Page 1

READ AND SAVE THESE INSTRUCTIONS

Part #469003

®

Model Vektor™-H

Installation Operation and Maintenance Manual

for Vektor-H Laboratory Exhaust System

Receiving

Greenheck model Vektor-H fans are thoroughly inspected, test run at the factory, and shipped on a skid or

packaged to minimize damage during shipment. The transportation carrier has the responsibility of delivering

all items in their original condition as received from Greenheck. The individual receiving the equipment is

responsible for inspecting the unit for obvious or hidden damage and recording any damage on the bill of lading

before acceptance of the equipment. All claims (if necessary) shall be filed with the final carrier.

Lifting

Lugs

Lifting

Lugs

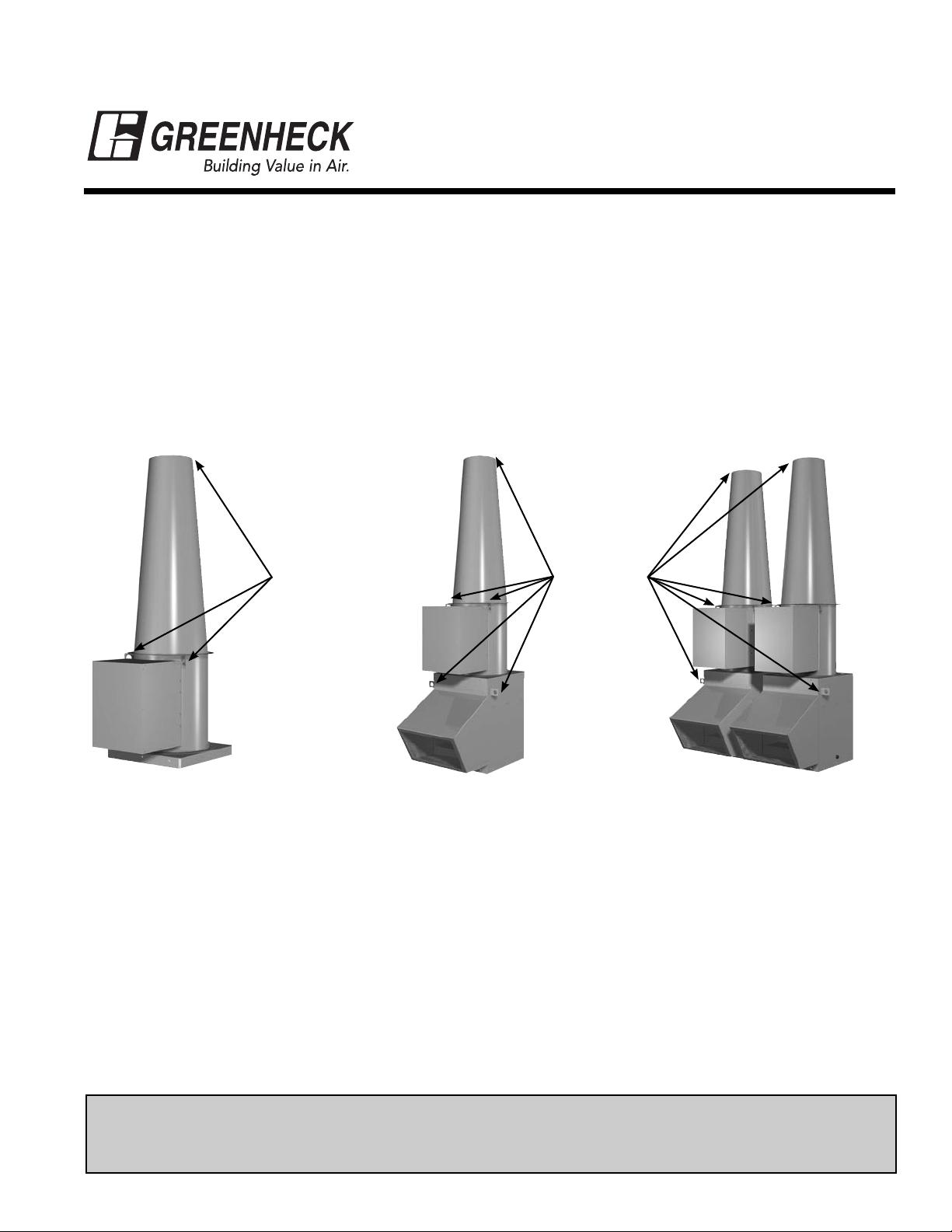

Single Blower

System

Handling & Installation

The Greenheck Vektor-H laboratory exhaust system is shipped in subassembly sections for easy rigging

and installation. Depending on the options ordered, the sections can include: Roof Curb, Bypass Air Plenum

Assembly, Blower Assembly, Stack Extension, and Discharge Nozzle.

