Document 471849

Energy Recovery Ventilator

®

VersiVent

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

VersiVent - Model VER

General Safety Information

Only qualified personnel should install this system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

DANGER

Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, the internal components may

be hot enough to cause pain or injury. Allow time for

cooling before servicing.

CAUTION

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electric Code (CEC) in Canada.

2. All moving parts must be free to rotate without

striking or rubbing any stationary objects.

3. Unit must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan RPM. Adjustments to fan speed

significantly affects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to the unit while it is

running.

Precaution should be taken in explosive atmospheres.

VersiVent Energy Recovery Ventilator

1

Table of Contents

General Safety Information ...................1

Receiving, Handling and Storage ..............3

Product Overview ...........................4

Optional Subassemblies ......................4

Installation

Unit Dimensions and Weights ..................5

Curb Outside Dimensions and Weights ...........6

Service Clearances ..........................7

Access Panel Descriptions and Locations ........8

Recommended Roof Openings .................9

Handling ...................................9

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Roof Curb Mounting ........................10

Rail Mounting/Layout ........................10

Duct Connections ..........................11

Electrical Installation

Warnings .................................12

Procedure .................................12

Field-Provided Disconnect ....................13

Discharge Air Temperature Sensor .............13

Typical Control Center Components ............13

Optional Accessory Wiring Schematics ..........14

Piping Installation

Optional Gas Piping .........................15

Gas Connections ...........................15

Optional Coil Piping .........................15

Water Coils ..............................15

Direct Expansion .........................15

Condensate Drain Trap ....................16

Unit Overview

Basic Unit .................................17

Optional Component Overview

Economizer ...............................17

Frost Control ..............................18

Variable Frequency Drive .....................18

CO2 Sensor ...............................18

Phase Monitor .............................18

Rotation Sensor ............................18

Dirty Filter Sensor ..........................18

Microprocessor Controller ....................19

Unoccupied Recirculation Damper .............19

Service Outlet ..............................19

Vapor Tight Lights ..........................19

Hot Gas Bypass Valve .......................19

Hot Gas Reheat Valve .......................19

Digital Scroll Compressor ....................19

Cooling System Overview

Packaged DX ..............................20

Start-Up

Warnings .................................21

Special Tools Required ......................21

Start-Up Procedure .........................21

Voltage Imbalance ..........................21

Pre-Start-Up Checklist .......................22

Start-Up Checklist .......................

Optional Accessories Checklist ................24

22-23

Start-Up Components

Energy Wheel ..............................25

Fans - Supply and Exhaust ................25-26

Vibration ..................................26

Hot Gas Bypass Valve .......................26

Optional Components Start-Up

Dirty Filter Sensor ..........................27

Economizer ...............................27

Frost Control ..............................28

Variable Frequency Drives ................29-30

Routine Maintenance

Maintenance Frequency ......................31

Units with Packaged DX .....................31

Maintenance Procedures

Lubrication ..............................32

Dampers ................................32

Gas Furnace .............................32

Fan Belts ...............................32

Fan Motors ..............................32

Fan Wheel and Fasteners ..................32

Bearings ................................32

Internal Filter ............................32

External Filter ............................33

Coils ...................................33

Door Seals ..............................33

Energy Wheel ............................34

Troubleshooting

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Refrigeration Circuit ......................36-39

Energy Wheel ..............................39

Controller Alarms ...........................40

Rotation Sensor ............................40

Digital Scroll Compressor ....................40

Economizer ...............................41

Reference

Technical Assistance Information ..............41

Additional Installation, Operation and

Maintenance Manuals .....................41

Component Location ........................42

Maintenance Log ...........................43

Our Commitment ....................Backcover

VersiVent Energy Recovery Ventilator

2

Receiving

Upon receiving the product check to make sure all items

are accounted for by referencing the bill of lading to

ensure all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notification on the delivery receipt acknowledging any

damage to the product. All damage should be noted on

all the copies of the bill of lading which is countersigned

by the delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival and

reported to the Traffic Department. If damaged upon

arrival, file claim with carrier. Any physical damage to

the unit after acceptance is not the responsibility of

manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Handling

Units are to be rigged and moved by the lifting brackets

provided or by the skid when a forklift is used. Location

of brackets varies by model and size. Handle in such

a manner as to keep from scratching or chipping the

coating. Damaged finish may reduce ability of unit to

resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR — The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C)

and 110°F (43°C) (wide temperature swings may

cause condensation and “sweating” of metal parts).

All accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice, or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach room

temperature. To dry parts and packages use a portable

electric heater to get rid of any moisture build up. Leave

coverings loose to permit air circulation and to allow for

periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off the

floor on wooden blocks covered with moisture proof

paper or polyethylene sheathing. Aisles between parts

and along all walls should be provided to permit air

circulation and space for inspection.

OUTDOOR — Units designed for outdoor applications

may be stored outdoors, if absolutely necessary. Roads

or aisles for portable cranes and hauling equipment are

needed.

The fan should be placed on a level surface to prevent

water from leaking into the unit. The unit should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels, and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To minimize

water accumulation, place all unit parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Inspection and Maintenance during

Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the fan wheel by hand ten to fifteen

revolutions to distribute lubricant on motor. Every three

months, the fan motor should be energized. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lint-free

cloths. Polish any remaining rust from surface with

crocus cloth or fine emery paper and oil. Do not destroy

the continuity of the surfaces. Wipe thoroughly clean

with Tectyl

hard to reach internal surfaces or for occasional use,

consider using Tectyl

or the equivalent.

REMOVING FROM STORAGE — As units are removed

from storage to be installed in their final location, they

should be protected and maintained in a similar fashion,

until the equipment goes into operation.

Prior to installing the unit and system components,

inspect the unit assembly to make sure it is in working

order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base, and accessories for

tightness.

2. Rotate the fan wheel(s) by hand and assure no parts

are rubbing.

®

506 (Ashland Inc.) or the equivalent. For

®

511M Rust Preventive or WD-40®

VersiVent Energy Recovery Ventilator

3

Product Overview

The VER units bring in fresh, outdoor air and remove

stale, exhaust air. Prior to discharging the exhaust air,

the energy recovery wheel transfers energy from the

exhaust air to the outdoor air at an efficiency of 7080%. Simply put, this unit preconditions the outdoor

air to save money on heating and cooling costs. These

particular units also have cooling and heating options

available after the recovery wheel to further condition

the fresh air.

Optional Subassemblies

Dampers

Backdraft dampers are always included as an integral

part of the exhaust hood assemblies. Motorized outdoor

air and return air dampers are optional and are factorymounted (and wired) at the intake.

Hot Water / Chilled Water Coils

Water coils can be used for a single purpose such

as heating or cooling, or their function can be

alternated between heating and cooling by changing

the temperature of the water flowing through the coil.

Depending on the application, it may be necessary to

use a glycol mixture to prevent the liquid from freezing.

The water coils are engineered to operate at pressures

up to 250 PSIG and temperatures up to 300°F, but

ancillary equipment such as valves and pumps will often

dictate lower operating temperatures. All water coils

are pressure tested at the factory with 450 PSIG of dry

nitrogen.

Electric Post-Heaters

The optional post-heater is used as a heat source for

the building and is integrated into the supply airstream.

A temperature sensor (with a field-adjustable set point)

is mounted in the supply airstream after the post-heater

to turn the post-heater on. A SCR heater allows for

an infinite amount of modulating control of the heat to

provide an accurate discharge temperature during the

call for heat.

As standard, the post-heater control panel is not single

point wired to the unit control center. Separate power

must be supplied to the post-heater disconnect (located

in unit control center). Electric heaters are available in

208, 230, 460, or 575 VAC (refer to heater nameplate for

voltage).

Indirect Gas Furnace

An optional indirect gas furnace may be installed and

provides supplementary heat to the building. Refer to

the PVF/PVG Indirect Gas-Fired Heat manuals provided

with the unit. A unit-specific wiring diagram is located

inside the furnace housing access door.

Outdoor Air Weatherhood

Outdoor air weatherhood will be factory-mounted.

Exhaust Air Weatherhood

The exhaust weatherhood is shipped separately as a

kit with its own instructions. Backdraft dampers are

always included as an integral part of the exhaust hood

assemblies.

Packaged Direct Expansion (PDX)

The DX system comes fully charged from the factory

with refrigerant and is ready for installation upon arrival.

All units come standard with two compressors. This

allows for staging of compressors to meet a wider range

of outdoor air loads while reducing the amount of cycles

per compressor.

Integral Components

All units are provided with an expansion valve, hermetic

scroll compressor(s), liquid line filter drier, high pressure

manual reset cutout, low pressure auto-reset cutout,

time delays for compressor protection, service/charging

valves, moisture indicating sight glass, and optional hot

gas bypass. The compressors also come standard with

a crankcase heater for additional protection.

