Page 1

September

2005

Page 2

®

Table of Contents

SECTION PAGE NUMBER

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1: Types of Commercial Kitchen Ventilation Hoods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2: Determining Exhaust Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3: Supply and Make-Up Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4: Room Balance and Airflow Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5: Grease Extraction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6: Fire Suppression Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7: Energy Management Systems (Variable Volume Driven) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8: Unit Selection

Exhaust Fan Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Make-Up Air Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9: Ductwork and Pressure Losses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10: Utility Distribution Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

11: Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

12: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13: Quick Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49-52

Greenheck Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Free Foot Area Consideration and Hood Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

References, Codes, and Informational Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Commercial Kitchen Ventilation Web sites. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Our Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2

Page 3

®

INTRODUCTION

A kitchen hood is not just a box. Every commercial kitchen requires ventilation, and in the past, the importance

of a proper ventilating system has been overlooked. Today, designers, installers, and operators are recognizing

the value in well-designed commercial kitchen ventilation (CKV) systems. Emphasizing “system” because it is

not just a box, it is an engineered system of exhaust hoods, ventilators, make-up air ventilators, grease removal

apparatuses and more. Taking time to properly design a CKV system will increase the health and safety of the

kitchen operators and increase the efficiency and energy savings for the owner.

This guide discusses many of the factors that must be analyzed when designing an efficient kitchen ventilation

system. It offers a background in the basic theories of CKV design, product types with their application,

necessary calculations with examples, troubleshooting, and more. This guide will assist in the development of a

well-balanced and functional system.

Although this guide will aid in a successful design, it is important to keep in mind the variation in standards

and codes which have been adopted. Each county may have slightly different requirements for the designer

to meet. The local authority having jurisdiction (AHJ) should be consulted to ensure the final design meets the

requirements set forth. See the design and code reference section on pages 52 and 53 of the guide for a listing

of common codes. If you would like to discuss any of the topics to further detail please contact Greenheck.

1

Make-Up Air Unit

Upblast Exhaust Fan

Vented Curb Extension

Variable Volume Controls

Fire Suppression Controls

Commercial Kitchen Hood

Filter Bank

3

Page 4

®

1

TYPES OF COMMERCIAL KITCHEN VENTILATION HOODS

Two Types of Hoods

Two different types of kitchen hoods are used in the commercial kitchen. These hoods are classified as a

TYPE I or TYPE II ventilation hood. TYPE I hoods are used over cooking equipment producing heat and grease

laden effluent. These hoods require a fully-welded ducting system. TYPE II hoods are used over non-grease

producing cooking equipment exhausting heat and condensation. Various categories of TYPE I and TYPE II

ventilation hoods exist for different applications and personal preferences.

TYPE I Canopy Hood

The canopy hood uses the updraft concept to capture and contain the contaminated

air generated by the cooking process. Heated air is less dense than

the surrounding air causing it to become buoyant. If no

cross drafts are present, the contaminated air will

rise up into the hood where it is captured and

contained until it can be exhausted through

the grease filters to the outside. Wall, single

island, and double island represent the three

configurations of canopy hoods. Although

each configuration is mounted from the ceiling

directly above the cooking equipment, each is

used for a different application.

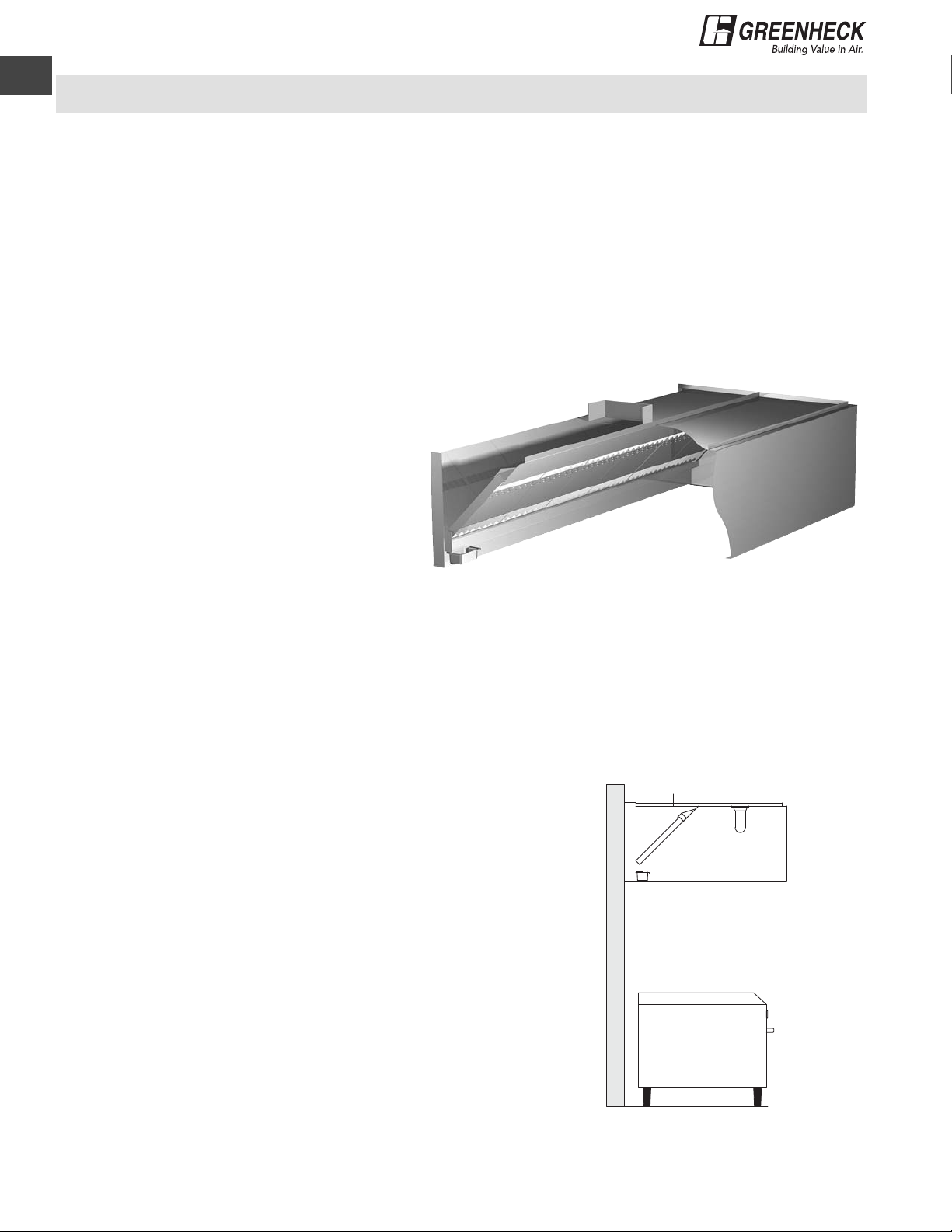

Wall Canopy Hoods

The wall canopy hood is used when the cooking equipment is placed against a wall. Hoods that are used

against a wall have a tendency to capture and contain the effluent using less airflow than in an island type

application. Make-up air from the kitchen enters the area below the hood replacing the air being exhausted.

The wall located on the backside of the hood will cause the make-up air to enter at the front and sides of the

hood creating a front-to-rear airflow pattern. The plume will rise from the appliance and will be attracted to

any surface parallel and near the cooking equipment, in this case, the wall. This phenomena is known as the

Coanda Effect. The plume is then directed into the hood, enhancing capture and containment. Cross drafts still

threaten spillage, but to a lesser degree than island style hoods.

National Fire Protection Association (NFPA 96) and International

Mechanical Code (IMC) should always be consulted when using a

wall canopy hood. Wall canopy hoods may or may not be mounted

directly against the wall depending on the type of wall. NFPA 96

defines three types of walls; non-combustible, limited combustible,

and combustible. Most commercial kitchen applications have

limited combustible walls which require a 3-inch air space between

the back of the hood and the wall. Most hood manufacturers

provide a 3-inch space with the hood enabling it to be placed

against the wall.

IMC requires a minimum hood overhang of 6 inches from

the cooking equipment on each end of the hood, and it is

recommended that there is a minimum overhang of 6-12 inches

beyond the widest cooking appliance for the front. Greater

overhangs will increase capture and containment.

