Page 1

Document 479653

!

!

!

!

Generation 2

®

Constant Pressure/Air Flow Control

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with instructions could result in personal injury and/or property damage!

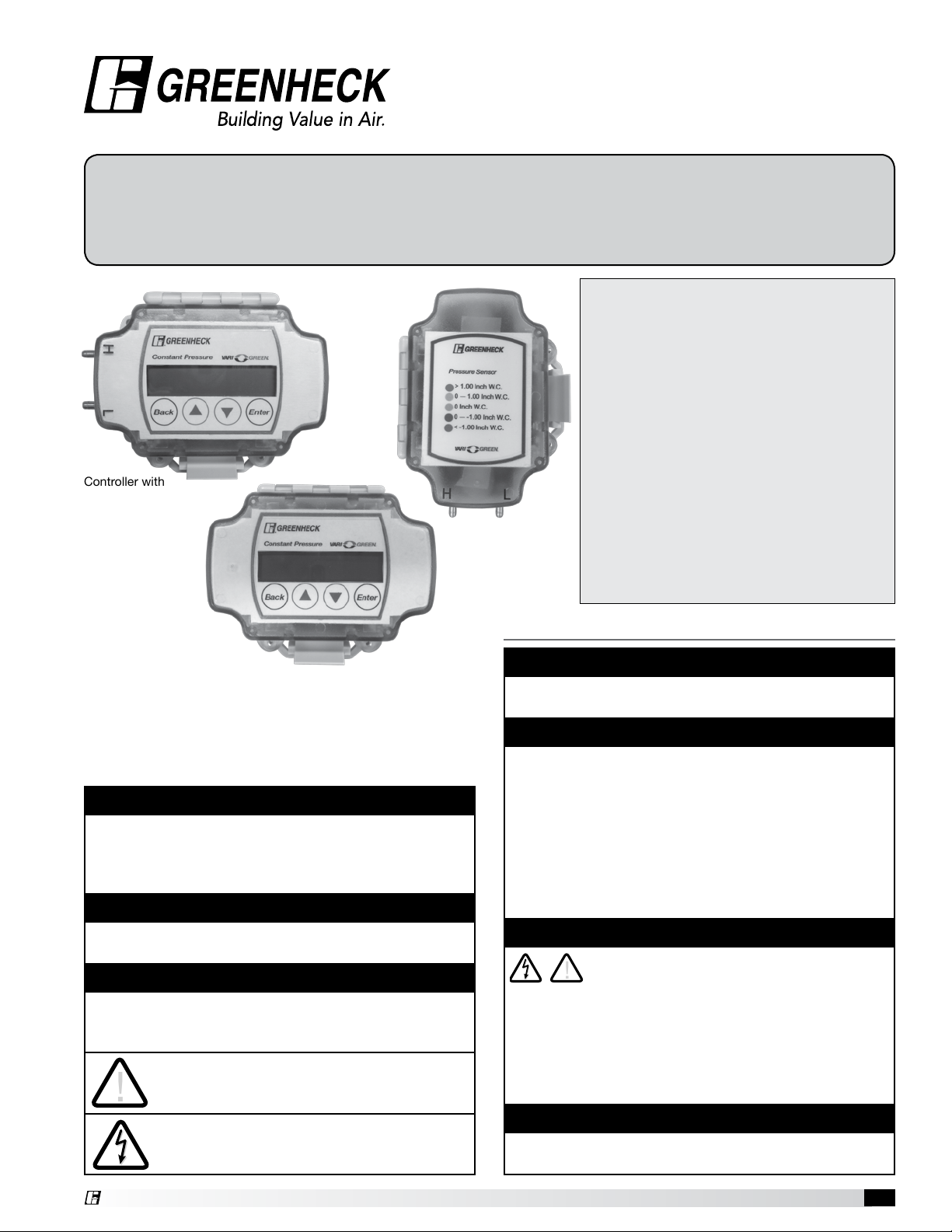

Remote

Transducer

Controller with

Integral Transducer

Controller with

Remote Transducer

Precautions and Warnings

To prevent injury and property damage, follow these

instructions. Failure to adhere to installation/operation

procedures and all applicable codes may result in

hazards as indicated by warning codes outlined below:

DANGER

Indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

This signal word is to limited to the most extreme

situations.

WARNING

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

This is the safety alert symbol. Read and

follow instructions carefully to avoid a

dangerous situation.

This symbol alerts the user to the presence

of “dangerous voltage” inside the product

that might cause harm or electrical shock.