Split DX

The unit can be equipped with two evaporator coils

that will be connected to a separate condensing unit

(provided by others). Depending on controlling options,

the condensing unit will be controlled by others or could

receive a call for stage 1 and stage 2 of cooling with the

integral microprocessor controller. The microprocessor

controller will only provide a call for cooling, it will not

send a digital control signal to the compressors. Piping

components such as thermostatic expansion valve, filter

drier, sight glass, etc., shall be field-provided.

VersiVent Energy Recovery Ventilator

4

Installation

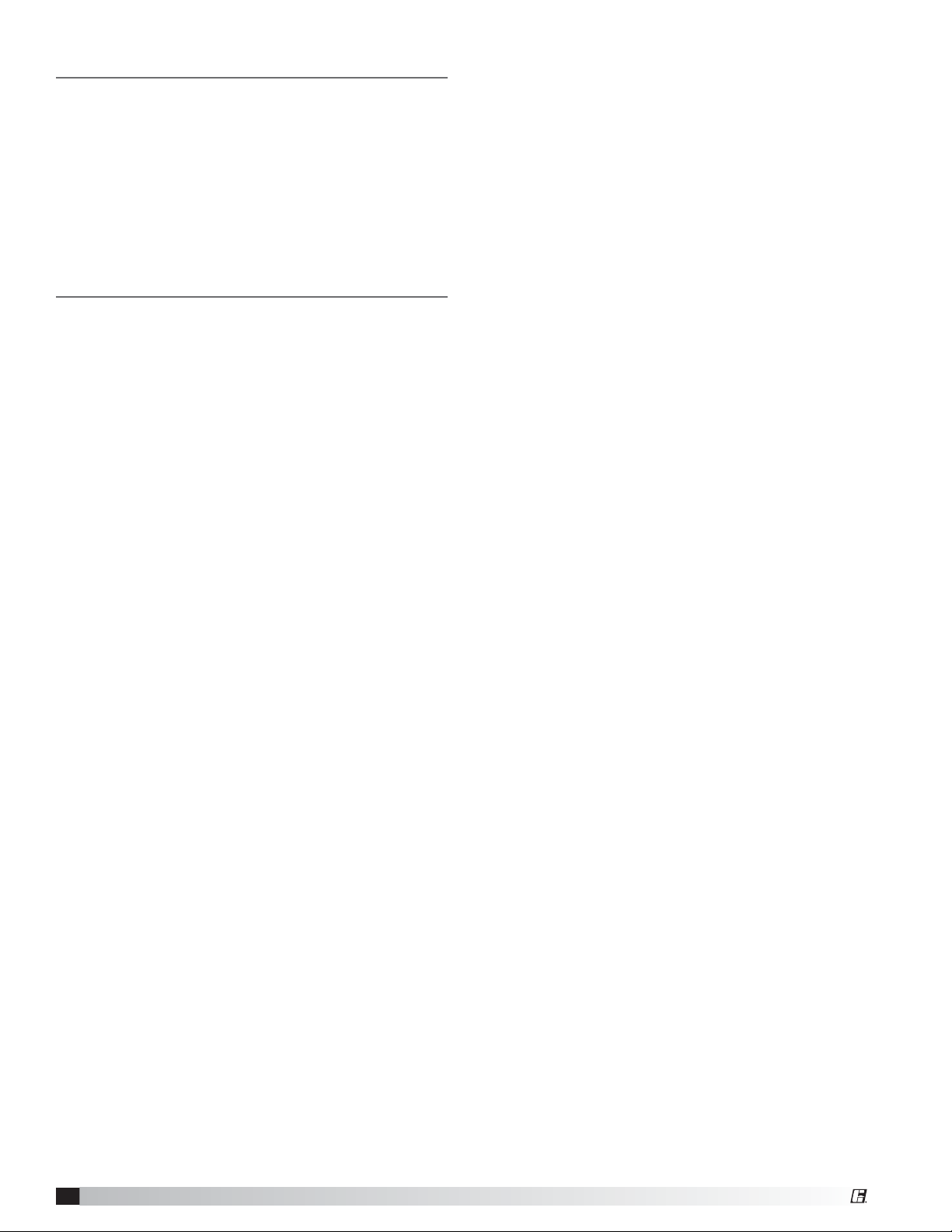

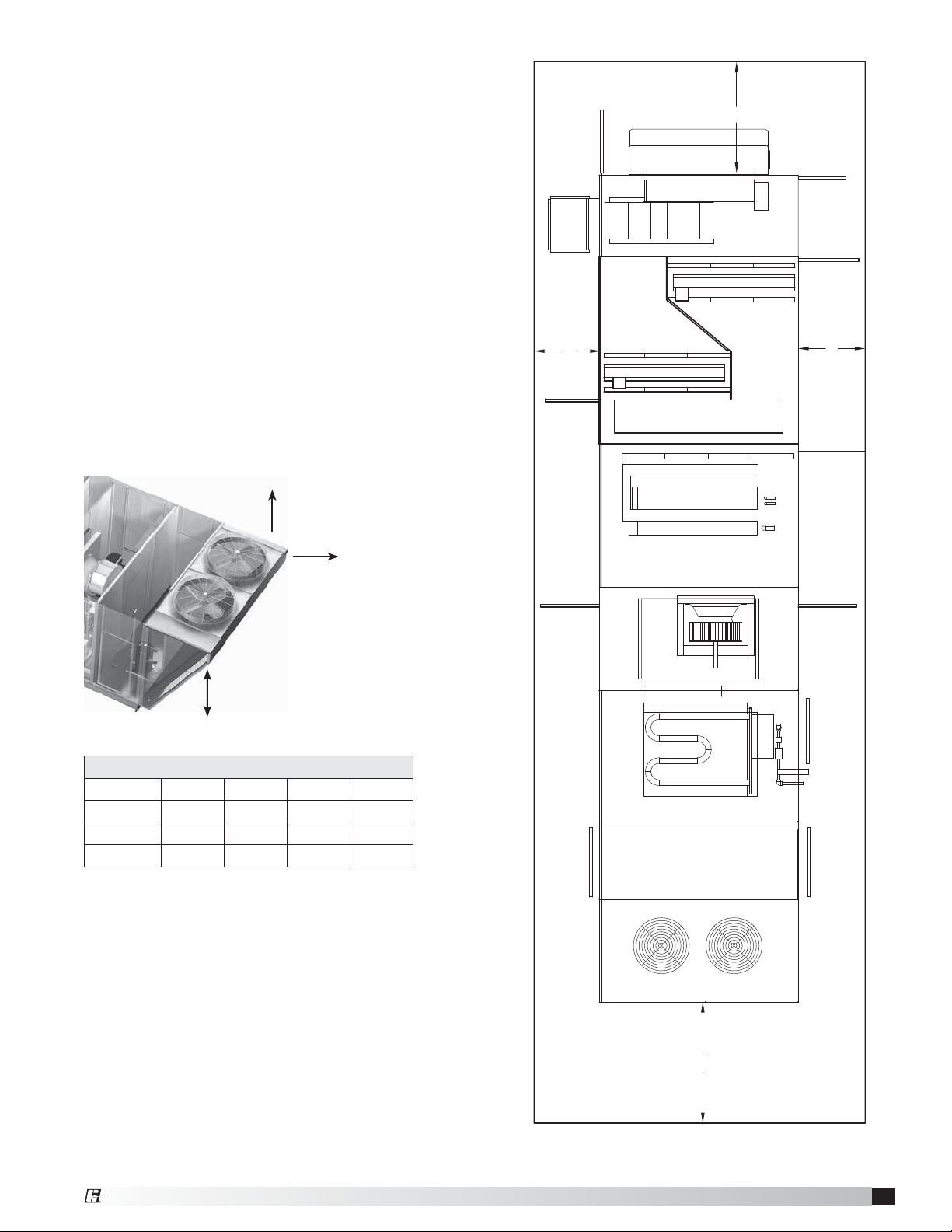

Unit Weights & Dimensions

A

W

I

Plan View

BC D*L*EF G

Electrical Box

Wheel Cassette

Exhaust Air

Discharge

Wheel

Section

2-inch Filters

4-inch Final Filters

Return Air

Intake

Optional

Coil Section

Blower

Section

Optional

IG Heater Section

Supply Air

Discharge

Optional

Condensing Section

2-inch Filters

Outdoor Air Intake

Intake

Section

Condensing Coil

H

Outdoor Air Hood

2-inch Filters

Wheel Cassette

2-inch Filters

Drain Pan Connection

4-inch Final Filters

Condensing Coil

IG Gas Connection

Elevation View

*

Unit

Size

VER-45 16.381 28.146 44.627 30.159 36.159 44.159 50.275 36.312 47.571 63.964 65.851 18.780 69.987

VER-65 16.381 30.825 46.597 30.159 36.159 44.159 50.275 38.124 47.571 65.958 72.098 23.358 76.246 6300

VER-90 16.381 34.825 85.658 30.159 36.159 44.159 50.275 41.312 47.571 65.958 65.851 23.358 91.010 7250

All dimensions shown in inches.

