Page 1

Part Number 474754

®

Grease Grabber™ Power Play

Kitchen Exhaust Pollution Control System

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

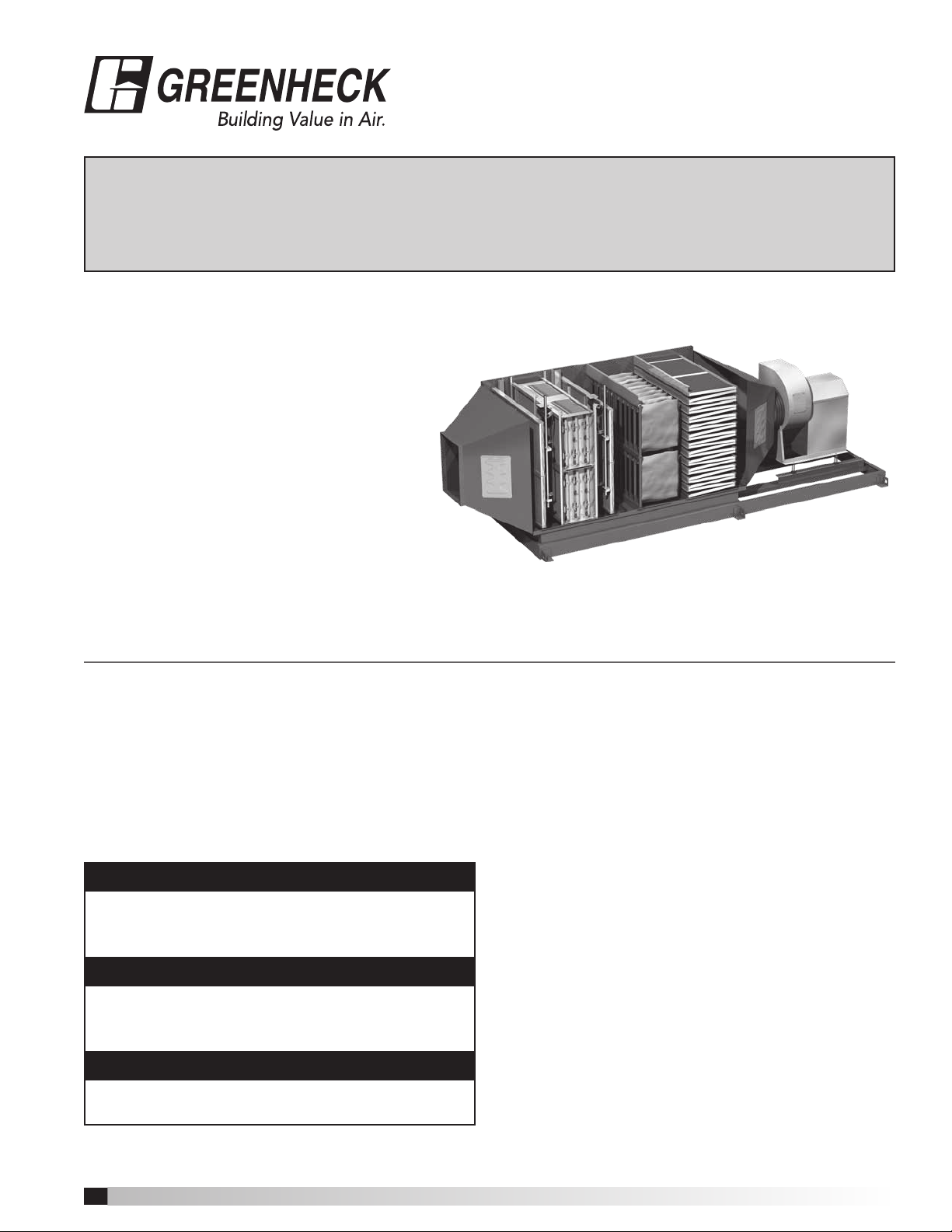

Grease Grabber™ Power Play

The Greenheck Grease Grabber™ Power Play

is a pre-engineered electrostatic precipitator

type filtration pollution control unit with

integral exhaust fan (available without exhaust

fan as an option). The unit is designed to

remove grease and smoke particles as well

as odor molecules from the kitchen exhaust

airstream. This installation manual covers

procedures for receiving, installing, and

maintaining the filtered section of the unit.

For additional instructions and maintenance

information on the integral exhaust fan,

when applicable, refer to the fan nameplate

to determine model type and visit www.greenheck.com to

download the corresponding manual.

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch

or breaker to prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Do not install this equipment in explosive

atmospheres.

• Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in

Canada.

• The rotation of the fan wheel is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

• Fan motor must be securely and adequately

grounded.

• Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

• Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

• Verify that the power source is compatible with the

equipment.

• Never open access doors to a duct while the fan is

running.

• The precipitator contains safety electrical interlock

switches at all maintenance access doors. Do not

attempt to defeat these interlocks.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

1

Page 2

Receiving

Upon receiving the product check to make sure all

items are accounted for by referencing the packing

list ensuring all items were received. Inspect each

crate for shipping damage before accepting delivery.

Notify the carrier if any damage is noticed. The

carrier will make notification on the delivery receipt

acknowledging any damage to the product. All

damage should be noted on all the copies of the bill

of lading which is countersigned by the delivering

carrier. A Carrier Inspection Report should be filled

out by the carrier upon arrival and filed with the

Traffic Department. If damaged upon arrival, file claim

with carrier. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited

to only items on the packing list. Filters and carbon

panels are shipped on separate skids in their original

packaging. Do not remove factory packaging or install

filters until just prior to commissioning. Remove all

other shipping/packing materials including fan tie

down straps.

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration

of the unit during storage. The user assumes

responsibility of the unit and accessories while in

storage. The manufacturer will not be responsible

for damage during storage. These suggestions are

provided solely as a convenience to the user.

INDOOR

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should

be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

2

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages

use a portable electric heater to get rid of any

moisture build up. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

OUTDOOR

Units designed for outdoor applications may be stored

outdoors, if absolutely necessary. Roads or aisles for

portable cranes and hauling equipment are needed.

The unit should be placed on a level surface to

prevent water from leaking into it. The unit should be

elevated on an adequate number of wooden blocks

so that it is above water and snow levels and has

enough blocking to prevent it from settling into soft

ground. Locate parts far enough apart to permit air

circulation, sunlight, and space for periodic inspection.

To minimize water accumulation, place all unit parts on

blocking supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during

Storage

While in storage, inspect equipment once per month.

Keep a record of inspection and maintenance

performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lintfree cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Wipe thoroughly

clean with Tectyl® 506 (Ashland Inc.) or the equivalent.

