Page 1

Document 476072

®

Vektor

®

with Variable Geometry Nozzle (VGN) Technology

Laboratory Exhaust

Electrical Controls Information

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Table of Contents

General Safety Information ......................1

Receiving, Handling and Storage .................2

VFD Controller Nozzle Controller

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces, or chemicals.

Replace cord immediately if damaged.

3. Verify the power source is compatible with the

equipment.

DANGER

Always disconnect power before working on or

near a unit. Lock and tag the disconnect switch or

breaker to prevent accidental power up.

CAUTION

When servicing the unit, variable frequency drives

(VFD) may be hot enough to cause pain or injury.

Allow motor to cool before servicing.

Component Checklist - Electrical ...............2

System Components ...........................3

Wiring Installation .............................3

Fan Operation - Single Fan

Set Point and Minimum Variables ...............4

Defined Modes .............................4

VGN Technology Control Flow Chart ............5

Fan Operation - Multiple Fans, No Staging

Set Point and Minimum Variables ...............6

Defined Modes ........................... 6-7

VGN Technology Control Flow Chart ............8

Fan Operation - Multiple Fans, With Staging

Set Point and Minimum Variables ...............9

Defined Modes ............................10

VGN Technology Control Flow Chart ...........11

Factory-Supplied Variable Frequency Drive

System Diagram .............................12

Wiring Diagram ..............................13

Communication BACnet® and LonWorks® Protocol . 14

Start-Up Procedure - Electrical Controls ..........15

System Test and Balance for VGN ...............16

Nozzle Velocity Adjustment .....................16

Customer-Supplied Variable Frequency Drive

System Diagram .............................18

Wiring Diagram ..............................19

VGN Nozzle Controller Intro. and Tutorial ....... 20-22

Communication ..............................23

Start-Up Procedure - Electrical Controls ..........24

System Test and Balance for VGN ...............25

Nozzle Velocity Adjustment .....................25

Troubleshooting ..............................26

Maintenance ................................27

Electrical Replacement Parts ...................27

Our Commitment .............................28

®

VGN Technology

1

Page 2

General Electrical Controls Information

Receiving

Upon receiving the product, check to ensure all items

are accounted for by referencing the delivery receipt or

packing list. Inspect each crate or carton for shipping

damage before accepting delivery. Alert the carrier

of any damage detected. The customer will make

a notation of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading which

is countersigned by the delivering carrier. If damaged,

immediately contact your Greenheck Representative.

Any physical damage to the unit after acceptance is not

the responsibility of Greenheck Fan Corporation.

Component Checklist - Electrical

Check off the following system components to verify all

components are received.

ABB Eclipse Variable Frequency Drive (VFD) with

bypass mode and internal wiring kit.

(VGN with factory-supplied VFD)

VGN nozzle controller

(VGN customer-supplied VFD)

Transducer/terminal enclosure with Sure Aire™

pressure transducer and system terminals in

NEMA3R enclosure

24 volt VGN nozzle with modulating actuator

0/2-10 VDC with feedback

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing; report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

atmosphere. Remove any accumulations of dirt, water,

ice, or snow and wipe dry before moving to indoor

storage. To avoid “sweating” of metal parts, allow cold

parts to reach room temperature. To dry parts and

packages use a portable electric heater to eliminate any

moisture build up. Leave coverings loose to permit air

circulation and to allow for periodic inspection. The unit

should be stored at least 3½ in. (89 mm) off the floor on

wooden blocks covered with moisture proof paper or

polyethylene sheathing. Aisles between parts and along

all walls should be provided to permit air circulation and

space for inspection.

Inspection and Maintenance during

Storage

While in storage, inspect equipment once per month.

Keep a record of inspection and maintenance

performed. If moisture or dirt accumulations are found

on parts, the source should be located and eliminated.

Removed From Storage

As units are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion, until the equipment goes

into operation. Prior to installing the unit and system

components, inspect the unit assembly to make sure it

is in working order.

1. Check all fasteners, and accessories for tightness.

Handling

Handle in such a manner as to keep from scratching or

chipping the coating. Damaged finish may reduce ability

of unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

INDOOR - The ideal environment for the storage of

units and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F (-1°C)

and 110°F (43°C) (wide temperature swings may

cause condensation and “sweating” of metal parts).

All accessories must be stored indoors in a clean, dry

VGN Technology

2

®

Page 3

General Electrical Controls Information

System Components

System Components (supplied by Greenheck)

Quantity Description

1 Pressure transducer with adjustable pressure

range and VDC signal

1 VFD with bypass mode and integrated controller

(VGN with factory-supplied VFD)

1 VGN nozzle controller.

(VGN, customer-supplied VFD)

1 to 4 Actuator motor(s) (nozzle)

24 volts, modulating VDC signal with feedback

Varies Actuator motor (bypass damper), if provided by

manufacturer

Varies Actuator motor (isolation damper) 24 volts,

open/close. Quantity will be zero if isolation

damper actuator is supplied by others or if gravity

style isolation damper is used.

System Components (customer-supplied)

Quantity Description

Varies Wiring, conduit, miscellaneous fittings

1 Building control system with required

communication wiring and shielding

Varies Pressure transducer for duct pressure

Varies Actuator motor (bypass damper) if provided by

others

1 Actuator motor (isolation damper), if provided

by others. Quantity will be zero if gravity style

isolation damper is used.

Varies 1/4 inch tubing. Connection from Sure-Aire

termination plate mounted on fan to mounting

location of transducer/terminal enclosure.

1 Fan motor VFD.

(VGN, customer-supplied VFD)

Wiring Installation

NOTE

All field installation and wiring of electrical

equipment must be done to meet NEC and local

codes.

NOTE

Be sure to use appropriately sized wire for the full

load amp draw.

The following items are a list of requirements necessary

to install the controls for the VGN Technology system.

1. Mount variable frequency drive in the desired

location; indoors or outdoors. Maximum distance

from fan is 100 feet (30.5 meters).

2. Mount transducer/terminal enclosure at fan or

bypass air plenum (BAP).

3. Run main power wiring from building breaker panel

to variable frequency drive. By others.

4. Run motor power wiring from service disconnect

switch to variable frequency drive. Wire length to be

less than 100 feet. By others.

5. Connect control wiring pigtail (by factory) from VGN

nozzle actuator(s) to transducer/terminal enclosure.

(See wiring diagram).

Optional: Connect wiring from isolation damper

actuator(s) to transducer/terminal enclosure. By

others.

6. Run control wiring from transducer/terminal

enclosure to variable frequency drive or nozzle

controller terminal strip. Wire length to be less than

100 feet (See wiring diagram).

7a. Run communication cable from variable frequency

drive to Building Management System (BMS). See

VFD manual for type and maximum length. By

others. (VGN with factory-supplied VFD).

7b. Run VGN nozzle controller system wiring from main

control panel to Building Management System

(BMS). By others. (Customer-supplied VFD).

8. Run nozzle actuator feedback control wire from

transducer/terminal enclosure at the fan to BMS

controls.

9. Install 1/4 inch pressure tubing (by others) from

transducer/terminal enclosure to Sure-Aire

connection plate on fan. By others.

10. Install BMS with duct pressure control system. By

others.

11. For specific device installation reference the

appropriate component cut sheet or IOM. Also

reference the following system and wiring diagrams

on pages 4 and 7 for more detail.

®

VGN Technology

3

Page 4

General Electrical Controls Information

Fan Operation - Single Fan

Set point and minimum variables

1. System will maintain a minimum of 3000 fpm velocity

(factory default) at the outlet of the fan, based on

the airflow monitoring station. Building Management

System (BMS) to monitor nozzle actuator feedback

and keep fan speed above the minimum required set

point to maintain velocity.

2. Fan to run at BMS defined operation for speed and

bypass mode. Mode reference will be determined by

minimum fan speed and by minimum nozzle actuator

feedback.

a. If the BMS speed is equal to the minimum specific

fan speed and nozzle feedback is minimum for a

set time period (user-defined) the BMS will begin to

modulate the bypass damper open to assist with

pressure control.

b. If the bypass damper is at full closed for a set time

period, the BMS will increase fan speed and the fan

control will increase the nozzle area as required to

assist with pressure control.

c. The PID sequence to be programmed at the BMS

for bypass damper operation. The BMS to provide

fan enable and VFD speed reference.

Definition of typical operation modes:

Mode #1: Unoccupied. Defined as no one inside the

lab(s), all lab hoods are closed.

1. Fan will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan. BMS to monitor nozzle actuator

feedback and keep fan speed above the minimum

required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper as required if system speed is equal

to the minimum fan speed and nozzle actuator is at

minimum for a time period.

4. VFD speed, duct pressure control and bypass

damper operation is provided by the BMS system.

Mode #2: Occupied; no lab hoods being used.

Defined as people entering the lab(s), no work being

done at the hoods.

