Page 1

Document 473681

Vari-Green® Motor and Controls

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or property damage!

Table of Contents

Reference part number listed in chart to locate specific motor

information page number.

RPM

HP Voltage

1/6 115 300-1725 TENV

1/6 208-240 300-1725 TENV 1.6 Pot/0-10V

1/4 115 300-1725 ODP

115/

1/4

208-240

1/4 208-240 300-1725 ODP 2.3 Pot/0-10V

1/2 115 300-1725 ODP

115/

1/2

208-240

1/2 208-240 300-1725 ODP 4.2 Pot/0-10V 313235 3

1/2 115 300-2500 ODP

3/4 115 300-1725 ODP

115/

3/4

208-240

3/4 208-240 300-1725 ODP 6.6 Pot/0-10V 314534 3

3/4 115 300-2200 ODP

1 115 300-1725 ODP 12.4 Pot/0-10V

115/

1

208-240

115/

1

208-240

1 208-240 300-1725 ODP 8.6 Pot/0-10V 314945 3

2 208-240 300 - 1725 TEFC 12.0 Pot/0-10V 310420 4

Actual maximum RPM may vary. See RPM column in chart on

*

*

Range

300-1725 ODP 3.3/1.8 Pot/0-10V 310175 6

300-1725 ODP 6.8/3.5 Pot/0-10V 310176 6

300-1725 ODP 9.0/4.9 Pot/0-10V 310177 6

300-1725 ODP 11.4/6.3 Pot/0-10V 310178 6

300-1725 TEFC 12.0/6.0 Pot/0-10V 311156 4

Encl. FLA

10.1 0-10V Only 309026

10.1 Pot Only 309029

10.6 Pot/0-10V

11.3 0-10V Only 310306

11.3 Pot Only 310475

11.3 Pot/0-10V 312361 3

Control

Method

3.1 0-10V Only 311352

3.1 Pot Only 311353

3.4 Pot/0-10V

3.9 0-10V Only 310107

3.9 Pot Only 310108

3.7 Pot/0-10V

6.2 0-10V Only 309025

6.2 Pot Only 309028

6.7 Pot/0-10V 311812 3

6.5 0-10V Only 310307

6.5 Pot Only 310476

6.5 Pot/0-10V 312360 3

pg.10 for specific motor and fan combinations.

Motor

Part No.

311731

313712

313233

313713

311377

313714

313234

313715

311388

312619

310359

312362

Pg.

2

3312359

3

2

3

3

2

2

2

3

2

3

Controls .................................7-9

Maximum RPM Table ....................... 10

Vari-Green® Motor

The Vari-Green Motor is an electronically commutated

(EC) motor that uses AC input power and internally

converts it to a DC power supply which provides an

80% turndown capability and increased energy savings.

NOTE

When using a clamp meter to measure input amp

draw, the meter must be capable of reading a

non-linear current. Erroneous readings will occur

otherwise.

WARNING

To reduce the risk of fire or electric shock,

do not use this motor with any solid-state speed

control device.

®

Vari-Green Motor and Controls

1

Page 2

Features, Operation,

Wiring and Troubleshooting

Features

Soft start – All motors

feature soft-start

technology which

eliminates inrush

current at startup. The motors will

reliably start at any

speed setting.

Overload protection – If the motor becomes

overloaded, it will automatically reduce its speed until it

is no longer overloaded. This means that the motor will

never operate in the “service factor” which is possible

with many AC motors.

Locked rotor protection – If the motor ever encounters

a locked-rotor scenario, the motor will automatically

shut itself down. It will try to restart up to 3 times, and if

after the 3rd time the motor will still not rotate, the motor

will not attempt to start again until power is cycled.

Thermal protection – The motors have a one-shot fuse

thermal protector. This is meant to protect the motor

from a severe temperature rise. Additionally, the motors

have on-board temperature sensors which will reduce

the speed of the motor should it become too hot. The

fuse is used as a last resort to prevent a fire.

RPM measurement – The motors have a small shaft

extension on the end of the motor to measure motor

RPM with either a contact or optical tachometer.

