Greenheck Vektor -MH Installation Manual

Document 464652

®

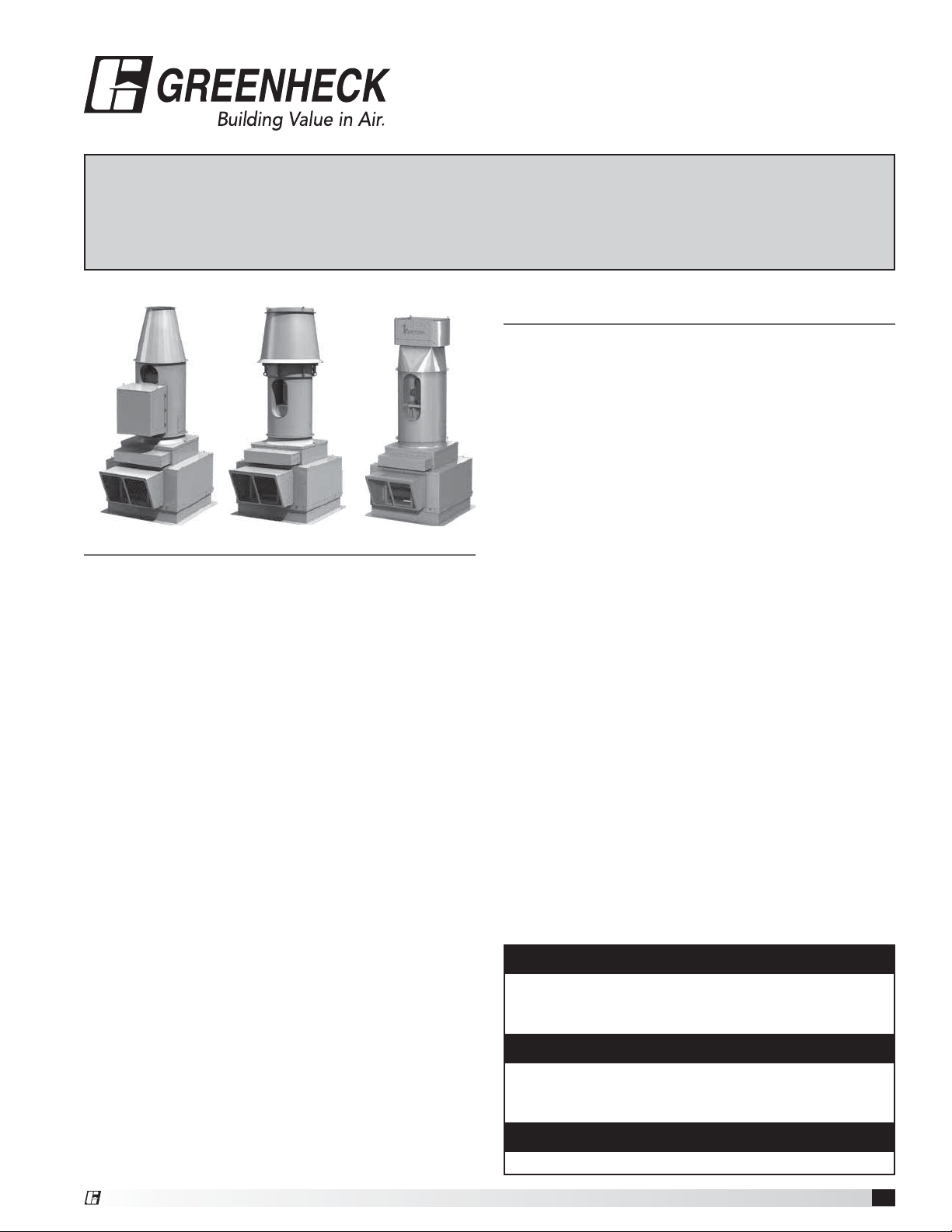

Model Vektor

®

-MH, Vektor ®-MD

and Vektor

Laboratory Exhaust System

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Vektor-MH, Vektor-MD, and Vektor-MS

General Safety Information

Only qualified personnel should install this fan system.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