For hard to reach internal surfaces or for occasional

use, consider using Tectyl® 511M Rust Preventive or

WD-40® or the equivalent.

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion, until the equipment

goes into operation. Prior to installing the unit and

system components, inspect the unit assembly to

make sure it is in working order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories for

tightness.

2. Rotate the fan wheel(s), where applicable, by hand

and assure no parts are rubbing.

Page 3

Table of Contents

Installation .................................4

Rigging/Placing Equipment .................4

Duct Connections .........................5

Plumbing ..................................5

Detergent Dispenser .......................5

Cabinet Assembly .........................5

Electrical ..................................6

Electrostatic Cell Wiring ....................6

Exhaust Fan Motor Wiring ..................7

System Control Panel Wiring ................7

Initial System Start-Up .......................7

Manual vs. Auto Operation ..................8

Operation ..................................8

Washing ..................................9

Reset Mode ...............................9

Detergent Dispenser .......................10

Adjustments ..............................10

Flow Control Valve Adjustment ...............10

Maintenance ..............................10

Maintenance Log ...........................12

Warranty ..................................12

An aluminum mesh pre-filter removes large airborne

particles from the incoming airstream prior to reaching

the ionizer cell. The permanent electrostatic collector

section removes grease and smoke particles from

the airstream using a high voltage ionizer cell(s). The

ionizer imparts a positive charge on the grease and

smoke particles as they pass. These particles are then

repelled by positively charged plates and collected

on negatively charged plates. Upon completion of

each cooking day, a wash sequence is initiated for the

self-cleaning function of the electrostatic cell via the

remote mounted control panel. The aluminum mesh

mist eliminator prevents wash water from entering

the safety filter and carbon panel sections of the unit.

The safety bag filter is intended to protect the carbon

panel section if power is lost to the ionizer collector

cell.

NOTE

Power Play is designed to remove sub-micron,

airborne particulate generated from cooking

processes. This system is NOT INTENDED to

eliminate regular hood and ductwork cleaning and

service. Improper care and maintenance of this

system and associated hoods and ductwork may

present a fire hazard.

Grease Grabber™ Power Play

System Function

Grease Grabber Power Play is an electrostatic

precipitator style air filtration unit, with an additional

carbon filter module, designed for two specific

functions:

• Remove smoke/grease particles from kitchen

exhaust.

• Remove odor molecules from kitchen exhaust.

NOTE

Grease Grabber Power Play must be connected to a

listed exhaust hood assembly and must be installed

in accordance with local building codes, NFPA 96

and NEC.

NOTE

The unit must be installed with a minimum 18 inch

clearance to combustible materials and must be

installed as part of a listed duct assembly.

System Components

NOTE

The installation criteria for each of the system

components shown below should be considered

when selecting a site for install. For further

detail on installing the components, refer to the

INSTALLATION section on page 4.

Cabinet Assembly

The unit body is shipped on a common mounting

rail ready for installation. If the unit was ordered with

an exhaust fan, the fan will also be mounted as part

of the cabinet assembly. Unless specified at time of

order, the cabinet assembly must be mounted indoors

and be protected from weather as well as be easily

accessible for service personnel. (1) 1½ or 2 inch

(depending on unit size) water supply line and (1)

3inch waste water drain line is required at the unit for

the system’s wash function.