Wall Canopy

4

Page 5

®

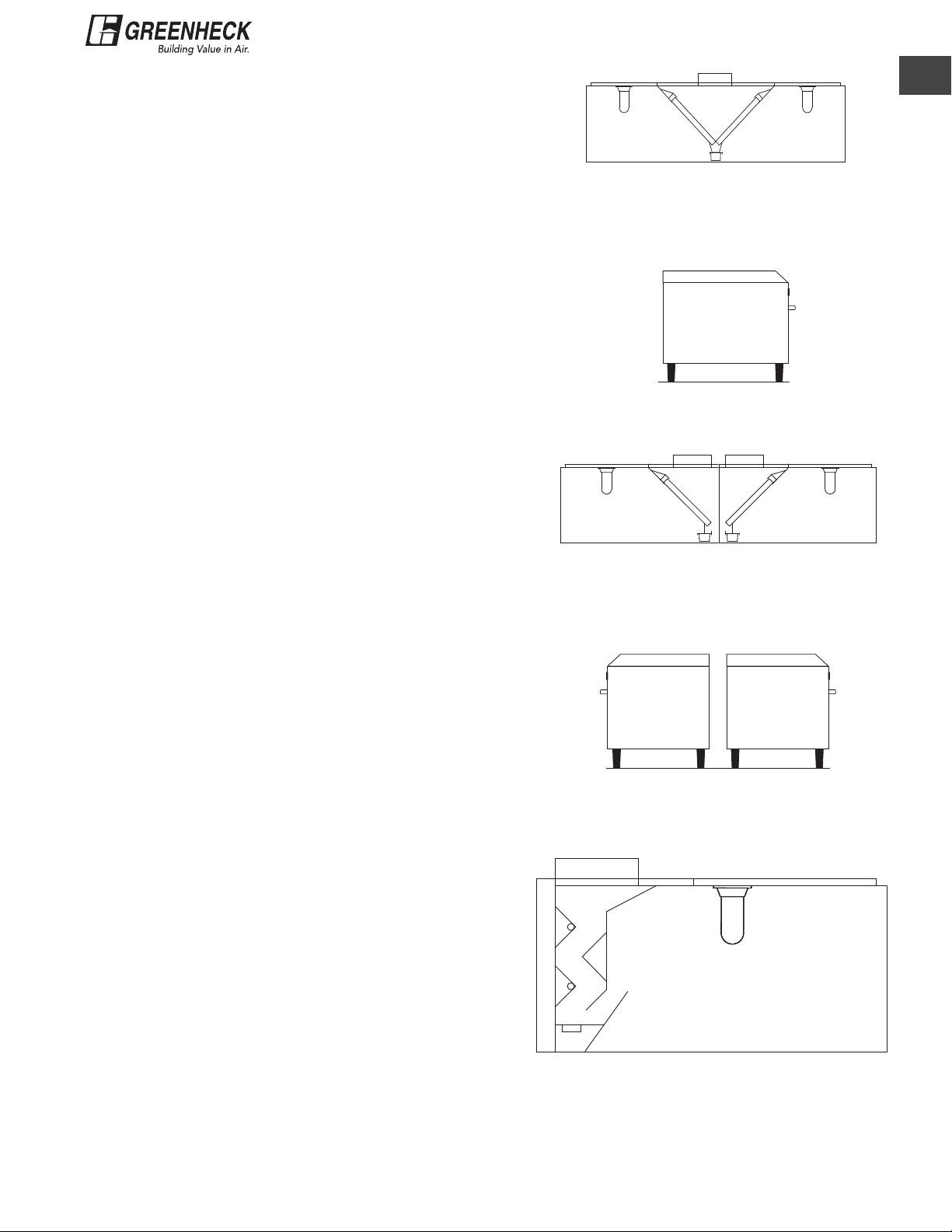

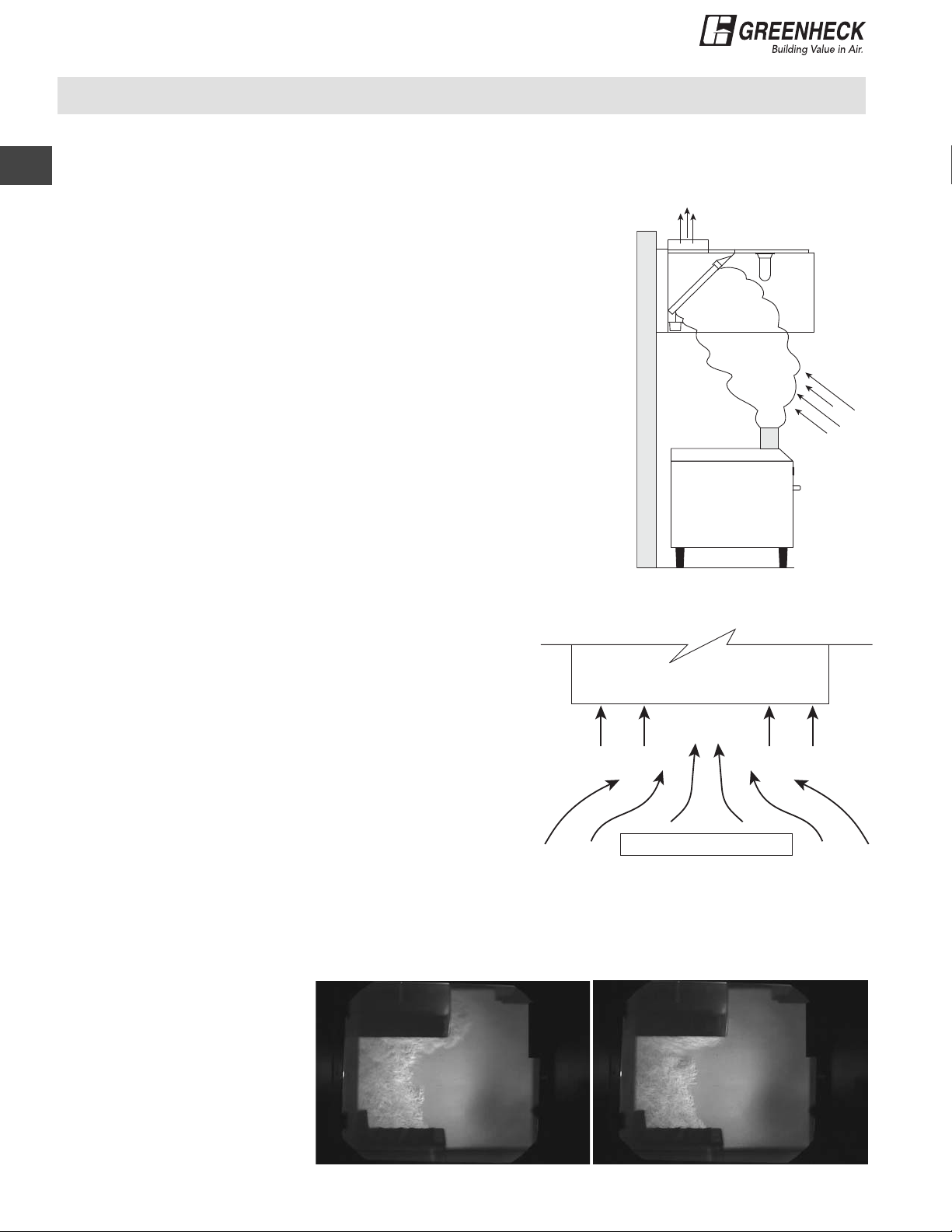

Single Island Hoods

A single island hood is used over one row of cooking

equipment placed where no walls exist. Single island

hoods can be seen from all directions, therefore, have

four finished sides. With four exposed sides, this type of

hood is more susceptible to cross drafts, spillage, and is

dependent only on the thermal updraft of heat from the

cooking equipment and how quickly the exhaust fan can

rid the hood of contaminated air. These hoods should be

sized larger and use more airflow than a wall canopy hood

with the same cooking battery. The single island hood must

overhang the cooking equipment by a minimum of 6 inches

on all four sides of the hood. However, it is recommended

that the overhang be extended to 12 inches on all sides

of the hood. Extending hood overhangs increases capture

volume which aids capture and containment. To eliminate

the front to back airflow on a single island, a V-bank of

filters improves capture and containment by directing the

contaminated air to the center of the hood.

A wall canopy can be installed as an island hood with

a finished back enhancing its aesthetic appearance.

However, it is not recommended because the front to

back airflow pattern of a wall canopy will cause capture

problems when being utilized as a single island canopy.

1

Single Island Canopy

Double Island Hoods

A double island hood is placed over two rows of cooking

equipment placed back to back. This configuration

is made up of two wall canopy hoods placed back to

back, thus creating four finished sides. This category of

hood performs similar to the wall canopy hood due to

two thermal plumes rising against each other, but is still

susceptible to cross drafts. A double island hood must

overhang the equipment by a minimum of 6 inches on all

four sides of the hood but would benefit from additional

overhang.

Water Wash Hoods

Available in a wall canopy or double island configuration,

water wash hoods are a cartridge type canopy hood,

meaning the grease filtration device is built into the

exhaust plenum. Water wash hoods utilize water spray

nozzles in the exhaust plenum to clean the grease

collected by the filtration system (see Figure 35 on page

24) after a certain period of operation. These wash cycles

can be programmed to run for a specified length of time

and can be set to run automatically at the end of the day.

Continuous water mist can be used to extinguish embers

on a solid fuel cooking operation. The hood is controlled

through a remote mounted control box including an

adjustable flow detergent pump, a wash cycle timer in

a solid state programmable controller, and a detergent

reservoir. These hoods have a high up-front cost and have

a higher operating cost than other types of hoods.

Double Island Canopy

Water Wash Hood - End View

5

Page 6

®

A

C

1

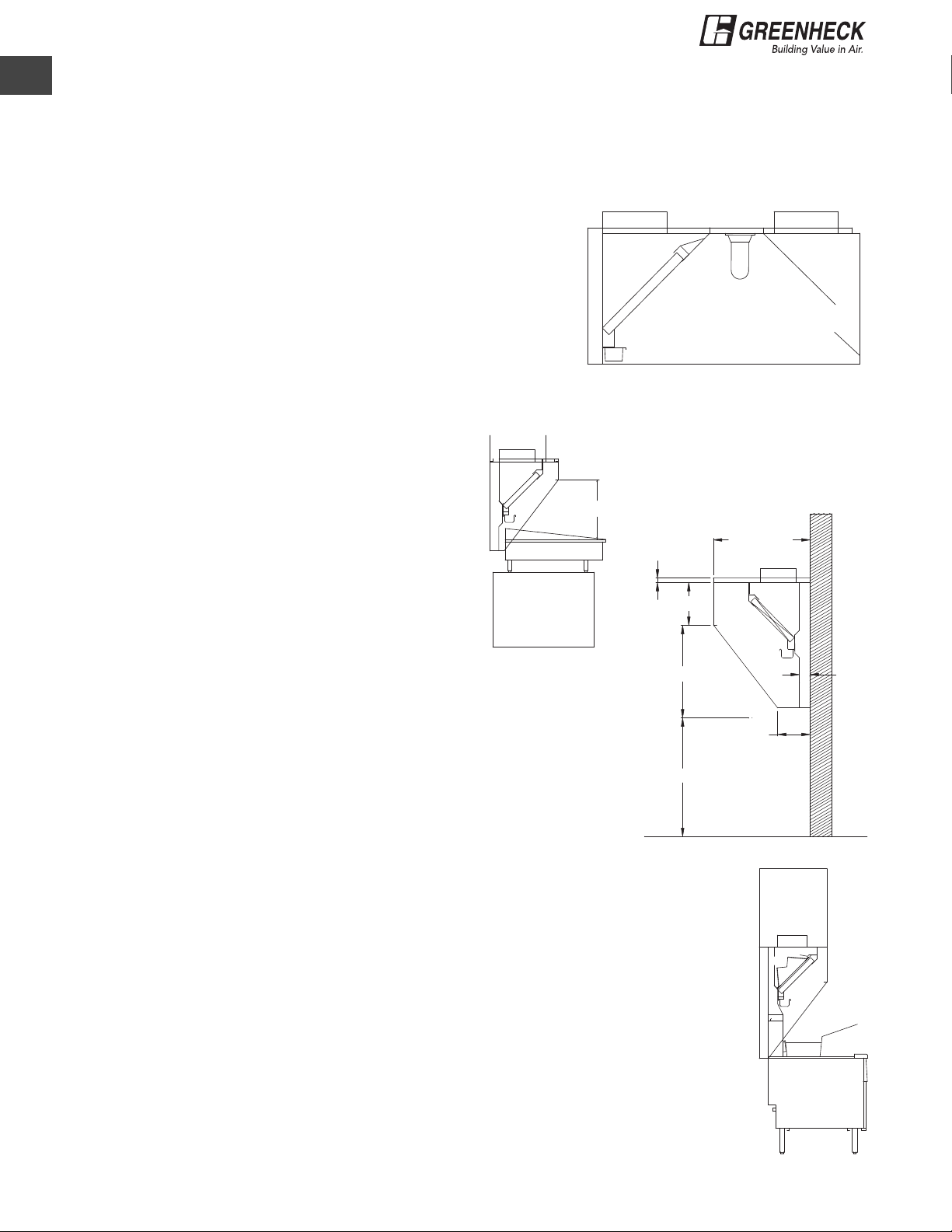

Short Circuit Hoods *Warning: NOT RECOMMENDED*

Short circuit canopy hoods were once thought of as an energy saving device. The theory, by introducing

untempered make-up air inside the hood reservoir it would reduce the amount of tempered air being exhausted

from the kitchen, minimizing heating and cooling loads. This was done to get around old codes which set a

minimum exhaust rate that was much higher than needed to achieve capture and containment. Make-up air

was short-circuited by as much as 80-90% of the exhaust rate resulting in spillage of the contaminated air.

*Schlieren Imaging (see Schlieren Imaging on page 8) confirms that

only 15% of the minimum capture and containment airflow can be

brought through the hood without causing spillage.

Short circuit hoods are ineffective because they do not discharge the

make-up air in the correct location. Think of the cooking equipment

as a generator of contaminated air. The purpose of make-up air is to

replace the air that is being generated at the cooking surface. Both

the hood and exhaust system are designed to capture and contain the

airflow generated by the cooking equipment. Short circuit hoods dump

make-up air into the capture and containment area, thus overfilling the

hood and releasing a mix of make-up and contaminated air into the

Short-Circuit Hood - End View

room causing greasy surfaces and increased heat loads. For these

reasons, short circuit hoods are not recommended.

*Data provided by Architectural Energy Corporation,

and Fisher-Nickel, Inc.

UL Vertical Distance

Above Cooking Surface

Proximity Hood

Hanging Height

Proximity Hoods (Backshelf)

Proximity hoods are TYPE I hoods that are shorter in

1.5 INCH OPTIONAL SHELF

height and depth than a typical canopy hood. The name

“Proximity” or “Backshelf” refers to the close location of

the hood with respect to the cooking equipment. Actual

6 OR 12 INCHES

distance from the cooking equipment varies between

manufacturers due to their UL listing; typically mounted

at 10-36 inches above the appliance. Cooking equipment

may extend past the face of the hood creating underhang, therefore cooking

17 TO 36 INCHES

equipment such as large skillets and ovens may not be used. See the

manufacturer’s UL listing. Even with underhang, these hoods are still able

to capture the contaminated air due to their close proximity. Large surges

3 INCH TO EQUAL TO

HOOD DEPTH

of contaminated air may escape from the hood, therefore proximity hoods

are best suited for light and medium duty cooking applications such as

griddles. The major benefit is reduced airflow required to obtain capture and

COOK SURFACE

containment compared to a canopy hood with the same cooking lineup. The

savings are realized through reduced heating and cooling loads.

Flue Bypass Proximity Hoods

Proximity hoods are mounted closer to the cooking equipment subjecting the grease filters to

abnormal heating loads from appliance flues. When gas-fired cooking equipment with flues

are used, flue bypass proximity hoods offer another advantage. Instead of allowing the heat

from the flues to pass-thru the face of the filters, the flues are ducted to discharge the hot air

directly to the back of the exhaust plenum, bypassing the grease filters. Normally, this heat

would hit the filters, causing them to radiate heat onto the cooking personnel. Radiant heat

loads are greatly reduced with the absence of the hot flue gases and grease is less likely to

bake to the filter face which enables the filters to be cleaned more easily. Airflow requirements

are lowered because the hood does not have to capture the excess heat, only the heat and

grease from the cooking surface must be contained.

The flues on the equipment must be sized correctly to the bypass chamber to ensure grease

is not pulled into the flue. Dampers control the amount of hot flue gases that exit through

the exhaust plenum. This airflow is critical to cooking equipment performance, therefore,

the dampers must be set according to the cooking equipment beneath the particular hood.

Greenheck should be consulted prior to ordering flue bypass proximity hoods to ensure a

proper hood-to-equipment fit. Flue bypass is recommended for fryers and griddles.

23 TO 36 INCHES

Flue Bypass

3 INCH

OPTION

CLEARAN

6

Page 7

®

TYPE II Hoods

TYPE II hoods are commonly referred to as oven or condensate hoods. In essence, these are stripped down

exhaust only canopy hoods. The purpose of the TYPE II hood is to remove heat, moisture, and odor-ridden air

from non-grease producing appliances. The hoods do not contain grease filter banks but rather a duct collar

to exhaust the contaminated air. A TYPE II hood duct does not

need to be fully-welded, instead it can be a standard galvanized

duct because there is no grease loading. Flex-duct is not

allowed for TYPE II hoods.

Oven Hood

The oven hood is an exhaust only canopy hood with an exhaust

duct collar for the removal of heat and vapor. These hoods are

the simplest of all hoods and are usually placed over ovens or

small appliances only producing heat and odor. For complete

capture and containment, overhangs should be measured with

the oven door open.

Condensate Hood

The condensate hood is an exhaust only canopy hood with

U-shaped gutters to capture and direct condensate to a drain.

It also has an exhaust duct collar for heat, moisture, and

odor-ridden air to exit. Many manufacturers have options for

condensate baffles in the hood to help condense the moisture

laden air, one or two baffle configurations are typical, depending

on the moisture content of the contaminated airstream.

Condensate hoods are usually found mounted over dishwashers.

For complete capture and containment of large plumes of heat

and steam, 18-36 inches of overhang are recommended.

Oven Hood - End View

Condensate Hood - End View

1

HOOD CERTIFICATION

Most jurisdictions require TYPE I exhaust hoods to bear the Underwriters Laboratory (UL) label. UL 710 is

the test criteria in which UL listed exhaust hoods are tested. Tests include temperature, cooking, flare-up,

fan failure, fire, and burnout testing. In order to complete the analysis, these hoods have to be operating at a

minimum exhaust airflow rate to obtain capture and containment determined under laboratory conditions.

