Page 1

Part Number 474753

®

Grease Grabber™ Triple Play

Kitchen Exhaust Pollution Control System

Installation, Operation and Maintenance Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the

product described. Protect yourself and others by observing all safety information. Failure to comply with instructions

could result in personal injury and/or property damage! Retain instructions for future reference.

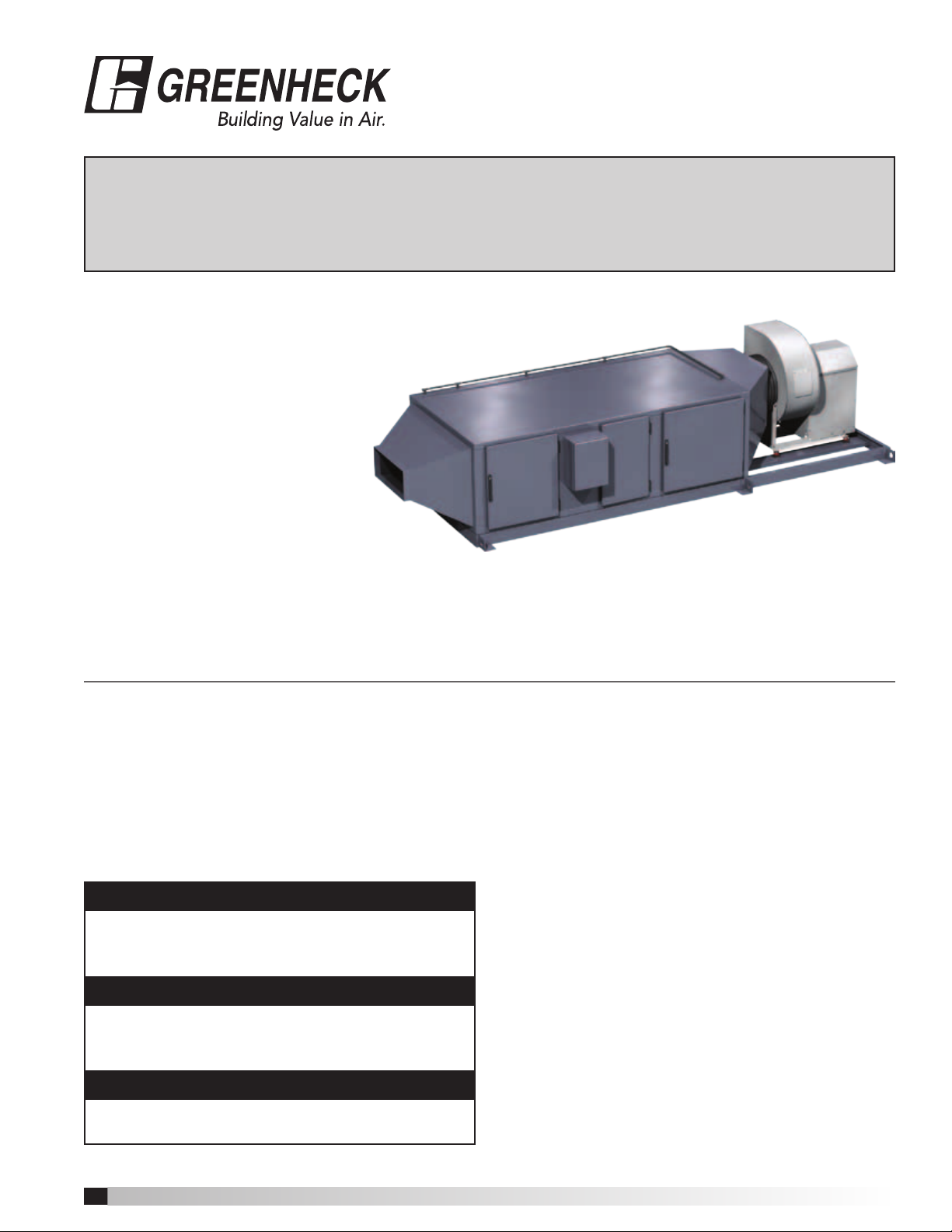

Grease Grabber™ Triple Play

The Greenheck Grease Grabber™ Triple Play is a preengineered mechanical filtration pollution control unit

with integral exhaust fan (available without

exhaust fan as an option). The unit is

designed to remove grease and smoke

particles as well as odor molecules

from the kitchen exhaust airstream.