Safety Filters & Carbon Panels

Filter and ionizer cell quantities for each stage are

based on unit size (see table on page 4). A consistent

quantity of filters/ionizer cells are provided for

each stage of the unit (pre-filter, ionizer cells, mist

eliminator, and safety bag filter). Quantity of carbon

panels will vary based upon unit exhaust rate. Install

filters and carbon panels only when system is ready

for start-up.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

3

Page 4

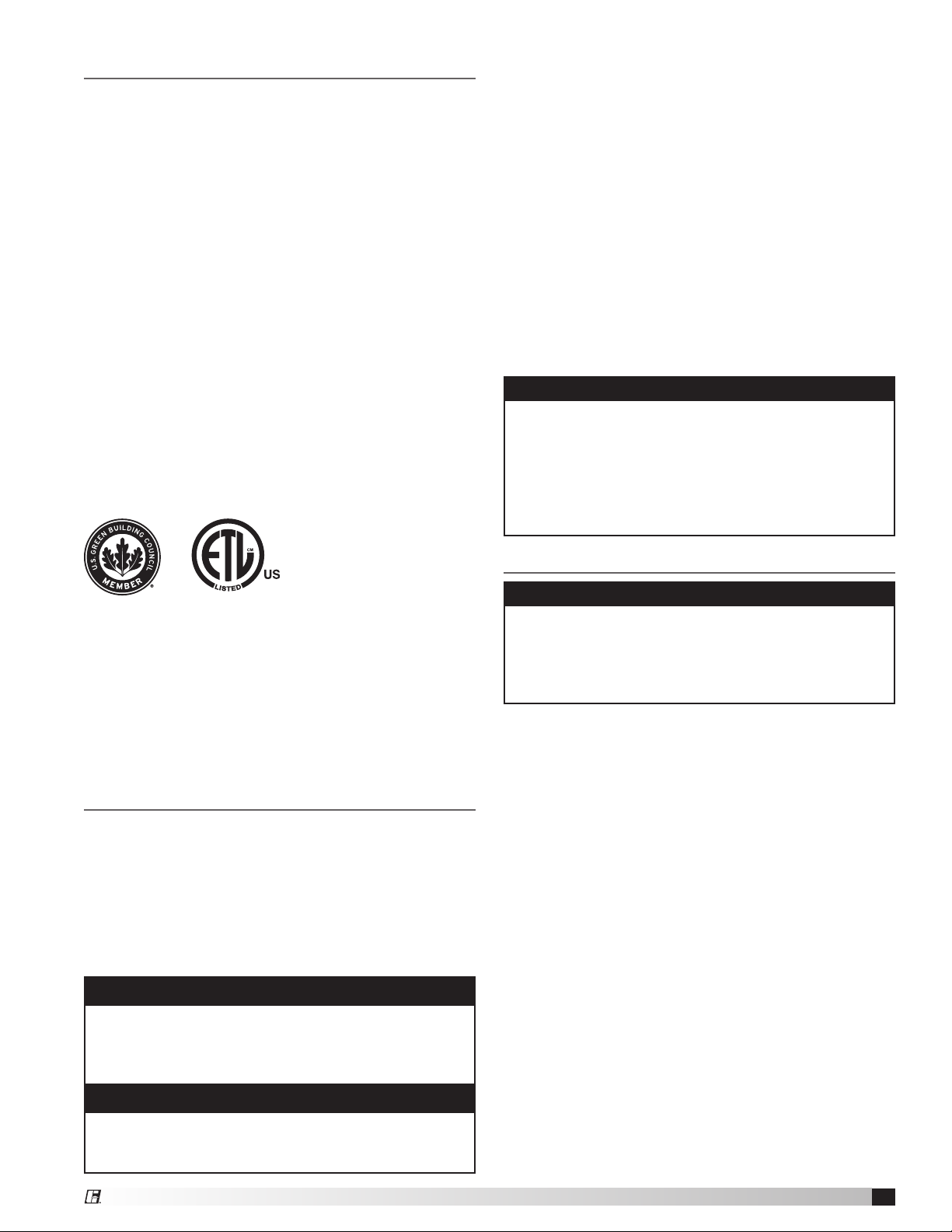

Filter Quantities

Unit

Size

02-03 1 1

02-04 2 0

02-05 2 1

02-06 3 0

04-03 2 2

04-04 4 0

04-05 4 2

04-06 6 0

04-07 6 2

04-08 8 0

04-09 8 2

06-03 3 3

06-04 6 0

06-05 6 3

06-06 9 0

06-07 9 3

06-08 12 0

06-09 12 3

Remote Mounted Detergent Dispenser

A 55 gallon remote mounted detergent dispenser

is included as part of the electrostatic collector

self-wash system. Included as part of the 55 gallon

dispenser assembly is a solenoid valve, pressure

gauge, ball valve, y strainer, and backflow preventer.

The detergent dispenser must be mounted indoors

on a solid, level foundation, as close to the cabinet

assembly as possible, and in a freeze protected

location accessible to maintenance personnel. The

1/2 inch line from the detergent dispenser must be

connected to the water supply line within 5 feet of

the precipitator. Refer to the PLUMBING section for

details on plumbing connections.

Remote Mounted System Control Panel and

Power Pack (2 pieces)

The system control panel allows the user to interface

with the unit and controls operation as well as

monitors wash and other functions. The Power

Pack contains a power transformer and works in

conjunction with the System Control Panel and the

unit’s high voltage ionizer cells. The System Control

Panel should be mounted in an area easily accessible

to daily operational staff. The Power Pack should be

mounted as close as possible to the System Control

Panel and both should be mounted as close to the

cabinet assembly as possible. Allow adequate room

from the face of the panels for door swing clearance

and servicing.

Safety Filter

Quantity

(2 ft. tall x 2 ft. wide)

Safety Filter

Quantity

(2 ft. tall x 1 ft. wide)

High Voltage Cable

High voltage cable is supplied to connect the ionizer/

collector sections of the precipitator to the ionizer and

collector terminals in the Power Pack. The red cable

(50 ft supplied) is used for the ionizer and the blue

cable (50 ft supplied) is used for the collector. Refer to

the ELECTRICAL section for details on wiring.

Installation

Rigging/Placing Equipment

1. The unit is furnished with lifting lugs at the four

corners and along the length as necessary.

2. Lift into place using all the lifting lugs.

3. Field weight will vary depending upon final

selections such as fan type, accessories, etc.

Approximate weights are shown in the table below.

Unit Size

02-03 3100 1409

02-04 3620 1645

02-05 4025 1830

02-06 4280 1945

04-03 4000 1818

04-04 4580 2082

04-05 5200 2364

04-06 5700 2591

04-07 6420 2918

04-08 7080 3218

04-09 7560 3436

06-03 5200 2364

06-04 6140 2791

06-05 6800 3091

06-06 7325 3330

06-07 8275 3761

06-08 8800 4000

06-09 9510 4350

4. The unit can be positioned on a base or curb

suitable for this purpose.

5. The unit must be anchored to its base/curb.

6. Alternatively, the unit may be suspended from

an adequate overhead structure, using suitable

undercarriage or hanging rods (by others). If the

unit is suspended by hanging rods, minimum

1/2inch (12.7 mm) diameter threaded rod is to be

used. All hanger brackets/lifting lugs must be used

to ensure proper support of the unit. The unit must

also be hung level to ensure proper operation.

7. A service clearance of 42 inches must be provided

on the access door side of the unit.

8. A minimum 18 inch clearance must be maintained

between this unit and any combustible material.

Approximate

Weight (lbs)

Approximate

Weight (kg)

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

4

Page 5

9. The remote mounted detergent dispenser frame

mounts to a foundation using the four mounting

holes located at the base of the unit. For details on

wiring this item, refer to the ELECTRICAL section.

For details on plumbing connections, refer to the

PLUMBING section.

Duct Connections

Ductwork must conform to the IMC and SMACNA

guidelines.

As specified in NFPA 96, Ch. 7.5 (latest edition),

exhaust duct systems must be constructed in the

following manner; unless otherwise specified by the

local authority having jurisdiction (AHJ).

Materials

Ducts shall be constructed of and supported by

carbon steel not less than 1.37 mm (0.054 in.) (No. 16

MSG) in thickness or stainless steel not less than 1.09

mm (0.043 in.) (No. 18 MSG) in thickness.

Installation

All seams, joints, penetrations, and duct to hood collar

connections shall have a liquid-tight external weld.

An inlet transition is furnished to match the inlet duct

size. The inlet transition is furnished with a listed duct

access door for inspection and cleaning.

Units intended for indoor mounting are provided with

an outlet mounting flange, either at the unit discharge

or as part of a factory supplied UL 762 listed exhaust

fan. Outlet ductwork from the exhaust fan is required to

be per the above mentioned methods unless otherwise

specified by the local authority having jurisdiction

(AHJ).

NOTE

All water piping exposed to freezing temperatures

must to be trace heated and insulated to prevent

damage to the unit.

NOTE

For unit sizes 06-08 and 06-09, a minimum 2 inch

incoming water service is required.