Table of Contents

General Safety Information ......................1

Receiving / Unpacking / Handling / Storage .....2-3

General Information

Unit and System Identification ..................3

Pre-Installation Information ....................3

Electrical Disconnects / Moving Parts / Guards ....3

Air Pressure and Suction ......................3

System Components .........................4-5

Roof Curb and Mounting Details .................5

Bypass Air Plenum

Rigging, Lifting and Installation ...............6-7

Fan Housing

Rigging, Lifting and Installation ...............6-7

Nozzle, Windband, Silencer, Weatherhood ........8

Duct Connections - Side Inlet ...................9

Bottom Inlet .................9

Plenum Drainage Piping / Trap Detail ..............9

Bypass Air Plenum - Isolation Damper and

Actuator Mounting ..........................10

Field Coating Touch-Up .......................10

Electrical Connections ........................11

Start-Up ....................................12

Vibration ...................................13

Routine Maintenance

Fan / V-Belt Drive / Motors / Bearings / Nozzle 14-15

V-Belt Drive Installation ........................15

Bearing Replacement - Belt or Direct Drive .....16-17

Jib Crane Assembly (Optional) ..................17

Motor Change-Out Procedure ..................18

High Strength Metal Disc Coupling. . . . . . . . . . . . . . .18

Troubleshooting ..............................19

Nozzle Parts and Assembly .............Backcover

Our Commitment ......................Backcover

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. The rotation of the wheel is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan wheel faster than maximum

cataloged fan rpm. Adjustments to fan speed

significantly effects motor load. If the fan RPM is

changed, the motor current should be checked to

make sure it is not exceeding the motor nameplate

amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

DANGER

Always disconnect power before working on or near a

fan. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

®

-MS

®

Laboratory Exhaust Systems

1

Receiving

Greenheck model Vektor-MH, Vektor-MD and Vektor-MS

fans are thoroughly inspected, test run at the factory,

and shipped on a skid or packaged to minimize damage

during shipment. The transportation carrier has the

responsibility of delivering all items in their original

condition as received from Greenheck. The individual

receiving the equipment is responsible for inspecting the

unit for obvious or hidden damage and recording any

damage on the bill of lading before acceptance of the

equipment. All claims (if necessary) shall be filed with

the final carrier.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received, including accessory

kit containing gasketing, etc. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Handling

The Vektor-MH, Vektor-MD and Vektor-MS laboratory

exhaust system is shipped in subassembly sections

for easy rigging and installation. Depending on the fan

size, the sections can include: Blower Assembly, Stack

Extension, and Discharge Nozzle.

The Vektor-MH, Vektor-MD and Vektor-MS are designed

to be self-supporting and standing (without the use

of guy wires) when assembled per the instructions

provided within this manual. If additional components

are supplied, contact factory or reference submittal

if additional supports or guy wires are required. All

subassembly sections have lifting lugs as shown.

Storage

Fans are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the fan and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR - The ideal environment for the storage of

fans and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30° and 110°F.

(-1°C and 43°C). Wide temperature swings may

cause condensation and “sweating” of metal parts.

All accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts allow cold parts to reach room

temperature. To dry parts and packages use a portable

electric heater to get rid of any moisture build up. Leave

coverings loose to permit air circulation and to allow for

periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off the

floor on wooden blocks covered with moisture proof

paper or polyethylene sheathing. Aisles between parts

and along all walls should be provided to permit air

circulation and space for inspection.

OUTDOOR - Fans designed for outdoor applications

may be stored outdoors, if absolutely necessary. Roads

or aisles for portable cranes and hauling equipment are

needed.

The fan should be placed on a level surface to prevent

water from leaking into the fan. The fan should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To minimize

water accumulation, place all fan parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Fan wheels should be blocked to prevent spinning

caused by strong winds.

Inspection and Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed; see

backcover.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the wheel by hand ten to fifteen

revolutions to distribute lubricant on motor and

bearings. Bearings should be lubricated at three month

intervavls. The quantity of grease should be per the

lubrication label.

If paint deterioration begins, consideration should

be given to touch-up or repainting. Fans with special

coatings may require special techniques for touch-up or

repair.

Machined parts coated with rust preventive coating

should be restored to good condition promptly if signs

of rust occur. Immediately remove the original rust

preventive coating with petroleum solvent and clean

with lint-free cloths. Polish any remaining rust from

surface with crocus cloth or fine emery paper and oil.

Do not destroy the continuity of the surfaces. Wipe

clean thoroughly with Tectyl® 506 (Ashland Inc.) or

the equivalent. For hard to reach internal surfaces or

for occasional use, consider using Tectyl® 511M Rust

Preventive or WD-40® or the equivalent.

