Page 1

Evaporative Cooling Optimizer

Water Wizard™

Maximize Cooling and Reduce Water Waste

April

2006

Page 2

Water Wizard

Evaporative Cooling Optimizer

Cooling with the Wizard

reenheck’s Water Wizard provides complete evaporative cooling control. The Wizard measures the outside

G

temperature and humidity then adjusts the water supply to provide only the water needed for maximum

evaporative cooling. On cool or humid days, the Wizard knows the evaporative cooling potential is low and

educes the water supply to save you money. On hot or dry days, the Wizard increases the water supply to

r

meet the increased evaporative cooling potential, providing you with the most cooling possible.

Water Wizard Features

Freeze Protection

The Wizard protects the evaporative cooler from

freeze damage by automatically shutting off the water

and draining the supply line when the outside air

temperature approaches freezing.

User Friendly Interface

Four control keys and a large LED display provide a

simple and user friendly interface.

Optimum Evaporative Cooling

Water

Supply

Easy and Accurate Set-Up

Factory provided pressure gauge and manual supply

valve are standard, allowing the optimum water

pressure to be quickly and accurately dialed in for

peak performance.

Field Adjustable

The factory default settings are easily adjustable,

allowing you to maximize your cooling and savings.

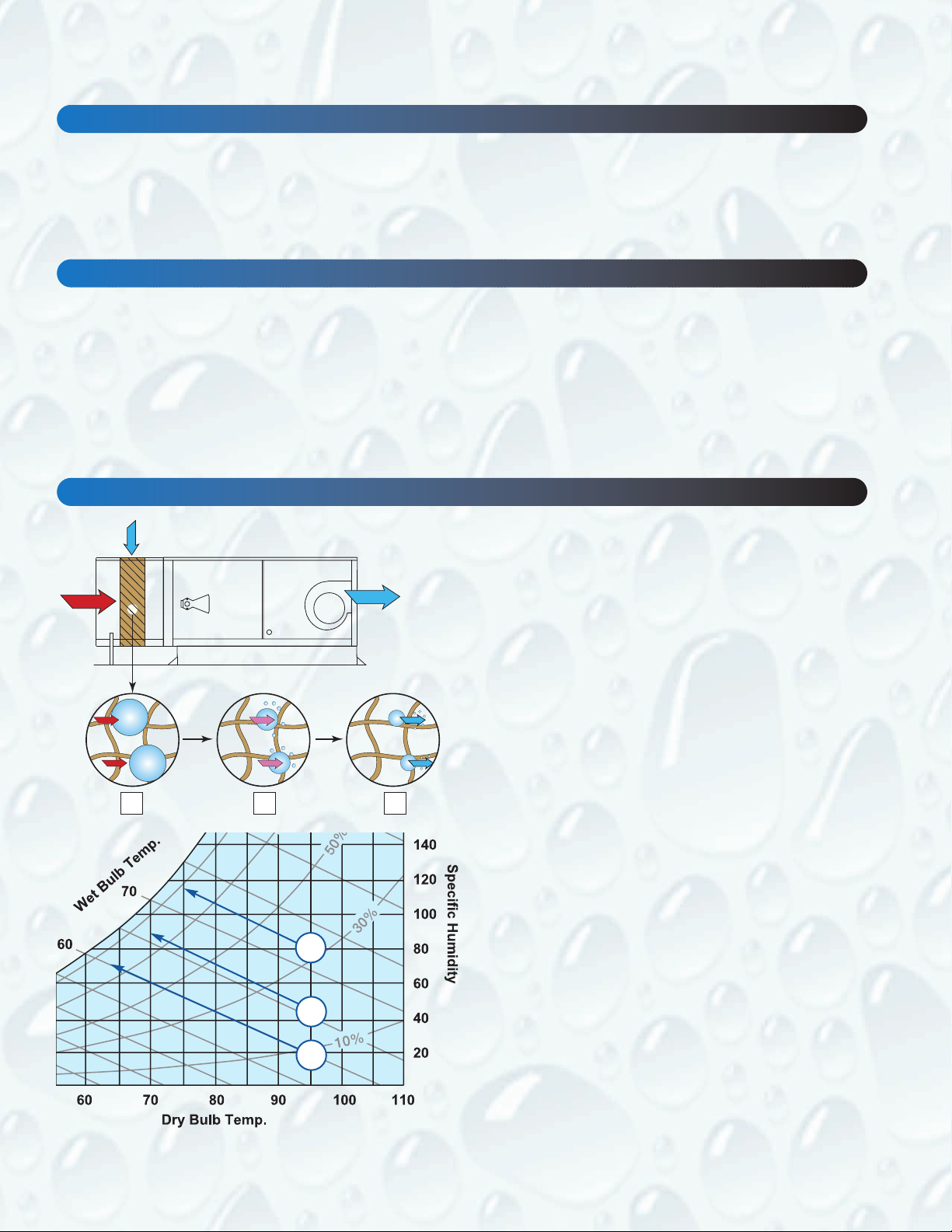

Optimum Evaporative Cooling

The Water Wizard guarantees you the optimum

evaporative cooling cycle for your conditions.