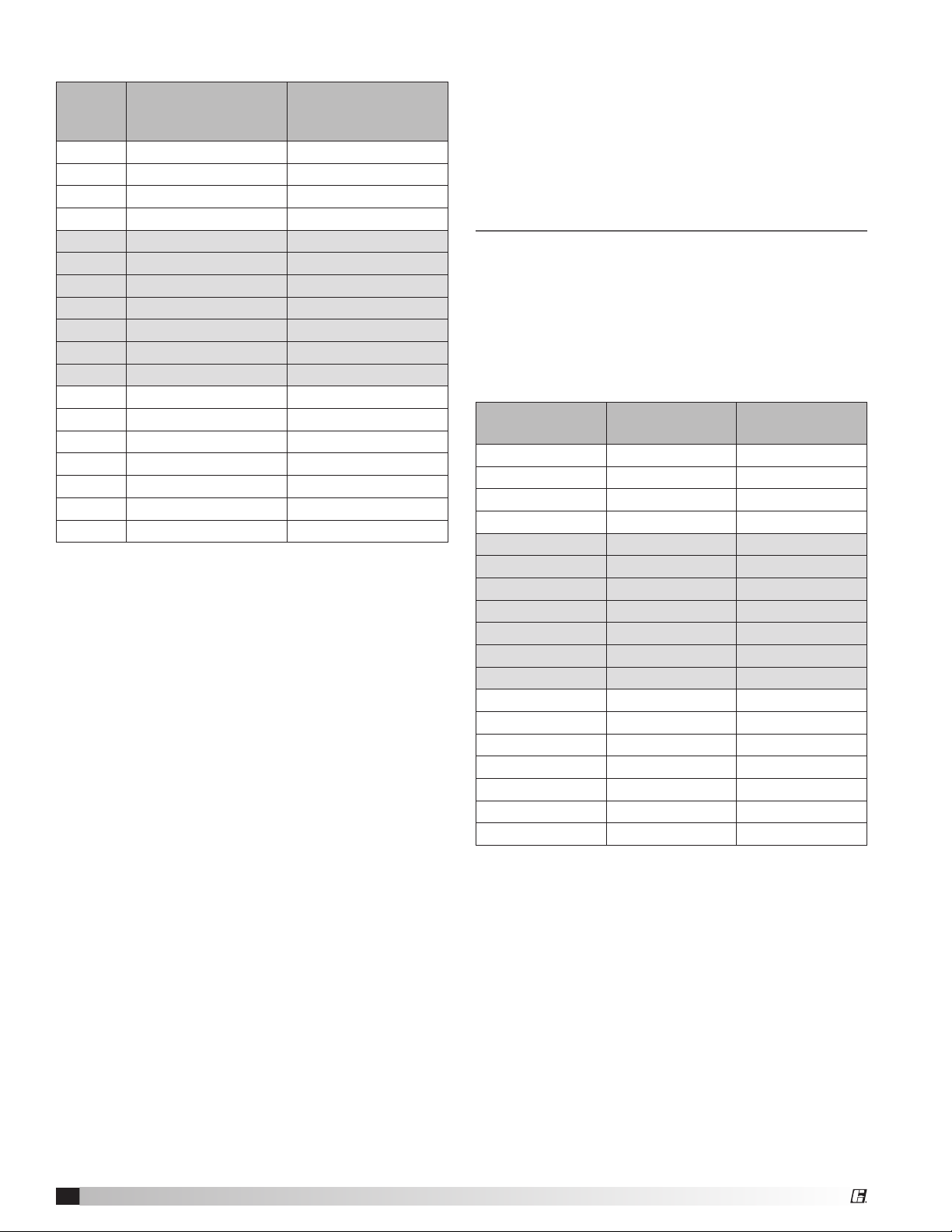

Wash Cycle

Unit Size

02-03 7.2 .36

02-04 9.6 .48

02-05 12.0 .60

02-06 14.4 .72

04-03 14.4 .72

04-04 19.2 .96

04-05 24.0 1.20

04-06 28.8 1.44

04-07 33.6 1.68

04-08 38.4 1.92

04-09 43.2 2.16

06-03 21.6 1.08

06-04 28.8 1.44

06-05 36.0 1.80

06-06 43.2 2.16

06-07 50.4 2.52

06-08 57.6 2.88

06-09 64.8 3.24

Detergent Dispenser

From the pump located on the base of the detergent

dispenser, connect a ½-inch piping connection for the

detergent supply to the 1½-inch water supply line. A

quarter turn ball valve (by others) can be installed on

this line if necessary for servicing. The connection of

the ½-inch detergent supply line to the 1½-inch water

supply line should be made within 5 feet of the cabinet

assembly.

Water Flow

Rate (gpm)

Wash Cycle

Detergent Flow

Rate (gpm)

Plumbing

Once all system components are installed, plumbing

connections for the system can be made. It is

recommended that plumbing connections be done

prior to making electrical connections.

From the building, a 1½- or 2-inch (refer to drawings)

hot water line is required for connecting the wash

system. Recommended water temperature is 140˚F

at 45 psi pressure. Refer to the chart on this page

for information on water and detergent quantity

requirements. Install the quarter turn ball valve

(provided) at the incoming water source to allow the

water to be turned off for servicing. Next, install the

strainer (provided), backflow preventer (provided),

pressure gauge (provided), and solenoid valve

(provided) respectively. Locate these items along

the incoming water line in a location convenient for

inspection/servicing.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

Cabinet Assembly

The unit is supplied with two (2) 1¼- or (2) 1½-inch

wash headers located at the top of the cabinet

assembly. Connect the water supply line to both of the

wash headers at the top of the cabinet. Bring a 3-inch

waste water drain piping connection with P trap to the

drain pipe on the side of the cabinet assembly. The

trap drain line water column for the drain should be

sized for the total system resistance plus 1 in. wg.

5

Page 6

Electrical

Once all system components are installed plumbing

connections for the system can be made. It is

recommended that plumbing connections be done

prior to making electrical connections.

CAUTION

RISK OF ELECTRIC SHOCK. All wiring to be done

by qualified personnel only.

NOTE

All wiring must be done according to the equipment

data plate information, NEC (National Electrical Code

NFPA 70), and local codes.

NOTE

All wiring must be permanently installed in conduit.

Under no circumstances should extension cords be

used to connect the source of electrical supply to

the equipment.

NOTE

The system control panel, power pack, and cabinet

assembly housing to a structural steel or earth

ground. The detergent pump motor and solenoid

valve must also be appropriately grounded.

Electrostatic Cell Wiring

Using the supplied red high voltage cable in a

dedicated conduit line, connect the terminal point of

the ionizer portion of the cells to the Ionizer terminal in

the system power pack. Using the supplied blue high

voltage cable in a separate dedicated conduit line,

connect the terminal point of the collector portion of

the cells to the collector terminal in the system power

pack (See FIGURE 1).

Figure 1

Red high voltage cable

from Power Pack

Blue high voltage cable

from Power Pack

Knockout locations for conduit connections to carry

the high voltage cables are located at the top and

side of the system power pack and the sides of the

terminal box on top of the cabinet assembly. Use a

knockout punch to open holes for minimum 1/2-inch

conduit. Use caution to keep the system power pack

and terminal box interiors free of scraps and other

debris.

NOTE

50 feet of each the red and blue high voltage cable

are provided with the unit. Under no circumstances

should the high voltage cable be spliced or

terminated at locations other than the specified

terminal points. If longer lengths of high voltage

cable are required for installation, consult the

manufacturer.