Laboratory Exhaust Systems

2

®

REMOVING FROM STORAGE

As fans are removed from storage to be installed in their

final location, they should be protected and maintained

in a similar fashion, until the fan equipment goes into

operation.

Prior to assembly and installation of the Vektor fan and

system components, inspect the fan assembly to make

sure it is in working order.

1. Check all fasteners, set screws on the fan, wheel,

bearings, drive, motor base and accessories for

tightness.

2. Rotate the fan wheel(s) by hand and assure no parts

are rubbing. Access to the wheel is obtained through

a bolted panel located on the side of the fan housing.

3. Ensure proper wheel settings for radial gap and

alignment (see page 18).

General Information

To ensure a successful installation, the instructions in

this manual should be read and adhered to. Failure to

comply with proper installation procedures may void the

warranty.

Unit and System Identification Tags

Each fan has a permanently affixed manufacturer’s

engraved metal nameplate containing the model

number and individual serial number.

The tag shown is

an example of an

identification nameplate

on the fan. The

information provides

general details about

the fan, as well as containing specific information

unique to the unit. When contacting your Greenheck

representative with future needs or questions, please

have the information on this label available. Tags are

mounted in an area which is clearly visible, usually on

the side of the fan cabinet.

Vektor fan systems may arrive in component pieces

due to shipping restrictions. Individual components of a

system have matching identification tags which should

be used to identify and assemble the complete system.

Assembling systems with different identification tags

can cause reductions in the fan(s) performance.

Prior to fully assembling and installing the VektorMH, Vektor-MD or Vektor-MS fans, inspect bypass air

plenums and the fan assembly to make sure they are in

working order.

Pre-Installation Information

Before installation, it is important to be certain the

mounting surface will bear the operating weight of the

unit. For proper unit operation, it is also important that it

be operated in a completely level position.

For further details on safety practices involving

industrial and commercial fans, please refer to AMCA

Publication410.

Electrical Disconnects

All fan motors should have disconnects located in close

visual proximity to turn off electrical service. Service

disconnects shall be locked-out when maintenance is

being performed.

Moving Parts

All moving parts must have guards to protect personnel.

Refer to local codes for requirements as to the number,

type and design. Fully secure fan wheel before

performing any maintenance. The fan wheel may start

“free wheeling” even if all electrical power has been

disconnected. Before the initial start-up or any restart,

check the following items to make sure that they are

installed and secure.

• Do not spin fan wheel faster than the maximum

cataloged fan rpm.

• Adjustments to fan speed significantly affects motor

load. If the fan RPM is changed, the motor current

should be checked to make sure it is not exceeding

the motor nameplate amps.

Guards (Motor Cover, Weatherhoods,

Actuator Cover)

Do not operate fans without proper protective devices in

place. Failure to do so may result in serious bodily injury

and property damage. Check local codes to ensure

compliance for all protective devices.

Plenum Access Doors

Before opening access doors, ensure the fan wheel has

stopped moving and that the wheel has been secured

from being able to rotate. Do not operate fan without

access door in its fully closed position.

Air Pressure and Suction

In addition to the usual hazards associated with rotating

machinery, fans also create a dangerous suction at the

inlet. Special caution needs to be used when moving

around a fan, whether it is in operation or not. Before

start-up, make sure the inlet area is clear of personnel

and loose objects.