1. Fan will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan. BMS to monitor nozzle actuator

feedback and keep fan speed above the minimum

required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper as required if system speed is equal

to the minimum fan speed and nozzle actuator is at

minimum for a time period (user-defined).

4. VFD speed, duct pressure control and bypass

damper operation is provided by the BMS system.

VGN Technology

4

Mode #3: Occupied; some or all lab hoods being

used. Defined as people in the lab(s), lab hood sashes

being used.

A. Sashes opening in the lab

1. Fan will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan. Typical system response

should be to increase fan speed and increase

nozzle open area.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. VFD speed, duct pressure control and bypass

damper operation is provided by the BMS system.

B. Sashes closing in the lab

1. Fan will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan. Typical system response

should be to decrease fan speed and decrease

nozzle open area.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper as required if system speed

is equal to the minimum fan speed and nozzle

actuator is at minimum for a time period (userdefined).

4. VFD speed, duct pressure control and bypass

damper operation is provided by the BMS system.

Mode #4: Fault mode. Defined as safety mode;

the system has an issue and needs to default to VFD

bypass.

1. VFD failure detected, automatically or manually put

into VFD bypass if available, by operator or BMS.

2. Nozzle area to increase proportional to fan airflow

which will increase as fan speed is at maximum.

3. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

4. Duct pressure control will modulate bypass damper

as required if system is in alarm mode. Duct pressure

control is provided and programmed by the BMS

system.

5. System manually to be reset and placed back in VFD

auto mode.

®

Page 5

General Electrical Controls Information

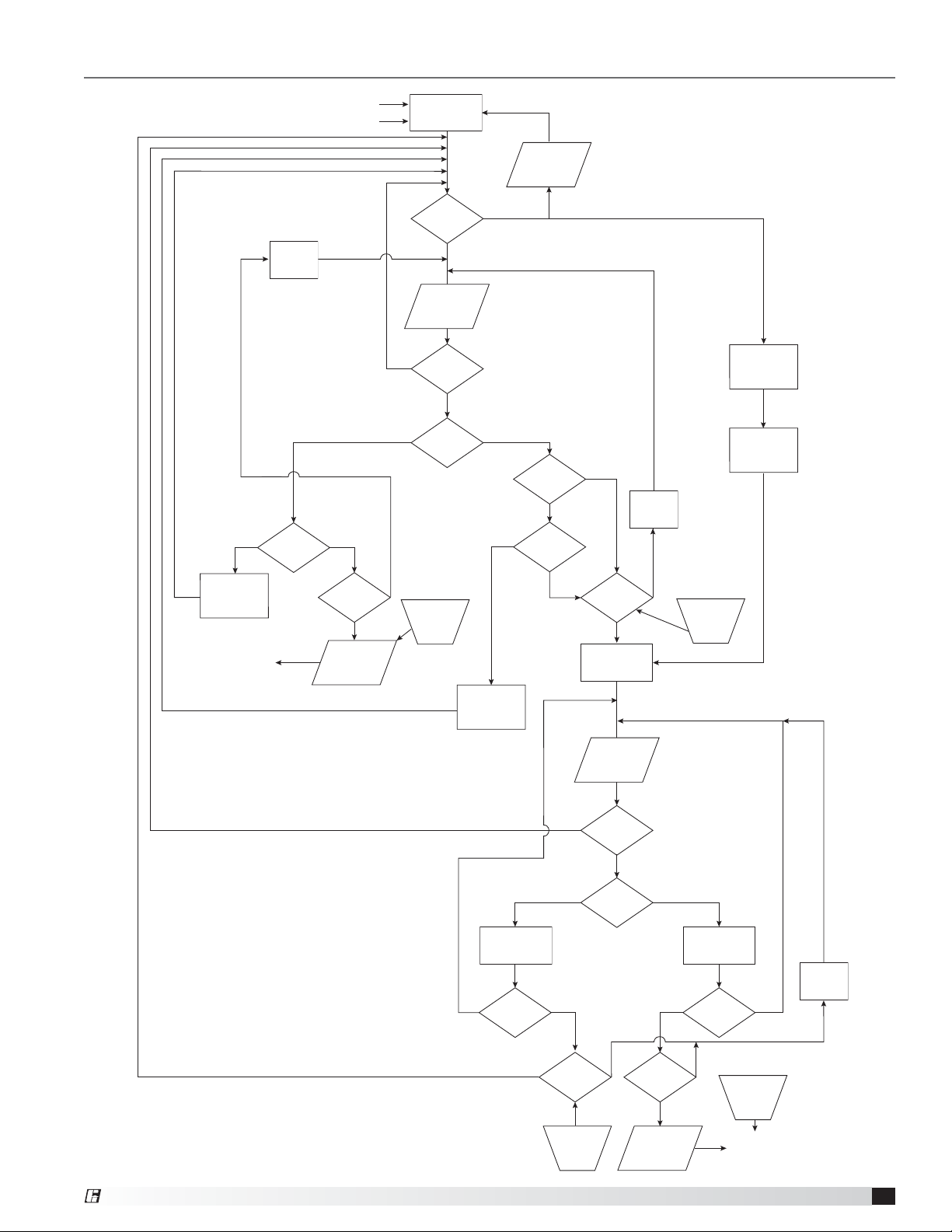

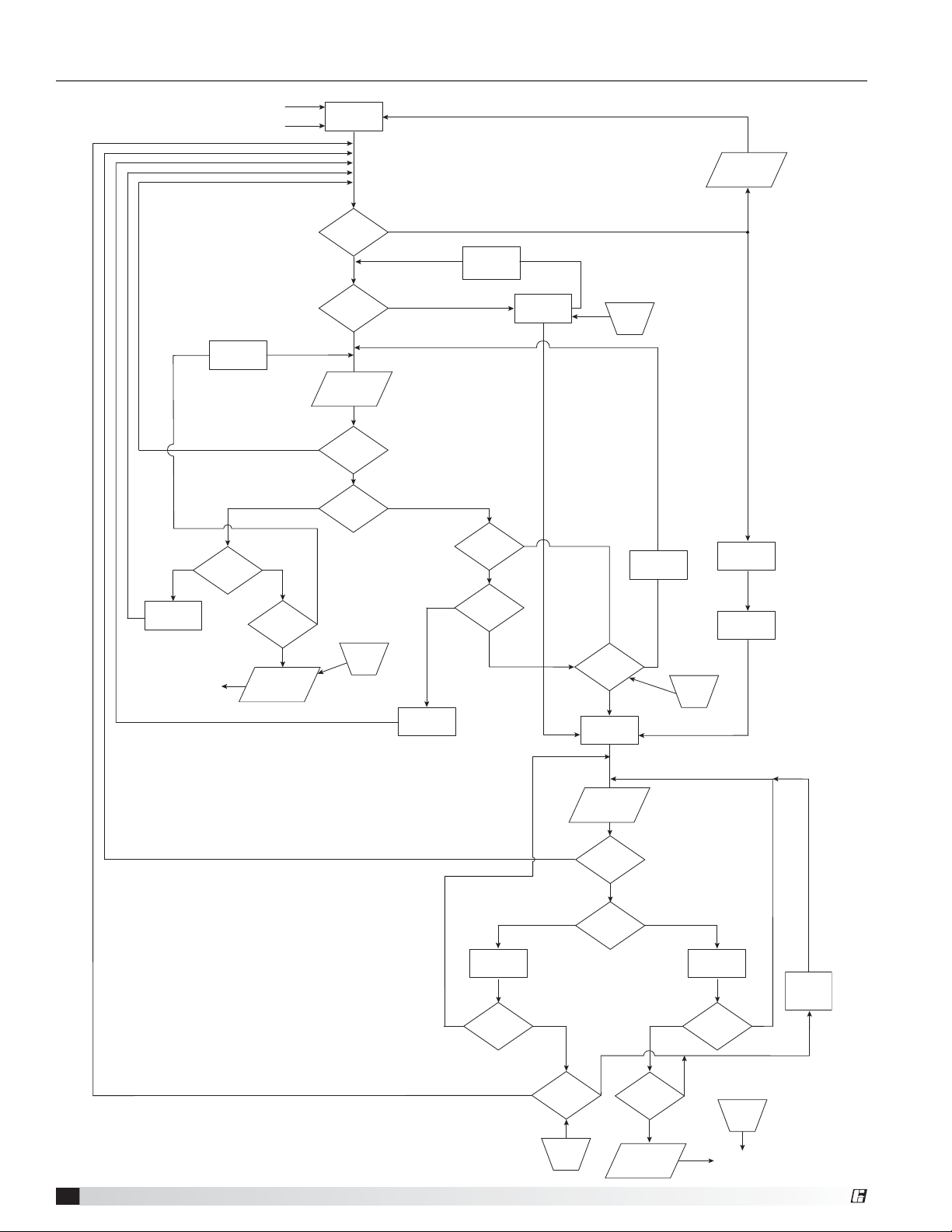

VGN Technology Control Flow Chart - Single Fan

Positive Pressure Fault

Negative Pressure Fault

Max. VFD

Monitor

Time

Above Setpoint

(more positive)

VFD

No

at Full

Speed

Yes

Yes

BMS Control

Drive

Fault Bypass

Mode

No

Static

Pressure

Valve

Static

Pressure =

Setpoint

No

Static

Pressure

Value

Drive Fault

Yes

Below Setpoint

(more negative)

Feedback at

Minimum

No

No

Minimum

Alarm

Nozzle

VFD at

Speed

Yes

Yes

Min. VFD

Monitor

Time

Fan at

Full Speed

Yes

Required

Nozzle Area

Increase

Fan Speed

Send to BMS

Controller

Time Period

Met?