*L Sum the lengths of the appropriate modules to get the total length of the unit.

^Weight: The weights shown are a worse case scenario based on the sheet metal and component weights for the unit. These weights include sheet metal

ABC

weights added together with the largest fans, coils and heaters for the unit.

D1 D2 D3 D4

HW HW + DX CW + HP HW + CW + HP

CW HW + CW DX + HP HW + DX + HP

DX EH + CW DX + HGRH EH + DX + HP

EH EH + DX DX + HW + HGRH EH + CW + HP

D1 D2 D3 D4

D* Coil Module Options

D

DX + EH + HGRH

EFGH IWL*

HW = Hot Water

CW = Chilled Water

DX = Direct Expansion

EH = Electric Heat

HP = Wrap-around Heat Pipe

HGRH = Hot Gas Reheat

^Weight

see

note

(lbs.)

4900

VersiVent Energy Recovery Ventilator

5

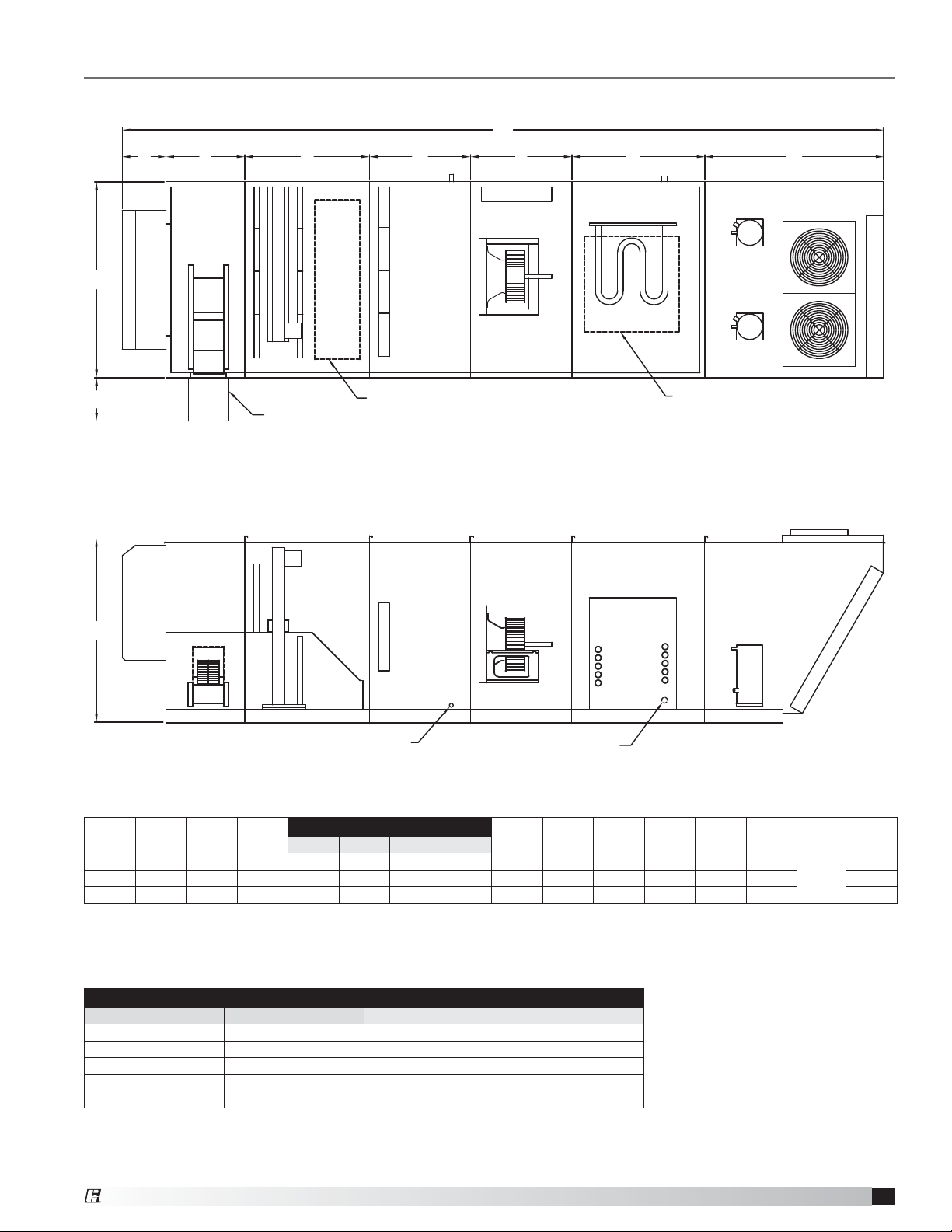

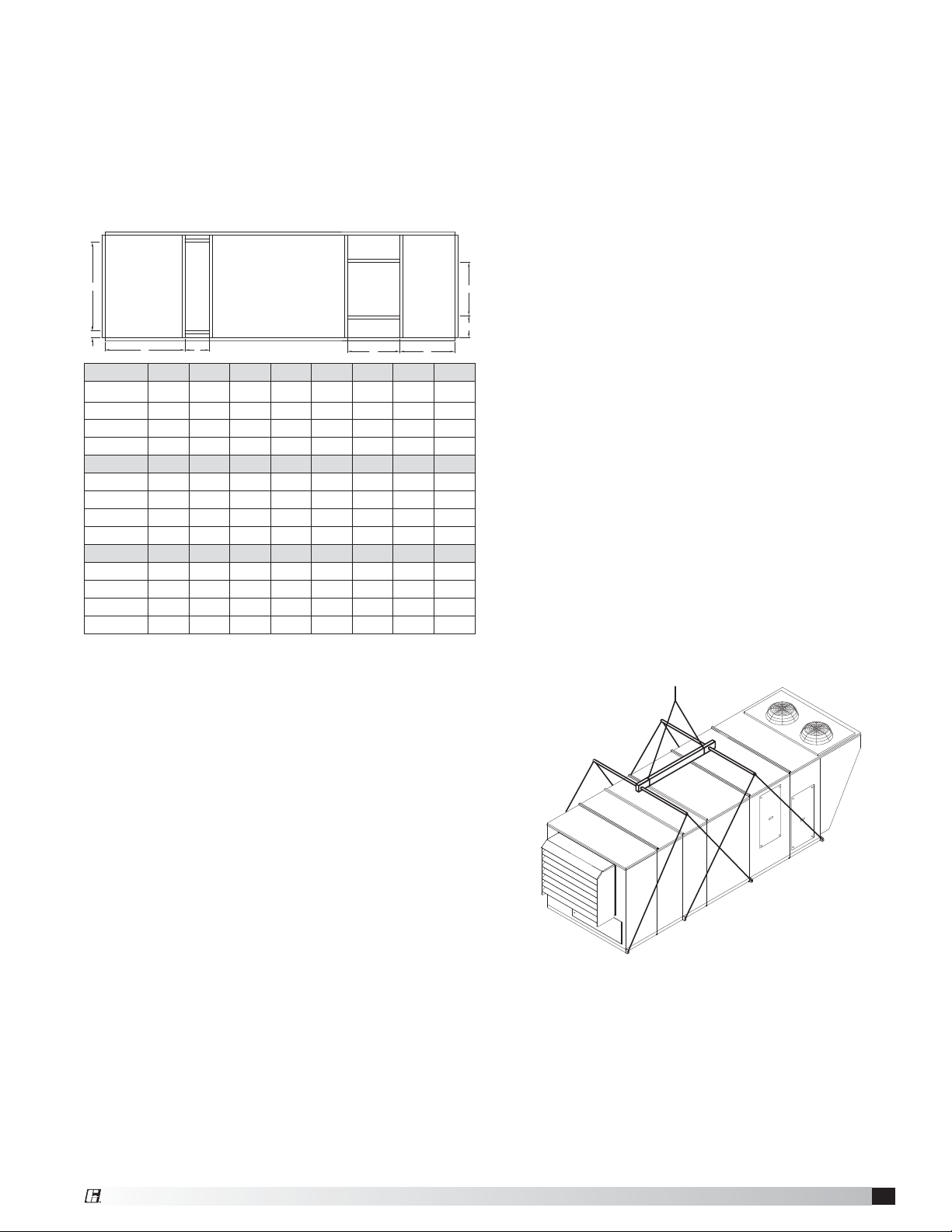

Curb Outside Dimensions and Weights

Outdoor Air Weatherhood

Intake

Section

2-inch Filters

Wheel

Section

Wheel Cassette

2-inch Filters

Optional

Coil Section

4-inch Final Filters

Blower

Section

IG Heater Section

Optional

Optional

Condensing Section

Condensing Coil

L* - 3.75 inches

W - 3.75 inches

A B C* D

Drain Pan Connection IG Gas Connection

L*

EF

Subtract 3.75 inches from dimensions

W & L* to get the outside curb dimensions.