This installation manual covers

procedures for receiving, installing, and

maintaining the filtered section of the

unit.

For additional instructions and maintenance

information on the integral exhaust fan, when

applicable, refer to the fan nameplate to determine model

type and visit www.greenheck.com to download the

corresponding manual.

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards.

Other considerations may be required if high winds

or seismic activity are present. If more information

is needed, contact a licensed professional engineer

before moving forward.

DANGER

Always disconnect power before working on or near

a fan. Lock and tag the disconnect switch or breaker

to prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive

atmospheres.

• Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in

Canada.

• The rotation of the fan wheel is critical. It must

be free to rotate without striking or rubbing any

stationary objects.

• Fan motor must be securely and adequately

grounded.

• Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

• Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

• Verify that the power source is compatible with the

equipment.

• Never open access doors to a duct while the fan is

running.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

1

Page 2

Receiving

Upon receiving the product check to make sure all

items are accounted for by referencing the packing list

ensuring all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notification on the delivery receipt acknowledging

any damage to the product. All damage should be

noted on all the copies of the bill of lading which

is countersigned by the delivering carrier. A Carrier

Inspection Report should be filled out by the carrier

upon arrival and filed with the Traffic Department.

If damaged upon arrival, file claim with carrier. Any

physical damage to the unit after acceptance is not the

responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative

to arrange for obtaining missing parts. Sometimes it

is not possible that all items for the unit be shipped

together due to availability of transportation and truck

space. Confirmation of shipment(s) must be limited

to only items on the bill of lading. Filters are shipped

on a separate skid in their original packaging. Do not

remove factory packaging or install filters until just

prior to commissioning. Remove all other shipping/

packing materials including fan tie down straps.

Handling

Units are to be rigged and moved by the lifting

brackets provided or by the skid when a forklift is

used. Location of brackets varies by model and size.

Handle in such a manner as to keep from scratching

or chipping the coating. Damaged finish may reduce

ability of unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration

of the unit during storage. The user assumes

responsibility of the unit and accessories while in

storage. The manufacturer will not be responsible

for damage during storage. These suggestions are

provided solely as a convenience to the user.

INDOOR

The ideal environment for the storage of units and

accessories is indoors, above grade, in a low humidity

atmosphere which is sealed to prevent the entry of

blowing dust, rain, or snow. Temperatures should

be evenly maintained between 30°F (-1°C) and

110°F (43°C) (wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To

avoid “sweating” of metal parts allow cold parts to

reach room temperature. To dry parts and packages,

use a portable electric heater to get rid of any

moisture buildup. Leave coverings loose to permit air

circulation and to allow for periodic inspection.

OUTDOOR

Units designed for outdoor applications may be stored

outdoors, if absolutely necessary. Roads or aisles for

portable cranes and hauling equipment are needed.

The unit should be placed on a level surface to

prevent water from leaking into it. The unit should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To

minimize water accumulation, place all unit parts on

blocking supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during

Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every

three months, the fan motor should be energized. If

paint deterioration begins, consideration should be

given to touch-up or repainting. Fans with special

coatings may require special techniques for touch-up

or repair.

Machined parts coated with rust preventive should

be restored to good condition promptly if signs of

rust occur. Immediately remove the original rust

preventive coating with petroleum solvent and clean

with lint-free cloths. Polish any remaining rust from

surface with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe

thoroughly clean with Tectyl® 506 (Ashland Inc.) or

the equivalent. For hard to reach internal surfaces or

for occasional use, consider using Tectyl® 511M Rust

Preventive or WD-40® or the equivalent.

Removing from Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion, until the equipment

goes into operation. Prior to installing the unit and

system components, inspect the unit assembly to

make sure it is in working order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories for

tightness.