Yes

Positive

Pressure

Alarm

No

Reset at

Fault CLR

Decrease

Fan Speed

Above Setpoint

(more positive)

Close

Bypass

Damper

Bypass

Feedback

= Mimimum

VDC

Yes

Yes

Yes

Time Period

Met?

Yes

BMS Control

Bypass Damper

PID

Static

Pressure

Value

Static

Pressure =

Setpoint

No

Static

Pressure

Value

No

Reset by

BMS

Below Setpoint

(more negative)

Bypass

Damper

Yes

Feedback

= Maximum

Open

Bypass

VDC

Damper

Position

Monitor

NoNo

Time

Yes

Time Period

Met?

Reset by

BMS

®

No No

Time Period

Met?

Yes

Negative

Pressure

Alarm

Reset at

Fault CLR

Send to BMS

Controller

VGN Technology

5

Page 6

General Electrical Controls Information

Fan Operation - Multiple Fans, No Staging

Set point and minimum variables

1. System will maintain a minimum of 3000 fpm velocity

(factory default) at the outlet of each fan, based on

the airflow monitoring station. Building Management

System (BMS) to monitor each fan nozzle actuator

feedback and keep fan speed above the minimum

required set point to maintain velocity.

2. Each fan to run at BMS defined operation for

fan on or off, and event timing, as required per

system airflow requirements. BMS is also required

to control fan speed for all fans. Bypass damper

mode reference will be determined by the following

scenario listed:

A. All fans in system running at minimum. Minimum

flow condition.

a. BMS will control fan speed and monitor nozzle

feedback as required to maintain system set point.

b. Decreased flow condition from minimum speed.

When the speed is equal to the minimum specific

fan speed and nozzle feedback is at minimum for a

set time period (user-defined), the BMS will begin to

modulate the bypass damper(s) open to assist with

pressure control.

Increased flow condition from minimum speed. If

the bypass damper(s) are at full closed for a set

time period (user-defined), the BMS will increase

fan speed and the fan control will increase the

nozzle area as required to assist with pressure

control.

c. The PID sequence to be programmed at the BMS

for the bypass damper(s) operation. The BMS to

provide fan enable and VFD speed reference.

B. Normal operation. Fan operation normal system

flow.

a. Flow requirement for system within reach of fan

operation. Fans operating will float together from

minimum speed to maximum speed to keep set

point.

b. If any of the fans run in the surge area for a set

time period, the BMS will need to add the bypass

damper(s).

c. The PID sequence to be programmed at the BMS

for the bypass damper(s) operation. The BMS to

provide fan enable and VFD speed reference.

Definition of typical operation modes:

Mode #1: Unoccupied. Defined as no one inside the

lab(s), all lab hoods are closed.

1. Fan(s) will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan(s). BMS to monitor nozzle

actuator feedback for each fan and keep fan speed

above the minimum required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value to

BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS system.

Mode #2: Occupied; no lab hoods being used.

Defined as people entering the lab(s), no work being

done at the hoods.

1. Fan(s) will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan(s). BMS to monitor nozzle

actuator feedback for each fan and keep fan speed

above the minimum required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS system.

Mode #3: Occupied; some or all lab hoods being

used. Defined as people in the lab(s), lab hood sashes

being used.

A. Sashes opening in the lab

1. Fan(s) will operate at BMS required speed and

nozzle will modulate as necessary to achieve the

required velocity. Typical system response should

be to increase fan(s) speed and increase nozzle

open area.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value

to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS

system.

VGN Technology

6

®

Page 7

General Electrical Controls Information

B. Sashes closing in the lab

1. Fan(s) will operate at BMS required speed and

nozzle will modulate as necessary to achieve the

required velocity. Typical system response should

be to decrease fan(s) speed and decrease nozzle

open area.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value

to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS

system.

Mode #4: Fault Mode. Defined as safety mode;

the system has an issue and needs to default to VFD

bypass.

1. VFD failure detected, automatically or manually put

into VFD bypass if available by operator or BMS.

2. Nozzle area to increase proportional to fan airflow

which will increase as fan speed is at maximum.

3. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value to

BMS.

4. Duct pressure control will modulate bypass

damper(s) as required if system is in alarm mode.

Duct pressure control is provided and programmed

by the BMS system.

5. System manually to be reset and placed back in VFD

auto mode.

®

VGN Technology

7

Page 8

General Electrical Controls Information

VGN Technology Control Flow Chart - Multiple Fans, No Staging

Positive Pressure Fault

Negative Pressure Fault

No

Increase

Fan(s) Speed

Send to

BMS Controller

Max. VFD

Monitor

Time

Above Setpoint

(more positive)

VFD(S) at

Full Speed

Yes

Time Period

Met?

Positive

Pressure

Alarm

Yes

Yes

BMS

Control

Drive Fault

Bypass

Mode

Fan(s) in

Stall Mode

Static Pressure

Value

Static

Pressure

= Setpoint

Static Pressure

Value

No

No

No

No

Reset at

Fault Clr

Yes

Yes

Below Setpoint

(more negative)

No

Decrease

Fan(s)

Speed

Fan Stall

Monitor Time

All Nozzle

Feedback at

Minimum

No

VFD(S)

Minimum

Speed

Yes

Yes

Time

Period

Yes

Reset by

BMS

Time Period

Time

Met?

Period

Yes

BMS Control

Bypass Damper

PID

Min. VFD

Monitor

Time

No

Reset by

BMS

Yes

Drive Fault

Alarm

Fan

Full Speed

Yes

Required

Nozzle Area

VGN Technology

8

No

Above Setpoint

(more positive)

Close

Bypass

Damper

Bypass

Feedback

= Min. VDC

Yes

Yes

Yes

Time Period

Met?

Reset by

BMS

Static Pressure

Value

Static

Pressure

= Setpoint

No

Static

Pressure

Value

Below Setpoint

(more negative)

Yes

Time Period

Met?

Yes

Negative

Pressure

Alarm

Feedback

= Max. VDC

NoNo

Open

Bypass

Damper

Bypass

BMS Controller

Reset at

Fault Clr

Send to

No

Damper

Position

Monitor

Time

®

Page 9

General Electrical Controls Information

Fan Operation - Multiple Fans, With Staging

Set point and minimum variables

1. System will maintain a minimum of 3000 fpm velocity

(factory default) at the outlet of each fan, based on

the airflow monitoring station. Building Management

System (BMS) to monitor each fan nozzle actuator

feedback and keep fan speed above the minimum

required set point to maintain velocity.

2. Each fan to run at BMS defined operation for fan

staging, on or off, and event timing, as required per

system airflow requirements. BMS is also required

to control fan speed for all fans. Bypass damper

mode reference will be determined by the following

scenario listed:

A. One fan in system running, all other fans off.

Minimum flow condition.

a. One fan in operation, BMS will control fan speed

and monitor nozzle feedback as required to

maintain system set point.

b. Decreased flow condition from minimum speed.

When the speed is equal to the minimum specific

fan speed and nozzle feedback is at minimum for a

set time period (user-defined), the BMS will begin to

modulate the bypass damper(s) open to assist with

pressure control.

Increased flow condition from minimum speed. If

the bypass damper(s) are at full closed for a set

time period (user-defined), the BMS will increase

fan speed and the fan control will increase the

nozzle area as required to assist with pressure

control.

c. If one fan is at maximum speed for a set time

period, another fan may be required to keep system

set point. Note section B for multiple fan operation.

d. The PID sequence to be programmed at the BMS

for the bypass damper(s) operation. The BMS to

provide fan enable and VFD speed reference.

B. Two or more fans running, normal operation. Fan

operation normal system flow.

a. Flow requirement for system within reach of fan

operation. Fans operating will float together from

minimum speed to maximum speed to keep set

point.

b. If all fans in operation are at maximum speed for

a set time period (user-defined) and other fans are

available, another fan can be added by the BMS as

required.

c. With additional fan added to the system, all fans in

operation will decrease and match speed of new

fan until set point is reached, then fans can float

together between minimum to maximum speed.