Elevation View

Unit

Size

AB

C1 C2 C3 C4

C*

DEFWL*

VER-45 28.146 44.627 30.159 36.159 44.159 50.275 36.312 47.571 27.909 69.987

VER-65 30.825 46.597 30.159 36.159 44.159 50.275 38.124 47.571 27.909 76.246 473

VER-90 34.825 85.658 30.159 36.159 44.159 50.275 41.312 47.571 27.909 91.010 621

All dimensions shown in inches.

L* — Sum up the applicable section dimensions (A–F) for your unit to get the overall length.

^ — Curb weights shown are for the worst case scenario (largest curb) possible for each size unit.

C* Coil Module Options

C1 C2 C3 C4

HW HW + DX CW + HP HW + CW + HP

CW HW + CW DX + HP HW + DX + HP

DX EH + CW DX + HGRH EH + DX + HP

EH EH + DX DX + HW + HGRH EH + CW + HP

DX + EH + HGRH

HW = Hot Water EH = Electric Heat

CW = Chilled Water HP = Wrap-around Heat Pipe

DX = Direct Expansion HGRH = Hot Gas Reheat

Most factory-supplied electrical components are prewired. To determine what electrical accessories require

additional field wiring, refer to the unit-specific wiring

diagram located on the inside of the unit control center

access door. The low voltage control circuit is 24 VAC

and control wiring should not exceed 0.75ohms.

Control wires should not be run inside the same conduit

as that carrying the supply power. Make sure that fieldsupplied conduit does not interfere with access panel

operation.

Curb Weight^

(lbs.)

447

see

note

If wire resistance exceeds 0.75 ohms, an industrial-style

plug-in relay should be added to the unit control center

Side of Unit

1 in.

2½ in.

1.195 in.

1 in.

and wired in lieu of the remote switch (typically between

terminal blocks R and G on the terminal strip (refer to

Typical Control Center Components). The relay must be

rated for at least 5 amps and have a 24 VAC coil. Failure

1 in.

to comply with these guidelines may cause motor

starters to “chatter” or not pull in which can cause

contactor failures and/or motor failures.

Note: Standard factory-installed electric post-heaters

have their own disconnect separate from the

unit disconnect. Thus, each electric post-heater

requires its own separate power connection.

Roof Curb

Recommended

2-inches of

Insulation

Curb Cap Details

VersiVent Energy Recovery Ventilator

6

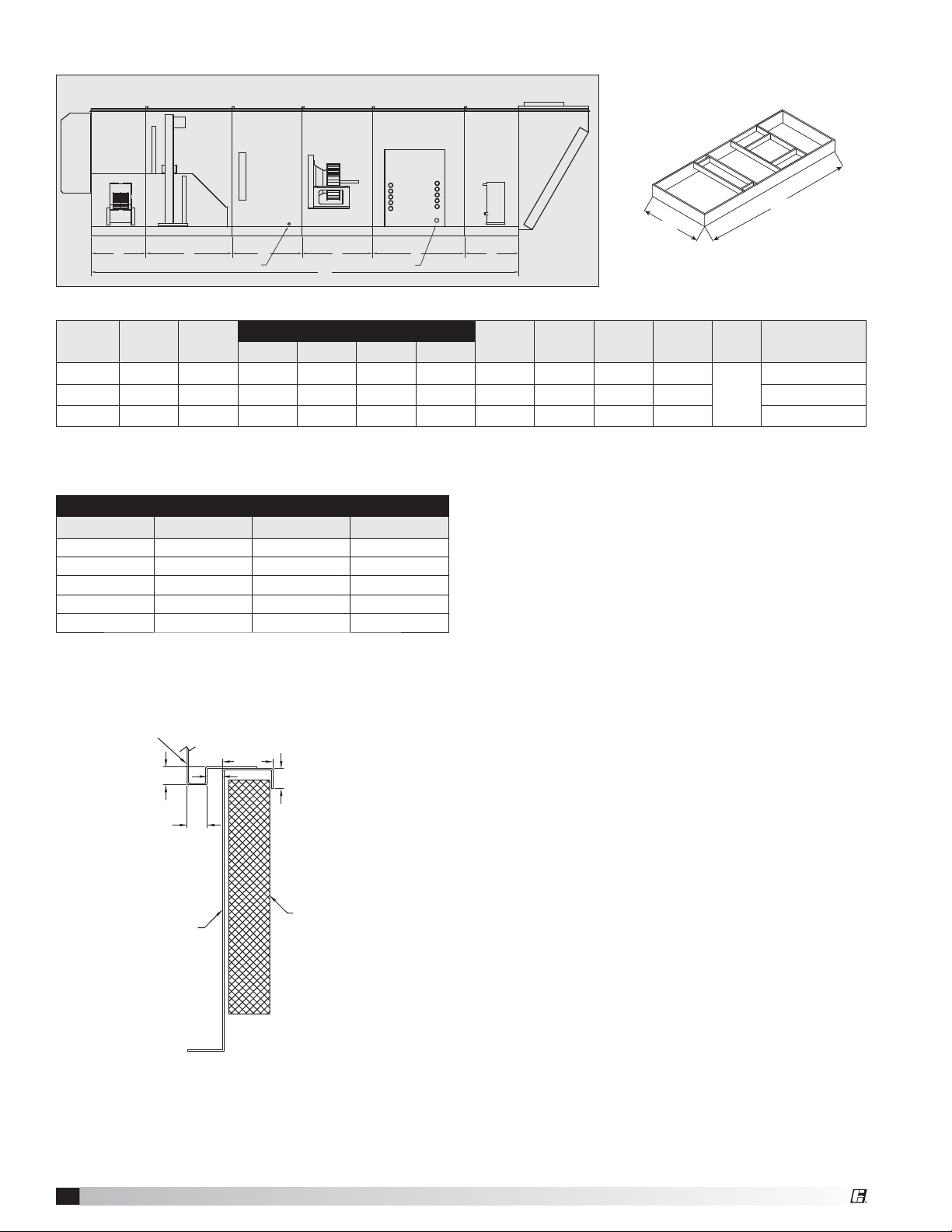

Service Clearances

VER-45, 65 and 90 units require minimum clearances

for access on all sides for routine maintenance. Filter

replacement, drain pan inspection and cleaning, energy

wheel cassette inspection, fan bearing lubrication and

belt adjustment are examples of routine maintenance

that must be performed. Blower and motor assemblies,

energy recovery wheel cassette, coil and filter sections

are always provided with a service door or panel for

proper component access. Clearances for component

removal may be greater than the service clearances,

refer to drawings for these dimensions.

Additional clearances for units with packaged DX

Clearances must be maintained on all sides of this unit.

This especially is true with the top of this unit. Hot air is

being discharged through the condensing fans during

operation, and the more clearance available, the better

the chance of avoiding recirculation or coil starvation.

This unit should never be placed under an overhang

or inside a building. A minimum of 48 inches over the

condensing fans is recommended.

Minimum 48 inches

clearance

ACCESS

PANEL

C

ACCESS

PANEL

VER-90

ONLY

B

ACCESS

PANEL

ACCESS

PANEL

TL

A

ACCESS

PANEL

TL

TL

TRTR

Minimum 24 inches

clearance

Condensing Coil Intake

Keep this area clear

Unit Clearances

Unit Size A B C D

VER-45 65 42 36 24

VER-65 70 42 36 24

VER-90 65 42 65 24

All dimensions shown in inches.

ACCESS

PANEL

ACCESS

PANEL

TL

TRTR

ACCESS

PANEL

TL

TR

ACCESS

TL

TR

TR

PANEL

ACCESS

PANEL

D

Access Panels may change depending on options

selected.