2. Rotate the fan wheel(s), where applicable, by

hand and assure no parts are rubbing.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

2

Page 3

Table of Contents

Installation .................................4

Rigging/Placing Equipment ..................4

Duct Connections .........................4

Electrical Connections ......................4

Fire System ..............................5

Filter Installation ...........................5

Operation ..................................5

Start-Up .................................5

Filter Status Indicator ......................5

Filter Replacement .........................6

Carbon Panel Replacement .................6

Maintenance ...............................6

Regular Scheduled Maintenance .............6

Replacement Filter/Parts Ordering ............6

Figures #1 and #2 ...........................7

Wiring Diagram ........................... 8-9

Maintenance Log ........................ 10-11

Warranty ..................................12

Filter stages 1, 2 and 3 are mechanical air filters of

progressive filtration efficiency that retain the smoke

and grease particles.

Each filter stage is monitored by an individual

pressure switch that signals when a particular filter

stage needs replacing. The pressure switches are

located inside the Pressure Switch Enclosure located

on the access door side of Triple Play housing,

between filter stages 2 and 3. When a filter stage

requires replacement, a signal from the pressure

switch lights an LED located on the remote mounted

Filter Status Indicator. This enclosure must be field

mounted in an area convenient for monitoring by the

cook staff.

System Components

Cabinet Assembly

The unit body is shipped on a common mounting rail

ready for installation. If the unit was ordered with an

exhaust fan, the fan will also be mounted as part of

the cabinet assembly.

Filters

Filter quantity for each filter stage is based on unit

size. A consistent quantity of filters is provided for

each stage of filtration (pre-filter, bag filter, and rigid

final filter). Quantity of carbon panels will vary based

upon unit exhaust rate.

Grease Grabber Triple Play

System Function

Grease Grabber Triple Play is a 3-stage mechanical air

filtration unit, with an additional carbon filter module,

designed for two specific functions:

• Remove smoke/grease particulate from kitchen

exhaust.

• Remove odor molecules from kitchen exhaust.

NOTE

Grease Grabber Triple Play must be connected to a

listed exhaust hood assembly and must be installed

in accordance with local building codes, NFPA 96

and NEC.

NOTE

Grease Grabber Triple Play is not intended for use

with solid fuel cooking appliances.

NOTE

The unit must be installed with a minimum 18 inch

clearance to combustible materials and must be

installed as part of a listed duct assembly.