Once conduit is in place and high voltage cable has

been run, terminate the high voltage cables at the

power pack by stripping approximately 3/8-inch

of insulation from each wire and attach a supplied

terminal ring to each. Securely attach the terminal

ring end of the red cable to the Ionizer terminal in

the power pack and the terminal ring end of the

blue cable to the collector terminal in the power

pack (See FIGURE 2). After the connections are

made, completely coat the terminal connection with

minimum 1/4-inch thick layer of silicone caulk (See

FIGURE 3).

Figure 2

Conduit with

bushing

Blue

Ring

terminal

AIR

FLOW

AIR

Airflow

FLOW

AIR

FLOW

NOTE

Do not connect the ends of the high voltage cable to

the terminal points until all conduits are installed and

the high voltage cable is run.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

6

Figure 3

Silicone

caulk

Collector

Ionizer

Cable must pass

through clamp

Red

Page 7

Terminate the other end of the high voltage cables

at the system cabinet on the unit housing. Ensure

enough cable is run to reach approximately 2 inches

past the high voltage spark plug terminal point on the

upper most electrostatic collector. Slide the silicone

boot over the end of the high voltage cable and strip

approximately 3/4 inch of insulation from the end of

the cable. Fold the exposed wire down and back over

the insulated end and tightly crimp on the supplied

terminal connection (See FIGURE 4). Slide the silicone

boot back over the terminal end of the cable and

firmly press onto the end of the high voltage spark

plug terminal point until the connection snaps into

place.

Figure 4

Strip 3/4 inch insulation

from cable

Fold wire down and back

Lay wire in terminal and

clamp tightly

Connect the power pack to the system control

panel using 14 gauge wire. Wire terminals 1, 2, and

3 in the power pack to terminals 1TB17, 2TB4, and

ground, respectively, in the system control panel. Wire

terminals 6, 7, 8, and 9 in the power pack to terminals

1TB16, 1TB18, 1TB15, and 1TB19, respectively, in the

system control panel.

Connect the junction box on top of the system cabinet

to the system control panel using 14 gauge wire.

Connect terminals 5TB1 and 5TB2 (access door safety

interlock) to terminals 1TB4 and 1TB13, respectively,

in the system control panel. Also connect terminals

5TB5, 5TB7 (upstream wash motor), 5TB8, and 5TB10

(downstream wash motor) to terminals 1TB21, 2TB18,

1TB22, and 2TB19, respectively, in the system control

panel.

NOTE

The system control panel is furnished with prewired circuits that can be interfaced/interlocked

with a make-up air unit, remote start/stop, remote

enunciator panel, fire suppression system, and/or

damper control. Please refer to the plumbing and

electrical schematics section for details on wiring

these components.

Slide silicone boot over

terminal

Exhaust Fan Motor Wiring

This unit is furnished with a remote-mounted motor

starter and an ON/OFF disconnect switch, mounted

adjacent to the fan and factory wired to the fan motor.

A three phase electrical supply must be field wired to

the motor starter, and from the motor starter to the

ON/ OFF disconnect switch. Refer to the applicable

fan installation manual for detailed instructions on

wiring the fan.

System Control Panel Wiring

Run a 120 volt, 30 amp service with 12 gauge wires to

the system control panel connecting to terminals L1

(hot), L2 (common) and ground.

Connect the detergent pump, using 14 gauge wire, to

the system control panel, terminals 1TB23 and 2TB20.

Ensure the detergent pump motor is adequately

grounded. Also connect terminals 6TB1, 6TB2, and

6TB3 at the detergent dispenser to terminals 3TB4,

4TB4, and 3TB15, respectively, in the system control

panel.

Connect the water supply line solenoid valve, using

14 gauge wire, to the system control panel, terminals

1TB26 and 2TB23. Ensure the solenoid valve is

adequately grounded.

Initial System Start-Up

1. Turn off fan at motor starter disconnect, also turn

off Power Pack.

2. Turn on System Control at disconnect switch and

push green “Start” button. At this point green

normal operation light should be on.

3. Turn on Power Pack, red and clear lights should be

on at Power Pack and at System Control. If lights

are not on, check to make sure door interlock

switch is made. With high voltage on, check

meter reading at Power Pack, it should read 12kv

and approximately 1mA per linear feet of ionizercollector cell. Random electrical arcing in the

collector cells is normal at initial power up. This

will settle down.

4. Turn fan on at disconnect.

5. System should now be in normal run mode.

6. Turn off System Control at disconnect switch.

System Control, Power Pack and fan should now

be off. Turn on System Control at disconnect

switch and push green “Start” button. System

control, powerpack, fan (entire system) should now

be on.

7. Make sure all water and detergent line manual

valves are open, then initiate the wash mode by

depressing the black manual wash button, yellow

wash in process light should be on. All other lights

should be off. See manual for wash sequence.

There is a 5 minute fan coast down time prior to

wash cycle starting. Check all piping for leaks.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

7

Page 8

Manual versus Auto Operation

Greenheck recommends the system be set up to

operate automatically. This will assure routine wash

cycles are completed, which will enhance system

reliability. Once automatic operation is set up, the

system will start-up, operate and shutdown at the

prescheduled times for each day of the week. The

wash will initiate automatically, also as prescheduled.

If manual operation/washing is required, follow the

instructions under “washing” in the operation section.

Automatic Operation

(E-1012 operator Interface is located in top left corner

of System Control door).

System Operating Schedule

• Scroll down to day of the week, scroll over to off,

press enter to switch day on or off.

• Scroll over to start hour, use numbered keypad to

enter hour in military time, press enter.

• Scroll over to start minute, use numbered keypad

to enter minutes, press enter.

• Scroll over to stop hour, use numbered keypad to

enter hour in military time, press enter.

• Scroll over to stop minute, use numbered keypad

to enter minutes, press enter.

• Enter all days of the week Sunday thru Saturday

either on or off, and start stop time.

System Wash Schedule

NOTE

The wash cycle start time must be later than the

system stop time, preferrably within 15 minutes.

• Scroll down to wash start.

• Scroll over to hour, use numbered keypad to enter

hour in military time, press enter.

• Scroll over to minute, use numbered keypad to

enter minutes, press enter.

• Scroll down to day of week.

• Scroll over to off, press enter to switch day on or

off.

• Enter all days of the week Sunday thru Saturday

either off or on.

Setting Clock

• Scroll down to clock.

• Scroll over to enabled, press enter to disable clock

for setting time.

• Scroll down to hour, use numbered keypad to enter

hour in military time, press enter.

• Scroll over to minute, use numbered keypad to

enter minutes, press enter.

• Scroll over to second, use numbered keypad to

enter seconds, press enter.

• Scroll down to month, day and year.

• Enter month using numbered keypad, press enter.

• Scroll over to day, using numbered keypad enter

day, press enter.