®

Laboratory Exhaust Systems

3

System Components

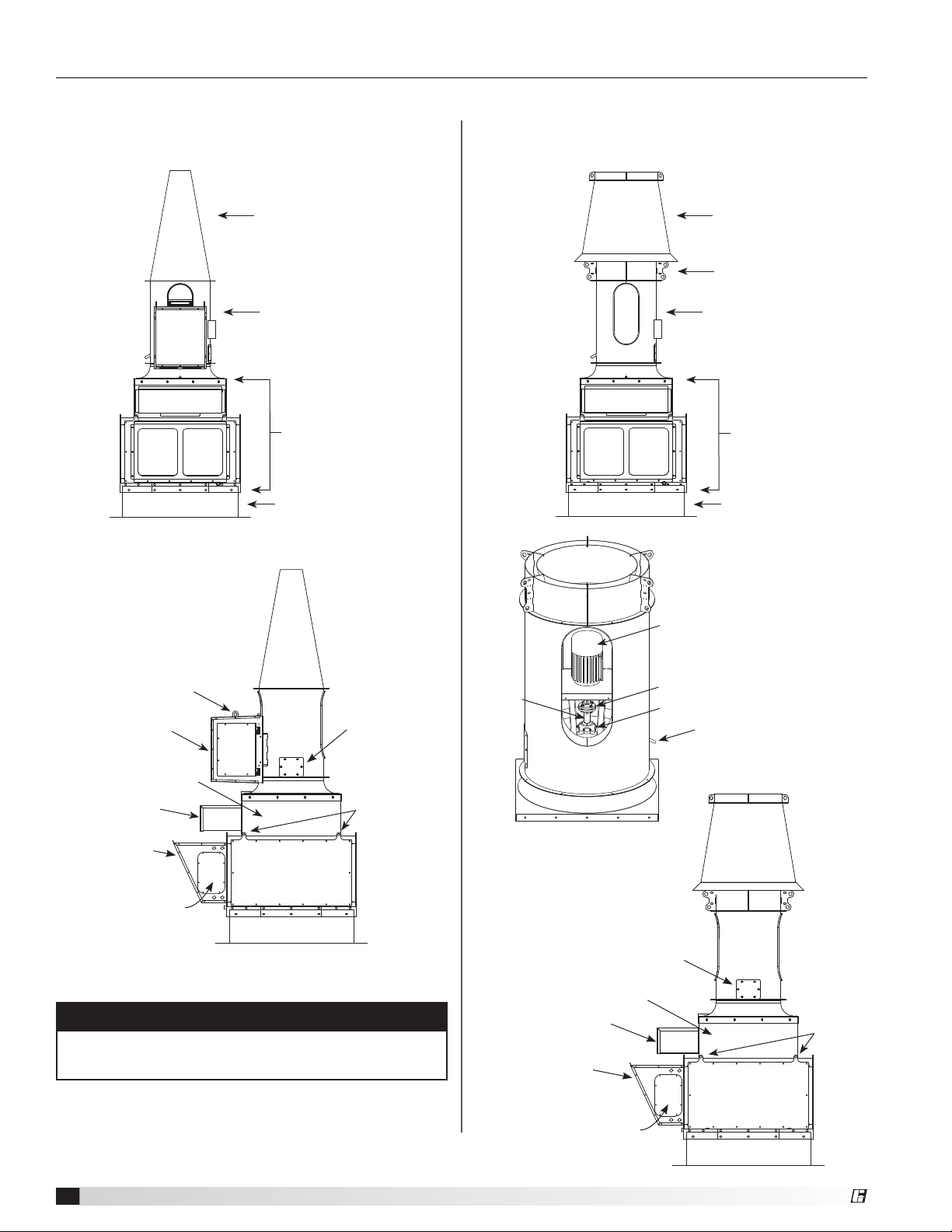

Vektor-MH Assembly View - Belt Drive

Belt and direct drive units share similar system

components and assembly configuration.

Nozzle

Blower Housing

Bypass Air Plenum

Roof Curb or

Structural Support

Vektor-MD Assembly View - Direct Drive

Belt and direct drive units share similar system

components and assembly configuration.

Windband

Nozzle

Blower Housing

Bypass Air Plenum

Roof Curb or

Structural Support

Motor Cover

Lifting Lug

Motor Cover/Access

Isolation Damper

Isolation Damper

Actuator Cover

Weatherhood

with Birdscreen

Bypass Damper

Actuator Access Door

Access Panel

Bolted / Gasketed

(all sides)

Blower Housing

Access Door

Panel Lifting

Lugs

NOTE

Actual component pieces may vary from these

images. Refer to your project submittal drawing.

Fan

Shaft

Direct Drive

Isolation Damper

Isolation Damper

Actuator Cover

Weatherhood

with Birdscreen

Bypass Damper

Actuator Access Door

Motor

Flex Coupling

Shaft Bearing

Drain

Blower Housing

Access Door

Panel

Lifting

Lugs

Access Panel

Bolted / Gasketed

(all sides)

Laboratory Exhaust Systems

4

®

Vektor-MS Assembly View - Direct Drive

Belt and direct drive units share similar system

components and assembly configuration.