Note section “C” if a dead band zone is created.

d. When more than one fan is operating and all are at

the minimum speed for a set time period and the

pressure is still too negative, the BMS will need to

subtract a fan.

e. When more than one fan is in operation and any of

the fans run in the surge area for a set time period,

the BMS will need to subtract a fan or bypass

damper(s) may need to be used.

f. With the subtraction of a fan from the system, the

BMS will need to increase speed of all remaining

fans and they will float together until set point is

reached. Note section “C” if a dead band zone is

created.

g. The PID sequence to be programmed at the BMS

for the bypass damper(s) operation. The BMS to

provide fan enable and VFD speed reference.

C. Dead band in system. Flow between fans cycle

on/off.

Flow requirement for system out of reach causing

undesirable fan cycling on and off. If the fans in

the system running at full speed is not enough air

and adding an additional fan and running all fans at

minimum is too much air, then the bypass damper

mode may be necessary to settle these dead band

zones.

a. The BMS notices and counts cycling of fans to

determine dead band zone. If a dead band is

determined, the BMS will begin to modulate the

bypass damper(s) open to assist with pressure

control.

b. If the bypass damper(s) are at full closed for a set

time period, the BMS will increase fan speed and

the fan control will increase the nozzle area as

required to assist with pressure control.

c. The PID sequence to be programmed at the BMS

for the bypass damper(s) operation. The BMS to

provide fan enable and VFD speed reference.

®

VGN Technology

9

Page 10

General Electrical Controls Information

Fan Operation - Multiple Fans, With Staging - continued

Definition of typical operation modes:

Mode #1: Unoccupied. Defined as no one inside the

lab(s), all lab hoods are closed.

1. Fan(s) will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan(s). BMS to monitor nozzle

actuator feedback for each fan and keep fan speed

above the minimum required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value to

BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS system.

Mode #2: Occupied; no lab hoods being used.

Defined as people entering the lab(s), no work being

done at the hoods.

1. Fan(s) will operate at BMS required speed and nozzle

will modulate as necessary to achieve the required

velocity out the fan(s). BMS to monitor nozzle

actuator feedback for each fan and keep fan speed

above the minimum required to maintain velocity.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller will report this value to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS system.

Mode #3: Occupied; some or all lab hoods being

used. Defined as people in the lab(s), lab hood sashes

being used.

A. Sashes opening in the lab

1. Fan(s) will operate at BMS required speed and

nozzle will modulate as necessary to achieve the

required velocity. Typical system response should

be to increase fan speed and increase nozzle open

area. Additional fans may be added as necessary.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value

to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS

system.

B. Sashes closing in the lab

1. Fan(s) will operate at BMS required speed and

nozzle will modulate as necessary to achieve the

required velocity. Typical system response should

be to decrease fan speed and decrease nozzle

open area. Removal of fans may be required as

necessary.

2. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value

to BMS.

3. Duct pressure control, by the BMS, will modulate

bypass damper(s) as required.

Note: Follow bypass damper(s) operation

depending on number of fans running.

4. VFD speed, duct pressure control and the bypass

damper(s) operation is provided by the BMS

system.

Mode #4: Fault Mode. Defined as safety mode; the

system has an issue and needs to default to VFD

bypass.

1. VFD failure detected, automatically or manually put

into VFD bypass if available by operator or BMS.

2. Nozzle area to increase proportional to fan airflow

which will increase as fan speed is at maximum.

3. Sure-Aire will measure airflow of the fan. VFD or the

nozzle controller for each fan will report this value to

BMS.

4. Duct pressure control will modulate bypass

damper(s) as required if system is in alarm mode.

Duct pressure control is provided and programmed

by the BMS system.

5. System manually to be reset and placed back in VFD

auto mode.

VGN Technology

10

®

Page 11

General Electrical Controls Information

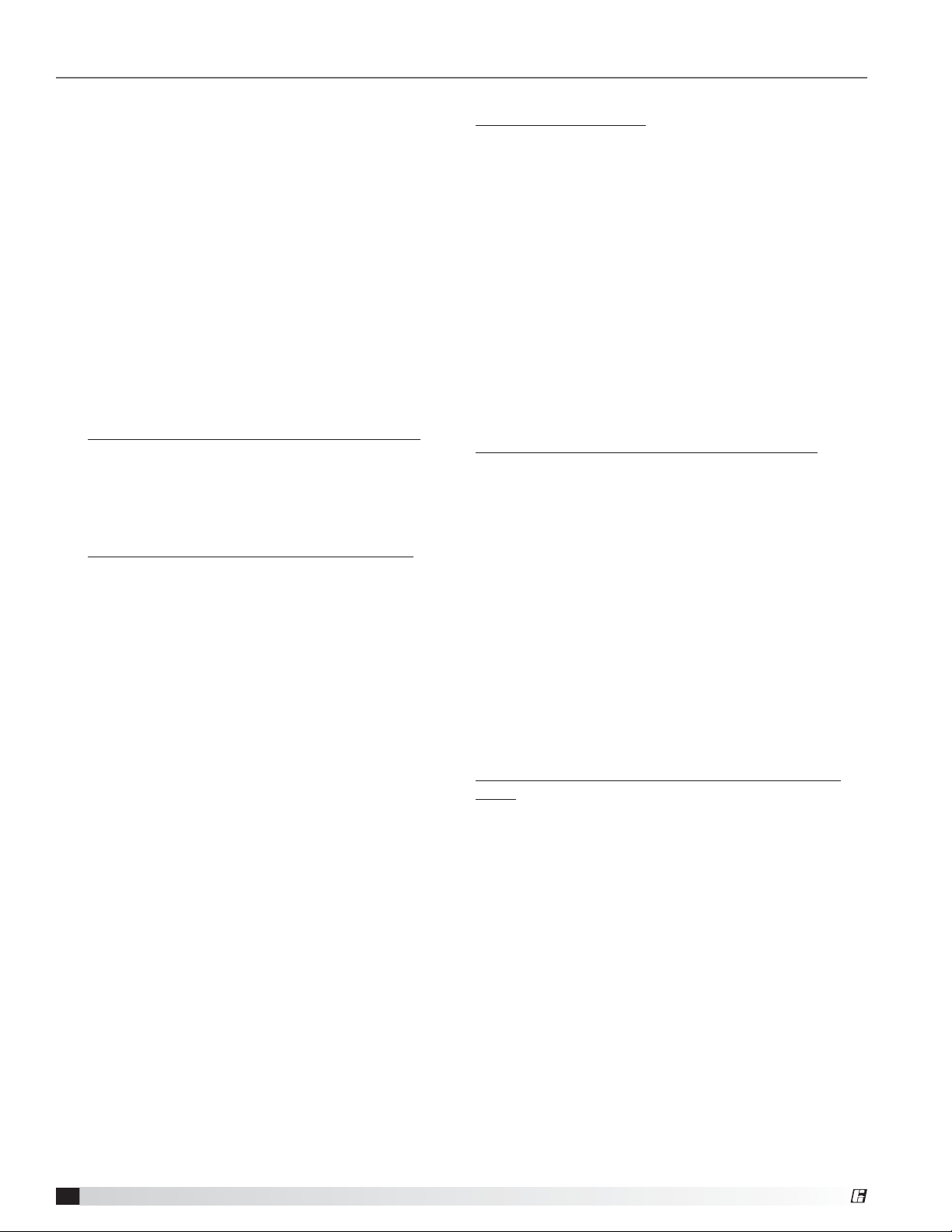

VGN Technology Control Flow Chart - Multiple Fans, With Staging

Positive Pressure Fault

Negative Pressure Fault

No

No

Increase

Fan(s) Speed

BMS Controller

Max. VFD

Monitor Time

Above Setpoint

(more positive)

VFD(S)

Full Speed

Send to

Yes

No

Yes

Fan(s)

available to

add

Time Period

Met?

Positive

Pressure

Alarm

BMS

Control

Deadband Range

Fan On/Off

Cycling

No

Drive Fault

Bypass

Mode

No

Fan(s) in

Stall Mode

No

Static

Pressure

Value

Static

Pressure

= Setpoint

No

Static Pressure

Value

Yes

No

Yes

Reset at

Fault

Clr

Yes

Yes

Yes

Time Period

Yes

Fan Stall

Monitor Time

Below Setpoint

(more negative)

Met?

Add a

Fan

No

Time Period

Met?

All Nozzle

Feedback at

Reset by

BMS

Decrease

Fan(s)

Speed

Minimum

No

VFD(S)

Minimum

Speed

Yes

Running

Time Period

BMS Control

Bypass Damper

Pressure

No No

Reset by

BMS

Fan(s)

= 1

Yes

Met?

PID

Static

Value

Yes

Yes

Time Period

Reset by

BMS

Remove

a fan

Met?