• Scroll over to year, using numbered keypad enter

year, press enter.

• Scroll up to clock.

• Scroll over to disabled; press enter to enable the

clock.

Daylight Savings Time

Scroll down to day light savings, scroll down to

enabled, press enter to switch enable or disable day

light savings time. Start and stop times can then

be set once the daylight savings setting has been

entered.

Operation

Power to the system is controlled by the disconnect

knob in the upper right corner of the control system.

The disconnect must be in the ON position for the

system to operate. The operation of the Power Play

system falls into four main categories:

1. NORMAL: System collects smoke and grease

particulate from the airstream

NOTE

As a safety precaution, the system will only operate

in the NORMAL mode when the access door of the

unit is completely closed and the plunger of the

safety switch is fully extended through keeper. If the

plunger of the safety switch is not fully extended,

the green NORMAL light on the control system will

illuminate, but the red POWER light and clear HIGH

VOLTAGE on the control panel and the red POWER

light and clear HIGH VOLTAGE light on the power

supply will not illuminate. During operation in the

NORMAL mode, depressing the EMERGENCY STOP

button will immediately shut down the system. The

red light adjacent to the EMERGENCY STOP button

will illuminate until the button is released. The system

will continue to operate in the NORMAL mode after

the EMERGENCY STOP button is released.

Figure 5: NORMAL Mode Indicating Light and

Component Status

Indicating Light Status

Control System

- NORMAL (green): On

- POWER SUPPLY (red): On

- POWER SUPPLY (clear): On

Power Supply

Component Status

- System Fan: On

- High Voltage Power Supply: On

- Wash Motors: Off

- Solenoid Valve: Closed

- Detergent Pump Motor: Off

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

8

Page 9

Figure 6: WASH Mode Indicating Light and

Component Status

Indicating Light Status

Control System

- WASH (yellow): On

WASH Mode Steps and

Component Status

Delay Period (5 min.)

- High Voltage Power Supply: Off

- Wash Motors: Off

- Solenoid Valve: Closed

- Detergent Pump: Off

- Blower: Off

Wash (2 min.)

- High Voltage Power Supply: Off

- Wash Motors: On

- Solenoid Valve: Open

- Detergent Pump: On

- Blower: Off

Soak (2 min.)

- High Voltage Power Supply: Off

- Wash Motors: Off

- Solenoid Valve: Closed

- Detergent Pump: Off

- Blower: Off

Rinse (2 min.)

- High Voltage Power Supply: Off

- Wash Motors: On

- Solenoid Valve: Open

- Detergent Pump: Off

- Blower: Off

Drip Dry (10 min.)

- High Voltage Power Supply: Off

- Wash Motors: Off

- Solenoid Valve: Closed

- Detergent Pump: Off

- Blower: Off

Fan Dry (60 min.)

- High Voltage Power Supply: Off

- Wash Motors: Off

- Solenoid Valve: Closed

- Detergent Pump: Off

- Blower: On

2. WASH: System goes through cycles to clean and

dry dirty ionizing-collecting cells

3. RESET: Returns the system to the NORMAL mode

if a WASH cycle is accidentally initiated

4. SLEEP: Waiting period after a WASH mode

Washing

Power Play’s PLC control is preprogrammed to

manually initiate and cycle through the wash, rinse,

dry and system standby steps, as described below.

To initiate a wash manually, with the system in the

NORMAL mode, depress the WASH push-button.

The WASH mode consists of 6 steps. FIGURE 6

describes the indicating light and system component

status while operating in the WASH mode. After the

WASH/FAN DRY cycle is completed, the system is

programmed to shut down and manual start next

morning. As indicated in FIGURE 6, there is a 5 minute

delay period, after wash initiation, before the wash

process begins. If the WASH cycle is accidentally

initiated, the operator may reset the system during

the 5 minute delay period, and the system will return

to NORMAL operation. If the system is reset after

the 5 minute delay period, the WASH cycle will be

accelerated and the system will return to the NORMAL

mode after the WASH cycle is complete.

During operation in the WASH mode, depressing

the EMERGENCY STOP button will immediately

shut down the system. The red light adjacent to

the EMERGENCY STOP button will illuminate until

the button is released. The system will continue to

operate in the WASH mode after the EMERGENCY

STOP button is released.

Reset Mode

On rare occasions, it may be necessary to reset

the system. This may be required if a WASH cycle

is inadvertently initiated. As indicated previously in

FIGURE 6, there is a 5 minute delay period after the

WASH button is pushed, before the wash process

begins. If the WASH cycle is accidentally initiated, the

operator may reset the system during the 5 minute

delay period, and the system will return to NORMAL

operation. If the system is reset after the 5 minute

delay period, the WASH cycle will be accelerated and

the system will return to the NORMAL mode after the

WASH cycle is complete.

FIGURE 7 on page 10 illustrates the sequence of

events that occurs when the system is reset during

the different stages of system operation. When the

system is in the RESET mode, the white RESET light

will illuminate on the control panel. It is recommended

that the system be programmed so that system on/

off and wash cycles are automatically initiated. This

programming will be done by the factory engineer

during commissioning.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

9

Page 10

Normal

Wash Delay

Wash

Soak

Rinse

Drip and Fan Dry

RESET

RESET

RESET

Figure 7 - RESET Mode Sequencing

Maintenance

Routine service is required in order to ensure optimum

performance and reliability of the system.

A. Aluminum Mesh Pre-filters & Post Filters: These

metal filters in the precipitator should be removed

and thoroughly cleaned on a minimum two (2)

week interval, removing any grease and particulate

buildup.

B. Ionizing-Collecting Cells: The ionizing-collecting

cells should be inspected for grease build-up on a

monthly basis. This monthly inspection should be

done after the system has completed a wash cycle.

If grease build-up is apparent, remove cells and

clean manually. The cells should be removed and

manually cleaned every 6 months minimum.

C. Safety Bag Filters: Safety filters change out

frequency depends on the volume of cooking.

Change filters every 3 months or prior to an

increase in resistance that affects hood capture

efficiency. See ordering instructions in this manual.

Detergent Dispenser

General: The detergent dispenser supplies detergent

to the wash system during the WASH mode. The

detergent dispenser is designed to operate for

the entire duration of the WASH mode (2 minutes),

and the amount of detergent delivered is regulated

by the flow control valve. The detergent reservoir

holds approximately 55 gallons of detergent. The

DETERGENT LOW light will illuminate when the

amount of detergent in the reservoir drops below eight

(8) gallons. The reservoir should be refilled as soon as

possible after the DETERGENT LOW light comes on,

to ensure that detergent is dispensed and to prevent

pump damage.

NOTE

The detergent pump motor will not operate while the

detergent low light is illuminated.