VersiVent Energy Recovery Ventilator

7

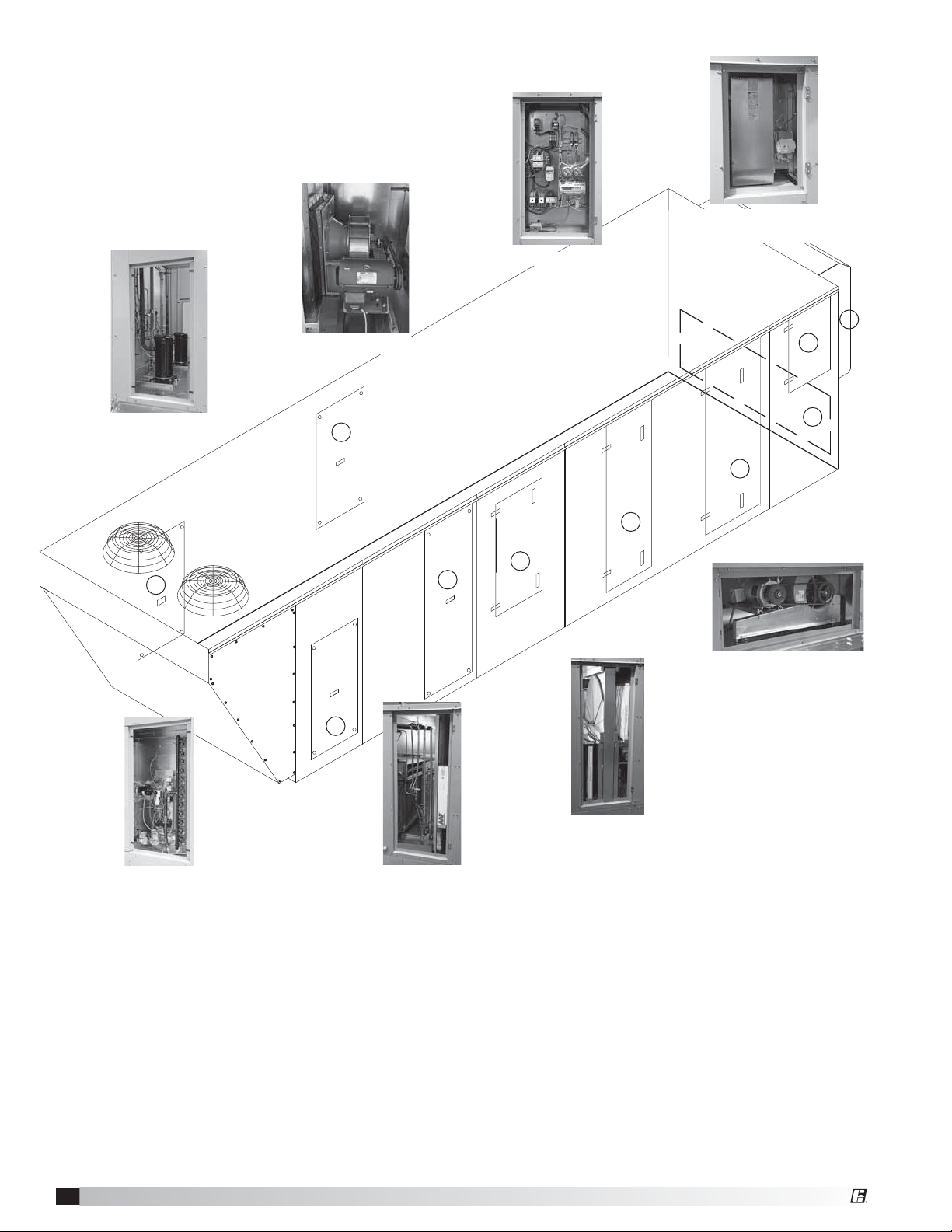

Access Panel Descriptions and Locations

Following is a list of items accessible through the

access doors shown on the diagrams. Some items are

optional and may not have been provided.

#8 – Supply Fan

#9 – Compressors

8

#6 – Control Panel

#2 – OA Intake Damper

and Electric Preheat

2

3

4

1

9

9

#7 – IG Furnace

Control Center

#5 – Packaged DX

Coil and Final Filter

1. Aluminum mesh filters (intake hood)

2. Outdoor air intake damper

Electric pre-heater

3. Exhaust fan, motor, and drives

4. Energy recovery wheel, motor, belt, and seals

Exhaust air filters

Return air intake damper (optional)

Outdoor air filters

Frost control sensors (optional)

Economizer sensors (optional)

5. Coil access / drain pan / final filters

Bypass damper (optional)

5

6

7

#4 – Filter & Wheel

6. Control center

All electrical controls

VFD for energy recovery wheel (optional)

7. Indirect gas furnace control center

8. Supply air fan, motor, and drives

(with indirect gas furnace)

Electric post-heater control center (optional)

9. Compressor(s) –

(optional)

#3 – Exhaust Fan

VersiVent Energy Recovery Ventilator

8

Recommended Roof Opening

A

Refer to weight and dimension data to determine the

exact location of the section containing the outdoor

air discharge opening. If the unit is equipped with

an Indirect Gas Heater (IG) section, the outdoor air

discharge opening will be in that section; if not, it will

be in the blower section. The return air intake will

be consistent for all units. The dimensions of these

openings and their locations are illustrated below.

Return Air Intake

Supply Air

Discharge

B

C

VER-45 A B C D E F G H

1 56.9 4.7 51.5 15.9 26.9 42.7 3.3 11.8

2 56.9 4.7 51.5 15.9 33.8 34.1 7.4 14.4

3 56.9 4.7 51.5 15.9 33.8 34.1 35.3 14.4

4 56.9 4.7 51.5 15.9 26.9 42.7 31.2 11.8

VER-65 A B C D E F G H

1 59.9 6.3 56.1 15.9 29.9 51.9 2.7 10.3

2 59.9 6.3 56.1 15.9 30.9 49.9 7.3 7.1

3 59.9 6.3 56.1 15.9 30.9 49.9 35.2 7.1

4 59.9 6.3 56.1 15.9 29.9 51.9 30.6 10.3

VER-90 A B C D E F G H

1 77.9 4.7 99.2 15.9 33.8 61.9 2.0 12.7

2 77.9 4.7 99.2 15.9 33.8 51.9 7.5 17.7

3 77.9 4.7 99.2 15.9 33.8 51.9 35.3 17.7

4 77.9 4.7 99.2 15.9 33.8 61.9 29.9 12.7

All dimensions are in inches.

IG = Indirect Gas Furnace; PDX = Packaged DX Cooling

1 = Any unit without IG and PDX.

Blower Module is at the end of the unit.

2 = Any unit with IG that does not have PDX.

3 = Any unit with IG and PDX

4 = Any unit without IG and with PDX

D

E

G

Handling

While this unit was constructed with quality and

dependability in mind, damage still may occur during

handling of the unit for installation. Exercise extreme

caution to prevent any damage from occurring to the

refrigerant system. This unit could contain a system

pressurized with refrigerant that, if damaged, could

leak into the atmosphere or cause bodily harm due to

the extreme cold nature of expanding refrigerant. Use

protective equipment such as gloves and safety glasses

to minimize or prevent injury in case of a system leak

during installation.

F

The system design and installation should follow

accepted industry practice, such as described in

H

the ASHRAE Handbook. Adequate space should be

left around the unit for piping coils and drains, filter

replacement, and maintenance. Sufficient space should

be provided on the side of the unit for routine service

and component removal should that become necessary.

Lifting

1. Before lifting, be sure that all shipping material has

been removed from unit.

2. To assist in determining rigging requirements,

weights are provided in the Unit Weights &

Dimensions section.

3. Unit must be lifted by all lifting lugs provided on

base structure.

4. Rigger to use suitable mating hardware to attach to

unit lifting lugs.

5. Spreader bar(s) must span the unit to prevent

damage to the cabinet by the lift cables.

When cutting only duct openings, cut opening oneinch

(25 mm) larger than duct size to allow clearance for

installation. Area enclosed by roof curb must comply

with clearance to combustible materials. If the roof is

constructed of combustible materials, area within the

roof curb must be ventilated, left open, or covered with

non-combustible material which has an “R” value of at

least five. If area within curb is open, higher radiated

sound levels may result.

Where the supply or warm air duct passes thru a

combustible roof, a clearance of one inch must be

maintained between the outside edges of the duct

and combustible material in accordance with NFPA

Standard 90A. Position the unit roof opening such that

the supply discharge and exhaust inlet of the unit will

line up with the corresponding ductwork. Be sure to

allow for the recommended service clearances when

positioning opening (see Service Clearances). Do not

face the outdoor air intake of the unit into prevailing

wind and keep the intake away from any other exhaust

fans. Likewise, position the exhaust discharge opening

away from outdoor air intakes of any other equipment.

6. Always test-lift the unit to check for proper balance

and rigging before hoisting to desired location.

7. Never lift units by weatherhoods.

8. Never lift units in windy conditions.

9. Preparation of curb and roof openings should be

completed prior to lifting unit to the roof.

10. Check to be sure that gasketing (supplied by

others) has been applied to the curb prior to lifting

the unit and setting on curb.

11. Do not use fork lifts for handling unit.

VersiVent Energy Recovery Ventilator

9

Roof Curb Mounting

Roof curb details, including duct location dimensions,

are available on VER roof curb assembly instructions.

Rooftop units require curbs to be mounted first. The

duct connections must be located so they will be clear

of structural members of the building.