SAVVE Nozzle

Blower Housing

NOTE

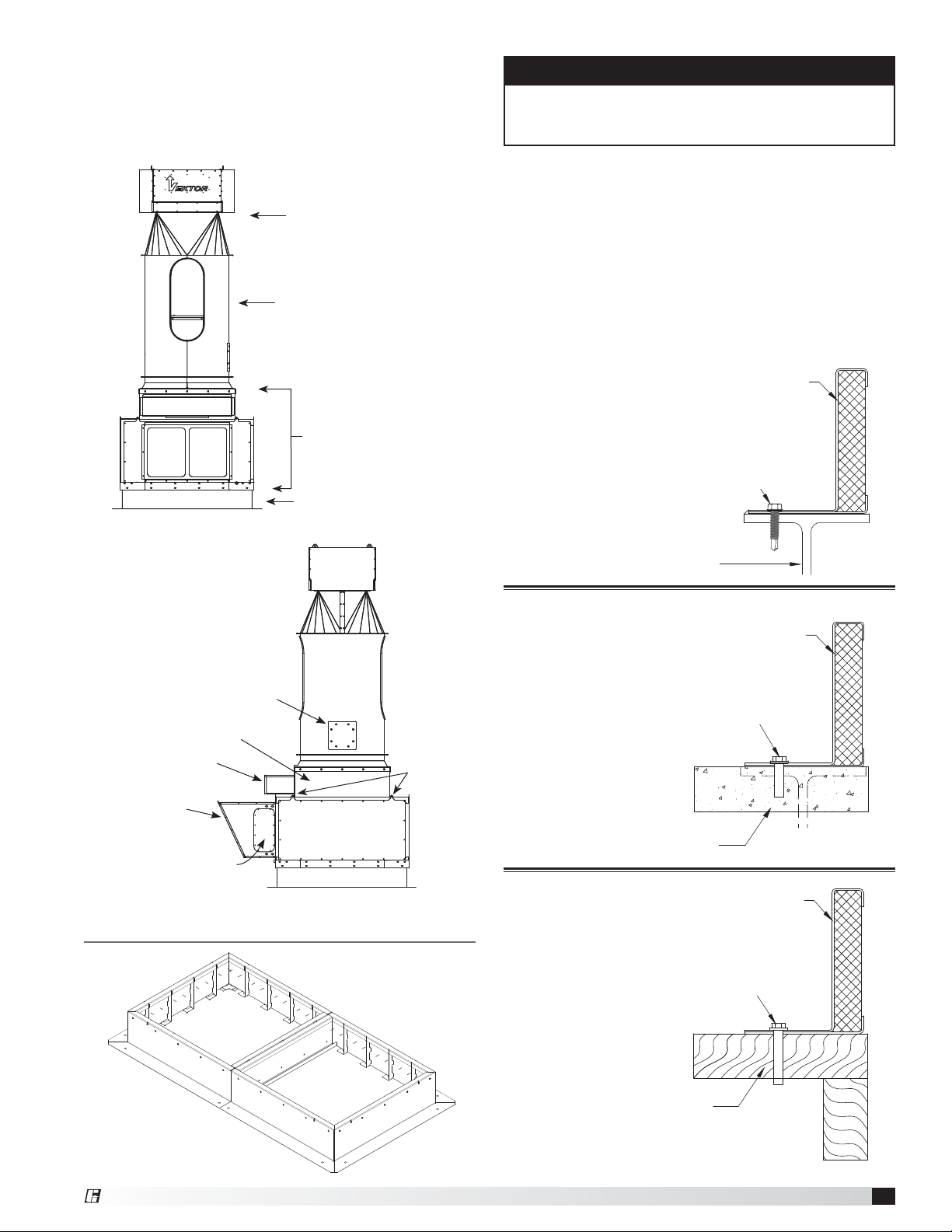

Steel, concrete or wood roof support is per structural

engineer and in accordance with load requirements

and applicable building codes.

Refer to stand-alone Vektor Roof Curb Assembly

Instruction found on greenheck.com within the

Laboratory Exhaust section. Chose applicable product

model.

The figures illustrates three common methods used to

install Vektor systems. Methods used to attach a Vektor

unit are dependent on local codes, roof construction

design and roof construction materials. Consult an

architect or structural engineer for proper means of

attachment.

Blower Housing

Isolation Damper

Isolation Damper

Actuator Cover

Weatherhood

with Birdscreen

Bypass Damper

Actuator Access Door

Access Door

Bypass Air Plenum

Roof Curb or

Structural Support

Access Panel

Bolted / Gasketed

(all sides)

Panel

Lifting

Lugs

Steel

Continuous weld or stitch weld.