Reset by

BMS

Yes

Time Period

Met

Yes

Reset by

BMS

Yes

Drive Fault

Alarm

Fan

Full Speed

Yes

Required

Nozzle Area

Static

Yes

Pressure

= Setpoint

Above Setpoint

(more positive)

Close

Bypass

Damper

Bypass

No

Feedback

= Min. VDC

®

Yes

Yes

Time Period

Met?

Reset by

BMS

No

Below Setpoint

Static

Pressure

Value

(more negative)

Yes

No No

Time Period

Met?

Yes

Negative

Pressure

Alarm

Open

Bypass

Damper

Bypass

Feedback

= Max. VDC

Reset at

BMS Controller

No

Fault

Clr

Send to

VGN Technology

Damper

Position

Monitor

Time

11

Page 12

Electrical Controls Information for Factory-Supplied Variable Frequency Drive

System Diagram

TO BMS CONTROL

VFD IN A NEMA 3R UL LISTED ENCLOSURE WITH

BYPASS AND INTEGRATED CONTROLLER

(SHIPPED LOOSE; FIELD MOUNTED)

COMMUNICATION WIRING

- BACNET® (STANDARD)

- ANALOG SIGNAL(S) (STANDARD)

- LONWORKS® (OPTIONAL)

DRIVE BMS COMMUNICATIONS

SYSTEM POWER WIRING

DUCT PRESSURE

NOZZLE FEEDBACK

CONTROL WIRING

CONTROL

WIRING BY GFC

EQUIPMENT BY GFC

WIRING BY OTHERS

EQUIPMENT BY OTHERS

NOTES:

STATIC PRESSURE

TRANSDUCER BOX

1/4 INCH PRESSURE TUBING

- All wiring in rigid metal conduit or flexible

metal conduit and liquid tight.

- All tubing and conduit to be UV resistant

for outdoor use.

STATIC PRESSURE PROBE

VGN NOZZLE

WITH MODULATING ACTUATOR(S)

EXHAUST FAN

VEKTOR ROOF

ALL GFC PROVIDED

CONTROL DEVICES

ARE 24V POWER

SERVICE

DISCONNECT

SWITCH

(INSTALLED BY OTHERS)

1/4 INCH PRESSURE TUBING

STATIC PRESSURE TRANSDUCER

AND TERMINAL BOX SHIPPED LOOSE

MOTOR WIRING

ISOLATION DAMPER

WITH OPEN/CLOSE ACTUATOR

ROOF LINE

EXHAUST DUCT

(MODULATING)

(CONTROLLED BY BMS)

BYPASS DAMPER ACTUATOR

VGN Technology

12

®

Page 13

Electrical Controls Information for Factory-Supplied Variable Frequency Drive

Wiring Diagram

ABB ECLIPSE DRIVE WITH VGN TECHNOLOGY

CBL#1 (BLACK)

CBL#1 (WHITE)

CBL#2 (WHITE)

CBL#2 (BLACK)

CBL#3 (ORANGE)

CBL#3 (ORANGE)

CBL#3 (BLACK)

CBL#3 (RED)

SET DIP

SWITCHES

SHIELD

ABB BYPASS MODULE

1

5

14

DIGITAL RELAY OUT

CLOSE WHEN FAN ON

16

ABB DRIVE MODULE

U I

1

ANALOG INPUT

2

SIGNAL SWITCH

SGND

AI1

SURE AIRE

AGND

AO1

VARIABLE N.

DRIVE DISCONNECT LOAD SIDE

2

1

GND

3

OUTGOING POWER - TO FAN MOTOR

T1

T2

T3

GND

TB1

Nozzle VDC

Sure-Aire VCD

Isolation Power

Manual Switch 1

Manual Switch 2

+24 Volts

+24 Volts

+24 Volts

Common

Common

Common

R1

TB2

TRANSDUCER/TERMINAL

ENCLOSURE

- AT THE FAN

TRANSDUCER 2

Power Supply +

Common

1

5

14

16

AI1

AGND

AO1

VGN PCB

FUSE

POWER SUPPLY

-+

SURE-AIRE SIGNAL

0

+24DC

+24DC

COM

+24DC

COM

COM

SURAIR

ISOPWR

NOZFB1

NOZVDC

GND

NOZFB2

GND

COMM

NOZZLE POSITION

FEEDBACK TO BMS

BMS SYSTEM

SUPPLIED BY OTHERS

BMS COMMUNICATIONS (STD)

- BACNET (STANDARD)

- LONWORKS (OPTIONAL)

REQUIRED WIRING:

-DIGITAL ON/OFF (THRU COMM)

-SPEED REFERENCE (THRU COMM)

-NOZZLE FEEDBACK (HARDWIRE)

-ALARM (THRU COMM)

-FAN FLOW (THRU COMM)

TRANSDUCER 1

-+

0

DUCT PRESSURE

SIGNAL COMPONENT

BY OTHERS

ACTUATOR 4

3

1 2

5

BYPASS DAMPER

COMPONENT

BY OTHERS

NOZZLE ACTUATOR FEEDBACK RECOMMEND 1 PER SHAFT

MAY BE MULTIPLE ACTUATORS PER NOZZLE BLADE SHAFT

FAN PRESSURE (LOW&HIGH)

ACTUATOR 1

ISOLATION DAMPER

ACTUATOR 2

NOZZLE ACTUATOR 1

FACTORY WIRING

TO SURE-AIRE CONNECTION

PLATE ON FAN

- +

5

1 2

3

FIELD WIRING

5

1 2

3

®

ACTUATOR 3,4,5

ADDITIONAL NOZZLE ACTUATORS

QTY. DEPENDENT ON UNIT SIZE

VGN Technology

13

Page 14

Electrical Controls Information for Factory-Supplied Variable Frequency Drive

Communication

The VGN Technology variable frequency drive (VFD)

has an embedded fieldbus as standard and optional

fieldbus adapter(s) that can be purchased. Greenheck

offers and supports BACnet® MS/TP as our standard

communication protocol and also LonWorks® as

an optional communication. The VFD does have

other languages available, but are not supported by

Greenheck, however, it may be supported by the VFD

manufacturer. Please contact the VFD factory support if

you have alternate communication requirements.

The following information is a guide to summarize

the set up of the VFD to a BMS system. The guide is

a general overview and it is suggested the controls

contractor and BMS group reference the VFD

manual for detailed installation and setup of the VFD

communications. It is also suggested to follow the

manufacturers recommendations for communication

cable type and maximum lead length. The

recommended cable is different for each protocol.

The following is only a general checklist and does not

specify exact parameters.

NOTE

All parameters are to be modified at the bypass

keypad, which is the lower keypad on the enclosure.

BACnet® MS/TP Protocol (standard)

Connect the communication wiring from the

appropriate VFD terminations to the BMS control

system. Reference the VFD manual for terminal

location and approved wiring type.

Apply power to the VFD.

Enable BACnet MS/TP as the desired Protocol.

Place the BACnet MS/TP channel in the reset

mode, this is required to set up all the remaining

parameters.

Define the system baud rate being used.

Define the Device object instance.

Define a unique object ID.

Confirm the communication.

Configure the device name.

Take the VFD out of reset mode.

Cycle power to the VFD to save all changes.

For a list of BMS points available for BACnet MS/TP

communication, see the manufacturer’s point listing

chart(s) in the manual.

LonWorks® Protocol (optional)

The LonWorks communication requires an optional

plug-in module that is added to the bypass module of

the VFD. The module needs to be specified at time of

ordering of the fan and control system.

It is also suggested to follow the manufacturers

recommendations for communication cable type and

maximum lead length for LonWorks. The recommended

cable is different for each protocol.

Verify mounting of plug-in module that nothing was

loosened in shipping.

Connect the communication wiring from the

appropriate VFD terminations to the BMS control

system. Reference the VFD manual for terminal

location and approved wiring type.

Apply power to the VFD.

Activate the field buss adaptor port.

Verify the HOST LED is lit to a solid green color.

Program the system enable control.

Program the bypass fault reset if required to reset

VFD from BMS.

Program the system VFD speed control.

Program the VFD fault reset if required to reset VFD

from BMS.

Cycle power to the VFD to save all changes.

For a list of BMS points available for LonWorks

communication, see the manufacturer’s point listing

chart(s) in the manual.

VGN Technology

14

®

Page 15

Electrical Controls Information for Factory-Supplied Variable Frequency Drive

Start-Up Procedure - Electrical Controls

The following start-up procedure is to be completed

in order to verify that the fan is in working order.

It does not cover the details for test and balance,

VFD programming, commissioning, or system

troubleshooting which is covered in other parts of the

Installation, Operation and Maintenance Manual.

Mechanical Component System Verification

For detailed descriptions to complete these operations,

see equipment Installation, Operation and Maintenance

Manual (IOM).

Fan assembly and installation completed.