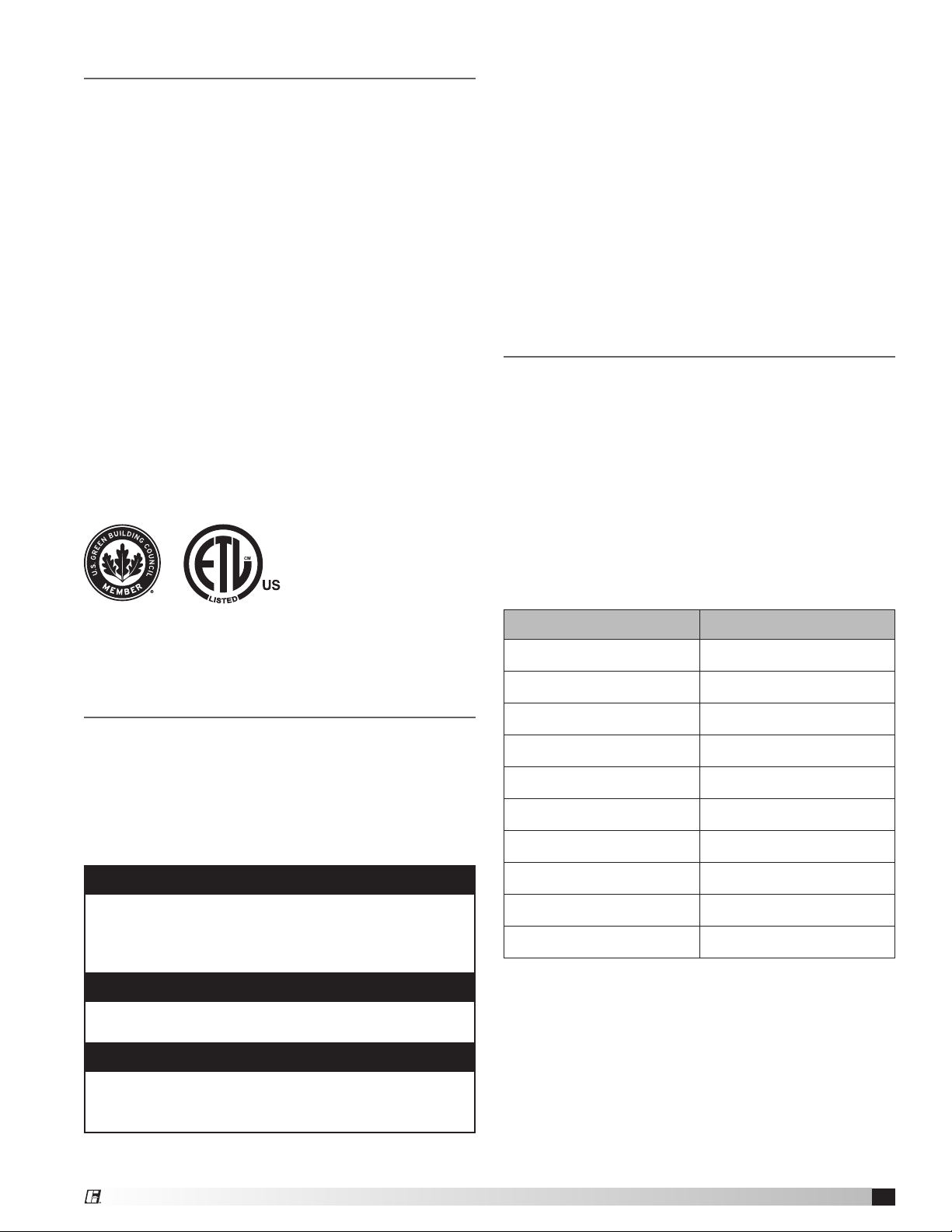

Unit Size Filter Quantity (each)

10-10 1

10-20 2

10-30 3

20-20 4

20-30 6

20-40 8

30-30 9

30-40 12

40-40 16

40-50 20

Remote Status Indicator (See Page 6)

At time of delivery, a remote status indicator is

mounted within the rigid filter section of the unit body.

This item must be removed and mounted remotely in

the cooking area prior to unit start-up.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

3

Page 4

Installation

Rigging/Placing Equipment (See Figure #1)

1. The unit is furnished with lifting lugs at the four

corners and along the length as necessary.

2. Lift into place using all the lifting lugs.

3. Field weight will vary depending upon final

selections such as fan type, accessories, etc.

Approximate weights are shown in the table

below.