1. Warm air enters the media.

2. Water evaporates and the airstream cools.

3. Cool air discharges from the moist media and the

water supply replaces the water that was

evaporated.

1 2 3

1.9 GPM

2.5 GPM

3.0 GPM

* Calculated at 48,000 CFM with a 90% efficient evaporative cooler.

B

A

C

Varying Humidities

Even in the best evaporative cooling climates, the

evaporative cooling potential can vary greatly from

day to day. With the Wizard, you can always be sure

your evaporative cooler is optimized – on a dry or

humid day. Consider the following example at a

95ºF Td*.

A. On a day with a 67ºF T

GPM of water and maximum cooling.

B. On a day with a 73ºF Tw, the Wizard reduces the

water supply to 1.9 GPM, saving you water while

oviding the maximum cooling.

still pr

C. On a day with a 60ºF Tw, the Wizard increases

the water supply to 3.0 GPM and provides you

with the maximum evaporative cooling.

, the Wizard pr

w

ovides 2.5

Page 3

Other Evaporative Optimizers

Without the Water Wizard, you are limited to a dry bulb system. While dry bulb systems adjust the water supply

ith the outside air temperature, they have one major fault that limits their performance: they don’t consider the

w

outside air humidity. This results in many hours of operation where the cooling system is either wasting water or

providing less than optimal cooling.

Water Waste

On humid days, the dry bulb system will supply too

much water, resulting in water waste and increased

operational costs. See point A on graph below.

1. Warm, humid air enters the media.

2. Water evaporates and the airstream cools.

3. The water supply provides more water than what

is evaporated, water drains from the

supersaturated media and is wasted.

Water Supply

Water Waste

Undercooling

On dry days, the dry bulb system will not supply

enough water and the media will dry out, resulting in

undercooling and reduced media life. See point B on

graph below.

1. Warm, dry air enters the media.

2. Airstream is cooled until all of the water

evaporates.

3. Dry media represents missed cooling opportunity.

Water Supply

1 2 3

Cooling with a Dry Bulb System

With a dry bulb system, the water flow rate is

adjustable but will typically be set in the field and

e, with the water supply

then left alone. Ther

emaining constant, changes in humidity go

r

unnoticed. Consider the following example where

48,000 cfm is being supplied thr

evaporative cooler. The water flow rate of 2.5 GPM

was established based on optimization at 67ºF T

A. On a day with a 73ºF Tw, where the humidity level

is higher than the 67ºF Tw optimization, the dry

bulb system will supply 2.5 GPM of water when

only 1.9 GPM is required for maximum cooling.

esults in a 32% water waste.

This r

B. On a day with a 60ºF Tw, where the humidity level

is lower than the 67ºF Twoptimization, the dry

bulb system will provide 2.5 GPM of water when

3.0 GPM is required for maximum cooling. This

results in a missed opportunity to provide

additional cooling for the space.

efor

ough a 90% ef

ficient

.

w

1 2 3

W

ater

Waste

2.5 GPM

Undercooling

2.5 GPM

A

B

Page 4

Specification

Operation

he Water Wizard shall control a supply solenoid to

T

adjust the water supply to the evaporative cooler

ased on the outside air dry bulb and wet bulb

b

temperatures. The Water Wizard shall increase the

water supply on days with a high evaporative

cooling potential and decrease the water supply on

days with a low evaporative cooling potential. The

Water Wizard shall respond to a change in both

temperature and humidity.

Freeze Protection

The Water Wizard shall be equipped with a freeze

protection function. The freeze protection shall

shut off the water supply and drain the supply line

if the temperature falls below the field adjustable

freeze temperature setting for longer than the field

adjustable freeze protection time delay setting.

Programming

The Water Wizard shall be pre-programmed at the

factory and have field adjustable set points.

Components

he Water Wizard shall include at

T

least one manual shut-off valve

nd pressure gauge factory

a

installed in the evaporative

cooler. The Water Wizard shall

include a four key user interface

with three-digit LED display

which shall be factory mounted in

the control center of the make-up

air unit. The Water Wizard shall

include temperature sensors for

measuring the dry bulb and wet

bulb temperatures. The sensors

shall be factory mounted when

the evaporative cooler ships

attached to the fan section. Solenoids may be

supplied by Greenheck (if selected) or by others.

Installation, piping and wiring of the solenoids shall

be the responsibility of the contractor.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the purchase date.

Any units or parts which prove defective during the warranty period will be replaced at our option when returned to our factory,

transportation prepaid. Motors are warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period,

responsible for any removal or installation costs.

As a result of our commitment to continuous improvement,

they should be returned to the nearest authorized motor ser

Greenheck reser

vice station.

ves the right to change specifications without notice.

Greenheck will not be

Greenheck P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2006 Greenheck Fan Corp. • Water Wizard Rev. 2 April 2006 RG

Loading...

Loading...