1. Factory-Supplied Roof Curbs

Roof curbs are Model GKD, which are shipped in a

knockdown kit (includes duct adapter) and require

field-assembly (by others). Assembly instructions are

included with the curb.

2. Install Curb

Locate curb over roof opening and fasten in place.

Check that the diagonal dimensions are within

±1/8 inch of each other and adjust as necessary.

For proper coil drainage and unit operation, it is

important that the installation be level. Shim as

required to level.

3. Install Ductwork

Installation of all ducts should be done in

accordance with SMACNA and AMCA guidelines.

Duct adapter provided to support ducts prior to

setting the unit.

4. Set the Unit

Lift unit to a point directly above the curb and duct

openings. Guide unit while lowering to align with duct

openings. Roof curbs fit inside the unit base. Make

sure the unit is properly seated on the curb and is

level.

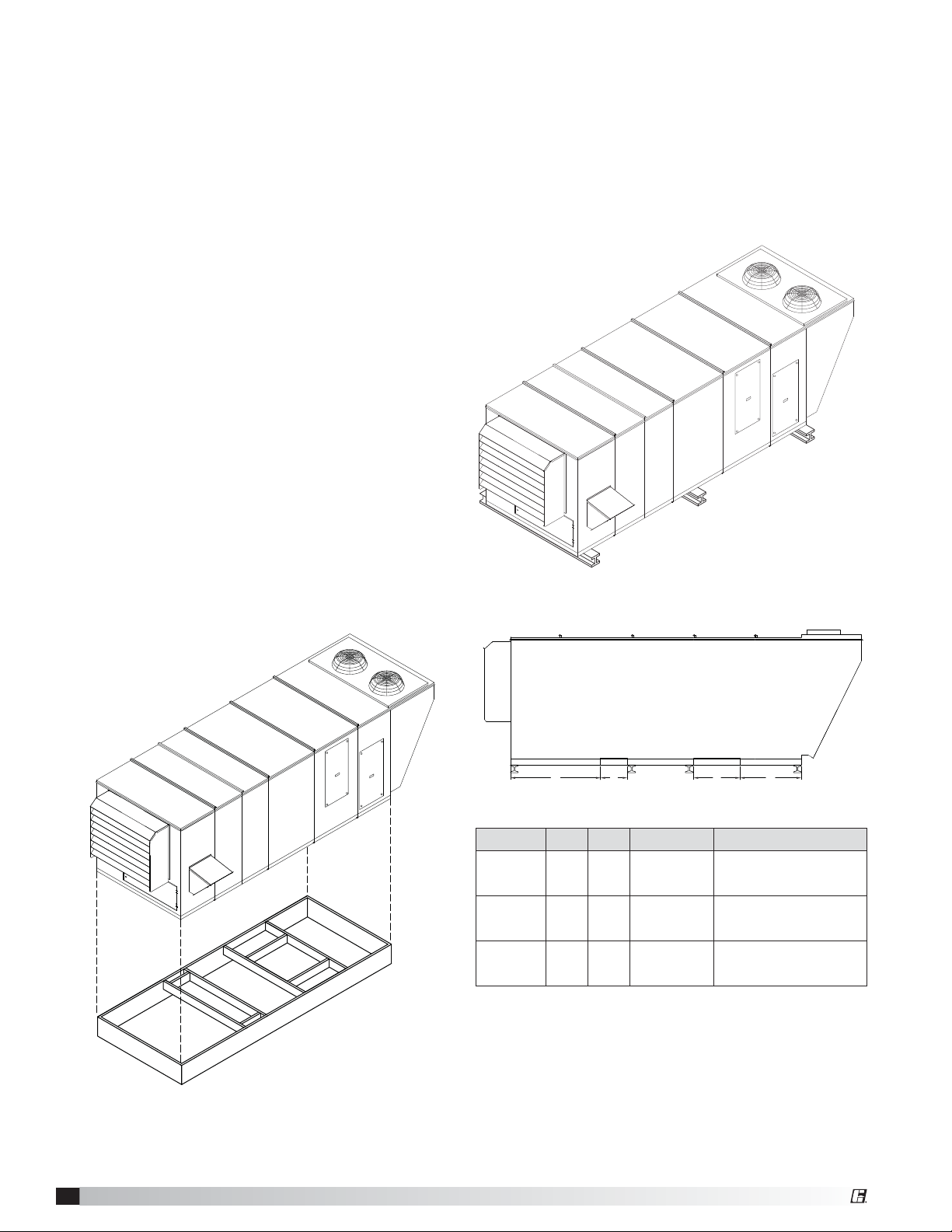

Rail Mounting and Layout

• Rails designed to handle the weight of the VER

should be positioned as shown on the diagram (rails

by others).

• Make sure that rail positioning does not interfere with

the supply air discharge opening or the return air

intake opening on the VER unit.

• Rails should run the width of the unit and extend

beyond the unit a minimum of 12 inches on each

side.

• Set unit on rails.

Rails are positioned in random places.

See table for proper location

Isometric View

Return Air

Intake

AB CD

Side View

Unit A B C D

VER-45 53.3 16

VER-65 58.1 16

VER-90 105.3 16

All dimensions shown in inches.

IG = Indirect Gas

CS = Condensing Section

33.8 w/IG

27 w/o IG

31.0 w/IG

30 w/o IG

33.8 w/IG

34 w/o IG

Supply Air

Discharge

9.2 IG w/o CS; 37.1 IG w/CS

5.2 w/o IG and CS

33.1 w/o IG and w/ CS

9 IG w/o CS; 36.9 IG w/CS

4.6 w/o IG and CS

32.5 w/o IG and w/ CS

9.2 IG w/o CS; 37.1 IG w/CS

3.7 w/o IG and CS

31.6 w/o IG and w/ CS

VersiVent Energy Recovery Ventilator

10

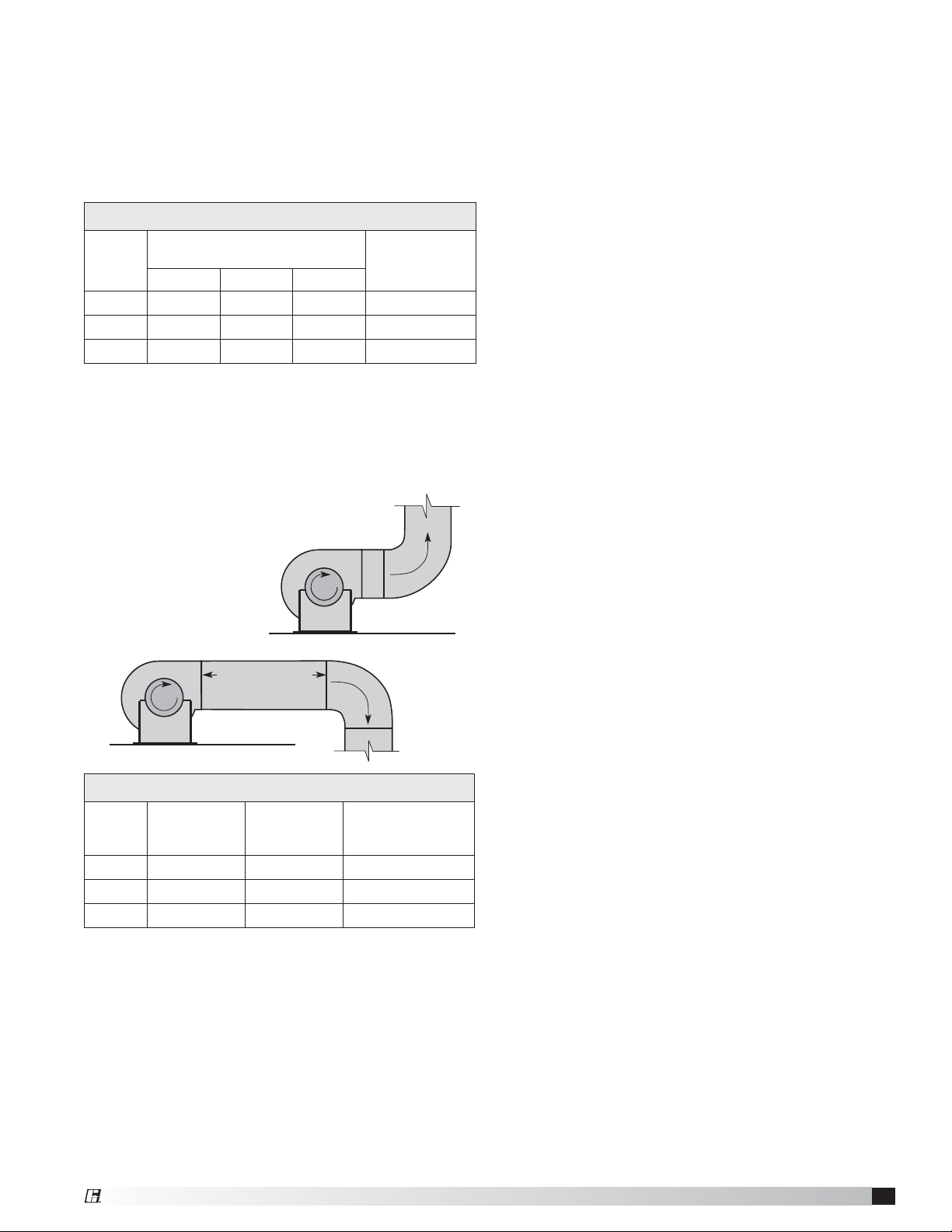

Ductwork Connections

Supply Fan

The supply fan in this unit is a plenum style fan. The

discharge opening dimensions are provided. For proper

fan performance, match the duct size to the dimensions

listed. Installation of all ducts should be done in

accordance with SMACNA.