The Vektor-H is designed to be self-supporting and standing (without the use of guy wires) when assembled per

the instructions provided within this manual. The roof curb must be securely fastened to the roof structure in

accordance with the contract documents. All subassembly sections have lifting lugs as shown.

Lifting lugs on each subassembly are designed to handle the weight of the subassembly section only.

Do not attempt to lift the entire system as a complete assembly.

Single Blower System with

Bypass Air Plenum

NOTE!

Multiple Fan System with

Bypass Air Plenums

Page 2

NOTE!

Be sure to rig each section separately using the lifting lugs provided.

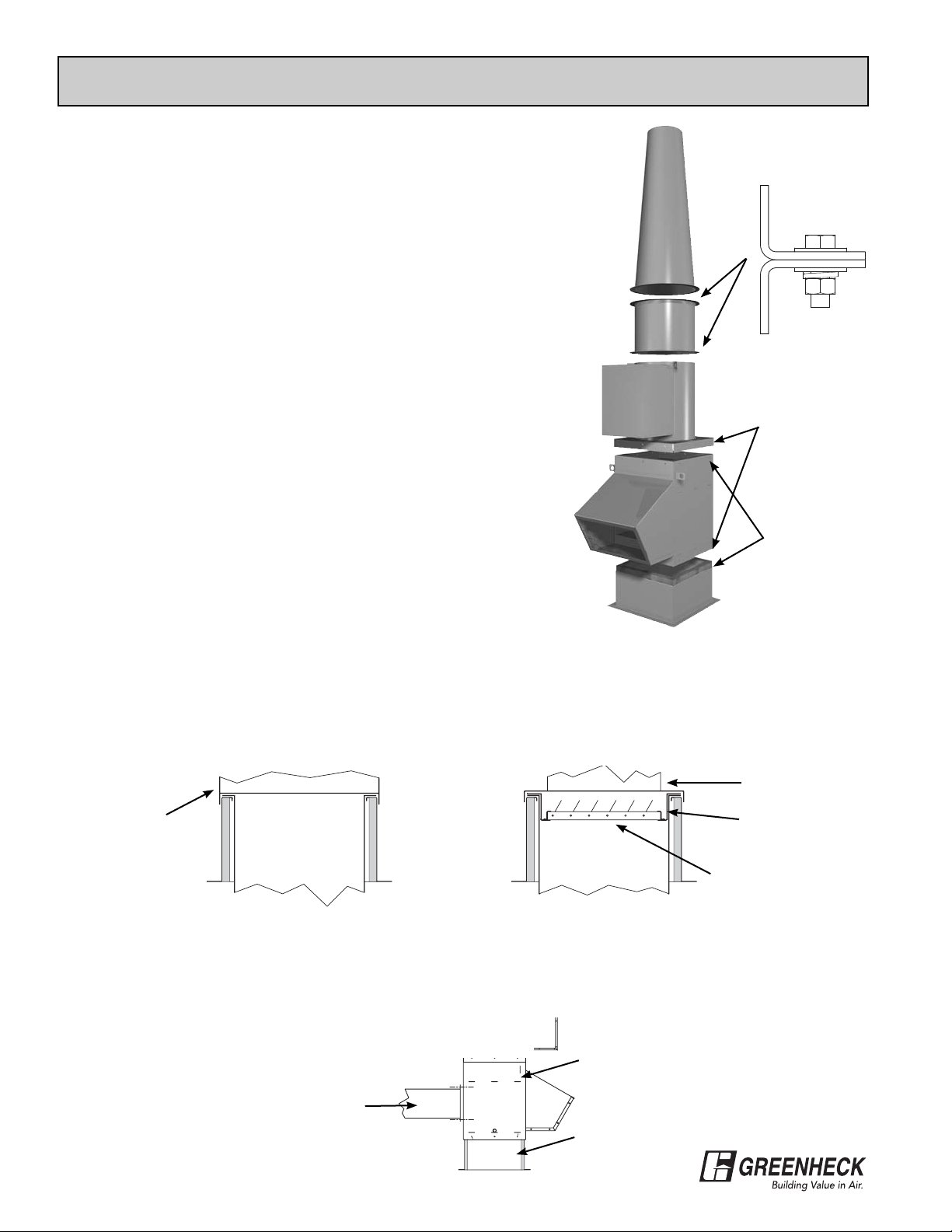

Installation Instructions

Note: When installing each section, be sure to rig each piece

separately using the lifting lugs provided.