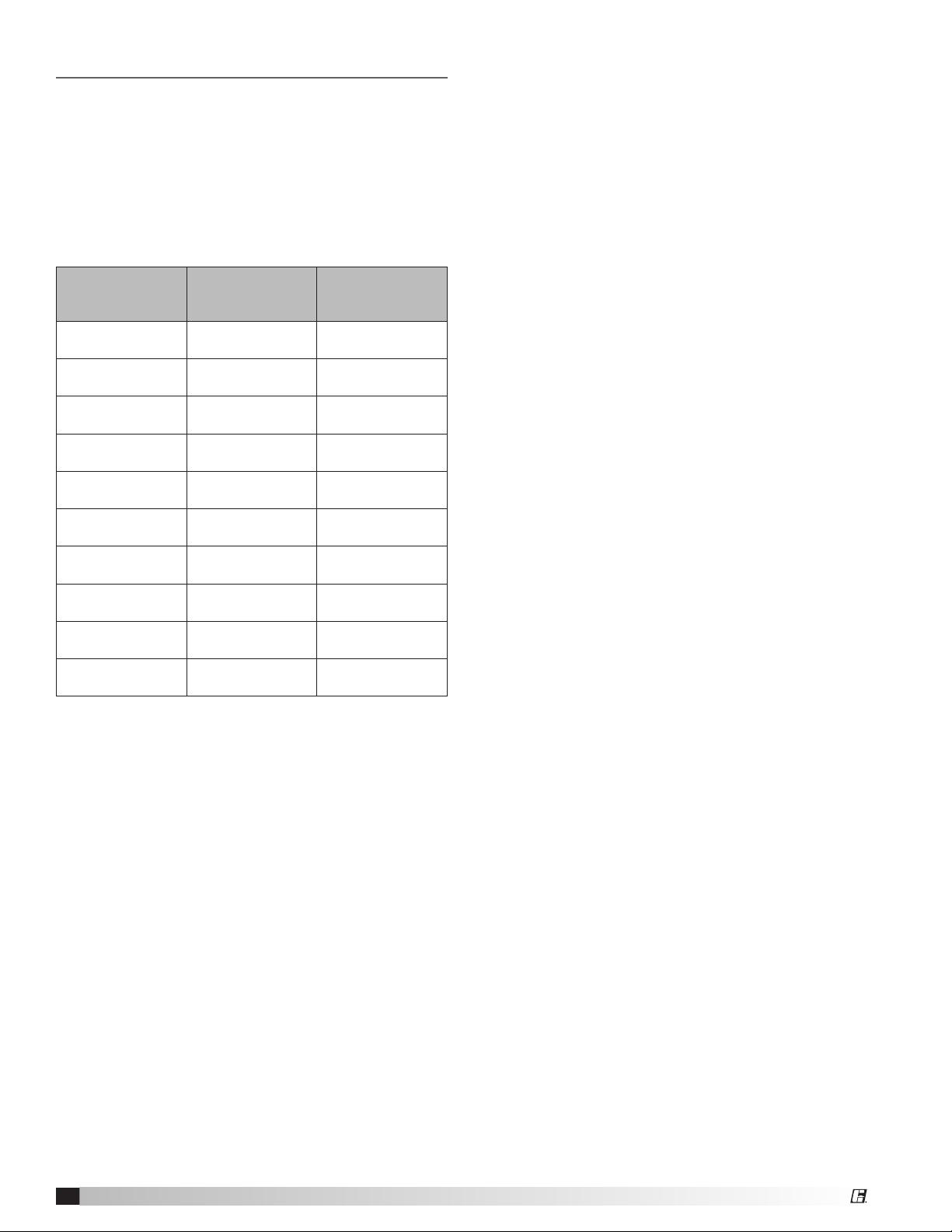

Unit Size

Approximate

Weight (lbs)

Approximate

Weight (kg)

Duct Connections

Ductwork must conform to the IMC and SMACNA

guidelines.

As specified in NFPA 96, Ch. 7.5 (latest edition),

exhaust duct systems must be constructed in the

following manner; unless otherwise specified by the

local authority having jurisdiction (AHJ):

Materials

Ducts shall be constructed of and supported by

carbon steel not less than 1.37 mm (0.054 in.) (No. 16

MSG) in thickness or stainless steel not less than

1.09 mm (0.043 in.) (No. 18 MSG) in thickness.

10-10 1100 500

10-20 1600 727

10-30 2150 977

20-20 2600 1182

20-30 3500 1591

20-40 4200 1909

30-30 4700 2136

30-40 5700 2591

40-40 7300 3318

40-50 8000 3636

4. The unit can be positioned on a base or curb

suitable for this purpose.

5. The unit must be anchored to its base/curb.

6. Alternatively, the unit may be suspended from

an adequate overhead structure, using suitable

undercarriage or hanging rods (by others). If the

unit is suspended by hanging rods, minimum

1/2 inch (12.7 mm) diameter threaded rod is to

be used. All hanger brackets/lifting lugs must be

used to ensure proper support of the unit. The

unit must also be hung level to ensure proper

operation.