Check all fasteners for tightness, as they may loosen

during shipping.

All pressure tubing lines installed as required.

All control enclosures and devices mounted in the

appropriate locations.

Verify fan wheel alignment.

Electrical Control Components System

Verification

For detailed descriptions to complete these operations,

see equipment Installation, Operation and Maintenance

Manual, National Electrical Code and local electrical

code.

Service feeder(s) to all controls completed.

Control wiring to all devices completed.

All field electrical connections tested and torqued.

Communication wiring to Building Management

System completed.

Electrical System Start-Up for VGN

Use appropriate electrical safety gear as required.

Make sure disconnect switch at the VFD is in the

‘OFF’ position.

Verify each power phase at the VFD disconnect is

not shorted to ground using a voltmeter.

Turn on the breaker that feeds the fan VFD.

Verify the voltage is correct from phase to phase

using a voltmeter at the VFD disconnect.

Apply power to the VFD by turning on the disconnect

switch that is interlocked to the door.

Verify that the VFD is in the ‘OFF’ mode at the VFD

keypad.

Check control voltage at drive terminals to verify the

control voltage is correct.

Turn on the service disconnect switch at the fan.

Open all lab hoods inside the building and verify duct

control is operational.

Note the fan speed at the VFD keypad; it should be

at full speed.

• Increase fan speed if required using the VFD

keypad up and down arrows.

Press the ‘HAND’ button at the VFD keypad.

• The isolation damper will start to open.

• The fan speed will start to accelerate to full

speed.

• As the fan speed increases the nozzle will open

to maintain constant velocity.

Verify fan wheel rotation. Verify it matches labeled

direction and IOM.

• If the fan wheel is rotating in the wrong direction,

turn off fan, disconnect power, and lockout main

feeder.

• Reverse two of the motor wiring leads to change

wheel direction.

Reapply power and press ‘HAND’ mode once again

at the VFD keypad.

Verify fan wheel rotation, verify it matches labeled

direction and fan Installation, Operation and

Maintenance Manual.

Use the up and down arrows at VFD keypad, change

the speed to verify nozzle reaction.

- As speed increases the nozzle will open.

- As speed decreases the nozzle will close.

®

VGN Technology

15

Page 16

Electrical Controls Information for Factory-Supplied Variable Frequency Drive

System Test and Balance for VGN

The VGN Technology control system needs to be set

up at a desired fixed fan speed and nozzle area. If the

following is not done, it will be difficult to do the test

and balance of the building as the fan will continually be

adjusting during changes in the building lab airflow.

The following steps listed are necessary to create a

stable fan system for the test and balance setup of a

building.

The fan speed can be set at a fixed speed by two

different options:

Option #1 is by selecting the bypass mode; this will put

the fan at full speed.

Option #2 is put the VFD in ‘HAND’ mode; this will

give you speed adjustment from minimum speed to full

speed.

The nozzle area can by set to a fixed position by

doing the following.

1. Minimum Nozzle Actuator Signal is adjusted by

the VFD parameter #1504 at the VFD keypad. Note

the factory default setting from Greenheck prior to

adjusting. Use the following table to record for your

reference.

2. Maximum Nozzle Actuator Signal is adjusted by

the VFD parameter #1505 at the VFD keypad. Note

the factory default setting from Greenheck prior to

adjusting. Use the following table to record for your

reference.

3. To create a fixed nozzle location, the Test and

Balance personnel can set the parameter #1504 and

#1505 to the same value within Greenheck range

and it will keep the nozzle fixed to a specific location.

For example, if the maximum value is 15 mA, do not

go over that maximum value.

By setting the value to the same number, the outlet

velocity and airflow of the fan can be set to a desired

reading for balancing the building.

Parameter & Description

Minimum Nozzle Actuator

Signal Parameter 1504

Maximum Nozzle Actuator

Signal Parameter 1505

Value

(Set at Factory)

After testing is completed, VFD parameters need to

be set back to Greenheck factory default numbers

for the nozzle to modulate. The fan can be put back

into the desired mode (off, hand, or auto).

For more information on the keypad details and how

to access the following parameters, see the VFD

manufacturer user’s guide.

New User

Set Point

Nozzle Velocity Adjustment

The VGN control system is shipped from the factory to

output an average minimum 3000 fpm nozzle velocity.

The VFD for the system will have a given cfm range that

is programmed into the parameter set. The following

parameters can be set as required if the desired velocity

is required to be higher than the factory default setting.

The following steps can be done to adjust the nozzle

velocity range of the fan.

Setting the minimum range parameter of the

system:

1. Minimum air volume range is adjusted by the VFD

parameter #1502 at the VFD keypad. The factory

default setting from Greenheck is specific to every

fan; note the parameter setting prior to changing the

value and record below for future reference.

2. To change the minimum value, follow the following

guidelines.

Example: 3,500 fpm (desired)

New VFD Reading = Current VFD Reading x

(3,500/3000)

Setting the minimum speed parameter of the

system:

1. Minimum fan speed is adjusted by the VFD

parameter #2007 at the VFD keypad. Note the

parameter setting prior to changing the value and

record below for future reference.

2. The minimum fan speed may be increase from the

factory value if a higher nozzle velocity is required.

It is not required to increase the minimum fan speed

but once the nozzle is at the minimum area the

velocity may potentially go lower than the desired

velocity. It is suggested by Greenheck however

that the value not be lower then the factory preset

minimum value set at time of shipment.

Adjust Fan RPM for velocity increase:

1. The fan may also need the pulley changed to adjust

the fan RPM. It is suggested to consult the factory to

size accordingly.

After completing the velocity changes, the fan can

be put into the desired mode (off, hand, or auto).

Parameter & Description

Minimum Range Value

Parameter 1502

Minimum Speed Value

Parameter 2007

Value

(Set at Factory)

For more information on the keypad details and how

to access the following parameters, see the VFD

manufacture user’s guide.

New User

Set Point

VGN Technology

16

®

Page 17

This page is intentionally blank.

®

VGN Technology

17

Page 18

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

System Diagram

DUCT PRESSURE

TO BMS CONTROL

VFD COMMUNICATION

ANALOG SIGNAL(S)

VFD POWER WIRING

VFD PROVIDED AND

PROGRAMMED BY OTHERS

CONTROL

WIRING BY GFC

EQUIPMENT BY GFC

WIRING BY OTHERS

EQUIPMENT BY OTHERS

NOTES:

- All wiring in rigid metal conduit or flexible

metal conduit and liquid tight.

- All tubing and conduit to be UV resistant

for outdoor use.

NOZZLE CONTROLLER

VGN NOZZLE

WITH MODULATING ACTUATOR(S)

SERVICE

DISCONNECT

SWITCH

ISOLATION DAMPER WIRING

FAN RUNNING

CONTROLLER

STATUS CONTACT

POWER WIRING

TO VFD BY OTHERS

NOZZLE FEEDBACK

MOTOR WIRING

ROOF LINE

STATIC PRESSURE

TRANSDUCER BOX

EXHAUST DUCT

1/4 INCH PRESSURE TUBING

STATIC PRESSURE PROBE

VGN Technology

18

VEKTOR ROOF

EXHAUST FAN

ALL GFC PROVIDED

CONTROL DEVICES

ARE 24V POWER

ISOLATION DAMPER

(INSTALLED BY OTHERS)

STATIC PRESSURE TRANSDUCER

AND TERMINAL BOX SHIPPED LOOSE

1/4 INCH PRESSURE TUBING

(MODULATING)

(CONTROLLER BY BMS)

WITH OPEN/CLOSE ACTUATOR

BYPASS DAMPER ACTUATOR

®

Page 19

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

Wiring Diagram

NOZZLE CONTROLLER

TRANSDUCER

TERMINAL

ENCLOSURE

- AT THE FAN

ID2 GND Y2 Y4 GND

NOZZLE

CONTROLLER

G GO B1 GND C1 NO1

+24V

+24V

+24V

+24V

+24V

COM

COM

COM

COM

COM

SURAIR

FNRUN

ALM

NOZVDC

CFM1

GND

GND

GND

GND

TRANSFORMERS

L1L1NNGND

GND

INCOMING POWER

120/1PH. 20 AMP CIRCUIT

ISOLATION DAMPER

ALM

CFM1

FAN RUN

CONTACT(S)

FROM VFD

BY OTHERS

MEASURE

0-10VDC

COM

MEASURE

2-10VDC

+24V

NOZFB1

NOZFB2

ISOPWRFNRUN

TRANSDUCER 1

DUCT PRESSURE

SIGNAL

COMPONENT BY

OTHERS

BMS SYSTEM

SUPPLIED BY OTHERS

BMS COMMUNICATIONS (STD)

- ANALOG SIGNAL(S)

- ON/OFF CONTACT(S)

REQUIRED WIRING:

-DIGITAL ON/OFF (HARDWIRE)