Minimum 6 inch (152.4 mm) stitch weld by

3.25 inch (82.5 mm) spacing minimum.

Minimum 6 inch (152.4 mm) weld on each corner.

OR

Install 5/16 inch (7.9375 mm) 24 Dril-Flex® Self-Drilling

Tapping Screws. 3/16 inch (4.7625 mm) minimum thread

engagement into A36 steel, centered in flange.

4.5 inch (114.3 mm) spacing

5/8 inch (15.875 mm) minimum edge distance

ALL HARDWARE BY OTHERS

STEEL STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Greenheck Roof Curb

Concrete

Greenheck Roof Curb

Install 3/8 inch (9.525 mm) SS power wedge bolts

2.5 inch (63.5 mm) maximum spacing from curb corners

4.5 inch (114.3 mm) maximum bolt spacing

3.5 inch (88.9 mm) minimum embedment

4.5 inch (114.3 mm) minimum edge

distance centered in flange

ALL HARDWARE BY OTHERS

CONCRETE STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Wood

Greenheck Roof Curb

Roof Curb and Mounting Details

®

Install 3/8 inch (9.525 mm) SS lag or thru-bolt with

1 inch (25.4 mm) O.D. washer

2.5 inch (63.5 mm) maximum spacing from curb corners

4.5 inch (114.3 mm) maximum bolt spacing

3.5 inch (88.9 mm) minimum tread engagement,

not including tapered tip

2 inch (50.8 mm) minimum edge distance,

centered in flange

Pre-drill holes 40-60% of lag diameter

ALL HARDWARE BY OTHERS

WOODEN STRUCTURAL SUPPORT

(BY OTHERS, SEE NOTE ABOVE)

