at least 24

inches above the roof deck

• Fan discharge must be at least 40 inches

above the roof deck

• Air intake shall have a horizontal separation

of 10 feet from the exhaust discharge

Note: Consult local codes and the authority

having jurisdiction if there are questions

concerning the use of this product.

Horizontal Discharge - Arrangement HZ

Combination Package - Arrangement DBC

The combination curb extension

is the component that pulls the

Combination Package together,

providing a factory engineered

interface between the roof curb

and the fans. It is also designed

to satisfy NFPA 96 requirements

- above the roof line - for

kitchen hood exhaust.

Thru-Wall Installation

Model DGX (Housing 12, 22, & 32 only) is available with a pre-engineered thru-wall installation option, which is

ideal when a roof penetration is not desirable.

Factory options that facilitate easy installation

and ensure problem-free operation:

Weatherhood: A full down turn design with

generous intake area to minimize intake velocity

and moisture entrainment.

Thru-Wall Sleeve: Sleeve provides attachment

interface between weatherhood and burner

section. Accommodates walls up to 15 inches in

depth.

Filter Section: Aluminum mesh media filters

outdoor air and strips fine mist from the air. A

drain pan weeps moisture out the front of the

wall sleeve.

5

Page 6

ACCESSORIES

Remote Control Panels

Accessories

Remote Control Panels

A wide variety of remote control panels are available. Specify the desired combination of switches, thermostats,

temperature selectors and indicator lights. A terminal strip at the unit control center and remote panel simplify

field control wiring.

Basic remote control panel with

thermostat for room temperature

control option.

Accessories

Special Coatings

Greenheck’s Permatector™ coating is available for a

durable, long lasting finish. Decorative paints are also

available in a variety of colors to match existing

building fixtures. Consult your Greenheck

representative for paint selections.

Roof Curbs

Factory provided roof curbs are available to ensure

compatibility between the make-up air unit and roof

curb. Standard construction is G90 galvanized steel.

Duct Adapter

Duct adapter is available with factory supplied roof

curbs. The duct adapter allows for easy alignment of

the supply duct connection.

V-Bank Filter Section

V-bank filter sections are available with 2-inch

washable aluminum mesh or 2-inch 30% efficient

disposable filters.

Weatherhood

Three weatherhoods are available: standard

weatherhood includes birdscreen, filtered

weatherhood includes aluminum mesh filters, and

louvered intake hood includes a drainable blade

louver at intake with 2-inch aluminum mesh filters.

Kitchen style remote panels

feature toggle switches and a

stainless steel face plate for

flush mounting to a wall. The

junction box is also included.

Spring Vibration Isolation

Spring blower vibration isolators are available in lieu of

neoprene isolators.

Exhaust Fan Starter(s)

Exhaust fan starters are available factory mounted and

wired. Exhaust fan starters allow for an electrical

interlock between the supply and exhaust fan(s).

Dirty Filter Switch

A dirty filter switch is available to monitor the pressure

drop across the filter section. If the pressure drop

across the filters is higher than the field adjustable

setting, the dirty filter switch trips indicating the need

to clean or replace the filters.

Freeze Protection

Electronic freeze protection is available to

automatically shut down the supply fan when the

discharge temperature is below the adjustable set

point for an extended amount of time. This prevents

the unit from discharging non-tempered air into the

building and freezing pipes and other temperature

sensitive items.

Inlet Air Sensor – Heat

The heating inlet air sensor will automatically turn the

heat on and off based on the outdoor air temperature.

Motorized Dampers

Intake or discharge dampers are available to prevent

backdrafts when the supply fan is not in operation.

Intake dampers are factory mounted and wired.

Discharge dampers ship loose for field mounting in the

supply air duct.

Fiberglass Insulation

One inch fiberglass insulation is available to line the

housing to prevent the formation of condensation and

to form an acoustical barrier.

Double Wall Construction

An interior metal liner is available to isolate the 1-inch

fiberglass insulation from the airstream.

6

Discharge Diffuser

Discharge diffusers are available as either 3-way for

horizontal discharge or 4-way for downblast discharge.

Service Receptacle

A 115 volt GFCI outlet is mounted externally in a NEMA

3R box for the convenience of service personnel. A

separate 115 volt power source is required.