-NOZZLE FEEDBACK (HARDWIRE)

-ALARM (HARDWIRE)

-FAN FLOW (HARDWIRE)

-ISOLATION DAMPER CONTACT (HARDWIRE)

-+

0

ACTUATOR 4

1 2

BYPASS DAMPER

COMPONENT BY

OTHERS

3

5

+

-

0

TRANSDUCER 2

FAN FLOW (LOW&HIGH)

TO FAN CONNECTION PLATE

+24V

+24V

+24V

COM

COM

COM

SURAIR

ISOPWR

NOZVDC

NOZFB1

GND

NOZFB2

GND

NOZZLE POSITION

FEEDBACK TO BMS

-

+

5

1 2

3

5

1 2

3

ACTUATOR 1

ISOLATION DAMPER

ACTUATOR 2

NOZZLE (REQUIRED)

ACTUATOR 3,4,5

ADDITIONAL NOZZLE ACTUATORS

QTY. DEPENDENT ON UNIT SIZE

FACTORY WIRING

FIELD WIRING

®

VGN Technology

19

Page 20

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

VGN Nozzle Controller

Controller Introduction and Tutorial

The VGN Nozzle Controller is located in the main control

panel. The controller has factory set points that can

be modified to configure the system for job specific

functions. The controller introduction and directions for

the setup screens are shown in this section.

The face of the controller has six buttons, allowing the

user to view unit conditions and alter parameters. The

controller is pre-programmed with easy to use menus.

Keypad Navigation

Escape Allows the user to exit the current menu, jumping to the Main Menu.

Up | Down

!

Ì

Alarm

Enter

Program Pressing the Program button allows the user to enter the Main Program Menu.

J GREENHECK VGN

SYSTEM SETTINGS

H FAN SIZE 36

FLOW MEASURE INLET

UNITS ENGLISH

ELEVATION 10000

OUTLET VELOCITY 3000

The arrow buttons allow the user to scroll through different screens and adjust

parameters.

Button will blink red, indicating an alarm condition. Press to review current alarms. To

review previous alarms, access the DATA LOGGER through the main menu.

A. In screens with adjustable parameters, pressing the Enter button moves the cursor

from the upper left corner of the screen to the parameter. The arrow buttons can then

be used to adjust the parameter.

B. To move to the next parameter on the same screen, press the Enter button.

C. To save the change, press the Enter button until the cursor moves back to the upper

left corner of the screen.

Example of Parameter Adjustment

The cursor always begins in the upper left corner of the display and will be

blinking. Press the button to move the cursor down for parameter adjustment.

GREENHECK VGN

SYSTEM SETTINGS

H FAN SIZE J 36

FLOW MEASURE INLET

UNITS ENGLISH

ELEVATION 10000

OUTLET VELOCITY 3000

J GREENHECK VGN

SYSTEM SETTINGS

H FAN SIZE 36

FLOW MEASURE INLET

UNITS ENGLISH

ELEVATION 10000

OUTLET VELOCITY 3000

VGN Technology

20

Once the cursor has reached the desired parameter, press the buttons to

adjust the value.

When satisfied with the adjustment, press the button to save the parameter.

When finished, make certain the cursor is in the upper left corner. If the

cursor is not in the upper left corner, the changes will not be saved. The

cursor must be in the upper left corner to enable screen advancement.

®

Page 21

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

Controller Menu Screens

The nozzle controller consists of five menu screens to operate the VGN system. The following information describes

the menu screens in detail.

GREENHECK VGN

AIR FLOW

FLOW xxxxx

FLOW VDC X.X VDC

LOW SCALE 0 TO XXXXX

NOZZLE OPEN XXX %

GREENHECK VGN

SYSTEM STATUS

FAN STATUS XXX

VELOCITY XXX

FAN FLOW XXX

ALARM CONTACT XXX

The following value ranges are specific to the Air Flow menu screen.

Flow Active reading calculated by the Sure-Aire system.

English = CFM; Metric = m3/hr

Flow VDC Scaled voltage output specific to the flow scale.

0 VDC = no flow; 10 VDC = maximum flow

Flow Scale Flow range specific to VGN fan.

English = CFM; Metric = m

3

/hr.

Nozzle Open Active reading stating the % open of the VGN nozzle.

0% = nozzle closed; 100% = nozzle open

The values in this menu are not user-editable and are locked by the controller program.

The following value ranges are specific to the System Status menu screen.

Fan Status Shows the status of the fan.

On or Off

Velocity Determines if outlet velocity is acceptable per system setting.

OK or Low

Fan Flow Determines if fan flow is acceptable per required nozzle area and velocity.

OK or Low

Alarm Contact Alarm and contact closure for the following.

Alarm list:

a. Velocity is below the required preset system value.

b. Fan is shown as running but no flow is being created.

The values in this menu are not user-editable and are locked by the controller program.

GREENHECK VGN

SYSTEM SETTINGS

H FAN SIZE XX

FLOW MEASURE XXXXX

UNITS XXXXXX

ELEVATION XXXXX

OUTLET VELOCITY XXXX

The following value ranges are specific to the System Settings menu screen.

H / M / C Fan Size Factory set for system fan size. Selects the correct fan

Flow Measure Sets the location of the airflow monitor location.

Units Sets up the control screen variables for the system.

Elevation Location above sea level the system is located to set air density.

Outlet Velocity Required velocity at the VGN Nozzle outlet.

All the values in this menu can be changed by the user. Note factory settings prior to making

adjustments.

GREENHECK VGN

TEST AND BALANCE

T&B BALANCING XXX

NOZZLE % OPEN XXX

FLOW CORRECT XXXX

The following value ranges are specific to the Test and Balance menu screen.

T&B Balancing Used to start the balancing process of the system.

Nozzle % Open Gives Test and Balance personnel complete control of nozzle

Flow Correct “K” factor for Test and Balance personnel to measure and adjust

All the values in this menu can be changed by the user. Note factory settings prior to making

adjustments.

variables for the control.

Inlet or outlet condition

English or Metric

0 to 10,000 feet

3,000 to 4,000 FPM; 912 to 1216 MPM.

Yes or No.

regardless of fan flow.

0% = closed; 100% = open

airflow. Note that “K” value is not CFM, but subtracts or adds to

the flow calculation within the program.

-2000 to +2000

®

VGN Technology

21

Page 22

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

GREENHECK VGN

DIAGNOSTIC

INPUT B1 XX.X

INPUT ID1 XXXXX

OUTPUT NO1 XXXXX

OUTPUT Y2 XX.X

OUTPUT Y4 XX.X

The following value ranges are specific to the Diagnostic menu screen. The menu

will tell the controls electrician who is troubleshooting the system what the status

is of each Input or Output of the controller.

Input B1 Value of B1 analog input of the controller (pressure transducer).

0 VDC to 10 VDC

Input ID1 Status of the ID1 digital input of the controller (fan status).

Open or Closed

Output NO1 Status of the NO1 digital output of the controller (alarm contact).

Open or Closed

Output Y2 Value of the Y2 analog output of the controller (nozzle actuator).

2 VDC to 10 VDC

Output Y4 Value of the Y4 analog output of the controller (BMS CFM scale).

0 VDC to 10 VDC

All of these points can be verified with a volt meter between the terminal point

specified and system common using either voltage or continuity settings on the

meter.

The values in this menu are not user-editable and are locked by the controller program.

VGN Technology

22

®

Page 23

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

Communication

The VGN Nozzle Controller uses digital and analog

signal(s) that need to be wired to the BMS system. The

electrical installer can reference the “Nozzle Controller”

wiring diagram for specific hookup locations and

information.

The following is a list of the BMS points from the Nozzle

Controller when the VFD is supplied by others and not

the factory.

Nozzle Controller Enclosure

1. Digital Input – Relay contact from the customer

supplied VFD to terminals +24V and FNRUN.

2. Digital Output – Dry relay contact for system alarms

from terminals ALM and COM.

3. Analog Output – Voltage output (0 to 10VDC) for fan

flow from terminals CFM1 and COM.

NOTE: CFM scale is displayed on the “AIR FLOW”

menu and then “FLOW SCALE” line.

Transducer J-Box Enclosure

Analog Output(s) – Voltage output from nozzle actuator

feedback as 2 VDC as the minimum signal. The

maximum voltage signal varies depending on fan size

but has a maximum signal of 10VDC. The terminal

connections are at NOZFB1 (shaft 1), NOZFB2 (shaft 2),

and COM.

NOTE: The feedback is necessary to monitor for

minimum VFD speed. When the output is 2VDC (and

nozzle is at minimum area) it is necessary not to drop

fan speed further as outlet velocity will drop below

desired preset value.

®

VGN Technology

23

Page 24

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

Start-Up Procedure - Electrical Controls

The following start-up procedure is to be completed

in order to verify that the fan is in working order.