7. A service clearance of 36 inches must be

provided on the access door side of the unit.

8. A minimum 18-inch clearance must be

maintained between this unit and any

combustible material.

9. The remote Filter Status Indicator (See Page

6) should be located in an area convenient for

monitoring by the cook staff. For details on wiring

this item, refer to the Electrical Connections

section on this page.

Installation

All seams, joints, penetrations, and duct to hood collar

connections shall have a liquid-tight external weld.

An inlet transition is furnished to match the inlet duct

size. The inlet transition is furnished with a listed duct

access door for inspection and cleaning.

Units intended for indoor mounting are provided with a

UL 762 listed exhaust fan with outlet mounting flange.

Outlet ductwork from the exhaust fan is required to be

per the above mentioned methods unless otherwise

specified by the local authority having jurisdiction

(AHJ).

Electrical Connections

Electrical wiring must conform to the equipment data

plate information and to the NEC and local code

requirements.

Motor

This unit is furnished with a remote-mounted motor

starter and an ON/OFF disconnect switch mounted

adjacent to the fan and factory-wired to the fan motor.

A 3-phase electrical supply must be field wired to the

motor starter and from the motor starter to the ON/

OFF disconnect switch.

Refer to the applicable fan installation manual for

detailed instructions on wiring the fan.

Remote Status Indicator

A single phase electrical supply must be field wired to

the pressure switch enclosure (located on the access

side of the Triple Play housing between filter stages 2

and 3, adjacent to the exhaust fan). For wiring details,

refer to the diagram on pages 8 and 9.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

4

Page 5

Fire System

This equipment is furnished with factory pre-piped

fire suppression nozzles and fusible link detector

brackets. The brand of the system was specified at

time of order (Amerex or Ansul). Factory installation

is according to the Fire System manufacturers

recommendations. Field connection, tanks, controls,

fusible link detectors, and commissioning is provided

and installed, on site, by others. The AHJ may require

additional protection.

Filter Installation (See Figure #2 on page 7)

All 4 stages of filters are shipped on a separate

skid in the original factory packaging. Do not

remove packaging or install filters until just prior to

commissioning the unit.

Care must be taken to ensure filters are installed in

the proper sequence and proper direction of airflow

for filter stages 1, 2 & 3 (stage 4 carbon panels are not

subject to airflow direction).

Open the access doors. Remove the filter

compression plates at stages 1, 2, 3 & 4. Install

filters and replace all 4 filter compression plates.

Compression plates must be in place to ensure proper

filter sealing integrity. Close and latch access doors.

NOTE

Access doors are on lift off hinges and can be easily

removed for more convenient filter servicing.

Operation

NOTE

Prior to starting the fan, remove fan tie down straps.

These are used only to prevent shipping damage.

After removing the tie down straps, the fan should

float freely on the spring isolators. Confirm that the

installation is completed as shown in the Installation

section.

Start-Up

Turn the unit on momentarily and then turn off.

Remove fan drive access cover and verify proper fan

wheel rotation. If rotation is backwards, reverse the

fan motor electrical input leads. After verifying proper

fan wheel rotation, the unit is ready for operation.

Filter Status Indicator

As filter stages 1, 2 and 3 load with smoke and grease

particles, resistance to airflow increases and the

exhaust air volume decreases. Pressure switches

continuously read the resistance across each filter

stage. Each pressure switch is factory preset to

transmit an alarm signal when that stage of filter has

reached its terminal resistance and needs replacing

with new filters. This terminal resistance setting is

based on the filter manufacturers rating. The alarm

signal lights an LED located on the face panel of the

remote Filter Status Indicator Enclosure.

Filter Stage

Pre-Filter

(Stage 1)

Bag Filter

(Stage 2)

Rigid Filter

(Stage 3)

Carbon Panel

(Stage 4)

Only UL 900, Class 1 filters are approved for use

in this equipment. Substitutions will void the

manufacturer’s warranty and the listing to UL

710. Please refer to the Maintenance section for

information on ordering replacement filters.