This is where the misconception of the UL listing becomes apparent. The minimum airflow that UL uses to

test hoods is obtained by first adjusting airflow to the manufacturer’s recommendation, then fine tuning it to

ensure complete capture and containment of the effluent generated by cooking hamburgers. This airflow is

then assumed to be the minimum capture and containment value for the UL testing of a particular hood in

a controlled laboratory environment. This airflow is then considered safe for the flare-up and burn tests that

follow. The temperature of the hood shall remain in a range that does not compromise the structural integrity

of the hood at the listed airflow. The airflow does not guarantee capture and containment.

UL minimum airflow ratings in the hoods exist only as a safety rating. It does not guarantee capture and

containment and therefore, should rarely be used as design criteria. It is important to realize that UL

established airflow rates are determined and utilized under laboratory conditions. More exhaust and/or

lesser supply rates may be required in real environments. There are situations where extremely light cooking

applications exist where the exhaust rate may be at or near the UL listings, but only in these light, low

volume, and light cooking battery situations.

7

Page 8

®

DETERMINING EXHAUST RATE

Having the proper exhaust rate is one of the most crucial calculations in a kitchen ventilation system. Not only

will it allow the system to capture as it is designed, but can save money each year through energy savings as

well as initial start-up costs. Throughout the industry there are two common methods to determine exhaust

2

airflow, which will be discussed in this section. It is important to establish how contaminated air is generated

and how it behaves.

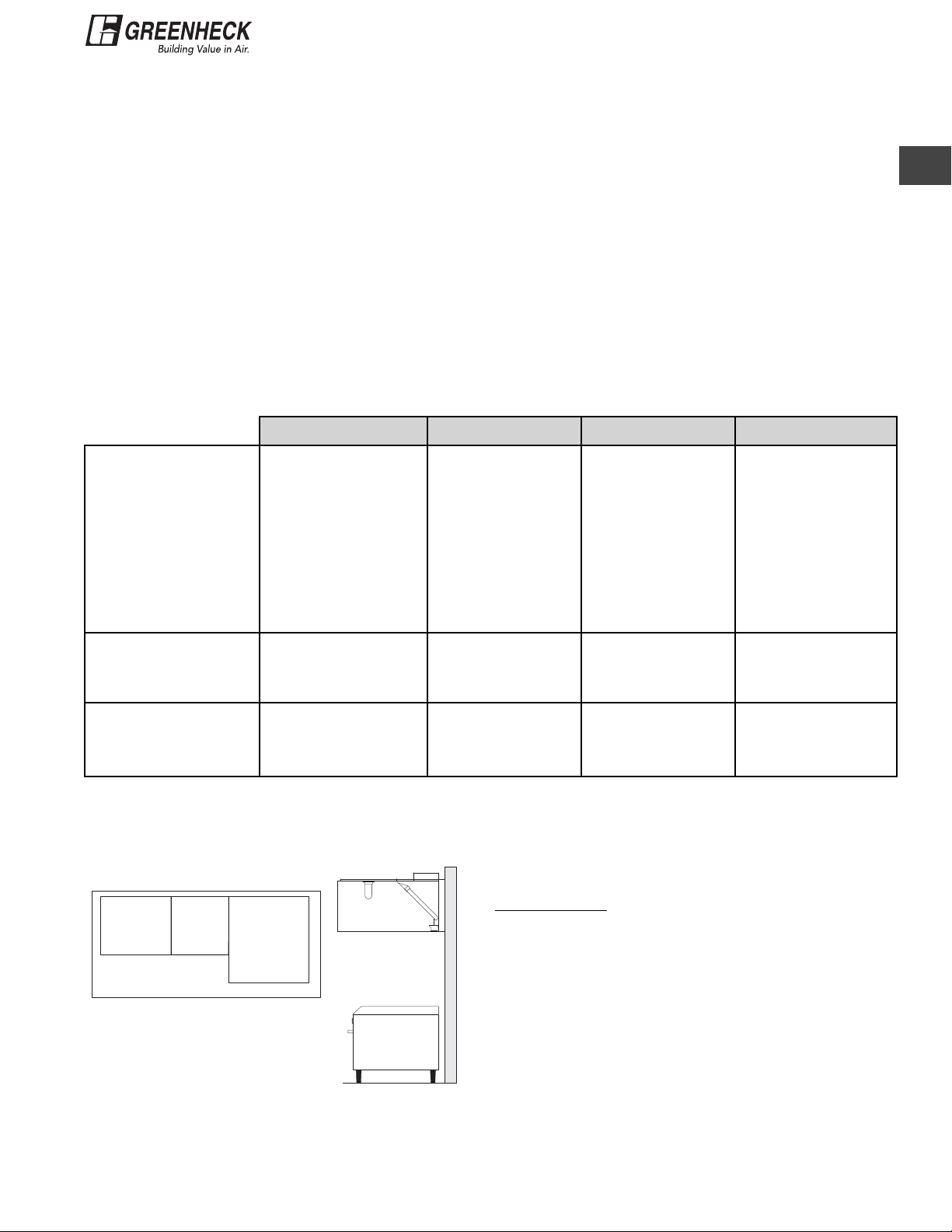

Cold vs. Hot

Concepts used to determine airflow rates in the past were developed through

testing on non-operating (cold) equipment. As shown in Figure 1, smoke

bombs were commonly placed at the front edge of the cooking equipment.

The exhaust rate would then be increased until all the smoke was captured,

thus determining a minimum capture velocity. Additionally, it increases the

amount of make-up air needed to balance the room which decreased overall

system efficiency.

Fortunately, the majority of tests are required to be completed over operating

(hot) equipment. Greenheck’s approach utilizes the thermal updraft produced

through the transfer of heat from the surface to air. The updrafts help to

transfer the contaminated air (heat, grease vapor, smoke, steam, and gas

combustion) to the kitchen hood as seen in Figure 2. Implementing this

approach can significantly reduce the airflow required to obtain capture and

containment. By realizing that hot air rises, a more efficient and less costly

system can be achieved.

Smoke

Cold

Cooking

Equipment

The Cooking Equipment

When using the “Greenheck Method” the cooking equipment can

be thought of as a generator of contaminated air. The quantity

of such air generated by each appliance is ultimately dependent

upon the temperature and size of the physical cooking surface.

Gas flues on gas equipment are also considered generators.

Heat from appliance surfaces cause a change in the density of

surrounding air creating a thermal updraft. While hot air rises, it is

replaced by air in the immediate vicinity as shown in Figure 2. The

replacement air assists in establishing minimal capture velocity at

the cooking surface and contains the contaminated air generated

by the cooking equipment. There are many factors that can alter

the direction and velocity of this air which are discussed in the

design consideration (pages 42-45) section of this guide.

Hood

Updraft

Heated Surface

Figure 1

Figure 2

Schlieren Imaging

Schlieren Imaging is a powerful tool now being used for research in the commercial kitchen ventilation industry.

Schlieren Imaging enables people to see the heat given off by appliances and watch its flow pattern in the

hood. It is an excellent way to test for capture and containment due to the ability to zoom in closely along

edges of the hood and observe any escaping effluent. Schlieren images are made visible by taking advantage

of the different air densities

yielding a high contrast

optical image.

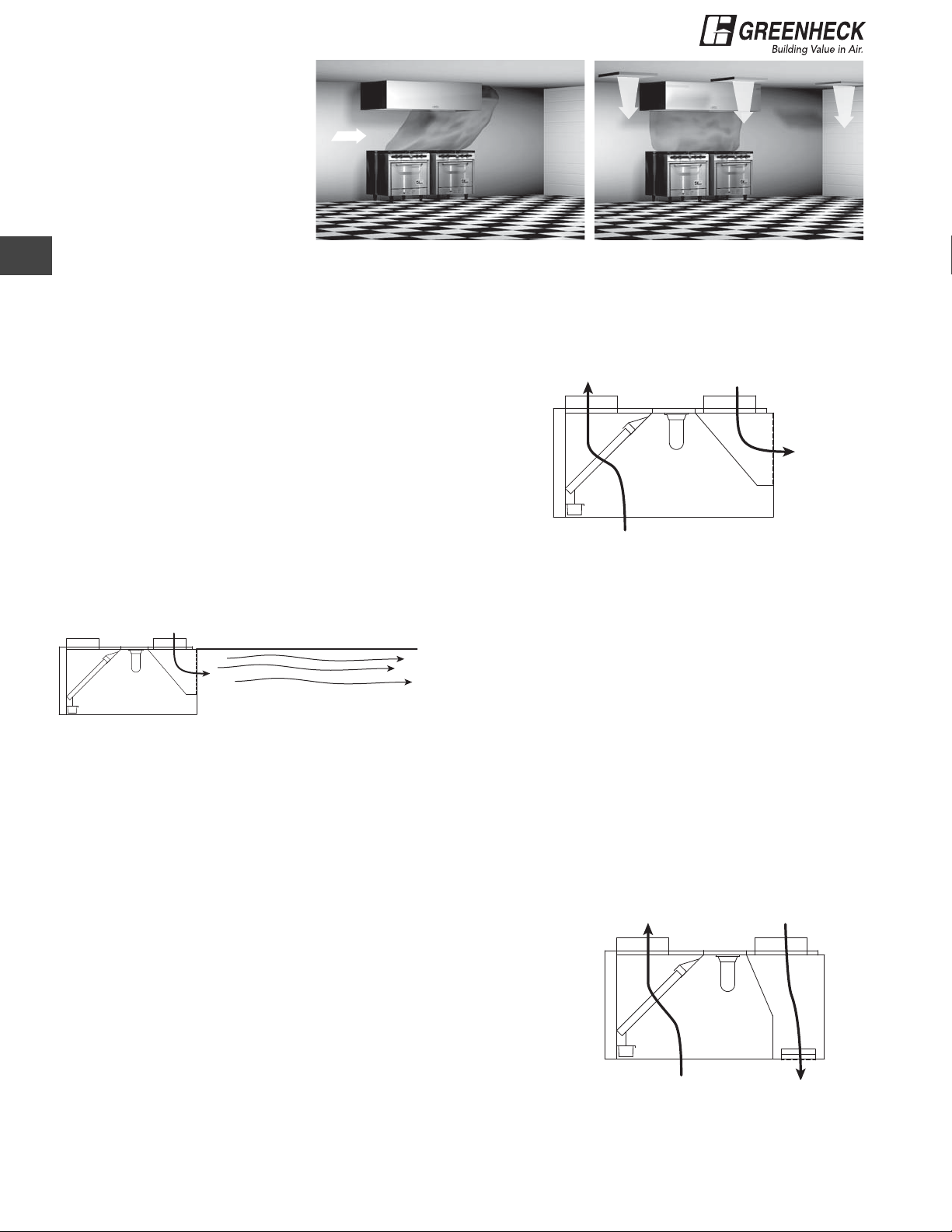

Figure 3A & 3B are an example of

the heat load seen in a common

kitchen application. Both hoods

use the same exhaust rate,

however, the hood in Figure 3A is

spilling heat into the space.

Figure 3BFigure 3A

8

Page 9

®

Previously undetectable to the eye, it is apparent that the heat gain to the space can be quite significant. Figure

3B demonstrates Greenheck’s PEL lip technology, which is a 1.5 inch return lip along the bottom edge of the

hood. This lip directs airflow back into the hood allowing cfm requirements to be reduced without spillage. A

properly designed system should look like the image on the right.

Utilizing Exhaust Flow Definitions

Using any of the concepts, every piece of cooking equipment can be placed into a category which assigns

a value to the actual updraft velocity or airflow volume per foot. These values can be used for CFM hood

calculations. Figure 4 categorizes common kitchen appliances and provides the updraft velocity factors and

International Mechanical Codes airflow volume per linear foot necessary to complete the calculations.

Recognize that the extra-heavy category contains nearly all solid fuel cooking appliances. Solid fuel is the most

volatile and uncontrollable fuel source in a commercial cooking operation. There is no on/off switch like most

appliances, but rather one can add fuel or let the fuel burn out. Thus, the load is extremely variable and may

exceed projected exhaust requirements. In these situations it is important to have additional airflow up front and

size exhaust and supply fans so their airflow can be increased if needed. Lastly, look into standards and code

requirements such as: Local Codes, State Codes, NFPA 96, IMC, or any other required agencies in the area to

ensure proper installation.