Adjustments

The liquid level sensor was setup during field

inspection and should not require adjustment.

Flow Control Valve Adjustment

The detergent dispenser will be adjusted during

commissioning to a detergent-to-wash water ratio

of 1:20, meaning one gallon of detergent is used

for every 20 gallons of wash water used. In some

applications, the amount of detergent used may

need to be increased. This may be done by adjusting

the flow control valve on the upper left front of the

detergent dispenser.

Adjustments to the flow control setting should be

done in small increments over a period of several

wash cycles. Turning the knob clockwise, increases

the amount of detergent used during a wash cycle.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

10

Ionizing section

of collector faces

upstream

Airflow

Figure 8

D. Activated Carbon Panels: Carbon panel change

out frequency is also dependent on the volume

of cooking. Replace when an increase in odor

breakthrough is first noticed. Change out should

range between 3 and 6 months.

E. System Fan/Motor: Fan, motor and drives should

be inspected, serviced and cleaned according to

the manufacturer’s instructions, annually.

F. Wash System Detergent: Greenheck specifies

GLT-33 detergent, manufactured by Green Ladder

Technologies. This detergent has been specially

formulated for this type equipment, and will

help ensure successful operation and optimum

performance. GLT-33 should also be used to

manually clean mesh filters and ionizing-collecting

cells. Substituting other types of detergent may

result in decreased system performance, system

shutdown or voided limited warranty. See detergent

ordering instruction sheet in this manual.

Page 11

To access the pre- and post-mesh filters and ionizing

collecting cells, follow these instructions.

1. Rotate the disconnect knob on the upper right

hand corner of the System Control to the OFF

position. “Lock Out” the system by flipping the red

lever in the handle outward and securing it with a

padlock.

2. Open the access door by turning the knob on the

red safety switch until the plunger is fully retracted,

then unscrew the black knobs to unlatch the door.

3. Slide the metal mesh filters from the tracks

4. Thoroughly clean the metal mesh filters using hot

water and a GLT-33 detergent.

5. Reinstall the filters in the tracks.

6. Remove the collector cells retaining brackets using

a 7/16-inch wrench.

7. Remove the red and blue high voltage cables and

jumper cables by firmly grasping the red boots and

pulling them from the high voltage plugs.

8. Carefully remove a cell from the cabinet. Each 2 ft.

cell weighs approximately 65 lbs., so use caution

when handling. Use care not to bend or dent the

collecting plates or framework.

9. Carefully inspect the cell for bent collector plates.

Bent plates may be carefully straightened by hand,

using needle-nose pliers.

10. Inspect the cell for residual grease that was not

removed during the wash process. Excessive

grease buildup indicates that the cells need to be

removed from the cabinet and thoroughly cleaned

manually, following the procedures under IonizingCollecting Cells in Maintenance.

11. Reinstall the cell to the location from which it was

removed. The serrated ionizing blades of the cell

must be facing upstream. There is an airflow arrow

on the cell end plate.

12. Reconnect the high voltage cables, and cell

retaining brackets.

13. Close the access door completely, engage the

door latch, and turn the knob on the red safety

switch until the plunger is fully extended.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

11

Page 12

WATER COLUMN

ESP DRAIN PAN

3 INCH DRAIN LINE

1/2-INCH DETERGENT

DISPENSER LINE

WASH MANIFOLDS

SOLENOID VALVE

BACKFLOW

PREVENTER

PRESSURE GAUGE

0-100 PSI

55 GALLON

DETERGENT DISPENSER

Y STRAINER

BALL VALVE

INPUT POWER

1/2-INCH DETERGENT

DISPENSER LINE

WASH MANIFOLDS

SOLENOID VALVE

BACKFLOW

PREVENTER

PRESSURE GAUGE

0-100 PSI

55 GALLON

DETERGENT DISPENSER

140° F WATER SUPPLY LINE

(BY OTHERS)

Y STRAINER

BALL VALVE

Plumbing and Electrical Schematics

FIELD WIRING DIAGRAM

___ VAC, 3 PH, __ HZ

L3

L2 L1

EXHAUST

FAN MOTOR

__ HP

NEMA 3R COMBINATION

MOTOR STARTER

DISCONNECT

MAIN

SOLENOID

VALVE

HOT

NEUTRAL

GROUND

DETERGENT

PUMP

MOTOR

HOT

NEUTRAL

GROUND

INPUT POWER

___ V, __ HZ, 1 PH.

__ AMP SERVICE

SYSTEM CONTROL

ENCLOSURE

HOT

NEUTRAL

GROUND

#2

MANIFOLD

DRIVE

MOTOR

HOT

NEUTRAL

GROUND

#1

MANIFOLD

DRIVE

MOTOR

HIGH VOLTAGE CABLES

TO ELECTROSTATIC CELLS

RUN IN SEPARATE METALLIC CONDUIT

IONIZER CABLES IN ONE CONDUIT

COLLECTOR CABLES IN ONE CONDUIT

WASH WATER PLUMBING SCHEMATIC

WASH MANIFOLDS

1/2-INCH DETERGENT

DISPENSER LINE

IONIZER (RED CABLE)

COLLECTOR (BLUE CABLE)

SOLENOID VALVE

55 GALLON

DETERGENT DISPENSER

Y STRAINER

POWER

SUPPLY

PRESSURE GAUGE

0-100 PSI

BACKFLOW

PREVENTER

DOOR SAFETY

INTERLOCK

BALL VALVE

140° F WATER SUPPLY LINE

(BY OTHERS)

H.V. POWER SUPPLY SHUT DOWN

FIRE SYSTEM N/C DRY CONTACT

THAT OPENS WHEN FIRE SYSTEM ACTIVATES.

DRAIN LINE PLUMBING SCHEMATIC

ESP DRAIN PAN

3 INCH DRAIN LINE

WATER COLUMN

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

12

Page 13

Fan Wiring

C

120 VAC

OL

FAN MOTOR

L3

L1

L2

T3

T1

T2

XOO

OOX

1TB28

POWER PLAY

322CR1

CONTROL PANEL

4201

1TB27

13 14

4202

G

X1 X2

F3

(BY OTHERS)

EVENT OF A FIRE

CLOSES IN THE

DRY CONTACT

FIRE SYSTEM N/O

6 4

FF

F F

.

F1 F2

___V, 60HZ, 3PH

INPUT POWER

OFF AUTO

HAND

F3

F

F

F

EXHAUST FAN

INPUT POWER

___V, 60HZ, 3PH

F

F

F

HAND

OFF AUTO

XOO

OOX

1TB27

F3

6 4

322CR1

4201

13 14

4202

1TB28

F1 F2

120 VAC

OL

FF

DENOTES TERMINAL CONNECTION IN POWER PLAY CONTROL PANEL

DENOTES FIELD WIRING

F

L1

L2

L3

.