Supply Fan Discharge Opening Dimensions

Supply Air

Unit

Discharge Location

Top End Bottom

VER-45 38.5 x 30 41.8 x 27

VER-65 50 x 31 50 x 31

VER-90 62 x 34 59.7 x 35

All dimensions shown in inches.

See diagram in Recommended Roof Openings section for the

*

Bottom Discharge opening sizes.

*

*

*

Exhaust Fan

The exhaust fan in this unit is a forward-curved fan.

Good and poor fan-to-duct connections are shown.

Airflow out of the fan should be

directed straight or curved the

same direction as the

fan wheel rotates. Poor

duct installation will

n

o

i

t

a

t

o

R

result in low airflow and

other system effects.

Length of

Straight Duct

(Supply Fan)

48

60

60

POOR

n

o

i

t

a

t

o

R

Length of Straight Duct

GOOD

Recommended Exhaust Fan Discharge Duct Size

Length of

Straight Duct

(Exhaust Fan)

Unit Duct Size

Exhaust

Blower Size

VER-45 20 x 20 12 48

VER-65 28 x 28 15 60

VER-90 32 x 32 18 60

All dimensions shown in inches.

• Recommended duct sizes are based on velocities across the

cfm range of each model at approximately 800 feet per minute

(FPM) at minimum airflow and up to 1600 fpm at maximum

airflow. Recommended duct sizes are only intended to be a

guide and may not satisfy the requirements of the project. Refer

to plans for appropriate job specific duct size and/or velocity

limitations.

• Straight duct lengths were calculated based on 100% effective

duct length requirements as prescribed in AMCA Publication

201. Calculated values have been rounded up to nearest foot.

VersiVent Energy Recovery Ventilator

11

Electrical Installation

WARNING

The roof lining contains high voltage wiring. To prevent

electrocution, do not puncture the interior or exterior

panels of the roof.

WARNING

To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch

open.

For units with a gas furnace, if you turn off the power

supply, turn off the gas.

IMPORTANT

Before connecting power to the unit, read and

understand the following instructions and wiring

diagrams. Complete wiring diagrams are attached on

the inside of the control center door(s).

IMPORTANT

All wiring should be done in accordance with the latest

edition of the National Electrical Code ANSI/NFPA70

and any local codes that may apply. In Canada, wiring

should be done in accordance with the Canadian

Electrical Code.

IMPORTANT

The equipment must be properly grounded and

bonded. Any wiring running through the unit in the

airstream must be protected by metal conduit, metal

clad cable or raceways.

CAUTION

If replacement wire is required, it must have a

temperature rating of at least 105°C, except for an

energy cut-off or sensor lead wire which must be rated

to 150°C.

DANGER

High voltage electrical input is needed for this

equipment. This work should be performed by a

qualified electrician.

CAUTION

Any wiring deviations may result in personal injury or

property damage. Manufacturer is not responsible

for any damage to, or failure of the unit caused by

incorrect final wiring.

WARNING

If unit is equipped with a microprocessor, terminals Y1,

Y2 and W1 cannot be wired to a thermostat. Wiring to

these terminals will bypass unit’s internal safeties.

1. Determine the Size of the Main Power Lines

The unit’s nameplate states the voltage and the unit’s

MCA. The main power lines to the unit should be

sized accordingly. The nameplate is located on the

outside of the unit on the control panel side.

2. Determine the Size of Electric Heater Wiring

An optional electric heater may require a separate

power supply. The power connection should

be made to the factory-provided electric heater

disconnect and must be compatible with the ratings

on the nameplate, supply power voltage, phase and

amperage. Consult ANSI/NFPA 70 and CSA C22.1

for proper conductor sizing.

3. Provide the Opening(s) for the Electrical

Connections

Electrical openings vary by unit size and arrangement

and are field-supplied.

4. Connect the Power Supplies

Connect the main power lines and electric heater

power lines to the disconnect switches or terminal

blocks and main grounding lug(s). Torque field

connections to manufacturer’s recommendations.

5. Wire the Optional Convenience Outlet

The convenience outlet requires a separate 115V

power supply circuit. The circuit must include short

circuit protection which may need to be supplied by

others.

6. Connect Field-Wired Low Voltage Components

Most factory-supplied electrical components are

prewired. To determine what electrical accessories

require additional field-wiring, refer to the unitspecific wiring diagram located on the inside of the

control center access door.

If unit is equipped with a microprocessor, terminals Y1,

Y2 and W1 cannot be wired to a thermostat. Wiring to

these terminals will bypass unit’s internal safeties.

Control wires should not be run inside the same conduit

as that carrying the supply power. Make sure that

field-supplied conduit does not interfere with access

panel operation. All low voltage wiring should be run in

conduit wherever it may be exposed to the weather.

The low voltage control circuit is 24 VAC and control

wiring should not exceed 0.75 ohms. If wire resistance

exceeds 0.75 ohms, an isolation relay should be added

to the unit control center and wired in place of the

remote switch (typically between terminal blocks R

and G on the terminal strip). The relay must be rated

for at least 5 amps and have a 24 VAC coil. Failure to

comply with these guidelines may cause motor starters

to “chatter” or not pull in which can cause contactor

failures and/or motor failures.

VersiVent Energy Recovery Ventilator

12

Field-Provided Disconnect

If field-installing an additional disconnect switch, it

is recommended that there is at least four feet of

service room between the switch and system access

panels. When providing or replacing fuses in a fusible

disconnect, use dual element time delay fuses and size

according to the rating plate.