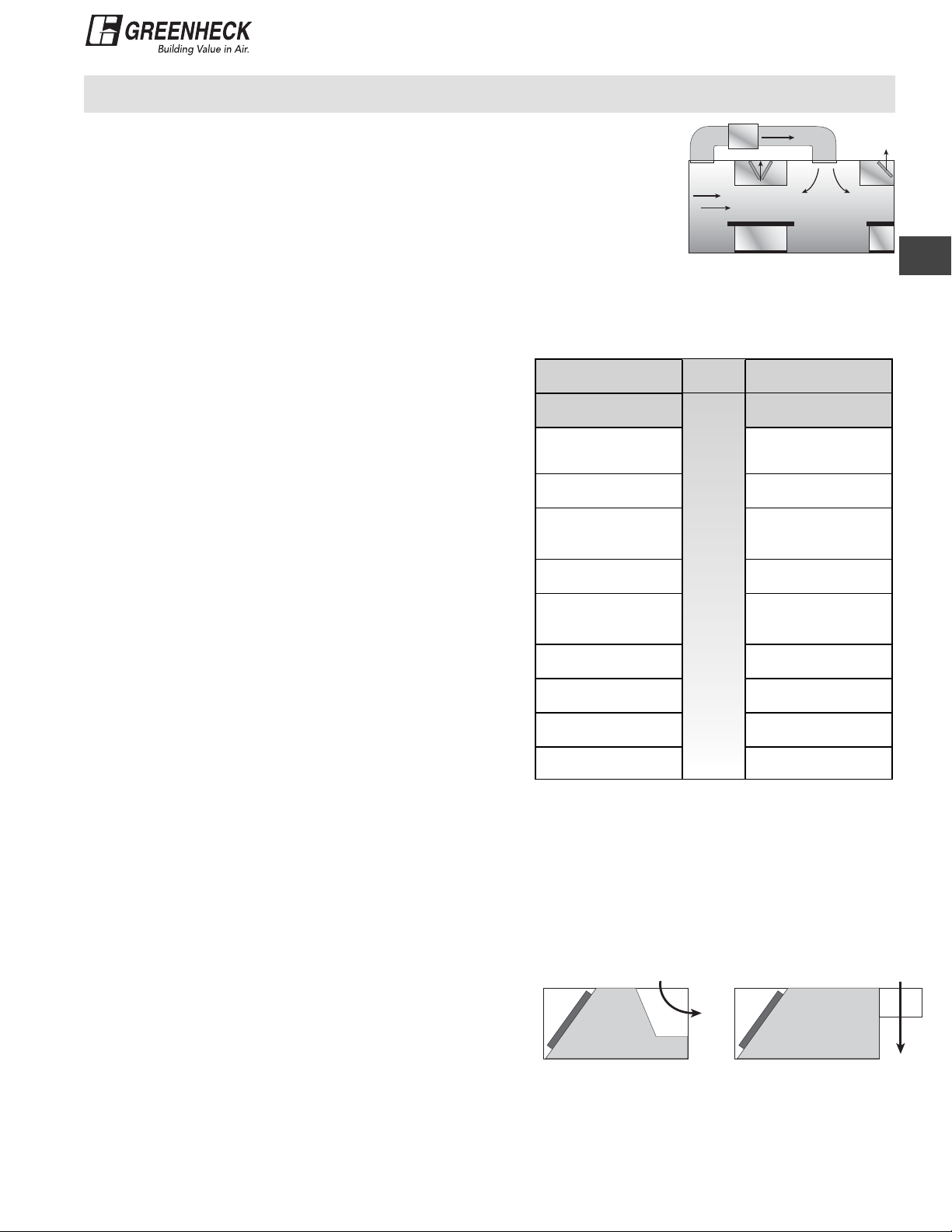

LIGHT MEDIUM HEAVY EXTRA-HEAVY

2

Equipment

(Greenheck’s Appliance

Classification)

Greenheck Method

(updraft velocity in feet

per minute)

International Mechanical

Code

2003 Edition

(cfm per linear foot)

Gas & Electric Ovens

Gas & Electric Steamers

Gas & Electric Ranges

Food Warmers

Pasta Cookers

Pizza Ovens

Non-Cooking Appliance

Smoker

Rotisserie

50 85 150 185

200 300 400 550

Combi-Ovens

Gas & Electric Fryers

Griddles

Tilting Skillets

Tilting Braising Pans

Grill

Hibachi Grill

Salamander

Upright Broiler

Electric Char-Broiler

Gas Char-Broiler

Mesquite

Infrared Broiler

Lava Rock Char-Broiler

Wok

Chain Broiler

Figure 4

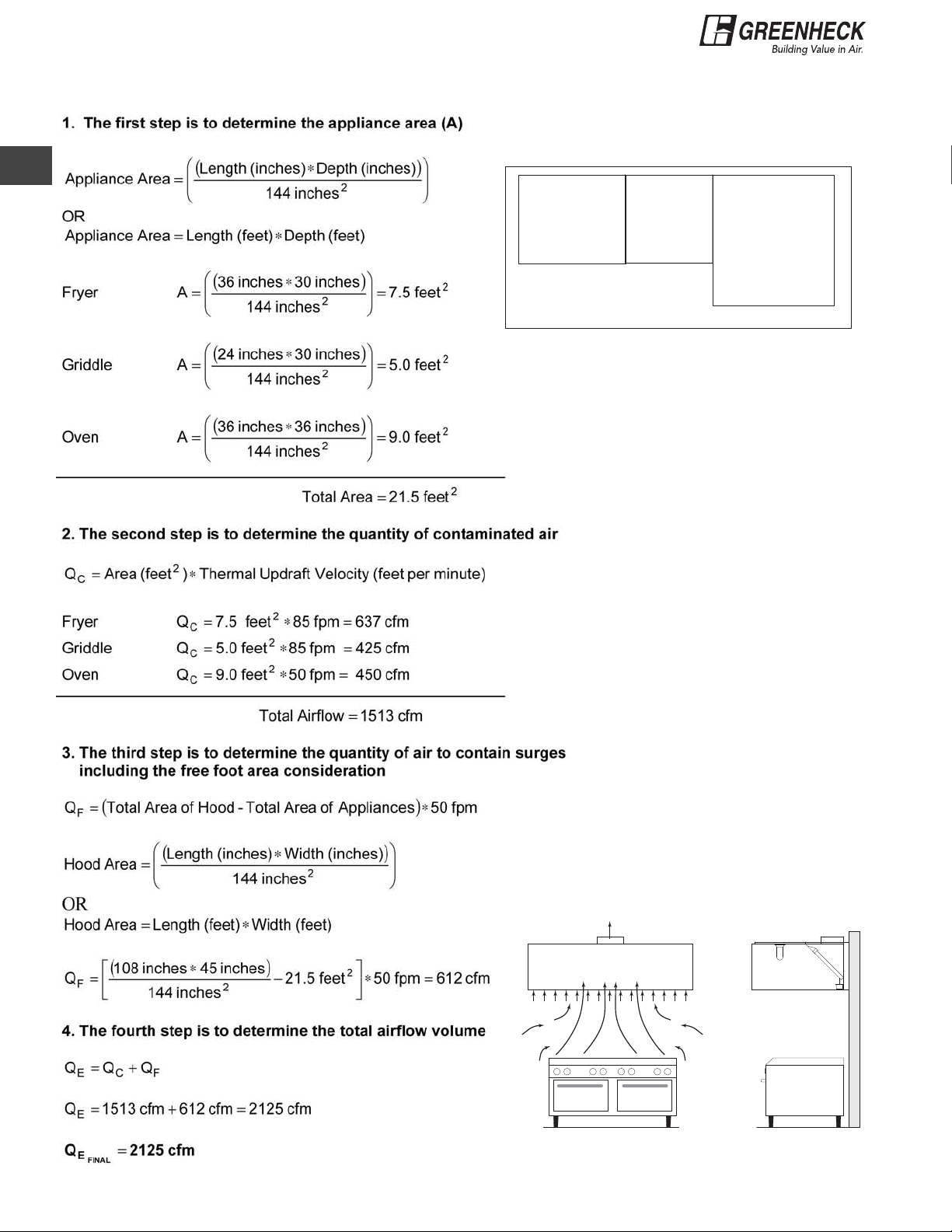

A typical cooking battery has been created and will be used to illustrate the IMC code method, Greenheck

Method, Free Foot Consideration, and Greenheck’s Airflow Volume per linear foot method. Figure 5 illustrates

the typical cooking battery.

ASSUMPTIONS

Fryers

36 in. x 30 in.

Griddle

24 in. x 30 in.

Oven

36 in. x 36 in.

• 3 inch spacing behind hood

• Typical 6 inch overhang required on sides and front

• Hood Dimensions: 9 ft. 0 in. long x 4 ft. 0 in. wide

• Greenheck Method uses actual containment area of

45 in. because of 3 in. integral air space

IMC EXAMPLE

Figure 5

IMC requires that when calculating the exhaust rate for a combination of appliances, the highest exhaust rate

be applied over the entire length of the hood. Therefore, in the case of the hood above, IMC requires 300 cfm/

ft. for the 9 feet of hood yielding a total of 2700 cfm. Furthermore, it is recommended by IMC and NFPA that any

hood over a solid fuel cooking battery shall have a separate hood, duct, and exhaust system.

9

Page 10

Greenheck Method

2

®

Fryers

36 in. x 30 in.

Griddle

24 in. x 30 in.

Oven

36 in. x 36 in.

QC - Quantity of contaminated air

generated by the cooking equipment.

Using Figure 4, identify the appropriate

updraft velocity and multiply it by the

area of the appliance.

10

QF - Quantity of air required to contain

surges and drafts. Use the minimum

updraft velocity of 50 fpm and multiply

it by the difference in area between

the hood containment area and the

appliance area.

Q

E

Q

F

Q

C

Page 11

®

Greenheck airflow volume per linear foot (cfm/linear foot) method

The commercial kitchen ventilation industry uses several different ways to calculate the exhaust airflow required

to obtain capture and containment. A vast majority of companies, standards, and codes use airflow in

cfm/lineal foot. To help do a comparison, Greenheck suggests the following cfm/lineal foot values shown in

Figure 6 below. The example calculation below uses the typical cooking battery from the Greenheck Method

example on the previous page. Like the Greenheck Method, the linear foot method is appliance specific. Use

the appropriate airflow volume rate across the length of each appliance. Use the light duty airflow for end

overhangs and the sum of the individual rates is the total airflow. Lastly, note that hood factors should be

applied after obtaining an exhaust value using cfm/lineal foot.

HOOD TYPE LIGHT MEDIUM HEAVY EXTRA - HEAVY

Wall Canopy 200 250 350 450

Backshelf 150 200 300 N/A

Note: 1. Double Island hoods are considered two wall canopy hoods

2. Single Island hoods need to be multiplied by the hood factor after using the wall mounted canopy value

Figure 6

EXAMPLE CALCULATION

2

Limits and Assumptions

Airflow (cfm) = Length (feet) ∗ Airflow Volume

cfm

linear foot

(for cfm per lineal foot calculations)

1. Used for hoods 54 in. or less in width

Left Overhang Airflow = 0.5 feet ∗ 200 = 100 cfm

cfm

linear foot

2. Cannot be used for pizza ovens

3. Cannot be used for cook chill

4. 6 ft. 6 in. hanging height

5. Vertical updrafts

6. Proper room ventilation

7. Proper overhangs

Fryer Airflow = 3 feet ∗ 250 = 750 cfm

Griddle Airflow = 2 feet ∗ 250 = 500 cfm

Oven Airflow = 3 feet ∗ 200 = 600 cfm

Right Overhang Airflow = 0.5 feet ∗ 200 = 100 cfm

cfm

linear foot

cfm

linear foot

cfm

linear foot

cfm

linear foot

Total Airflow = 2050 cfm

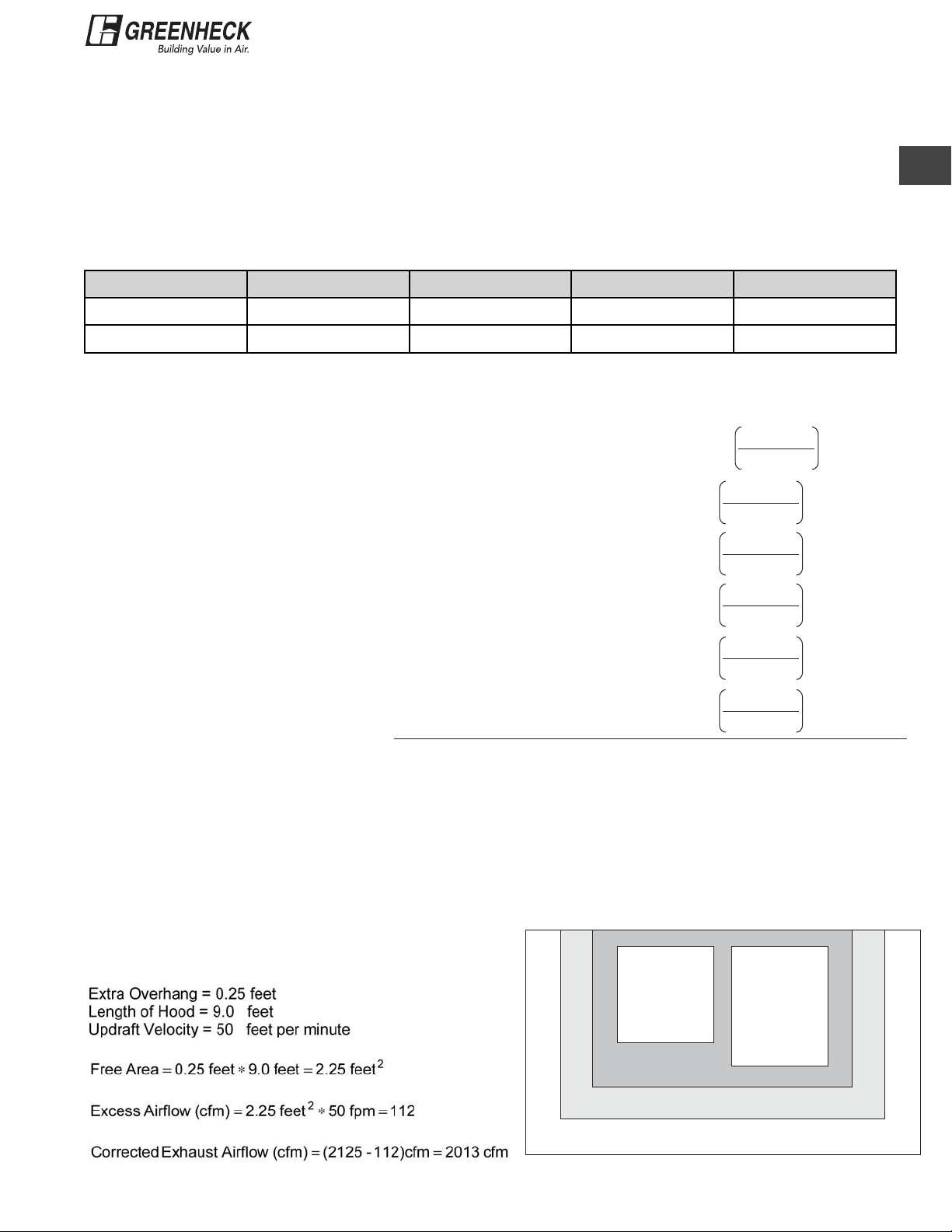

FREE FOOT AREA CONSIDERATION

The Greenheck Method assumes in most cases a 6 inch overhang on the front and ends of the hood under the

typical cooking battery and open end conditions. Unfortunately, the method penalizes for additional square feet

of empty hood. Additional overhang can help increase capture by utilizing a larger “holding tank” for the effluent

before it’s exhausted, helping with large momentary surge. However, there are limits to how much overhang is

effective. Therefore, Greenheck will allow a 1 foot extension beyond the built-in 6 inches of overhang creating

a free foot area without increasing the required airflow. This can be used for both Greenheck Method and CFM

per lineal foot. See Figure 7 below.