Operation and Wiring

-

Potentiometer Dial Only

Part Numbers Covered in this Section

309028 309029 310108 310475 310476

311353

These motors feature a potentiometer dial on the motor

for speed adjustment. A small screwdriver can be used

to make the speed adjustment. To increase the speed,

rotate the dial clockwise. To decrease the speed, rotate

the dial counter clockwise.

The motor is pre-wired at the factory and cannot be

changed inside the motor. Connect single-phase power

at the voltage listed on the nameplate.

These motors cannot be converted to receive a remote

control signal – a different motor is needed. Please

consult the factory.

Operation and Wiring

- 0-10V Input Only

Part Numbers Covered in this Section

309025 309026 310107 310306 310307

311352

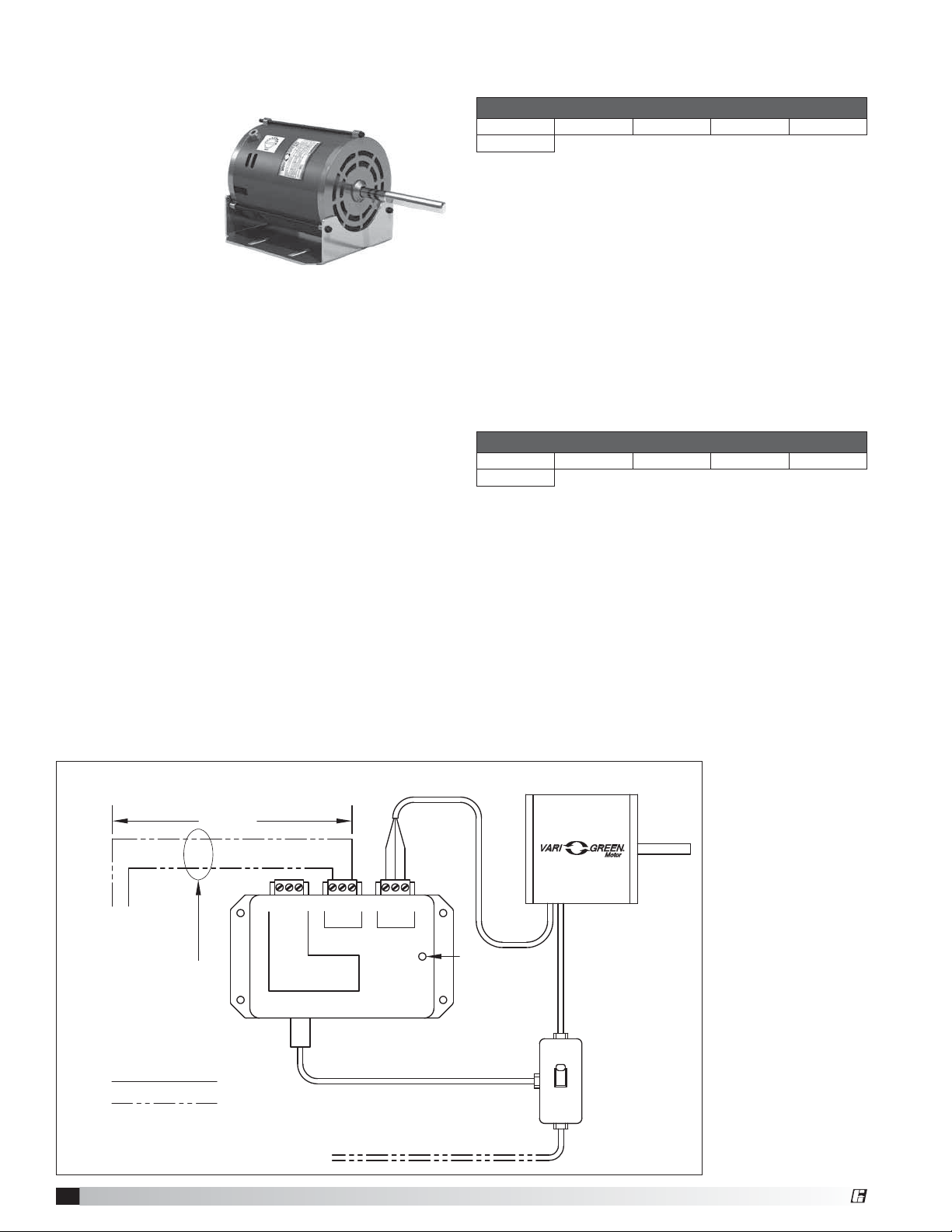

These motors will accept a 0-10 VDC control signal for

speed control. From 0-1.9V, the motor will be off, and

will operate in the 2-10V range. 24 VAC/DC power is

also required for operation. The motor will consume

0.7VA at 24 VAC or 25mA at 24 VDC. A factory mounted

transformer is available to supply this voltage. See Fig. 1

The motor is pre-wired at the factory and cannot be

changed inside the motor. Connect single-phase power

at the voltage listed on the nameplate, along with the

0-10 VDC and 24V signal for speed control.

NOTE: The motor will not operate without the proper

control voltages.

Fig. 1 0-10 VDC External connection with factory mounted transformer

Transformer Assembly

100 ft. or less

White

Black

Red

COM

24V

0-10V

COM

24V

0-10V

N.C.

COM.

N.O.

TO REMOTE DEVICE

PROVICED BY

OTHERS

Low voltage, route away

from high voltage lines

and/or use shielded cable

Vari-Green Motor and Controls

2

Factory Wiring

Field Wiring

Auxiliary

Contact

Trip Point = 1.85VDC

Contact Rating:

10A @ 24-240VAC

5A @ 30VDC

Control

TRANSFORMER

to match motor name plate

Motor

115/230 VAC input

Green indiator light

—Power present

2 x 4

Junction

Box

®

Page 3

Operation and Wiring

- Potentiometer Dial and 0-10V Input

Part Numbers Covered in this Section

310359 311731 311377 311388 311812

312359 312360 312361 312362 312619

313233 313234 313235 313712 313713