It does not cover the details for test and balance,

VFD programming, commissioning, or system

troubleshooting which is covered in other parts of the

Installation, Operation and Maintenance Manual.

Mechanical Component System Verification

For detailed descriptions to complete these operations,

see equipment Installation, Operation and Maintenance

Manual (IOM).

Fan assembly and installation completed.

Check all fasteners for tightness, as they may loosen

up during shipping.

All pressure tubing lines installed as required.

All control enclosures and devices mounted in the

appropriate locations.

Verify fan wheel alignment.

Electrical Control Components System

Verification

For detailed descriptions to complete these operations,

see equipment Installation, Operation and Maintenance

Manual, National Electrical Code and local electrical

code.

Service feeder(s) to all controls completed.

Control wiring to all devices completed.

All field electrical connections tested and torqued.

Communication wiring to Building Management

System completed.

Electrical System Start-Up for Nozzle

Controller

Use appropriate electrical safety gear as required.

System VFD (customer-supplied)

Make sure disconnect switch at the VFD is in the

‘OFF’ position.

Verify each power phase at the VFD disconnect is

not shorted to ground using a voltmeter.

Turn on the breaker that feeds the fan VFD.

Verify the voltage is correct from phase to phase

using a voltmeter at the VFD disconnect.

Apply power to the VFD by turning on the disconnect

switch that is interlocked to the door.

Verify that the VFD is in the ‘OFF’ mode at the VFD

keypad.

Turn on the service disconnect switch at the fan.

Nozzle Controller (factory-supplied)

Make sure feeder breaker for the nozzle controller is

in the “OFF” position.

Verify power wiring to the high voltage 120V

terminals (L1, N) is correct and is not shorted to

ground using a voltmeter.

Turn on the breaker that feeds the nozzle controller

panel.

Check control voltage to verify it is correct using a

voltmeter. Should be 24 volt control.

Verify and adjust the system controller settings in the

“System Settings” menu as required.

System Start-Up

Open all lab hoods inside the building and verify duct

control is operational.

Increase fan speed if required using the VFD keypad

up and down arrows.

Press the ‘HAND’ button at the VFD keypad.

The isolation damper will start to open.

The fan speed will start to accelerate to the set

value.

As the fan speed increases the nozzle will open to

maintain constant velocity.

Verify fan wheel rotation. Verify it matches labeled

direction and IOM.

If the fan wheel is rotating in the wrong direction, turn

off fan, disconnect power, and lockout main feeder.

Reverse two of the motor wiring leads to change

wheel direction.

Reapply power and press ‘HAND’ mode once again

at the VFD keypad.

Verify fan wheel rotation, verify it matches labeled

direction and fan Installation, Operation and

Maintenance Manual.

Use the up and down arrows at VFD keypad, change

the speed to verify nozzle reaction.

- As speed increases the nozzle will open.

- As speed decreases the nozzle will close.

VGN Technology

24

®

Page 25

Electrical Controls Information for Customer-Supplied Variable Frequency Drive

System Test and Balance for VGN

The VGN Technology control system needs to be set

up at a desired fixed fan speed and nozzle area. If the

following is not done, it will be difficult to do the test

and balance of the building as the fan will continually be

adjusting during changes in the building lab airflow. The

following steps listed are necessary to create a stable

fan system for the test and balance setup of a building.

The following steps need to be taken to do the test and

balance of the VGN system:

1. Set the VFD fan speed parameter to a desired fixed

position for testing.

2. Locate the main system control panel and access

the system controller.

a. At the controller, page thru the menu and locate

the “Test and Balance” screen.

NOTE: See “Controller Menu” screen for more

details.

b. At the “T&B Balancing” line select “YES” to

activate manual nozzle control.

c. Set the “Nozzle % Open” line to the desired fixed

value, the nozzle will not modulate and will remain

in the fixed position.

d. Take airflow measurement(s) and determine fan

flow in the system.

e. Compare controller “Fan Flow” at the menu

screen to the measured flow value in step “D”

f. Adjust the fan flow value by adjusting the “Flow

Correct” to match the airflow that was measured.

g. If the system is now balanced, change the

following at the “Test and Balance” menu.

• T&B Balancing line = NO

• Nozzle % open = 0

Nozzle Velocity Adjustment

The VGN Nozzle Controller is shipped from the factory

to output an average 3000 fpm (912 mpm) nozzle

velocity. The velocity can be adjusted by the user to

range between 3000 to 4000 fpm (912 to 1216 mpm).

The velocity is set as default from the factory as English

but can be changed to Metric.

The following steps can be done to adjust the nozzle

velocity range of the fan.

1. Locate the main system control panel and access

the system controller.

a. At the controller, page thru the menu and locate

the “System Settings” screen.

NOTE: See “Controller Menu” screen for more

details.

b. Move down the variable list to the “Outlet

Velocity” value. Note the default is 3000 fpm

(912 mpm).

c. To change the value use the up/down arrows

and adjust the velocity to the desired value

within the system range and press the enter key

to finalize the value.

These steps conclude the Nozzle Velocity portion of the

Nozzle Controller VGN system.

®

VGN Technology

25

Page 26

General Electrical Controls Information

Troubleshooting

General

Issue Possible Cause Recommended Action

Fan is running but no

pressure is being created

in the duct.

Nozzle actuator is not

responding to fan speed

changes.

Unstable fan conditions.

Fan is not balancing

the system and keeps

changing speed.

System has a positive

pressure condition.

System has an unfavorable

negative pressure

condition.

CFM reading is low or at

zero even though fan is

operating.

Isolation damper not open.

Bypass damper maybe open. Verify bypass damper is closed.

Sure-Aire transducer not reading air flow.

No power at the nozzle actuator. Verify power and signal at the actuator.

Low cfm due to laboratory hoods being

closed.

BMS PID timing is incorrect. Increase time functions in the system.

BMS PID overlap is incorrect.

Isolation damper not open.

BMS fan control not working properly.

Duct pressure transducer failure.

Broken fan belt. Check fan belt for failure.

Bypass damper maybe open. Verify bypass damper is closed.

Access panel is missing on fan or bypass air

plenum.

Nozzle is not operating and is at minimum

area.

BMS fan control not working properly.

Duct pressure transducer failure.

Bypass damper operation. Verify bypass damper operation.

Isolation damper is not open.

Sure-Aire tubing leak or blockage. Inspect tubing and blow out tubing with air.

Sure-Aire tube lines hooked up backwards. Flip the high and low tube lines.

Sure-Aire transducer for system is bad.

Laboratory hoods are closed in the building Open all laboratory hoods and verify operation.

Check power at isolation damper and determine

if it is open.

Inspect pressure tubing to transducer and verify

voltages.

Open all laboratory hoods to verify nozzle

operation.

Create an increased dead band between PID for

fan and bypass.

Check power at isolation damper and determine

if it is open.

Check BMS control and determine if condition is

occurring at full speed and bypass is closed.

Verify power and signal at duct pressure

transducer(s).

Replace missing access panels.

Check actuator power and signal.

Check BMS control and determine if condition is

occurring at fan low speed and bypass full open.

Verify power and signal at duct pressure

transducer(s).

Check power at isolation damper and determine

if it is open.

Test voltage with meter for 24V and output

signal.

VGN Factory-Supplied VFD

Issue Possible Cause Recommended Action

Fault on either keypad

display.

VFD is not communicating

to the BMS system.

Multiple.

Multiple. Consult VFD manufacturer communication guide.

Consult VFD manufacturer fault guide for

solution.

VGN Nozzle Controller Customer-Supplied VFD

Issue Possible Cause Recommended Action

Fan speed is too low. Not creating enough

airflow. Speed up fan.

Airflow not present. Check flow station and

components.

Alarm contact on nozzle

controller is “Active”

Velocity is below the required preset value

Fan is shown as running, but no flow is being

created.

General System Failure Mode

If the 2-10 VCD signal is lost from the controls and the 24V power is still present, the nozzle actuators will move to the minimum

area position.

If the 24V power is lost from the controls but the 2-10VCD signal is still present, the nozzle actuators will stay in place at the

moment when 24V power was lost.

VGN Technology

26

®

Page 27

General Electrical Controls Information

VGN Technology Maintenance

WARNING

Disconnect all electrical power and secure to the

“OFF” position prior to inspection or servicing.

Failure to comply with this safety precaution could

result in serious injury or death.

The following list is recommended preventive

maintenance of the controls system. All of these items

should be done before initial power up of the system

and then done on a routine maintenance schedule.

It is also recommended to follow the component

manufacturer maintenance recommendations that they

have stated in their IOM document(s).

Description Action Occurrence

Inspect System

Wire

Inspect System

Conduit

Inspect Wiring

Terminations

Inspect

Weather Proof

Gaskets

Inspect

Electrical

Enclosures

Inspect Nozzle

Moving

Components