CORRECTING FOR FREE FOOT AREA

11

12 in.

6 in.

12 in.

Steam Kettle

30 in. x 30 in.

(50 cfm/ft

“Greenheck Method” Area

(50 cfm/ft2)

2

)

Free Area Overhang (0 cfm/ft2)

Extended Area Outside Updrafts (50 cfm/ft

Oven

30 in. x 40 in.

2

(50 cfm/ft

6 in.

6 in.

)

12 in.

2

)

12 in.

Figure 7

Page 12

The table to the right illustrates the difference in exhaust

CFM between the Greenheck Method and the IMC

method. At a cost of approximately $2.00/cfm each year,

the Greenheck method offers significant savings. The

2

Greenheck Method considers all the cooking equipment

as a separate item to determine the best exhaust rate.

It not only is the most accurate, but is the lowest airflow

volume of the three methods. The Greenheck Method

is appliance specific to determine the proper amount

of exhaust required so that the system is not underexhausting or over-exhausting, costing more money in

either operation, cleaning, or upgrading costs.

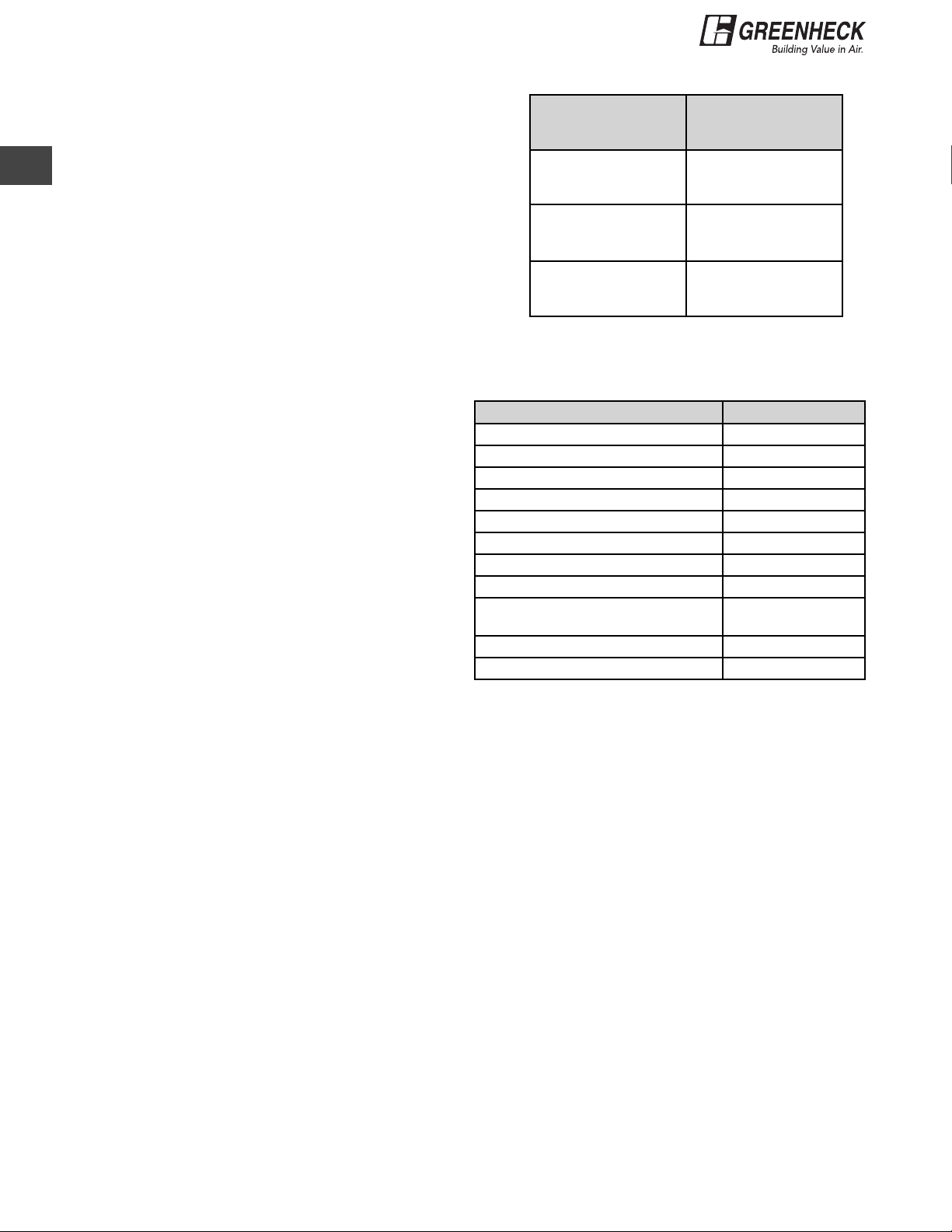

Method Exhaust CFM

International

Mechanical Code

Greenheck

Method

Greenheck

cfm/lineal ft.

®

2700

2013

2050

HOOD FACTORS

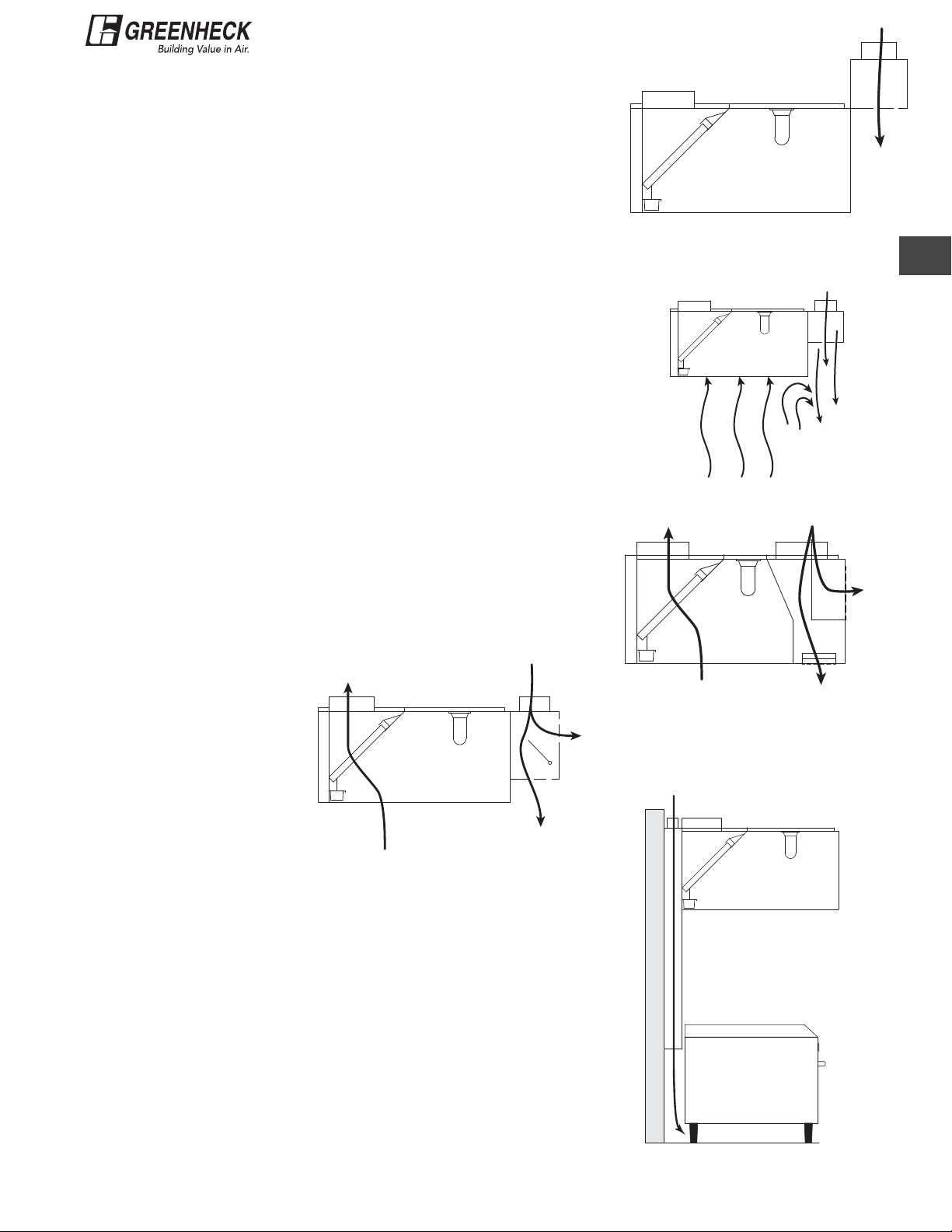

There are several design factors that can either hinder

or enhance the performance of the kitchen ventilation

system. For that reason, Figure 8 has customized

the exhaust airflow to the application. Notice there

are some scenarios that will increase the airflow

significantly and others that do not change or will

decrease the airflow. Use this chart after you have

already determined the airflow using the Greenheck

Method, or Greenheck airflow volume per lineal foot.

Simply multiply the cfm by the multiplication factors

for each item that applies.

Wall Canopy 1.0

Wall Canopy - Finished Back 1.3

Single Island - V-Bank 1.2

Double Island 1.0

Mini Skirts - 2x2 0.92

End Skirts - Full / Wall 0.90

Exhaust Only 1.0

Supply Plenums 1.1

Char-Broiler at end of Canopy or

under a Single Island hood

Hanging Height 6 ft. 6 in. 1.0

Hanging Height 7 ft. 0 in. 1.1

Condition Multiplying Factor

EXAMPLE HOOD FACTOR CALCULATION

Given a determined exhaust rate of 3000 cfm, it has now been determined that the application will

have the following conditions:

1. Char-Broiler at the end of the canopy (1.2)

2. Full End Skirts (0.9)

1.2

Figure 8

Therefore the new airflow will be: Airflow (cfm) = 1.2 * 0.9 * 3000 cfm = 3240 cfm

12

Page 13

®

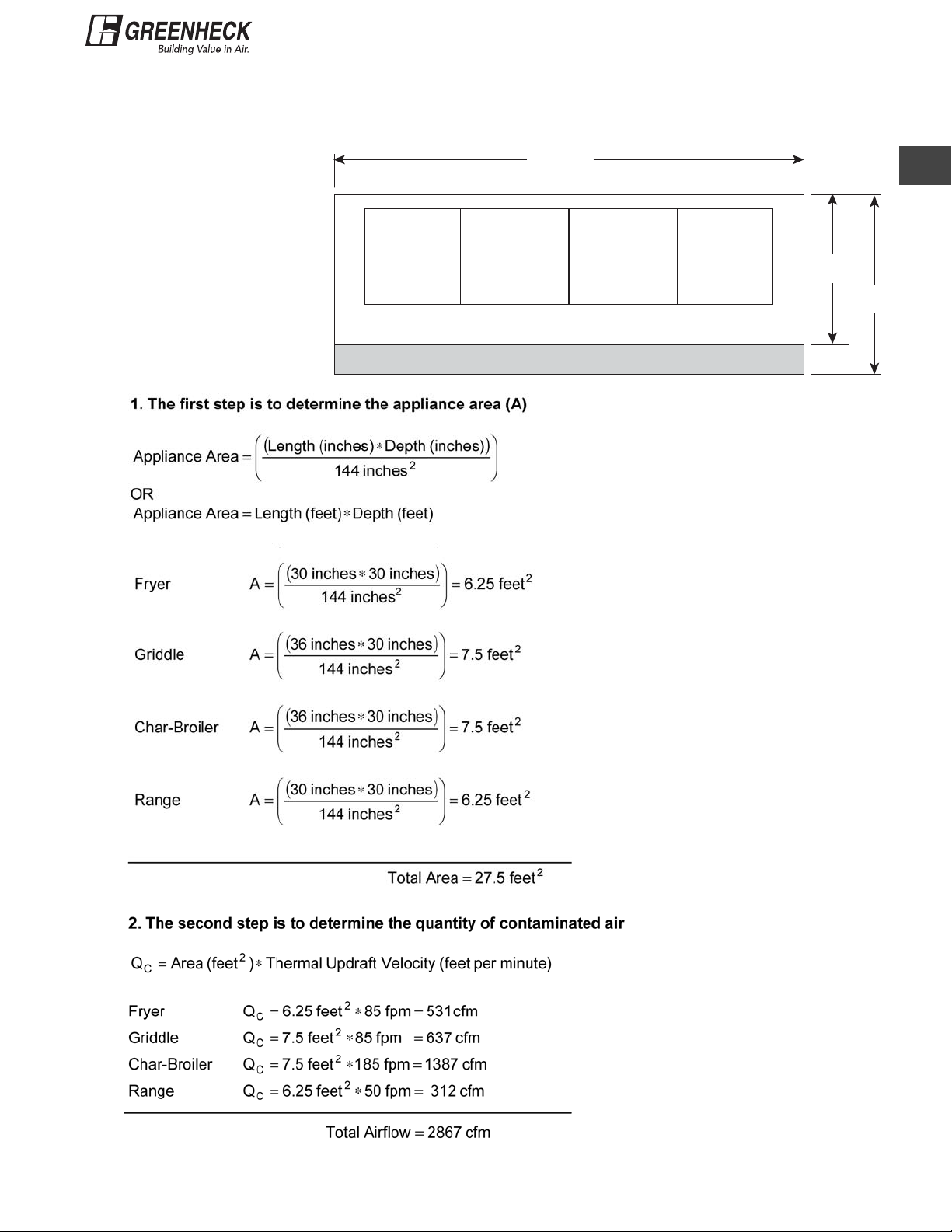

Putting it all together - complete example

To put all of the information

from this section together, the

following is a full example from

start to finish. Examine first the

cooking battery and hood to

the right and follow through the

calculations illustrated below.