313714 313715 314534 314945

These motors have both a potentiometer dial on the

motor for speed adjustment AND have the ability to

accept a 0-10 VDC signal for remote speed control.

There is a 4 second delay between the application of

power and the motor starting.

The motor is pre-wired at the factory and cannot be

changed inside the motor. Connect single-phase power

at the voltage listed on the nameplate. If remote control

is desired, connect the 0-10 VDC and 24V signal for

remote speed control.

Dial on motor – A small screwdriver can be used to

make the speed adjustment. To increase the speed,

rotate the dial clockwise. To decrease the speed, rotate

the dial counter clockwise. There is no need to connect

the control wires.

0-10 VDC signal – The dial on the motor must be

rotated fully clockwise to achieve the full speed range.

If this is not done, the dial will act as a maximum

speed limiter.

From 0-1.9V, the motor will be off, and will operate in

the 2-10V range. 24 VAC/DC power is also required for

operation. The motor will consume 0.7VA at 24 VAC

or 25mA at 24 VDC. A factory mounted transformer is

available to supply this voltage. See Fig. 1

A low voltage wiring harness is needed to supply the

0-10V signal to the motor. This harness is available from

the factory if conversion is necessary.

Low Voltage Harness Part Numbers

Type Use with Motor 18 in. long 36 in. long

3-pin 311731, 310359 384431 384432

312359, 311377,

311812, 311388,

312360, 312361,

312362, 312619,

9-pin

313233, 313234,

384804 384805

313235, 313712,

313713, 313714,

313715, 314534,

314945

NOTE

The 9-pin connector on the motor contains 6 wires.

The red, black and white wires are used for the

external control signal and the other three are used for

factory initialization and programing.

0-10V Analog input connection

Red + 0-10 VDC

White Common*

Black +24 VAC/DC

* Common is shared between both 24V power

and 0-10V signal.

The impedance of 0-10V circuit is 12KΩ

Troubleshooting

Motor does not operate

1. Check all wiring connections to ensure they are

correct and secure.

2. Verify that all voltages are present at the motor,

including 24V and 0-10 VDC, if applicable.