1. Mount roof curb to roof deck in accordance with local codes.

2. Install 3/16-inch thick x 1/2-inch wide, closed-cell neoprene gasket

on the top edge of the curb, adhesive side down (gasket provided).

Leave no gaps between gasket sections to ensure tight seal.

3. Place the bypass air plenum (BAP) onto the previously installed

gasket and secured roof curb. If a BAP is not provided for the unit,

skip to Step 5. Pre-drill pilot holes into the roof curb and attach

the BAP to the roof curb using the provided 5/16-inch self-tapping

screws. Screw fasteners are to be installed in all pre-punched curb

holes.

4. Install 3/16-inch thick x 1/2-inch wide, closed-cell neoprene gasket

on the top edge of BAP, adhesive side down (gasket provided).

Leave no gaps between gasket sections to ensure a tight seal.

5. Place the curb cap of the fan housing onto the gasket and BAP

(onto roof curb if BAP is not provided). Attach the curb cap

using the provided 5/16-inch self-tapping screws. If a BAP is not

provided, pilot holes must be drilled into the roof curb.

6. Install the final nozzle subassemblies as shown in the submittal

drawing. Align flange bolt holes and fasten sections using the 316

stainless steel bolts, washers, and lock washers provided.

7. Follow electrical connection and pre-start-up checks as listed on

page 3.

Bolt / Washer

Detail

5/16 in.

Self-tapping

Screws

Neoprene

Gasket

Duct Connection to Curb

The end of the customer supplied duct is secured between the roof curb’s top edge and the curb cap of either

the Vektor-H or bypass air plenum. If an isolation damper is present in the roof curb, the duct is located between

the roof curb and the damper adapter tray.

Vektor-H

Vektor-H or

bypass air

plenum

Vektor-H with or without by-

pass air plenum & no isolation

damper in roof curb

Vektor-H without bypass

air plenum & with isolation

damper in roof curb

Adapter Tray

Isolation Damper

Duct to Bypass Air Plenum

Vektor-H with Option B - Side Air Intake

Bypass Air Plenum

Laboratory Exhaust Duct

Duct flange and gasketing

by others

Roof Curb

2

®

Page 3

Vektor Installation

The

figures below illustrates four common methods used to install Vektor systems. Methods used to attach a

Vektor unit are dependent on local codes, roof construction design and roof construction materials. Consult an

architect or structural engineer for proper means of attachment.

Weatherhood

w/ birdscreen

(optional)

Bypass Air

Plenum

3/16 in. silicone gasket

3/8 in. bolt

(typical)

(by Greenheck)

Bolt or weld in field

(by others)

(by Greenheck)

Structural Support

(by others)

Fan, Plenum, and Curb to Structural Steel Fan and Plenum (no Curb) to Channel Base

5/16 in. self-tapping screws

(by Greenheck)

5/16 in. bolt

(typical)

(by Greenheck)

Fiberglass

Insulation

Roof Curb

5/16 in. bolt

(typical)

(by Greenheck)

Weatherhood

w/ birdscreen

(optional)

Field drilled and bolted

(by others)

Bypass Air

Plenum

3/16 in. silicone gasket

(by Greenheck)

Structural Support

(by others)

Weatherhood

w/ birdscreen

(optional)

3/8 in. bolt

(typical)

(by Greenheck)

Bolt or weld in field

(by others)

Bypass Air

Plenum

3/16 in. silicone gasket

(by Greenheck)

Exhaust Duct

(by others)

Fiberglass

Insulation

Roof Curb

Roof Line

(Roofing felt & material

by others)

3/8 in. bolt

(typical)

(by Greenheck)

Bolt or weld in field

(by others)

3/16 in. silicone gasket

(by Greenheck)

Exhaust Duct

(by others)

(Roofing felt & material

Fan

Fiberglass

Insulation

Roof Curb

Roof Line

by others)

Fan, Plenum, and Curb to Roof Deck Fan and Curb (no Plenum) to Roof Deck

Plenum Drainage Piping / Trap Detail (By Others)

There are multiple locations for pipe connections, one on each plenum section and another on each tubular fan

housing. Each drain should be properly connected to a drainage system to ensure proper disposal of any water

or condensate that may occur.