Fryer

30 in. x 30 in.

144 in.

Griddle

36 in. x 30 in.

Free Foot Area

Char-broiler

36 in. x 30 in.

2

Range

30 in. x 30 in.

39 in.

48 in.

13

QC - Quantity of contaminated air

generated by the cooking equipment.

Using Figure 4 on page 9, identify the

appropriate updraft velocity and multiply

it by the area of the appliance.

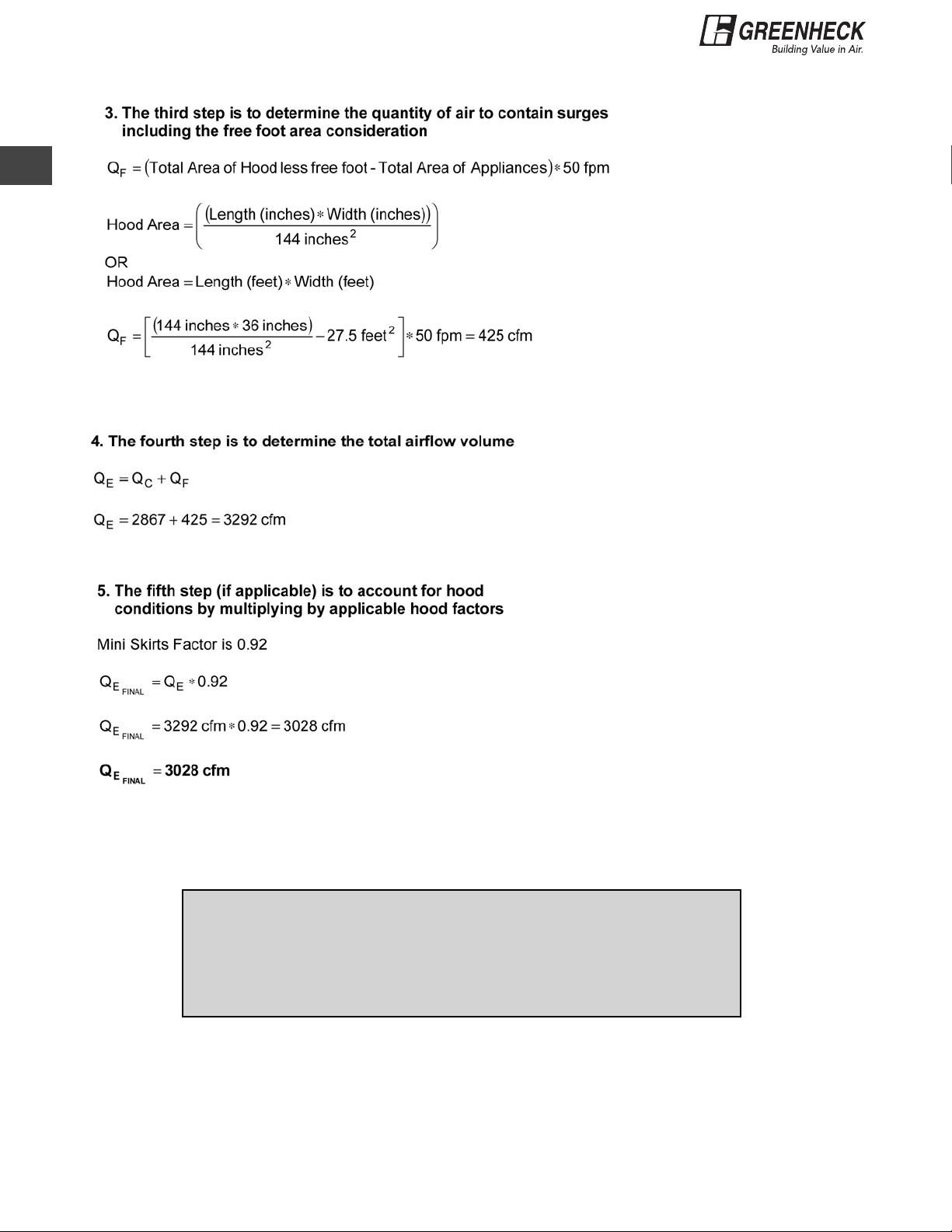

Page 14

2

®

QF - Quantity of air required to

contain surges and drafts. Use

the minimum updraft velocity

of 50 fpm and multiply it by the

difference in area between the

hood containment area and the

appliance area.

All calculations shown in this example have been built into Greenheck’s

Computer Aided Product Selection (CAPS) program. These examples

illustrate the logic used to properly determine exhaust rates. To obtain

CAPS, request online at www.greenheck.com or consult your local

Greenheck representative.

14

Page 15

®

SUPPLY AND MAKE-UP AIR

The design of the make-up air system will have the single largest affect on hood

performance. Supply air is defined as air that is brought into the space, but make-

Transfer

Fan

up air is dedicated to “making-up” the air being exhausted. Make-up air is brought

into the kitchen at approximately an equal rate to the air being exhausted by the

kitchen hood. This means that 100% of the air being exhausted must be made

up. This can be accomplished through one supply type, transfer air, or multiple

sources. A slight negative pressure is desirable in the kitchen with respect to the

dining room to keep odors out of the dining area, but pressure levels should not

exceed negative 0.02 in. wg. The key to designing a system is to introduce make-up air in the most

Figure 9

economical way without affecting the capture and containment of the hood. Maximum hood performance can

be obtained by distributing air at low velocities evenly throughout the room as seen in Figure9. This section will

layout which type of make-up air system is desirable for a restaurant’s particular needs.

Tempered or Untempered?

Air that is heated or conditioned before it is brought in from

Goal is Comfort Goal is Low Cost

Tempered MUA No Air Conditioning

the outdoors is called tempered air. If the goal is to make

the kitchen comfortable, then utilize tempered air. If the

goal is low cost, then use untempered air. Both tempered

and untempered can be introduced, however, selecting

the proper supply types will affect comfort and economic

efficiency. Once this decision has been made a type of

make-up air system can be selected, but always keep two

things in mind. When tempering the air, use a source that

will distribute the air throughout the kitchen to increase

Perforated Ceiling GOOD

Perforated Face Air Supply Plenum

Back Supply

Plenum

Air Supply Plenum Perforated Ceiling

Back Supply

Plenum

Perforated Face

employee comfort. When using untempered air, use a source

that will keep the air near the hood so it can be exhausted

quickly without mixing in the space causing discomfort and

Variable Supply

Plenum

Variable Supply

Plenum

increased heating/cooling loads. Make-up air temperature

should not vary more then 10º F from the air in the space.

However, this limit can be exceeded if the make-up air does

not decrease the comfort of the occupied space or is part of

an air conditioning system.

Northern climates with cold winters and short mild

summers will almost always require heated make-up air

and no cooling. Southern climates with long hot and humid

Register Face Air Curtain

4-Way Diffuser Short Circuit

Short Circuit Register Face

Air Curtain BAD 4-Way Diffuser

Figure 10

summers and short mild winters will want to minimize the amount of hot, humid air that has to be

conditioned by keeping make-up air near the hood. In a hot and dry environment the air can be

cooled in the make-up air unit using an evaporative cooler, which will greatly reduce air conditioning loads.

3

Figure 10 has two columns. The left column ranks various ways of bringing tempered air into the kitchen. The

best options all distribute the tempered air throughout the room. The right column ranks various ways of bringing

untempered air into the kitchen. The best options keep make-up air near the hood to decrease heating/cooling

loads seen in the rest of the building. The supply options listed at the top of each column are proven through

testing and research to be the best ways of introducing make-up air. Choosing the supply options listed near the

bottom will not work as well as options listed near the top.

Supply Options

Make-up air can be introduced through the hood with an

integrated supply plenum or an external supply plenum.

The advantages of using an external supply plenum verses

Integrated Supply

an integrated supply plenum can be seen in Figure 11.

The shaded region represents the volume of the hood. Increasing the volume allows more smoke and

heat to be held in the hood until it can be exhausted. This is important over cooking equipment that

produces a great deal of heat and smoke, such as a char-broiler. External supply plenums are usually less

expensive and can be retrofitted to most exhaust only hoods.

15

Exhaust Only

Figure 11

Page 16

®

Exhaust Only Hood with

Non-Directional Ceiling

Diffusers

This system will work best when

bringing tempered air into the

kitchen or can be used in climates

where outside air closely matches

desired indoor conditions. An

exhaust only hood has no make-up

air entering the room through the

3

hood. This system is the least complex and in most cases works the best, however, may not be the

most economical. The amount of exhausted air must be made up, therefore non-directional perforated ceiling

diffusers and/or transfer air would be used to make-up 100% of the air. The most important thing to remember

is to place many non-directional perforated diffusers throughout the room to keep air velocities low and uniform.

Uneven air distribution will cause drafts in the kitchen causing capture and containment to suffer (Figure 12).

Make sure the transfer air from another room, especially if supplied through a pass-thru window, is kept at

a low velocity. This can be accomplished by increasing the

amount of air through ceiling diffusers in the kitchen.

Figure 12

Face Supply

150 cfm/ft.

Located on the front of the hood (Figure 13), face discharge

is designed to throw make-up air across the room. Use

face supply when tempered air is brought in through MUA

into a tempered kitchen or when the MUA and kitchen

Integrated Face Supply Plenum

Figure 13

are untempered because mixing will occur with the air

in the space. Registers can be used for larger kitchens with longer throws, but perforated face panels

are recommended for lower air velocities, which will minimize drafts in the kitchen. The maximum supply

Hot

Air

Ceiling

rate is 250 cfm/ft. through perforated panels under

ideal conditions. For optimum performance design to

recommended values of 150 cfm/ft. Face supply should

not be used when a wall, another hood, menu board,

or other object is less than 6feet from the face.

Figure 14

The problem with bringing hot untempered air into an air-conditioned room can be seen in Figure 14. Hot air will

not fall into the room and cycle back out through the hood, rather the hot air will hug the ceiling because it is

more buoyant. If humidity is present in the hot make-up air, it will condense on the metal ceiling diffuser when

it mixes with the air-conditioned air brought through it. Most of the hot air along the ceiling will be taken in at

a return grill by the roof top unit (RTU) and conditioned before it is introduced back into the room, thus totally

defeating the purpose of bringing in untempered make-up air.

Integrated Air Curtain

The hood integrated air curtain (Figure 15) discharges air at the bottomfront edge of the hood and directs air downward. If spot cooling for the

cooking personnel is desired, use tempered air. This type of hood can

also be used to keep untempered air near the hood, although employee

comfort will suffer. Buoyant, hot, humid air will have a tendency to travel

out into the room with this type of hood as Figure 14 illustrates rather

than back into the hood. The maximum supply rate is 125 cfm/ft. through

perforated panels under ideal conditions. For optimum performance

design to recommended values of 65 cfm/ft. Caution must be used with

the design of air curtain hoods (See Figure 17).

16

Figure 15

Integrated Air Curtain

65 cfm/ft

Page 17

®

External Air Supply Plenum

The external air supply plenums (Figure 16) provide spot cooling when

using tempered air, but can also keep untempered air near the hood,

which will save on heating/cooling loads. There are advantages over

the integrated air curtain. Mounted 14-20 inches above the bottom

edge of the hood or flush with drop ceiling, external air supply plenums

can supply airflow at a maximum rate of 180 cfm/ft. For optimum

performance, design to the recommended rate of 110 cfm/ft. In addition,

external plenums can be attached to the face or ends of an exhaust only

hood to create a curtain of air on all exposed sides of the hood, thus

Figure 16

increasing the volume of air brought in at the hood.

In Figure 17 notice the pocket of low pressure caused by the air flowing from

the external air supply plenum. When velocities are too great, there is enough

pressure differential to cause the hood to spill heat and contaminate. This effect

can be observed on external and integrated air curtains, however, integrated

air curtains are more susceptible to it due to the location of discharge.

Combination Hood

Combination hoods (Figure 18) are a combination of face supply and air

curtain supply and are better suited for cooler climates where outside air

can be used to cool the kitchen. See Face Supply (pg. 16) and Integrated

Air Curtain (pg. 16) for design considerations for the different parts of

the combination hood. More make-up air can be brought through a

combination hood than a face or air curtain alone, but the same limits

exist for each part of the plenum, maximum 250 cfm/ft. from the face

and maximum 125 cfm/ft. from the air curtain. Perforated panels should

always be used to reduce air velocities and eliminate spillage from the

hood. Supply rates should be designed to recommended values of 150

cfm/ft. through the face and 65 cfm/ft. through the curtain for optimum

performance. An exhaust

only hood with a variable

supply plenum (Figure 19)

can be used instead of a

combination hood which

will increase maximum

supply rates (see external

air curtain, face supply) and

not take up valuable capture

and containment volume.