3. Make sure that the fan wheel will rotate freely and

there are no foreign objects in the wheel. If fan wheel

does not rotate freely, disconnect power from the

motor and adjust the wheel or housing until the

wheel can freely rotate. Apply power and the motor

should restart.

4. If motor has both the dial on the motor and 0-10VDC

control option, control wiring issues can be tested

by disconnecting the control wires from the motor.

The motor should then operate using the dial on the

motor for speed control.

Motor will not reach maximum speed

1. Make sure dial is rotated full clockwise, if applicable.

2. Make sure motor is receiving 10 VDC, if applicable.

3. There are some motor/fan combinations

where the motor may not reach nameplate

RPM. See Max RPM table on page 10 for the

maximum motor speed for your application.

Factory Mounted Transformer (Fig. 1)

A factory mounted transformer is available to

supply 24 VDC power to the motor when the

0-10V signal is by others. This transformer has

the capability to power a remote device if desired.

The power available to a remote device is 400mA

at 24 VDC. If the remote device is powered by

a different source, connect the analog output to

the 0-10V and COM terminals of the transformer.

This will pass the signal through to the motor.

WARNING

Do not connect an external 24V supply to the

transformer's control terminal labeled 24V. If the

external device providing the 0-10V signal is powered

elsewhere, this terminal can remain unused.

®

Vari-Green Motor and Controls

3

Page 4

Part Numbers Covered in this Section

310420 311156

0-10V Analog input connection

Red + 0-10 VDC

White Ground

Features

Speed control These motors can

be controlled by

either a dial on the

motor or a 0-10 VDC

signal for remote control.

Soft start – All motors feature soft-start technology

which eliminates inrush current at start-up. The motors

will reliably start at any speed setting. There will be up

to a 30 second delay between the application of power

and the motor starting. The motor will "rock" back and

forth upon startup as part of its normal operation.

Overload protection – If the motor becomes

overloaded, it will automatically shut itself down. The

maximum programed motor speeds have been selected

to prevent this from happening in normal operation.

Locked rotor protection – If the motor encounters a

locked-rotor scenario, it will automatically shut itself

down. It will try to restart up to 3 times, and if after the

3rd time the motor will still not rotate, the motor will not

attempt to start again until power is cycled.

Thermal protection – The motors have an automatic

reset thermal protector. This is meant to protect the

motor from a severe temperature rise.

RPM measurement – The motor RPM can be

measured by removing the cooling fan cover and using

a contact or optical tachometer. Be sure to replace the

cooling fan cover when finished.

Reversible rotation – The motor direction has been

pre-set at the factory for the rotation of the fan but can

be reversed if necessary.

Operation and Wiring

These motors can be controlled by either a dial on the

motor or a 0-10 VDC signal for remote control. The

motor will be supplied from the factory with the correct

accessory depending on what was ordered.

Dial on Motor - Turn the dial with your fingers to adjust.

To increase the speed, rotate the dial clockwise. To

decrease the speed, rotate the dial counter clockwise.

Turning the dial full CCW will turn the motor off.

0-10 VDC Signal - From 0-1.9V, the motor will be off,

and will operate in the 2-10V range. This motor does not

require 24V power for operation.

Wiring

1. All high and low voltage wiring connections are made

inside the motor control box at the factory. Normally,

there is no reason to enter the control box of the

motor. If there is a need to enter the control box,

disconnect power and wait at least five minutes to

allow the capacitors to discharge.

2. The motors are factory wired for the ordered voltage.

If the factory wired voltage does not match the

desired voltage, the voltage can be changed, with

exception of the 2HP motor (310420), which is

208-240V only.

115V: Connect 115 VAC to L1, connect Neutral to N.

The L2 terminal remains empty. Connect ground to

grounding stud.

115V Connection inside control box

208-240V - Connect Line voltage to L1 and L2. The

N terminal remains empty. Connect the ground to the

grounding stud.

208-240V Connection inside control box

Vari-Green Motor and Controls

4

®

Page 5

Dial on motor - the dial

is factory-wired into the

low voltage terminal block

inside the control box.