• Installed piping to have a downward angle to allow for drainage

• Fill trap to recommended level before start-up

Detail of

Bypass Air

Plenum and

Blower

Housing

1 in. drain coupling in Blower Housing

and Bypass Air Plenum

Y

X

Y Dim > System Pressure

X Dim > 1/2 System Pressure

1 inch of water

*Dimension of X and Y

are inches

3 4

Clean out location

®

Page 4

Electrical Connections

Before electrical connections are made, the supply voltage, phase and ampere capacity must be checked

for compatibility with the fan motor. In addition, the supply wiring must be properly fused and conform to

local and national electrical codes. If the unit is supplied with a safety disconnect switch, ensure proper

wiring to the fan motor. Be sure the disconnect is switched to the “OFF” position before connecting

supply wires. If no disconnect is supplied, ensure the supply wire is not live before connection. Supply

wires are then connected to the optional safety disconnect switch (if supplied) or motor.

Motor - Disconnect Wiring / Isolation Damper Wiring Diagram

208 / 230 / 460 / 575 V 3 PHASE

DISCONNECT

208 / 230 / 460 / 575 V 3 PHASE

208/230/460/575/60/3

FIELD WIRING

FACTORY WIRING

LINE IN

MOTOR

DISCONNECT IS MOUNTED TO FAN HOUSING. TRANSFORMER IS MOUNTED

TO MIXING BOX (BYPASS AIR PLENUM) WITH DAMPER ACTUATOR MOTOR.

FOR SYSTEMS THAT SHIP UNASSEMBLED BECAUSE OF PHYSICAL SIZE,

THIS CONNECTION AT DISCONNECT FROM TRANSFORMER MUST BE FIELD

INSTALLED. WIRE WITH CONDUIT AND FITTING IS PROVIDED PRE-CONNECTED

TO TRANSFORMER.

OPTIONAL FACTORY

MOUNTED AND WIRED

ISOLATION DAMPER

TRANSFORMER

208 / 230 / 460 / 575 V 1 PHASE

115V 1 PHASE

ISOLATION

DAMPER

ACTUATOR

POWER OPEN/SPRING CLOSE

MOTOR

ACTUATOR

Applications with Variable Frequency Drive (VFD)

For Vektor systems with single-point, three-phase wiring per blower, the isolation damper actuator will

be powered via a step-down transformer, which is wired to the fan disconnect, as shown in the diagram

above.

If fan flow (motor speed) is to be controlled using a variable frequency drive with this wiring, the reduced

voltage and frequency supplied to the fan will cause control problems with the isolation damper actuator.

When a project’s Vektor control sequence requires the use of a VFD, it is suggested that the control

contractor supply the isolation damper actuator voltage — independent of the power supplied to the

Vektor fan motor.

®

Page 5

Pre-Start-Up Checks

1. Check all fasteners for tightness.

2. The wheel should be aligned as shown. Although the wheel position is preset and the unit is test run

at the factory, movement may occur during shipment.

The radial gap should be consistent at all

locations between the centrifugal wheel and

the inlet cone. Centering may be accomplished

by loosening the inlet cone bolts and

repositioning the inlet cone.

To obtain the optimum performance, the

centrifugal wheel must overlap the inlet cone.

Adjustments can be made by loosening the set

Radial Gap

screws in the wheel and moving the wheel to

the desired position.

3. Wheel rotation should be in the same direction as the rotation decal affixed to the unit. For 3-phase

installations, fan rotation can be reversed by simply interchanging any two of the three electrical

leads. For single phase installations, follow the wiring diagram located on the motor.

4. Adjustable motor pulleys are preset at the factory for the specified fan RPM. Fan speed can be

increased by closing or decreased by opening the adjustable pulley. Two or three groove variable

pitch pulleys must be adjusted an equal number of turns open or closed.