Laboratory Exhaust Systems

5

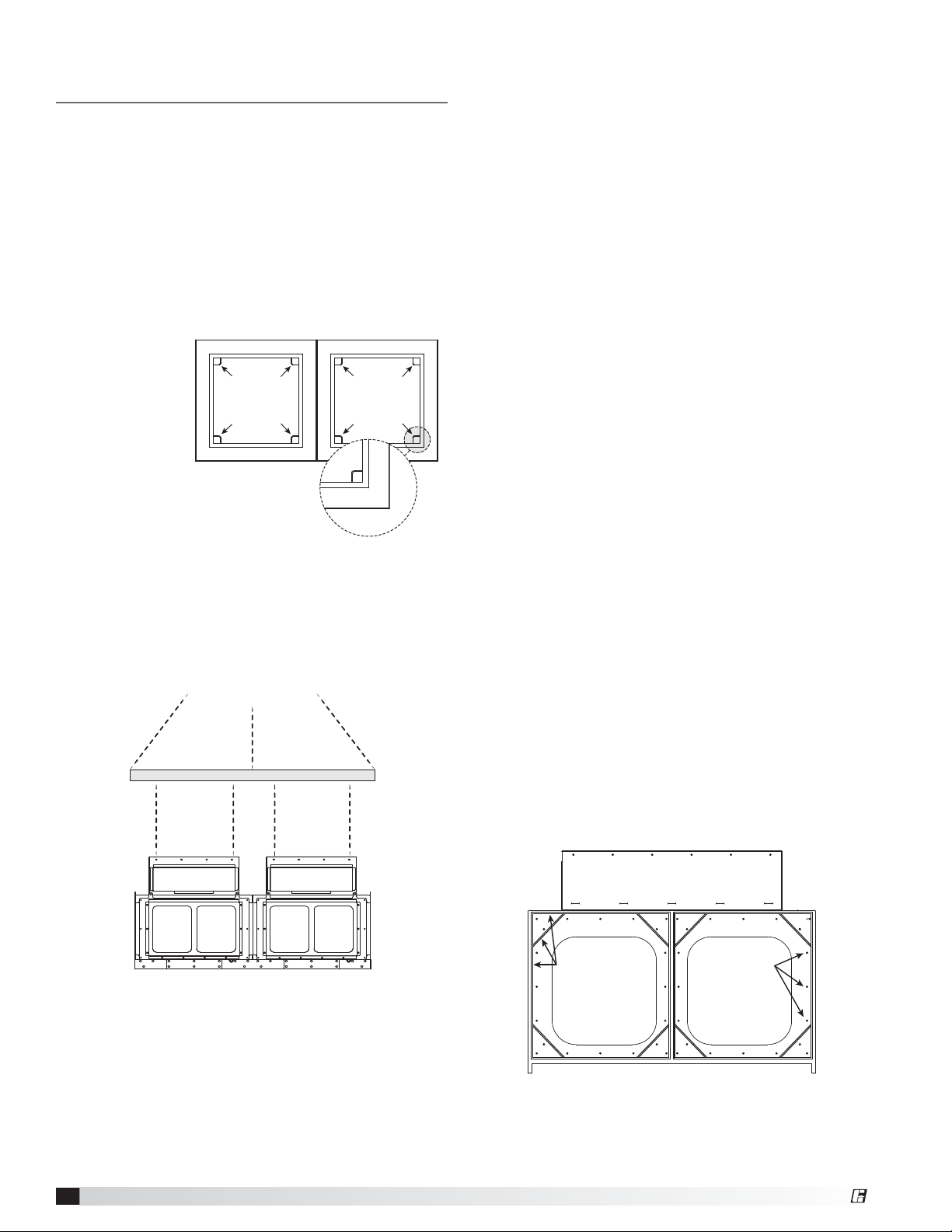

Bypass Air Plenum - Rigging,

Lifting and Installation

Prior to lifting any components, verify the weights on

the project submittal drawings for each component

or contact factory. Do not lift weights beyond the

capacities of the on-site lifting equipment. Proper

handling of the equipment is critical to avoid damage to

the unit.

Prior to setting the bypass air plenum (BAP), secure

1/4-inch thick by 3/4-inch wide EPDM gasket (provided)

around the perimeter of the roof curb top edge, if

mounting on a roof curb.

Bypass Air Plenum - Rigging and Lifting

Each section

will have four

(4) lifting points.

All lifting points

must be used

when lifting.

Spreader bars

of sufficient

length need to be used to

prevent damage to BAP walls and

components mounted to the BAP.

1. Always use all lifting lugs provided by

manufacturer. Lifting lugs are located around the

perimeter of each section.

2. A spreader bar must be used when lifting each

section to distribute the weight evenly and to

prevent the unit from being over-torqued. Avoid

unnecessary jarring or rough handling.

Chains

Spreader Bar

Lifting PointsLifting Points

Bypass Air Plenum Installation

Bypass air plenums (BAP) are delivered fully assembled

unless shipping restrictions require multiple sections.

If delivered in sections, all materials required to join

plenum sections together are provided.

Bypass air plenums are modular in construction and can

be disassembled to provide allowances for lower on-site

lifting capacities. Plenum sections are joined using

stainless steel fasteners. These are removed to separate

sections for lifting purposes. Save hardware as these

will be required to join the BAP sections together again.

If moving separate sections onto a roof curb or support

structure, each section should be joined to its mating

section after moving into position and before lifting any

additional section(s) into position.

Steps for joining multiple BAP sections together:

1. Lift / place first BAP section making sure that

mounting holes are positioned with curb mounting

holes or to structure BAP will be secured.

2. Attached provided gasket to plenum section using

the pattern shown in the image.

3. Ensure bolts are removed from both mating

sections to being joined together. Plenum will ship

with hardware in one section’s bolt holes or were

removed to disassemble BAP to reduce lifting load.

4. Lift / place next section into position using similar

lifting procedure.

5. Align holes between two mating sections.

6. Use fasteners (provided) to join the two sections

together, this will involve utilizing the nutserts in

each section on the inside perimeter. The fasteners

are tightened until the sections are pulled together

and the gasket material is compressed.

7. Caulk joint (provided) on the top and two sides

between sections for enhanced water protection.

8. Repeat steps 1 – 7 until all plenum sections are

lifted and joined together.

Any side panels removed to gain access to the interior

of the plenum should be reattached.

Plenums may be single sections or up to six in length

Two fan bypass air plenum shown.

3. Care must be taken to keep the unit in the upright

position during rigging.

4. Care must be taken to not damage the watertight

seams in the unit casing.

5. Avoid damage to the curb and curb gasketing when

rigging onto a curb.

6. Only use trained professional riggers when moving

equipment.

Laboratory Exhaust Systems

6

Plenum Section

Gasket Material

each plenum section

Bolt Holes

®

Loading...

Loading...