The wires are connected

RED

WHITE

BLACK

YELLOW

YELLOW

as shown.

Dial on motor connection inside control box

0-10 VDC Signal - a two-wire

pigtail is factory-wired into the

low voltage terminal block.

The wires are connected

as shown.

0-10 VDC Signal connection inside control box

RED

WHITE

YELLOW

YELLOW

If the motor needs to be tested before the 0-10 VDC

signal is available, a jumper can be placed between

terminals 1 and 2. This will force the motor to run at

full speed.

Troubleshooting

These motors have a diagnostic red LED on the circuit

board inside the control box, or on the exterior of the

control box, that will be solid (not flashing) when power

is applied to the motor and the motor is operating

normally. The LED may be solid even if the motor is not

spinning, such as when power is applied but the motor

may be commanded to be off with a 0-1.9V VDC signal.

1. If external LED is not present, to view the status of

the LED the control box cover must be removed

while power is applied to the motor. If the control

box cover is removed while power is applied,

extreme care must be taken not to touch any of the

components inside the box.

a. If a fault occurs, the LED will blink a specific

number of times to identify the fault that has

occurred. The fault indications are as follows:

Number of Blinks Indicated Fault

2 Hardware Fault

3 Overvoltage

4 Undervoltage

5 Communication Error

6 Sync Loss

7 Spin Fault

8 Motor overload

9 Motor Over Temperature

Motor Rotation

To reverse the rotation of the motor, swap any two of

the red, black and blue wires connecting the control

board to the motor at terminals T1, T2 and T3. Note

that motor warranty is void if motor is rotating in the

wrong direction. See fan instruction manual for correct

rotation direction.

T3

Rotation selection wires inside control box

3. When the LED is blinking, it will consecutively blink

from 2 to 9 times, followed by a pause, and repeat

the blink sequence. It is best to count the number

of flashes 2 or 3 times to ensure accuracy.

4. Under most fault conditions the motor will

automatically restart. If a motor overload fault occurs

more then 10 times in one hour, the motor will shut

down and require a power cycle to reset.

5. If the fault persists, consult the factory.

Motor does not operate

1. Verify the motor is wired for the correct voltage.

2. Verify that the dial on the motor is properly

connected to the control board - or - verify that

the 0-10 VDC wires are properly connected to the

control board.

3. Verify that the Status LED is solid red.

4. Verify that a jumper is in place between terminals

9 and 10. The motor will not run without this jumper

in place.

5. Verify that the two yellow wires coming from the

motor are in place on terminals 5 and 6.

®

Vari-Green Motor and Controls

5

Page 6

Part Numbers Covered in this Section

310175 310176 310177 310178

Features

Speed control These motors can

be controlled by

either the dial on the

motor or a 0-10 VDC signal for remote control.

Soft start – All motors feature soft-start technology

which eliminates inrush current at start-up. The motors

will reliably start at any speed setting. There will be a 4

second delay between the application of power and the

motor starting.

Overload protection – If the motor becomes

overloaded, it will automatically reduce its speed until

it is no longer overloaded. This prevents the motor

from operating in the "service factor" should the motor

be misapplied.

Locked rotor protection – If the motor ever encounters

a locked-rotor scenario, the motor will automatically

shut itself down. It will try to restart up to 3 times, and if

after the 3rd time the motor will still not rotate, the motor

will not attempt to start again until power is cycled.

Thermal protection – The motors have electronic

thermal protection. If the motor temperature exceeds

its limits, it will slow itself down until the temperatures

have dropped.

0-10 VDC Signal - From 0-1.9V, the motor will be off,

and will operate within the 2-10V range. This motor

does not require 24V power for operation. For 0-10V

operation, a 16-pin connector with two wires connected

to pins 8 and 16 is required. (18 in. #384822 •

36 in. #384821)

Wiring

A power cord with a 5-pin connector is required and

is shipped with the motor. A different cord assembly is

needed depending on the desired voltage:

115V - 18 in. #384824 • 36 in. #384823

Operation and Wiring

These motors can be controlled by either the dial on

the motor or a 0-10 VDC signal for remote control.