0-80 cfm/ft.

80-160

cfm/ft.

adjustable

damper

External Air Supply Plenum

>180 cfm/ft.

Low

Pressure

Pocket

Figure 17

65 cfm/ft.

Combination Hood

110 cfm/ft.

3

150

cfm/ft.

Figure 18

External Variable Supply Plenum

Figure 19

Back Supply Plenum

An effective way to introduce untempered make-up air into the

kitchen is from the rear of the hood through a back supply plenum

(Figure 20). These plenums are also ideal for heating air during the

colder months since hot air will rise from its low discharge position.

This plenum is mounted 31.25 inches above the finished floor and

directs airflow through perforated panels behind and below the

cooking equipment without affecting capture and containment,

cooking surface temperature, or pilot lights. When using untempered

air, utilizing low air velocities will keep the air near the hood. These

plenums are 6 inches deep and stretch across the entire length

of the hood, therefore they function as a backsplash panel and

provide the 3-inch clearance to limited combustibles needed in most

circumstances. Back supply plenums are able to supply a maximum

of 250 cfm/ft. For optimum performance design to the recommended

rate of 145 cfm/ft.

17

145 cfm/ft.

Back Supply Plenum

Figure 20

Page 18

®

Multiple Sources

Figure 21 depicts

two scenarios. The

picture on the left

shows air brought in

through one side of

the room while the

picture on the right

shows air brought

in evenly throughout

3

the room. To accomplish even airflow, use any one of the hood supply types along with multiple

non-directional ceiling diffusers, or transfer air from another room. The amount of air to each diffuser decreases

with an increase in number of diffusers, thus lowering air velocities. Various types of diffusers can be used,

but non-directional perforated panel diffusers work best. Transfer air can be brought into the kitchen through

non-directional ceiling diffusers from the building HVAC as long as air velocities are kept below 50 ft./min at the

hood. Figure 22 illustrates the spilling of effluent when using a 4-way diffuser within 10 feet of the hood. See the

room balance section of this guide for an example of multiple sources.

Figure 21

Figure 22

Roof Top Units (RTU’s)

In many places where comfort is the main goal, a roof top

unit will be used to supply the make-up air (Figure 23).

These units condition the space while only taking in some

200

800

RTU 1

1000

RTU 2 RTU 3

200

800

1000

200

800

1000

outside air. The example shows that each RTU is providing

1000 cfm, but removing 800 cfm for a net of 200 cfm per

RTU. Thus, the three RTU’s are providing a total of 600cfm.

RTU’s that are set to run in this situation should be in the

“ON” mode instead of the “AUTO” mode. The auto mode

Net 20% from each RTU

cycles the RTU’s on and off depending on the cooling

or heating load. When the units are not running, a huge

negative pressure will occur. When in the “ON” position, the

units will run constantly and only temper what is needed.

RTU’s are usually the most expensive to operate.

Non-Directional Ceiling Diffusers

When distributing tempered air, non-directional

perforated ceiling diffusers can dramatically

improve hood performance and employee

comfort. Using multiple non-directional diffusers,

small amounts of air are distributed throughout

the room introducing a large amount of makeup/supply air without high discharge velocities.

As many diffusers as possible should be used

to maximize kitchen hood performance. Nondirectional perforated panels are recommended

for use with ceiling diffusers to keep airflow even

and at a low velocity. Perforation causes the air

to gently enter the room without a fixed direction.

For this reason, these diffusers can be used near

the hood in smaller kitchens. The air velocity at

the edge of the hood capture area should not

exceed 50 ft./min. It is not recommended to use

diffusers near the hood, and 3-way and 4-way

diffusers should not be used in the kitchen.

Ceiling diffusers are typically used in combination

with another make-up air option.

Supply Type

Back Supply 6 wide 145 290

Air Supply

Plenum

Variable Supply

External

Plenum

Face Supply

Plenum

Perforated

Combination

Register

Combination

Perforated Face 16 high 150 150

Register Face 12 high 250 —

Internal

Perforated Air

Curtain

Register Air Curtain 8 wide 65 —

Short Circuit UL limits (not recommended)

Dimensions

(inches)

cfm/linear ft. fpm

12 wide 110 150

24 wide 180 150

11 high

9 wide

18 wide 150 150

16 high

8 wide

12 high

8 wide

8 wide 75 —

Recommended Supply Rates

Figure 24 is a summary of the recommended supply rates for each type of make-up air. These

values should be used when designing the system to achieve maximum hood performance.

600

Figure 23

Recommended

Supply Rate

160 150

150 150

130 —

Figure 24

18

Page 19

®

ROOM BALANCE AND AIRFLOW TESTING

Capture & Containment

Capture and containment (C & C) is the hood’s ability to catch the contaminated airflow and hold it inside the

hood until it can be pulled through the filters to the outside. A well-designed kitchen should have approximately

equal amounts of air entering the system as leaving it. If this rule is not followed, capture & containment will

suffer and there may be a noticeable amount of contaminated air spilling out of the hood, which will cause odor,

excess heat, and a greasy film on the walls and ceiling of the kitchen.

Cross Drafts

Another way to reduce spillage is to reduce cross drafts present in the kitchen. Cross drafts are created from

an unbalanced room, unequal air distribution, too much airflow from one source, or a separate air movement

source such as a fan. An unbalanced kitchen will become hot due to escaping heat. In an effort to cool the

kitchen, employees will open doors and run fans to cool themselves, which is a mistake. These two things will

create cross drafts and further disrupt capture & containment, making the situation worse. If cross drafts are

unavoidable, end skirts on both sides of the hood are the easiest and most inexpensive aid in reducing cross

draft effects. Figure25 illustrates the effects of an unbalanced room condition creating air currents. Figure26

shows the effects of having a fan in the space at or near the hood. Avoid both of the situations depicted in

Figures 25 and 26.

4

Room Pressure

Kitchen room pressure should be kept

at a slight positive to the outside at

all times. This can be accomplished

by providing slightly more air than

what is being exhausted. The dining

room should be kept at an even

greater positive pressure, which will

allow a slight airflow from the dining

area to contain heat and odors to the

kitchen. Even though both dining area

and kitchen are positive, the kitchen

is negative when compared to the

dining area. (See Figure 27) Positive

room pressure will also keep outdoor

contaminants such as dust and insects

from entering into the kitchen while

building doors are open for deliveries,

maintenance, or other patron traffic.

Figure 25

RTU

HVAC

Positive

Pressure

RTU Net

MUA

MUA

Positive

Pressure

Figure 26

Exhaust

Figure 27

19

Page 20

®

Illustrated below in Figure 28 is a typical supply air diagram for a kitchen and dining room arrangement with

the accompanying air balance tables. The hood has a dedicated exhaust fan and make-up air unit. The kitchen

also has a dedicated HVAC supply (RTU) unit to help take some of the conditioning load. In the dining area

another dedicated HVAC unit is used to supply the air and make up any losses from rest rooms or other small

exhausted areas. Notice, there is transfer air going into the kitchen from the dining area, thus the kitchen

is slightly negative to the dining area containing odors although the balance of the dining area of 200 cfm

exfiltration (EXF) shows that the building as a whole is at a slight positive to the outdoors as desired.

Air Balance (units of cubic feet per minute (cfm)

4

Kitchen Systems Airflow In Airflow Out

KX - Exhaust 4000

MUA - to Hood 1500

MUA - to Kitchen 1600

SUP - HVAC Supply 200

Total 3300 4000

KX-4000

MUA-3100 OSA-200

MUA-1600

600

SUP-800

Dining Room Systems Airflow In Airflow Out

OSA - Outside Air 1100

TRA - Transfer Air to Water Closet 200

Transfer Air to Kitchen 700

Total 1100 900

Net = 1100-900 = 200 ExfiltrationNet=4000-3300= 700 transfer (TA) from dining

OSA-1100

TX-200

3900

SUP-2500 SUP-2500

EXF-200

KX-4000

MUA-1500

TRA-700

20

DiningKitchen

Water

Closet

Figure 28

Page 21

®

EXHAUST AND SUPPLY RATE TESTING APPARATUSES

An AMCA test and balance uses a pitot tube to measure air velocities in the duct. However, codes require

a fully-welded duct for kitchen exhaust systems, therefore prohibiting penetration of the duct when using a

pitot tube. The following two apparatuses are nonintrusive alternatives to measuring air velocities in kitchen

ventilation systems.

AIRDATA™ Multimeter by

Shortridge Industries

The Shortridge multimeter is a new

alternative to the rotating vane anemometer.

This meter can measure airflow, velocity,

pressure, and temperature quite easily.

It consists of two main components,

the velgrid to sense the airflow and the

meter itself. Additionally, it can store up

to 200 readings and automatically senses

the temperature of the air so that it can

account for the local air density when taking

readings. Different conversions for different

types of filters are required in order to

convert the reading from feet per minute to cubic feet per minute. Greenheck has charts with instructions to do

so for its filters. Figure29 is an illustration of the Shortridge setup and operation.

Figure 29

4

Rotating Vane Anemometer (RVA)

The RVA is used for measuring air

velocities, shown in Figure 30. Moving air

rotates fan blades, which is converted to

an air velocity reading on the instrument.

When measuring hood filter airflow, take

6 readings per filter, then average the

readings. The RVA should be 2inches

from the filter and perpendicular to

airflow direction. The RVA is also

directional, the arrow should point in

the direction of airflow travel. Airflow

velocity can be converted to CFM by

multiplying a correction factor to the

average filter velocity. The appropriate

CFM reading can be obtained from each

filter in the hood, the total hood CFM can be measured by adding each filter CFM.

OPEN

Exhaust Air Balancing Baffle (EABB)

The Exhaust Air Balancing Baffle is a simple device

offered as a Greenheck option that enables balanced

airflow of multiple duct collars in long hoods, double

island hoods, or in multiple hoods running from a

single fan as shown in Figure 31. When a different

airflow is needed, the baffle can be adjusted to

change the size of the collar opening. The hood

should be tested to ensure proper airflow after each

adjustment. See page 22 for static pressure calculations.

Figure 30

FULLY BALANCED

Figure 31

21

Page 22

®

Duct Velocity FPM

Increase in Collar Staitc Pressure

Checking for Balance

Every hood with an EABB has a range for its static pressure. The low number in this range is given by the

standard calculation for hood static (static that is printed with the CAPS submittal). The maximum increase

above the low number can be calculated from the duct velocity at the low static (also provided on the CAPS

submittal). This is then added to the low number to get the highest static pressure possible with an EABB.

The maximum potential increase in static is given in the graph or can be calculated from:

Max. Inc. = 0.00000036 x (Duct velocity)

After the range for each hood is calculated, it should be compared to the hood with the highest static pressure.

If the highest hood falls inside of the range, then the hoods can be balanced with the EABB. If it is higher than

the range, the hoods cannot be balanced.

Example 1:

Hood 1: Ps = 0.58 inH2O

Duct Velocity = 1900 fpm

4

Hood 2: Ps = 0.44 inH2O

Duct Velocity = 1800 fpm

Hood 2 has the lower Ps, at 1800 fpm the maximum increase in Ps is 1.17. The range for hood 2 is 0.44 to 1.61.

Hood 1 is less than 1.61 so these hoods can be balanced.

Example 2:

Hood 3: Ps = 2.00 inH2O

Duct Velocity = 2000 fpm

2

Hood 4: Ps = 0.44 inH2O

Duct Velocity = 1500 fpm

Hood 4 has the lower Ps, at 1500

fpm the maximum increase in Ps

is .81. The range for hood 4 is

0.44 to 1.25. Hood 3 is higher than

1.25 so these hoods cannot be

balanced.

Note 1: For many systems, an

EABB may not be needed on the

hood that has the highest static

pressure. The exception to this

is if the individual ductwork has

uneven static pressures.

Note 2: When sizing the fan,

use the static pressure from the

highest hood and sum the cfm

from all the hoods.

Maximum Increase in Static Pressure for Exhaust Air Balancing Baffle

(Fully Closed)

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

500 1000 1500 2000 2500 3000 3500

Figure 32

22

Page 23

®

GREASE EXTRACTION

The removal of grease from the exhaust airflow is a very important part of commercial kitchen operation.

Without proper filtration, grease will:

• Collect in the exhaust plenum and ducts creating:

- A fire hazard

- An increase in the frequency of costly duct cleaning

• Collect on the fan causing it to become unbalanced and lead to premature failure

• Create odor in or near the restaurant

• Collect on the rooftop causing deterioration of roof materials

• Collect on the rooftop equipment and cooling coils

These problems can be greatly reduced through the use of proper grease filtration devices.

History

For years, the commercial kitchen industry has been without a standard for rating filtration devices. This has

led to many manufacturers listing efficiency ratings of 90% on their filters. These claims are made from the old

Navy test, ULC 710, and UL 1046 grease loading safety tests required for all filters in TYPE I hoods which are

inaccurate because grease particle size is not taken into account. Research started in the mid 1990’s to develop

a standard test that would account for particle size with filter efficiency. With this standard, grease filters will be

directly comparable.

Grease Emissions

When food is cooked it releases

grease, water, vapor and combustion

by-products from the energy source

or food products that are burnt or

changed by chemical reactions

during the cooking process. These

emissions are vapor and particulate

matter that are exhausted through

the kitchen exhaust system. This

particulate clings onto ducts, fans,

and roofs.