Wheel

Overlap

Direction

of Airflow

Inlet Cone

Note: Any increase in fan speed represents a substantial increase in horsepower required from

the motor. Always check motor load amperage and compare to nameplate rating when

changing fan speed.

Maintenance

WARNING

DISCONNECT ALL ELECTRICAL POWER TO THE FAN AND SECURE TO THE “OFF” POSITION

PRIOR TO INSPECTION OR SERVICING. FAILURE TO COMPLY WITH THIS SAFETY

PRECAUTION COULD RESULT IN SERIOUS INJURY OR DEATH.

Once the fan has been put into operation, a periodic maintenance program should be set up to preserve

the reliability and performance of the fan. Items to be included in this program are:

• BEARINGS • SET SCREWS

• BELTS • MOTORS

• FASTENERS • REMOVAL OF DUST/DIRT

Bearings

Bearings are the most critical moving part of the fan and should be inspected at periodic intervals.

Locking collars and set screws, in addition to fasteners attaching the bearing to the bearing plate, must

be checked for tightness. In a clean environment with temperatures above 32º F and below 200º F, fan

shaft bearings with grease fittings should be lubricated semi-annually using a high quality lithium based

grease. If unusual environmental conditions exist such as temperatures below 32º F or above 200º F,

moisture or contaminants, more frequent lubrication is required.

With the unit running, add grease very slowly with a manual grease gun until a slight bead of grease

forms at the seal. Be careful not to unseat the seal by over lubricating or using excessive pressure.

Bearings without grease fittings are lubricated for life.

5

®

Page 6

Belts

Premature belt failures are frequently caused by improper belt tension (either too

Deflection =

Belt Span

64

tight or too loose) or misaligned pulleys. The proper tension for operating a V-belt is

the lowest tension at which the belts will not slip at peak load conditions. For initial

tensioning, the proper belt deflection half-way between pulley centers is 1/64 inch for

each inch of belt span. For example, if the belt span is 64 inches, the belt deflection

should be one inch using moderate thumb pressure at midpoint of the drive.

Belt Span

Check belt tension two times during the first 24 hours of operation and periodically

thereafter. To adjust belt tension, simply loosen four fasteners (two on each side of

the motor plate) and slide the motor plate away from the fan shaft until proper belt

tension is attained. On some fans, fasteners attaching the motor to the motor plate

must be loosened in order to adjust the belt.

It is very important that the drive pulleys remain in proper alignment after

adjustments are made. Misalignment of pulleys will result in premature belt wear,

noise, vibration and power loss.

Fasteners and Set Screws

A periodic inspection should include checking all fasteners and set screws for tightness. Particular attention

should be paid to set screws attaching the propeller to the shaft and the shaft to the bearings. Loose bearing

set screws will lead to premature failure of the fan shaft.

Motors

Many fractional horsepower motors installed on the smaller fans are lubricated for life and require no further

attention. Motors supplied with grease fittings should be greased according to directions printed on the motor.

Removal of Dust and Dirt

Dirt clogs cooling openings on the motor housing, contaminates bearing lubricant, and collects on the impeller

causing severe imbalance if left unchecked. The exterior surface of the motor and impeller should be thoroughly

cleaned periodically. Use caution and do not allow water or solvents to enter the motor or bearings. Under no

circumstances should motors or bearings be sprayed with steam or water.

Exhaust Fans Part List

Each fan bears a manufacturer’s nameplate with model number and serial number embossed. This information

in addition to the parts list shown, will assist the local Greenheck representative and the factory in providing

service and replacement parts.

Side View Top View

MOTOR

PLATE

MOTOR

COVER

(OPTIONAL)

BEARING

SUPPORT

MOTOR

PULLEY

MOTOR

BELT

WHEEL

BELT

TUBE

SHAFT

PULLEY

BEARING

COVER

INLET CONE

(VENTURI)

BEARINGS

SHAFT

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year

from the purchase date. Any units or parts which prove defective during the warranty period will be replaced at

our option when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer

for a period one year. Should motors furnished by Greenheck prove defective during this period, they should be

returned to the nearest authorized motor service station. Greenheck will not be responsible for any removal or

installation costs.

As a result of our commitment to continuous improvement,

Greenheck reserves the right to change specifications without notice.

#469003 Vektor-H IOM

Copyright © 2006 Greenheck Fan Corp.

Rev. 2, August 2006

Loading...

Loading...