Auxiliary Contacts

Normally open and normally closed contacts are

available for supply fan status and supply fan

interlocks.

Page 7

AIR PERFORMANCE

Blower

Size

108

109

Housing 12

110

112

115

Housing 22

118

120

Housing 32

122

125

Housing 35

127

130

Housing 38

133

136

Housing 42

CFM

800

1,200

1,500

2,400

2,000

3,000

2,600

4,400

4,000

6,500

6,500

9,500

10,000

15,000

15,000

19,000

19,000

23,000

24,000

30,000

26,000

34,000

32,000

40,000

42,000

48,000

TOTAL PRESSURE in inches WG

0.75 1.00 1.25 1.50 1.75 2.00

RPM 1109 1216 1311 1399 - -

BHP 0.26 0.31 0.35 0.40 - -

RPM 1347 1445 1530 - - -

BHP 0.59 0.68 0.75 - - -

RPM 1014 1140 1255 1361 1460 -

BHP 0.45 0.54 0.63 0.73 0.84 -

RPM 1216 1306 1397 1484 1569 1648

BHP 1.1 1.3 1.4 1.6 1.7 1.9

RPM 912 1013 1110 1199 - -

BHP 0.59 0.71 0.08 0.10 - -

RPM 1097 1172 1244 1315 1386 1455

BHP 1.4 1.6 1.7 1.9 2.1 2.2

RPM 761 853 934 1009 - -

BHP 0.7 0.9 1.0 1.2 - -

RPM 939 1006 1073 1137 1197 1254

BHP 2.1 2.4 2.6 2.9 3.1 3.3

RPM 681 756 822 892 - -

BHP 1.3 1.5 1.8 2.1 - -

RPM 850 906 960 1013 1062 1110

BHP 3.5 3.9 4.3 4.7 5.1 5.5

RPM 609 668 724 777 - -

BHP 2.1 2.5 2.8 3.2 - -

RPM 736 783 827 872 914 954

BHP 4.9 5.4 5.9 6.4 6.9 7.4

RPM 590 634 678 723 765 803

BHP 4.0 4.5 5.0 5.6 6.1 6.6

RPM 763 795 829 861 892 921

BHP 10.9 11.6 12.3 13.1 13.8 14.5

RPM 605 637 667 698 727 755

BHP 8.3 8.9 9.6 10.4 11.1 11.9

RPM 720 746 771 796 821 845

BHP 15.2 16.1 17.0 17.8 18.6 19.4

RPM 563 594 625 655 683 711

BHP 9.8 10.7 11.7 12.8 13.8 14.8

RPM 643 671 967 723 748 -

BHP 15.9 16.9 18.0 19.2 20.4 -

RPM 451 478 504 530 554 578

BHP 11.6 13.0 14.3 15.8 17.2 18.6

RPM 525 548 571 593 613 -

BHP 19.6 21.4 23.2 24.9 26.6 -

RPM - 412 440 467 494 520

BHP - 12.5 13.9 15.2 16.8 18.3

RPM 454 477 499 519 542 -

BHP 21.5 23.1 24.8 26.4 28.3 -

RPM 371 397 422 446 467 488

BHP 15.7 17.5 19.2 21.0 22.6 24.3

RPM 426 448 470 491 512 531

BHP 27.1 29.1 31.5 33.7 35.8 37.9

RPM 405 426 445 464 482 499

BHP 27.7 29.8 32.0 34.1 36.3 38.5

RPM 447 465 483 500 - -

BHP 39.0 41.5 44.0 46.4 - -

Note: The air performance data shown does not include internal static pressure losses due to items such as filters, dampers, and coils. For

exact air performance data based on specific unit configuration, use the Greenheck CAPS selection program.

7

Page 8

Typical Specifications

General: Make-up air unit shall be as manufactured by

Greenheck or approved equal provided all specifications are

met. Greenheck Model DGX equipment is used as the basis of

design. Performance to be as scheduled on plans. Make-up air

unit shall be ETL listed to ANSI Z83.4 -1999, CSA 3.7 - M99 (for

100% outdoor air) or ANSI Z83.18-2000 (for recirculation).

Gas Train and Controls: Direct gas-fired system shall have

a draw through design and field adjustable burner baffles.