Dimensions (inches)

Description

24 x 24 x 4 thick

MERV 8

Pleated metal frame filter

24 x 24 x 22 deep

MERV 14

Bag filter

24 x 24 x 12 thick

MERV 16

95% DOP HEPA-type filter

24 x 24 x 1 thick

Bonded carbon panel

NOTE

IMPORTANT

Replace filters immediately after the Filter Status

Indicator light comes on. Failure to do so may

cause a reduced exhaust air volume allowing

smoke to escape into the kitchen, or may cause

filters to rupture, or both. The terminal resistance

for each stage of filters is factory set at the values

shown below. Altering these settings without first

contacting Greenheck Fan Corp. will void the

manufacturers warranty and void the UL 710 listing.

Filter Stage Resistance Setting

1 1.2 in. wg.

2 1.0 in. wg.

3 1.7 in. wg.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

5

Page 6

Filter Replacement

REMOTE FILTER

STATUS INDICATOR

STATUS INDICATOR

Determine which stage(s) of

filter needs replacing as shown

by lighted LED(s) located

on the face panel of the

remote Filter Status Indicator

Enclosure.

1. Have the correct type and

quantity of filters available

at the unit.

2. Turn off and lockout

power to the fan.

3. Open the appropriate

access door(s) and

remove the filter pressure

plate(s).

4. Remove the spent filter(s)

by sliding them out of

the housing access door

opening.

5. Replace with the proper

new filter(s) making sure

REMOTE FILTER

direction of airflow is

correct.

6. Replace filter compression plate(s).

7. Close and latch access door(s).

8. Turn on power to the fan.

9. Proper filter disposal is important to the

environment. Refer to local landfill codes.

CHANGE

PRE FILTER

R

CHANGE

BAG FILTER

R

CHANGE

RIGID FILTER

R

Maintenance

Regular Scheduled Maintenance

1. Replace stage 1, 2 and 3 filter(s) immediately

after the remote Filter Status Indicator LED(s)

light up.

2. Replace carbon panels at the first sign of odor

breakthrough.

3. Remove all filters and carbon panels and

pressure wash/clean the housing interior yearly.

Only use degreasers that are compatible with

painted metal surfaces. Use caution so as to

not damage static pressure tips, tubing or fire

system nozzles and detectors. Dry the housing

interior and replace Stage 1-4 filters, replace filter

pressure plates, close and latch access doors.

4. Remove/open fan scroll access door and

pressure wash/clean all internal surfaces of the

fan every 6 months. Check sheave-belt alignment

and belt tightness.

Replacement Filter/Parts Ordering

Replacement filters and carbon panels can be

obtained through any source offering UL 900,

Class 1 filters as specified in the Filter section under

Filter Installation. As a recommendation, replacement

filters are available through AirScrubbers Inc.

Phone: 919-718-5818

www.airscrubbersinc.com

Carbon Panel Replacement

Unlike particulate filters, technology has yet to

develop a cost-friendly method of determining when

the carbon panels need replacing. So, the industry

standard is the human sniff test. As the carbon begins

to lose its effectiveness, odor breakthrough gradually

occurs and odor concentration increases. Based on a

variety of cooking applications/installations, life of the

carbon panels can range from a few months to one

year. Replace carbon panels when odor breakthrough

is first noticed. When replacing carbon panels,

follow the instructions in the Operation section, Filter

Replacement, Steps 2-10. There is no particular

direction of airflow for carbon panels.