The motor will be supplied from the factory with the

correct accessory depending on what control option

was ordered.

Dial on Motor - Turn the dial with your fingers to adjust.

To increase the speed, rotate the dial clockwise. To

decrease the speed, rotate the dial counter-clockwise.

Turning the dial full CCW will turn the motor off. A 16-pin

connector with two jumper wires must be installed for

the dial to function. (p/n 384962) See image below.

208-230V - 18 in. #384826 • 36 in. #384825

Vari-Green Motor and Controls

6

®

Page 7

Controls: Operation,

Wiring and Troubleshooting

Remote Dial/Touch Remote and

2-Speed Control

Remote Dial/Touch Remote Assembly

Remote Dial/Touch Remote Assembly

COM

24V

0-10V

0-10V

24V

COM

REMOTE DIAL/

TOUCH REMOTE

Low voltage, route away

from high voltage lines

and/or use shielded cable

100 ft. or less

Factory Wiring

Field Wiring

Other Vari-Green® controls, such as the Constant

Pressure and Air Quality families of controls, have their

own manual that ship with the controller. They can also

be found on Greenheck.com. See table on page 9 for

document numbers.

24V

0-10V

N.C.

COM.

N.O.

Auxiliary

Contact

Trip Point = 1.85VDC

Contact Rating:

10A @ 24-240VAC

5A @ 30VDC

TRANSFORMER

Control

COM

Red

24V

0-10V

Motor

Black

*

COM

White

Green indiator light

—Power present

NOTE: Black wire not

*

used on some motors

2 x 4

Junction

Box

Remote Dial

Installation Overview: The remote dial is provided

with the fan, shipped loose for remote installation.

It also includes a factory mounted 24 VDC transformer.

1. Disconnect power to the fan.

2. Identify where the remote dial will be mounted.

3. Mount a standard single-gang 2x4 junction box.

4. Run a 3-wire control cable from the remote dial

to the fan motor compartment. The maximum

distance from the fan to the remote dial is 100 feet.

If a greater distance is required, signal loss may

occur and cause the fan to operate erratically.

5. Connect control cable to transformer mounted

inside fan motor compartment. Connect control

cable to remote dial.

6. Secure remote dial to 2x4 junction box.

Touch Remote

Follow installation instructions above. After Power is

applied to the system, operate as follows:

1. Touch power button to turn fan on.

2. Touch UP/DOWN arrow to increase/decrease speed.

3. Subsequent touches of the power button will start

the countdown timer of 90, 60, 30 or 10 minutes.

4. LED's will turn off after a periods of inactivity.

5. To lock/unlock buttons, hold the UP and DOWN

arrows for 3 seconds. When locked, the power

button will light up red.

115/230 VAC input

to match motor name plate

CAUTION

Even though the motor may not be operating,

high voltage power may still be present at the motor.

Make sure to disconnect power to the fan before

servicing.

Troubleshooting -

Remote Dial Touch Remote

Remote Dial does not adjust motor RPM

1. Check voltage to ensure the motor and transformer

are receiving the correct line voltage.

2. Check voltage at the remote dial. 24 VDC should

be present across the 24V and COM terminals.

0-10VDC should be present across the 0-10V and

COM terminals.

3. Verify all of the connections at the transformer and

make certain that they are secure.

4. Touch remote: Verify that the touch remote is

unlocked.

Terminals Desired Voltage

24V-COM 24 VDC Nominal

0-10V-COM

0-10 VDC

(varies with dial position)

®

Vari-Green Motor and Controls

7

Page 8

115-230 VAC

Digital

Input

FACTORY MOUNTED

2 SPEED CONTROL

L1(115V-230V)

L2(115V-230V)

NEUTRAL

Switch/Relay

by others

A

B

Dry

Contact

Input

to match motor name plate

SPDT

115-230 VAC

NEUTRAL

Two Speed Assembly

2 Speed Assembly

Low voltage (<10V), route

away from high voltage lines

and/or use shielded cable

100' or less

Red

Black

*

White

COM

24V

0-10V

Motor

Speed A

Adjustment

Speed B

Adjustment

Out

Green indicator light

—Power present

COM

115/230 VAC Input

Factory Wiring

Field Wiring

®

NOTE:

*

Black wire not used

on some motors

Digital Input Logic

L1 or L2 = Speed B

L1 and L2 = Speed A

No input = Off

2 x 4

Junction

Box

Two Speed

Installation Overview: The two speed control is factory

mounted to the fan and may be set to provide any two

speeds the application requires. It also includes a 24

VDC transformer. A green LED will be illuminated when

the 2-speed control is powered.

1. There are two methods of toggling between speed A

and speed B:

a. Dry contact input - this utilizes an external

switching device such as a relay or SPDT switch

to toggle between the two speeds.

• Connect terminal “A” to “COM” for speed A.

• Connect terminal “B” to “COM” for speed B.

If no contact is made between either terminal the

motor will be off.

b. AC Digital input - this input allows an AC voltage

signal to be fed directly into the 2-speed control

to change speeds.

• Send 115-230V AC to L1 OR L2 for speed B.

• Send 115-230V AC to L1 AND L2 for speed A.

If no voltage is applied to either terminal, the

motor will be off.

c. DO NOT CONNECT BOTH DRY CONTACT AND

DIGITAL INPUTS SIMULTANEOUSLY.

2. To test fan operation before the external control

devices are installed, a jumper wire can be

connected between the COM and A or B terminal on

the dry contact input for fan operation.

Troubleshooting - Two Speed

1. Check all wiring connections to ensure they are

correct and secure.

2. Verify AC line voltage is present at the motor and

2-speed control.

3. Verify 24V DC is present at the 24V and COM

terminals of the "Motor" terminal block.

4. Measure DC voltage between the 0-10V and COM

terminals of the "Motor" terminal block. This voltage

should match the dial position of the active dial.

a. If using dry contact input - ensure contact closure

is connecting the proper terminals.

b. If using AC digital input - disconnect connector

from 2-speed control and measure voltage

between L1 and Neutral or L2 and Neutral.

Vari-Green Motor and Controls

8

®

Page 9

Motorized Backdraft

Damper Control

The available factory mounted transformer

(PN 385253) has the ability to signal a

motorized back draft damper to open/close

as the motor starts/stops.

A N.O./N.C. set of contacts is provided

which will change state when above or

below a control voltage of 1.85 VDC. See

wiring diagram for example.

Contact Rating:

• 10A @ 24-240 VAC

• 5A @ 30 VDC

Motorized Damper

N.O.

COM

N.C.

Motorized damper operation

with Vari-Green

(Motor/control wiring omitted for clarity)

To control

To motor

COM

24V

0-10V

0-10V

24V

COM

®

Control

Neutral

(Damper Power Source)

Fans Where Dial on Motor

is Not Accessible

A control is available to mount on the outside of a fan

where the dial on motor may be difficult to access

(model SQ). This control is powered by the line voltage

entering the fan and will send 24VDC and 0-10 VDC to

the motor. Control Part Number is 385611

Factory Wiring

Line

Auxiliary

Contact

Trip Point = 1.85VDC

Contact Rating:

10A @ 24-240VAC

5A @ 30VDC

FACTORY MOUNTED

TRANSFORMER

Control

Motor

Green indicator light

—Power present

FACTORY MOUNTED

SPEED CONTROL

Input: 85-265VAC

Output: 24VDC, 0-10VDC

®

Field Wiring

Voltage

Present

COM 24V 0-10V

Red

Black

White

*

115/230 VAC Input

to match motor name plate

®

NOTE: Black wire not

*

used on some motors

2 x 4

Junction

Box

Vari-Green Motor and Controls

9

Page 10

Multiple Motors on One Control

See the table below for the recommended number of

motors to be driven from one controller. Note that the

controllers do not have the ability to distinguish between

more than one motor, therefore all motors will receive

the same control voltage. Control voltage must be wired

in parallel to all motors.