Mass of Emissions (lb/1000 lb food)

Total Emissions - Vapor & Particulate

35

30

25

20

15

10

5

0

Particulate Vapor

5

Grease particulate is liquid or solid

particles of grease that have become

suspended in the air. The particulate

Gas Griddle Hamburger

Electric Griddle Hamburger

Gas Fryer Potatoes

Electric Fryer Potatoes

Gas Broiler Hamburger

Electric Broiler Hamburger

Gas Broiler Chicken Breast

Electric Broiler Chicken Breast

Gas Oven Sausage Pizza

Electric Oven Sausage Pizza

Gas Range Spaghetti

Electric Range Spaghetti

Figure 33

can range in size from .01 to 100μ

(μ = microns). A human hair = 100 microns. Grease vapor refers to grease in the gaseous state that is much

smaller than grease particulate. Vapor is condensable and may condense into grease particulate or remain in a

vapor state while being exhausted into the atmosphere. Figure 33 shows the amount of grease particulate and

vapor produced when cooking 1000 lbs. of different foods on different types of cooking equipment.

Theoretically, emissions down to 0.01 μ can be filtered out of the airstream, however, vapors cannot be filtered

using traditional filters. Grease particulate larger than 10 - 20 μ is too heavy to remain airborne and will drop out

of the airstream. Most grease filters operate between 1 - 10 μ.

Cooking Equipment

Another important concept to understand is the variation of emissions given off by different cooking equipment.

A study was done in 1998 by the University of Minnesota for ASHRAE, report 745-RP, which identified the type

and size of grease emitted from various cooking equipment. Different amounts of various sized particles are

emitted from the cooking equipment depending of the type of equipment being used and type of food being

cooked. Appliances that produce a large heat load typically produce a larger amount of emissions. The total

shaded region in Figure 35 shows the mass of emissions vs. particle size for a griddle.

23

Page 24

®

System Efficiency = 68%

Filter Efficiency

Filters can seldomly be given a single meaningful efficiency number. This is because a filter has a different

efficiency for different size particles, different flow rates, and different phase of particles. A filter that is 90%

efficient at removing 5 μ particles

may only be 75% efficient at

removing 1 μ particles.

A fractional efficiency curve is a

graph that gives the efficiency

of a filter over a range of particle

sizes. Fractional efficiency curves

are created by subjecting a test

filter to a controlled distribution

of particles and measuring the

quantity of particles at each given

size before and after the filter. The

amount of reduction in particles is

used to calculate the efficiency at

each given size. Figure 34 shows

5

the particulate efficiency curves for

different 20 x 20 filters at 600 cfm

per filter.

100

90

80

70

60

50

40

30

Particulate Efficiency

20

10

0

0.1 1 10 100

Efficiency Baffle Filter Efficiency Grease-X-Tractor™ Efficiency Grease Grabber™

Efficiency Water Wash Hood Efficiency Cartridge Filter

Efficiency vs. Particle Size

600 cfm per filter

GG

GX

Water Wash

Dry Cartridge Filter

Baffle

Particle Size μm

Figure 34

Interaction of Cooking and Filtration

The amount of grease particulate removed and the amount of grease particulate exhausted into the ductwork

can be calculated by multiplying the efficiency at each point along the curve by the mass emissions from each

type of cooking equipment. The ratio of particulate matter removed to total particulate matter generated gives

system efficiency for that range of particle sizes for a specific cooking application. It is important to remember

that the graphs and efficiencies shown here are only for grease in the particulate form. There is also a vapor

component of the grease that is being exhausted. Some of the vapor condenses and is removed as particulate

prior to the filter. Some of the vapor condenses in the duct and accumulates on the ductwork and fan. Using

Figure 35 and the new understanding of filter efficiency, it is possible to determine the total amount of grease

removed for the different systems. When cooking hamburger on a gas griddle the baffle filter has a particulate

system efficiency of 33%. When vapor is included the total system efficiency drops to 19%. The Grease-XTractor™ drops from 77% for particulate system efficiency to total system efficiency of 46%. The Grease

Grabber™ goes from 99% to 62%.

Types of Filters and Efficiencies

Mass & Efficiency vs. Particle Size

Water Wash Hood Over Griddle with Hamburger

Interpreting the Graph

Figure 35 represents the efficiency of a water

wash hood. Each filter type has a graph similar

to this. The overall shaded area represents the

amount of grease emissions given off from

the cooking equipment. The dark shaded area

represents the amount of grease taken out of

the airstream by the filter. The lightly shaded

area represents the grease particulate that

escaped past the filter. The ratio of dark shading

to light shading at a particular particle size is

represented by the fractional efficiency curve.

Filters with higher efficiencies will have more

of the total shaded area darkened. This can be

seen in Figures 35-38.

100

90

80

70

60

50

40

Particulate Efficiency

30

20

10

0

0.1 1 10 100

Gas Griddle Hamburger Emissions Grease not Removed Efficiency Water Wash Hood

Fractional Efficiency Curve

Grease Removed

Grease not Removed

Particle Size μm

24

200

180

160

140

120

100

80

60

40

20

0

Figure 35

)

3

Mass (mg/m

Page 25

®

System Efficiency = 99%

(

g

)

System Efficiency = 31%

Particle Size μm

System Efficiency = 73%

Water Wash / Dry Cartridge Hoods

These hoods have the filtration system built into the hood and are 50% efficient at about 6.5 μ. The point at

which a filter is 50% efficient is called its cut point. This shows that the water wash / dry cartridge hoods are

still dependent on inertial impaction. Their higher efficiencies than the baffle filter are also reflected by a much

higher static pressure. Typical pressure drops for a 9 ft. x 4 ft. hood at 2050 cfm will be 1.1-1.3 in. wg. See

Figure 35.

Baffle

The efficiency curve for the

baffle filter and the cartridge

filter shows that at 8 μ its

ability to remove particulate is

30%. Baffle filters use inertial

impaction, which is the

principle of the particle’s

momentum throwing the

particle out of the airflow

as it changes direction, to

100

90

80

70

60

50

40

Particulate Efficiency

30

20

10

0

0.1 1 10 100

remove grease from the airflow. Typical pressure drops

for a 9 ft. x 4 ft. hood at 2050 cfm will be 0.5-0.6 in. wg.

Gas Griddle Hamburger Emissions Grease not Removed Efficiency Baffle Filter 600 cfm

See Figure 36.

Centrifugal Filter

The Grease-X-Tractor™ is 50%

efficient at 5 μ. A cut point of 5 μ

is typical of a centrifugal filter.

Its efficiency improves rapidly

above 5 μ and drops below

5 μ. The use of centrifugal

force rather than twodimensional impaction allows

the efficiency to be improved

without a high penalty in

static pressure. Airflow

enters the filters louvers and is spun in a chamber

until it exits the back of the filter. Grease particles are

thrown from the airflow during its helical path. The velocity of the airflow determines how small of

a particle can be removed. The static pressure is between a baffle filter and a water wash hood.

Typical pressure drops for a 9 ft. x 4 ft. hood at 2050 cfm will be 0.7-0.8 in. wg. See Figure 37.

100

90

80

70

60

50

40

Particulate Efficiency

30

20

10

0

0.1 1 10 100

Gas Griddle Hamburger Emissions Grease not Removed 600 cfm Efficiency Grease-X-Tractor™

Mass & Efficiency vs. Particle Size

Baffle Filter Over Griddle with Hamburger

Particle Size μm

Mass & Efficiency vs. Particle Size

Grease-X-Tractor

TM

Filter Over Griddle with Hamburger

Figure 36

200

180

160

140

120

100

80

60

40

20

0

Figure 37

200

180

160

140

120

100

80

60

40

20

0

3

/m

m

Mass

5

)

3

Mass (mg/m

Multi-Stage Filtration

The Grease Grabber™

uses a centrifugal type

filter as the primary stage

of filtration along with a

packed bead bed filter

as the second stage.

Interception is the main

filtration mechanism which

works by adsorption of

grease particles as they

come in contact with the

packed bead bed. The

Grease Grabber™ has a cut point at 2 μ. Its efficiency

increases to near 100% at 7 μ and drops for particles

smaller than 2 μ. This reduction in the size of particles

100

90

80

70

60

50

40

Particulate Efficiency

30

20

10

0

0.1 1 10 100

Gas Griddle Hamburger Emissions Grease not Removed 600 cfm Efficiency Grease Grabber™

Mass & Efficiency vs. Particle Size

Grease Grabber

TM

Over Griddle with Hamburger

Particle Size μm

200

180

160

140

120

100

80

60

40

20

0

Figure 38

that can be removed indicates that the Grease Grabber™ uses a combination of all filtration

mechanisms. The static pressure drop is the highest of the filters evaluated but only slightly higher than water

wash. Typical pressure drops for a 9 ft. x 4 ft. hood at 2050 cfm will be 1.1-1.3 in. wg. See Figure 38.

25

)

3

Mass (mg/m

Page 26

®

FIRE SUPPRESSION SYSTEMS

UL 300

Every commercial kitchen hood requires a UL 300 listed commercial fire system. In summary, UL 300 involves

heating vegetable shortening or oil to an auto ignition temperature of 685º F or higher. After the oil has autoignited, it must remain in a pre-burn state for 2 minutes with the exception of griddles, which remain in a preburn state for 1 minute. The extinguishing agent is then applied to suppress the fire. If after 20 minutes no fire

has returned, the fire suppression system successfully passes certification.

Wet Chemical

Wet chemical fire suppression systems use a potassium based chemical extinguishing agent. The agent is

discharged over the entire cooking battery and reacts with hot grease to form a blanket of foam in a process

called saponification that seals the hazard depriving the fire of oxygen. The wet chemical system is available in

two types:

Appliance Specific

These systems are designed specifically for appliances and require knowledge of the cooking battery under

the hood. Specific nozzles and fusible links are chosen based on the type of appliance. The systems use

a temperature rated fusible link to hold a scissors link together (Figure 40). When the fusible link melts,

the scissors opens activating the system. This is a dedicated detection system that requires permanent

6

equipment placement — if the equipment is moved or changed, re-piping is necessary.

Full Flood

Full flood systems require no prior knowledge of the cooking battery

with the exception of shelves, salamanders, and upright broilers. Full

flood systems have drops evenly spaced across the length, the spacing

is dependent on the manufacturer’s UL listing. The detection system is

either a pneumatic tube (Figure 41) that runs the full length of the hood,

or fusible link detection with the links evenly spaced along the length

of the hood. The advantage of the full flood system is that cooking

equipment can be moved and changed without having to alter the fire

suppression piping. See Figure 39 for an example of full flood coverage.

Length of Hood

Dual Agent

Dual agent fire suppression systems uses both wet chemical and water to suppress the fire. Similar to the other

systems, a wet chemical agent is used to blanket the fire with foam followed by water to cool the hazard. By

cooling the area the chance of a flare-up is reduced. Dual agent fire suppression systems are available both as

appliance specific and full flood, and utilize a fusible link detection system.

Figure 39

Before choosing a type of dual agent fire suppression it is imperative that the water pressure at the jobsite be

verified. The dual agent system requires 33 psi for large systems and continuous piping systems. For branch

piping and average size systems, 22 psi of water pressure will be sufficient. Check with the fire system supplier

to determine the required water pressure for the application.

Water Spray

The Water Spray fire suppression system is an automatic system, designed to protect the cooking equipment,

hoods, ducts, plenums, and filters in facilities designed with wet-pipe sprinkler systems. Once activated, the

system provides a focused continuous water mist until it is manually turned off. Water spray fire suppression

only discharges onto the fire area, not over the entire cooking battery. In 1997, UL removed the listing from the

EA-1 fryer nozzles. Greenheck, with several other manufacturers, has developed the Dual Tech nozzle for use

over fryers. The nozzle has self-contained chemical canisters that discharge on the fryer first, followed by water.

Due to the poor performance of water spray fire protection, many local and state codes prohibit the use of

these types of systems. Thus, check with the local code authority on the job to get approval in writing before

specifying and purchasing a water spray fire suppression system.

26

Page 27

®

DECISIONS TO BE MADE WHEN CHOOSING A FIRE SUPPRESSION SYSTEM

Appliance Specific or Full Flood

Choose whether the system is to be designed using a full flood system without knowledge of the cooking

battery (with the exception of shelves, salamanders, or upright broilers) or an appliance specific system.

If appliance specific, standard wet chemical or dual agent

Choose between wet chemical only or a dual agent with wet chemical and water. Be aware that dual agent is

considerably more expensive and requires a water connection.

Complete System or Pre-Pipe Only

Decide whether the hood should include the entire system or only piping drops and nozzles while remaining

components are left for field installation. Some manufacturers and systems may only offer the product as

a complete system. The pre-pipe option allows for concealed, pre-piping of the hood, and the flexibility of

choosing your local fire system distributor to complete your system.

Hood Mounted or Remote

Choose to have the system mounted in a cabinet at the end of the hood or remotely mounted at another

location in the kitchen or utility room. If remote mounted, be advised that there are limitations on the distance

the cabinet can be mounted from the hood.

Other considerations that may or may not apply:

Gas Valve — If all electric appliances, a valve is not needed. If using gas appliances, a mechanical or electric

shut-off valve must be selected to stop the flow of fuel to the cooking appliances in the event of a fire.

K-Class Fire Extinguisher — Most codes require a separate fire extinguisher mounted on the wall of the

kitchen.

Permits — License fee required by the local authority — sometimes multiple permits are required —

municipality as well as state. Check with the local authority having jurisdiction for local requirements.