C

G

X1 X2

T1

T2

T3

FAN MOTOR

MAKE-UP AIR UNIT (BY OTHERS)

POWER PLAY

CONTROL PANEL

322CR2

F

F

42224221

1TB301TB29

24

23

POWER PLAY

CONTROL PANEL

F F

FIRE SYSTEM N/O

DRY CONTACT

CLOSES IN THE

EVENT OF A FIRE

(BY OTHERS)

INPUT POWER

___V, 60HZ, 3PH

F F

F

F

F

F

.

___ VAC

120 VAC

OFF AUTO

L1

L2

L3

OL

T1

.

T2

T3

C

F

FAN MOTOR

F

FIRE SYSTEM N/C

DRY CONTACT

OPENS IN THE

EVENT OF A FIRE

(BY OTHERS)

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

13

Page 14

WATER SOLENOID VALVE

120V, 60, 1PH

INRUSH (VA) 21

HOLD (VA) 12

(OPTIONAL BY CUSTOMER)

SYSTEM DAMPER CONTROL

4202

4201

1TB28

322CR1

1TB27

13 14

EXHAUST FAN

CONTROL TERMINALS

1TB29

4221

322CR2

414M

M

2TB23

1TB26

416SOL

1TB25

2TB22

4162

1001

4142

1001

SYSTEM FAN CONTROL

H.V. POWER SUPPLY SHUT DOWN

SEE SHEET #2

Plumbing and Electrical Schematics

HIGH VOLTAGE CABLE

SUPPLIED BY GREENHECK

50' BLUE

RUN IN SEPARATE CONDUIT

BLUE

RED

IONIZER

COLLECTOR

50' RED

HIGH VOLTAGE POWER PACK

120V, 60HZ, 1PH

POWER 550 WATTS MAX.

CURRENT 6.5 AMPS MAX.

DETERGENT PUMP MOTOR

1/2 HP, 1725 RPM

120V, 60HZ, 1PH

7.2 FULL LOAD AMPS

DETERGENT LOW LEVEL

AUXILIARY LIGHT

(OPTIONAL BY CUSTOMER)

HOT

COM.

GND.

120V, 60HZ, 1PH, 30A

POWER PACK

HIGH VOLTAGE

1021

1001

GREENHECK

POWER PLAY SYSTEM CONTROL

1

HOT

1283

1061

2

1TB17

1TB4

COM.

1001

2TB4

1281

3

GND.

4

4022

5

1001

6

1283

7

1TB16

1321

1TB18

4062

8

1283

1TB15

1001

9

1341

1TB19

410M

M

4102

1TB23

1121

412PL

X1 X2

1001

2TB20

4TB4

1141

2101

4122

1TB24

1001

2TB21

5TB1

5TB2 1TB13

ESP JUNCTION BOX

ACCESS DOOR

SAFETY INTERLOCK

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

14

5TB5 1TB21

5TB7 2TB18

WASH MOTOR

UP STREAM

120V, 60HZ, 1PH

1/20 HP, 15 RPM

5TB8 1TB22

5TB10 2TB19

1/20 HP, 15 RPM

120V, 60HZ, 1PH

DOWN STREAM

WASH MOTOR

BLU

BRN

6TB1 3TB4

DETERGENT DISPENSER

BLK

6TB2

6TB3 3TB15

DETERGENT LEVEL

SENSOR

Page 15

WATER SOLENOID VALVE

120V, 60, 1PH

INRUSH (VA) 21

(OPTIONAL BY CUSTOMER)

SYSTEM DAMPER CONTROL

HOLD (VA) 12

H.V. POWER SUPPLY SHUT DOWN

ANSUL N/C DRY CONTACT

THAT OPENS IN THE

EVENT OF A FIRE

(OPTIONAL BY CUSTOMER)

NORMAL OPERATION

SYSTEM START

SYSTEM STOP

PRIMARY POWER

H V POWER SUPPLY

H V POWER SUPPLY

HIGH VOLTAGE

WASH IN PROCESS

MANUAL WASH

RESET INDICATOR

RESET

DETERGENT LOW LEVEL

414M

M

4142

1TB25

1001

322CR1

1TB27

4201

2TB22

13 14

416SOL

4162

1TB28

4202

1TB26

1001

2TB23

322CR2

1TB29

4221

24

23

3081

1TB31

3082

1TB30

4222

1TB32

1001

G

428PL

3161

3161

7TB15

X2

X1

1001

7TB14

2121

250PB

1121

1121

43

7TB9

2121

7TB10

2141

252PB

1121

1121

1TB-33

4381

3 4

7TB11

2141

7TB12

1001

R

426PL

1341

1341

7TB3

X2

X1

1001

2TB-25

4382

424PL

7TB4

1001

C

1321

1321

7TB1

X2

X1

1001

7TB2

1001

Y

430PL

3181

3181

7TB17

X2

X1

1001

7TB16

2041

246PB

1121

1121

3 4

7TB5

2041

7TB6

1001

W

432PL

3201

3201

7TB19

X2X1

1001

7TB18

2081

248PB

1121

1121

3 4

7TB7

2081

7TB8

1001

B

434PL

4122

4122

7TB21

X2

X1

OPTIONAL REMOTE CONTROL

1001

7TB20

SYSTEM FAN CONTROL

SEE SHEET #2

EXHAUST FAN

CONTROL TERMINALS

MAKE-UP FAN

CONTROL TERMINALS

SEE SHEET #2

S1

OPTIONAL SYSTEM AUTO START

N1

(TEMPERATURE INTERLOCK)

FIRE SUPPRESSION WIRING NOTES

IF WIRED, AS SHOWN AND THE FIRE SUPPRESSION SYSTEM DISCHARGES.

Grease Grabber™ Power Play Kitchen Exhaust Pollution Control System

3. THE HIGH VOLTAGE POWER SUPPLY WILL SHUT OFF.

1. THE MAKE UP AIR FAN REMAINS ON, OR STARTS

2. THE SUPPLY FAN WILL SHUT OFF

15

Page 16

Maintenance Log

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the shipment date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

AMCA Publication 410-96, Safety Practices for Users and Installers of Industrial and Commercial Fans, provides additional

safety information. This publication can be obtained from AMCA International, Inc. at: www.amca.org.

®

Phone:(715)359-6171•Fax:(715)355-2399•E-mail:gfcinfo@greenheck.com•Website: www.greenheck.com

474754 • Grease Grabber™ Power Play, Rev. 1, January 2012 Copyright 2012 © Greenheck Fan Corp.

16

Loading...

Loading...