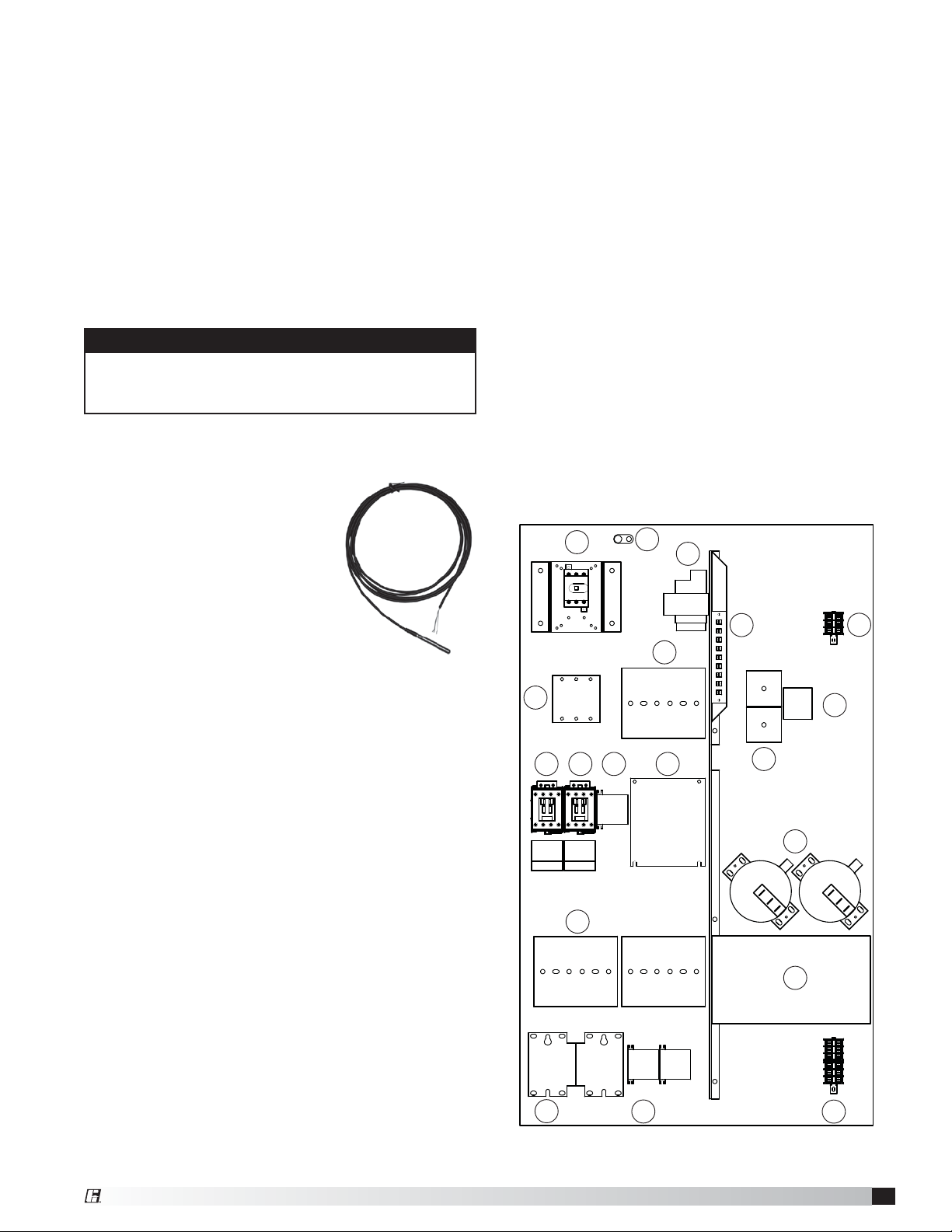

Discharge Air Temperature Sensor

Without Indirect Gas Furnace

For units without an indirect gas furnace, the discharge

air temperature sensor is factory-mounted in the blower

discharge section of the unit behind the blower cut off

plate.

WARNING

Discharge air temperature sensor is to be fieldinstalled prior to unit start-up on units with an indirect

gas furnace.

With Indirect Gas Furnace

For units with an indirect gas furnace, the discharge

air temperature sensor is to be

field-installed prior to unit start

up at least three duct diameters

downstream of the heat exchanger

or where good mixed average

temperature occurs in the ductwork.

The discharge air sensor is shipped

loose and can be found in the unit’s

control center. See the unit-specific

wiring diagram for connection locations.

Typical Control Center Components

1. Main Disconnect (non-fusible, lockable)

2. Motor Starter - Exhaust Air Fan

3. Motor Starter - Supply Air Fan

4. Motor Contactor - Energy Wheel

5. 24 VAC Control Transformer

6. 24 VAC Terminal strip

7. Fuses for blower motors*

8. Grounding lug

9. Distributor block*

10. Compressor fuse blocks*

11. Compressor contactors*

12. Condensing fan contactors*

13. Compressor relay*

14. Terminal block*

15. Compressor cycle timers*

Optional Control Center Components

16. DDC controller*

17. Dirty filter pressure switches*

18. Terminal block

19. Energy recovery wheel VFD*

*Not always provided

1

8

5

6

7

18

9

2

10

11

3 4 19

12

13

15

17

16

14

VersiVent Energy Recovery Ventilator

13

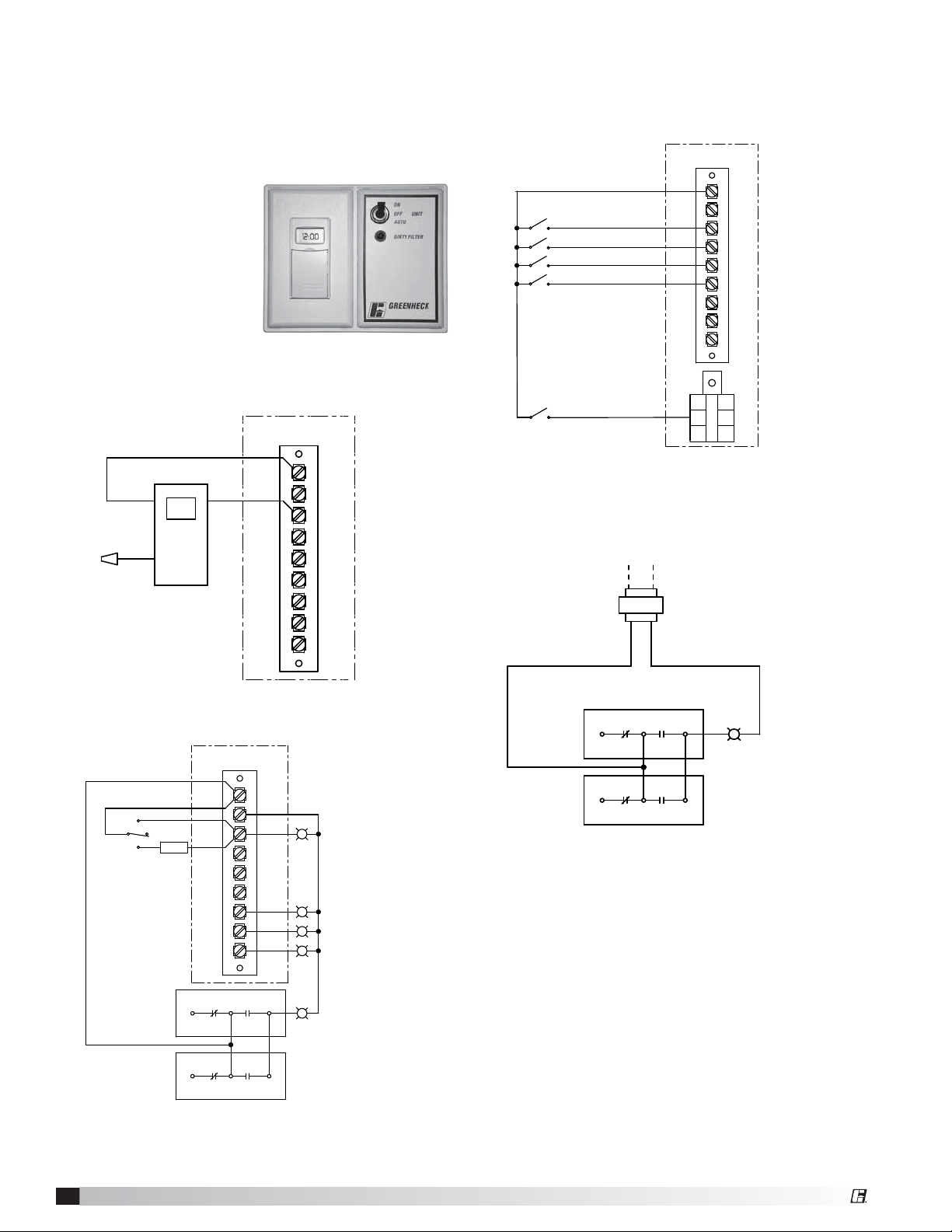

Optional Accessory Wiring Schematics

Remote Panel

The remote panel is available with a number of different

alarm lights and switches to control the unit. The remote

panel ships loose and requires mounting and wiring in

the field. The remote panel is available with the following

options:

• Unit on/off switch

• Unit on/off light

• 7-day time clock

• On/off/auto switch

• Dirty filter light

• Economizer light

• Frost control light

• Wheel rotation sensor light

Unit Interfacing Terminals

Heating/Cooling Switches and Night Setback Switch/

Timer

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

R

UNIT ON/OFF

S1

COOL STAGE 1 / ECONOMIZER

S6

COOL STAGE 2

S7

HEAT

S4

C

G

Y1

Y2

W1

6

7

12

7-Day Timer

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

R

BLACK BLUE

RED

(CAPPED)

TIMER

C

G

Y1

Y2

W1

6

7

12

On/Off/Auto Switch & Indictor Light Wiring

TERMINAL BLOCKS IN

UNIT CONTROL CENTER

UNIT ON/OFF

FROST CONTROL

ECONOMIZER

WHEEL ROTATION

ON

OFF

AUTO

* -- BMS, TIMECLOCK,

TSTAT, RTU, ETC.

*

R

C

G

Y1

Y2

W1

6

7

12

UNOCCUPIED RECIRCULATION

S5

Dirty Filter Indicator

(Powered by others)

HOT COMMON

SUPPLY DIRTY

FILTER SWITCH

EXHAUST DIRTY

FILTER SWITCH

NC

NC

A

C

NO

C

NO

DIRTY FILTER

C

SUPPLY DIRTY

FILTER SWITCH

EXHAUST DIRTY

FILTER SWITCH

ON/OFF/AUTO SWITCH ALLOWS THREE MODES OF OPERATION

"ON" - UNIT IS TURNED ON MANUALLY

"OFF" - UNIT IS TURNED OFF MANUALLY

"AUTO" - UNIT IS CONTROLLED VIA SCHEDULER OF BMS, TIMECLOCK, TSAT, ETC.

VersiVent Energy Recovery Ventilator

14

NC

NC

NO

C

NO

DIRTY FILTER

Loading...

Loading...