Controls Max. Motor Quantity

Remote Dial 4

2 Speed 6

Constant Pressure/Airflow 4

Temperature/Humidity 2

VOC 2

Maintenance

Vari-Green® motors use brushless technology with

sealed bearings. No routine maintenance is required

other than keeping any debris from accumulating on the

motor and controls.

Notes:

Other Vari-Green® Control

Instruction Manuals

Description Document Number

Indoor Air Quality - VOC 475407

Indoor Air Quality -

Temperature/Humidity

Constant Pressure Control 474766

Generation 2 Constant

Pressure/Airflow Control

475573

479653

Vari-Green Motor and Controls

10

®

Page 11

Maximum RPM Table

This table will show the available motor and fan

combinations with the correlating maximum

motor RPM for each combination.

G Max RPM Motor HP

60-75 1725 1/6

80-95 1725 1/6

97-99 1725 1/4

103 1725 1/4

103HP

123

1725 1/4

2500 1/2

1200 1/4

1725 1/2

1150 1/4

133

1550 1/2

1725 3/4

900 1/4

143

1200 1/2

1300 3/4

1725 1

1500 1/4

143HP

1725 1/2

2200 3/4

750 3/4

163

1200 1

1725 2

900 3/4

183

1000 1

1400 2

SE1/SS1 Max RPM Motor HP

8-440* 1725 1/6

10-440* 1725 1/6

12-426 1725 1/4

12-432 1725 1/4

12-436 1725 1/4

14-432 1725 1/4

14-436 1725 1/2

14-440 1725 1/2

16-421 1725 1/2

16-426 1725 1/2

16-428 1725 3/4

16-436 1725 3/4

18-424 1725 3/4

18-429 1725 3/4

20-420 1725 1

CUE/CW Max RPM Motor HP

60-75 1725 1/6

80-95 1725 1/6

99 1725 1/4

101 1725 1/4

101HP

121

1725 1/4

2500 1/2

1400 1/4

1725 1/2

1200 1/4

131

1450 1/2

1725 3/4

1000 1/4

141

1300 1/2

1550 3/4

1725 1

1450 1/4

141HP

1725 1/2

2200 3/4

1000 1/2

161

1200 3/4

1300 1

1725 2

1300 1/2

161HP

1650 3/4

1725 1

875 3/4

180

1000 1

1400 2

LD/LDP Max RPM Motor HP

80-95 1725 1/6

100 1725 1/4

120 1725 1/2

SFD Max RPM Motor HP

6 1725 1/4

7.5 1725 1/2

SP/CSP Max RPM Motor HP

510 1200 1/6

710 1510 1/4

*SE1Model Only

SWD Max RPM Motor HP

7

8

10

1725 1/4

2500 1/2

1725 1/4

2500 1/2

1725 1/4

2200 3/4

1200 1/4

13

1550 1/2

1725 3/4

1150 1/2

15

1400 3/4

1725 1

900 3/4

16

1300 1

1725 2

850 3/4

18

950 1

1300 2

SQ Max RPM Motor HP

60-75 1725 1/6

80-95 1725 1/6

97

98

99

1725 1/4

2500 1/2

1725 1/4

2200 3/4

1725 1/4

2200 3/4

100 1725 1/4

120 1725 1/2

130 1725 3/4

1250 1/4

130HP

1450 1/2

1950 3/4

140

1500 3/4

1725 1

1100 1/2

140HP

1450 3/4

1725 1

1140 3/4

160

1300 1

1725 2

850 1/2

160HP

1000 3/4

1600 1

1725 2

®

Vari-Green Motor and Controls

11

Page 12

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties can be located on greenheck.com within the product area tabs and

listed in the Library under Warranties.

AMCA Publication 410-96, Safety Practices for Users and Installers of Industrial and Commercial Fans, provides additional safety

information. This publication can be obtained from AMCA International, Inc. at www.amca.org.

®

Phone: (715) 359-6171 • FPhone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

473681 • Vari-Green Motor and Controls, Rev. 10, February 2015 Copyright 2015 © Greenheck Fan Corporation

12

Loading...

Loading...