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

6

Page 7

Figures

Figure #1

INLET TRANSITION (OPTIONAL)

PRESSURE SWITCH

ENCLOSURE

ACCESS DOOR

ON/OFF DISCONNECT

Figure #2

STAGE # 2 FILTER

COMPRESSION PLATE

STAGE # 1 FILTER

COMPRESSION PLATE

STAGE # 1 FILTER

STAGE # 2 FILTER

PRESSURE SWITCH

ENCLOSURE

STAGE # 3 FILTER

STAGE # 4 FILTER

ACCESS DOOR SIDE

(Elevation View)

STAGE # 3 FILTER

COMPRESSION PLATE

STAGE # 4 FILTER

COMPRESSION PLATE

ACCESS DOORS REMOVED

(Elevation View)

ON/OFF DISCONNECT

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

7

Page 8

Wiring Diagram

132

134

136

F F

112M

FAN MOTOR

208-230/460V, 60HZ, 3PH

1725 RPM

INPUT POWER

208-230/460V, 60HZ, 3PH

F F F F

DISCONNECT SWITCH CIRCUIT BREAKER

100 DISC

__ A

MCB

1101

1121

1141

F

F

1102T21122

T1

130CR1

130CR2

L1

F

F

STEPDOWN TRANSFORMER

PRIMARY FUSE

ON/OFF MOTOR

DISCONNECT SWITCH

F

F

1142

T3

130CR3

122 T

FAN VOLTAGE

1102

1142

50VA

H4

H3

H2

H1

L2

L3

0.5A

120FU-2

0.5A

120FU-1

X1

X3 X2 XF

SECONDARY FUSE

115 VAC

1143

124FU 0.6A

1262

INDICATOR LIGHT

PRIMARY POWER

1262

G

128 LT

1301

FAN CONTROL

2TB1

1262

130CR

X1 X2

1302

130CR4

1TB4

1301

13011261

C

110, 112, 114, 126

2TB2

A2

A1

96

95

1TB5

COMBINATION MOTOR

STARTER DISCONNECT

106

108

100

102

104

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

8

110

112

114

116

118

120

122

124

1261

126

130 SW

128

OFF

ON

1301

130

1TB2

XOO

43

1TB1

Page 9

HIGH PRESSURE LIGHT

PRE FILTER

BAG FILTER

HIGH PRESSURE LIGHT

HIGH PRESSURE LIGHT

RIGID FILTER

4TB-1

1262

3TB-4

1361

SERIES ADPS-03-2-N

ADJUSTABLE DIFFERENTIAL

136DPS

3 2

(COM) (NO)

1261

3TB-1

4TB-2

1262

3TB-5

1401

PRESSURE SWITCH

(NC)

READ ACROSS PREFILTER

1

SERIES ADPS-05-2-N

2

140DPS

3

1261

3TB-2

4TB-3

1262

3TB-6

1441

READ ACROSS BAG FILTER

PRESSURE SWITCH

ADJUSTABLE DIFFERENTIAL

1

(NO)

(NC)

144DPS

(COM)

1261

3TB-3

SERIES ADPS-05-2-N

ADJUSTABLE DIFFERENTIAL

READ ACROSS RIGID FILTER

PRESSURE SWITCH

1

(NC)

(NO)

3 2

(COM)

R

136PL

F F

PRESSURE SWITCH ENCLOSURE

(located on access door side of Grease Grabber Triple Play housing)

X2

X1

R

140PL

F F

X1 X2

R

144PL

F F

X2

X1

LOCATE IN KITCHEN AREA

REMOTE FILTER STATUS INDICATOR

132

F F

134

136

138

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

9

Page 10

Maintenance Log

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

10

Page 11

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Date __________________ Time _____________ AM/PM

Notes:___________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Grease Grabber Triple Play Kitchen Exhaust Pollution Control System

11

Page 12

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the shipment date. Any units or parts which prove defective during the warranty period will be replaced at our option

when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of

one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the

nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Greenheck Grease Grabber Triple Play catalog provides

additional information describing the equipment, fan

performance, available accessories, and specification data.

AMCA Publication 410-96, Safety Practices for Users and

Installers of Industrial and Commercial Fans, provides

additional safety information. This publication can be

obtained from AMCA International, Inc. at: www.amca.org.

®

Phone:(715)359-6171•Fax:(715)355-2399•E-mail:gfcinfo@greenheck.com•Website: www.greenheck.com

474753 • Grease Grabber Triple Play, Rev. 1, September 2011 Copyright 2011 © Greenheck Fan Corp.

12

Loading...

Loading...