Gas trains up to 400,000 Btu/hr shall include a direct spark

ignition system. Gas trains greater than 400,000 Btu/hr shall

include a pilot ignition system and shall have digital coded

fault indicator capability. Fault indicator shall provide service

history by storing codes for the last five faults. Dual safety

shutoff valves shall be industrial duty and use 120 VAC control

signals. Temperature control shall incorporate a Maxitrol

electronic modulation control system.

Unit Casing and Frames: Unit shall be of internal frame type

construction of galvanized steel. All frames and panels shall

be G90 galvanized steel. Where top panels are joined there

shall be a standing seam to insure positive weather protection.

All metal-to-metal surfaces exposed to the weather shall be

sealed, requiring no caulking at job site. All components shall

be easily accessible through removable doors.

Insulation: Unit casing to be lined with 1 inch fiberglass

insulation where specified. Insulation shall be in accordance

with NFPA 90A and tested to meet UL 181 erosion requirements.

Double wall shall be provided where specified.

Fan Section: Centrifugal fans shall be double width, double

inlet. Fan and motor shall be mounted on a common base and

shall be internally isolated. All blower wheels shall be balanced.

Ground and polished steel fan shafts shall be mounted in

permanently lubricated ball bearings or ball bearing pillow

blocks. Bearings shall be selected for a minimum (L10) life in

excess of 100,000 hours at maximum cataloged speeds.

Motors and Drives: Motors shall be energy efficient,

complying with EPACT standards, for single speed ODP

and TE enclosures. Motors shall be permanently lubricated,

heavy duty type, matched to the fan load and furnished at the

specified voltage, phase and enclosure. Drives shall be sized

for a minimum of 150% of driven horsepower. Pulleys shall

be cast and have machined surfaces, 15 horse power and less

shall be supplied with an adjustable drive pulley.

Electrical: All internal electrical components shall be prewired

for single point power connection with exception of the larger

evaporative cooling sections. All electrical components shall

be UL listed, recognized or classified where applicable and

wired in compliance with the National Electrical Code. Control

center shall include motor starter, control circuit fusing,

control transformer for 24 VAC circuit,

integral disconnect switch and terminal

strip. Contactors, Class 20 adjustable

overload protection and single phase

protection shall be standard.

Filter Section: Filter section shall be

designed such that velocities across

the filters do not exceed 550 feet per

minute. Filters shall be 2-inch washable

aluminum mesh or 2-inch disposable.

Weatherhood: Weatherhood shall be

constructed of G90 galvanized steel

with birdscreen mounted at the intake.

Recirculation (optional): Recirculation

airflow shall be controlled by adjustment

of return damper position. Input signal

for return damper shall be from building

pressure sensors, potentiometer,

external signal, or manual switch.

Recirculated air shall not be permitted

to pass across the burner. Return air

shall be filtered.

Variable Volume (optional): Volume shall be varied by either

a 2-speed motor or variable frequency drive. Input signal for fan

speed shall be from building pressure sensors, potentiometer,

external signal, or manual switch. A self-adjusting burner

bypass damper shall maintain a constant air volume across

the burner to ensure proper gas combustion. Bypass damper

shall operate automatically without an electronic signal.

Cooling Coil (optional): Direct expansion (DX) or chilled

water coil shall be factory tested and rated in accordance

with ARI 410. Coils shall have copper tubes with permanently

expanded aluminum fins, 12 fpi or less. DX coils shall be

equipped with distributors to receive expansion valves at the

liquid connections. Drain pans shall extend at least 12 inches

downstream of coil and be sloped to drain connection. Cooling

coil shall meet UL 1995 specifications for non-protected coil.

Evaporative Cooling Section (optional): Evaporative

cooling section shall include a galvanized steel housing with

louvered intake, 2 inch aluminum mesh filters and a stainless

steel evaporative cooling module all provided by the make-up

air unit manufacturer. The louver shall be stationary type with

drainable blades, and be designed to withstand wind loads of

25 PSF. Evaporative cooling media shall be 12 inches deep,

with a UL 900 class II fire rating for a cooling effectiveness of

90%. Drain and overflow connections shall be piped through

the side of the evaporative cooling section.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the

purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option when returned

to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of one year. Should motors

furnished by Greenheck prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without

notice.

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2007 Greenheck Fan Corp. • Catalog DGX Rev. 4 March 2007 SP

Loading...

Loading...