Table of Contents

Constant Pressure Control .................. 2

Installation ........................................... 2

General Operation .......................... 3 - 5

Initial Setup Menu Structure ................ 6

Setpoint Edit Menu Parameters .......... 7

Initial Setup Menu Parameters ............ 8

Wiring Diagrams Overview ............. 9-10

Part Number Table ............................. 10

Air Density Correction Factors .......... 11

Specifications .................................... 11

Assembly Part Numbers .................... 11

Mounting Hole Pattern ...................... 11

Safety Instructions

DANGER

Equipment can start automatically. Lockout/tagout

before servicing.

CAUTION

As with all electrical products, read manual

thoroughly. Only qualified, expert personnel should

perform maintenance and installation. Contact the

nearest authorized service facility for examination,

repair, or adjustment. Do not disassemble or repair

unit unless described in this manual; death or

injury to electrical shock or fire hazard may result.

Specifications and manual data subject to change.

Consult factory for additional information.

DANGER

HAZARDOUS VOLTAGE

• Disconnect and lock out all power before installing

or servicing equipment.

• This equipment may require locking out multiple

power sources prior to service.

• Install and wire in accordance with all applicable

local and national electrical and construction codes.

WARNING

FAILURE TO FOLLOW THESE INSTRUCTIONS

MAY RESULT IN DEATH OR SERIOUS INJURY.

Constant Pressure Control 1

Page 2

Constant Pressure Control

The Greenheck Constant Pressure Control is designed

to maintain a constant level of static pressure or airflow

by automatically adjusting the speed of a fan or position

of damper. The Constant Pressure Control output is

compatible with the Vari-Green® Motor, many variable

frequency drives (VFDs), or dampers with modulating

actuators.

The Constant Pressure Control is available with duct

or room mounted probes for static pressure control,

as well as a pitot tube or Greenheck’s AMS (Airflow

Monitoring Station) for maintaining airflow. Common

applications include:

• Multi-story

• Variable volume exhaust systems serving bathrooms

• Residential kitchen hoods or clothes dryers

• Room pressurization and filtered supply/exhaust

where constant airflow is required as the filters

become dirty

Receiving

Upon receiving the control, check to ensure all items

are accounted for by referencing the delivery receipt or

packing list. Inspect each crate or carton for shipping

damage before accepting delivery. Alert the carrier

of any damage detected. The customer will make

notification of damage (or shortage of items) on the

delivery receipt and all copies of the bill of lading which

is countersigned by the delivering carrier. If damaged,

immediately contact your Greenheck Representative.

Any physical damage to the unit after acceptance is not

the responsibility of Greenheck Fan Corporation.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts.

Storage

Controls are protected against damage during

shipment. If the control cannot be installed and

operated immediately, precautions need to be taken

to prevent deterioration of the control during storage.

The user assumes responsibility of the control and any

accessories while in storage. The manufacturer will

not be responsible for damage during storage. These

suggestions are provided solely as a convenience to the

user.

Indoor - The ideal environment for the storage of control

is indoors, above grade, in a low humidity atmosphere

which is sealed to prevent the entry of blowing dust,

rain or snow. Temperatures should be evenly maintained

between 30° to 110°F (-1° to 43°C). Wide temperature

swings may cause condensation and “sweating” of

metal parts. All accessories must be stored indoors in a

clean, dry atmosphere.

Removing from Storage

As controls are removed from storage to be installed

in their final location, they should be protected and

maintained in a similar fashion until the control goes into

operation.

Installation

Parts Needed

• Control voltage wiring – 18-20ga recommended

• Pressure tubing – 1/4 inch (6mm)

• Fasteners for mounting

• Conduit fittings (1/2 inch (13mm) NPSM)

Note: Mounting hole pattern for controller and

transducer on pg. 11.

Controller – Integral Pressure Transducer

The controller with integral pressure transducer is a

NEMA-4 rated enclosure. Mount the controller in a

location where it can be accessed for programming and

status viewing. The controller should be mounted in an

environment where the temperature remains between

45° and 80° F. (7° and 27°C). This temperature range

is due to the temperature compensation range of the

integral pressure transducer. If the controller needs to

be mounted in a location that will routinely exceed this

range, the controller that accepts a remote transducer

should be used.

The controller should be mounted with the hinge of the

door on top. Keep in mind wiring and tubing lengths

when selecting a location.

Controller – Remote Pressure Transducer

The controller with remote pressure transducer is used

for applications where the controller must be mounted

in areas where the temperature may exceed the

compensation range of the pressure transducer.

Both the controller and remote pressure transducer are

in a NEMA-4 rated enclosure. The pressure transducer

should be mounted in an environment where the

temperature remains between 45° and 80°F

(7° and 27°C)

Maximum Recommended Distances

Tubing Wiring

Probe to Transducer 100 feet (30.5m) N/A

Transducer to Controller N/A 200 feet (61m)

Controller to Fan/Motor/VFD N/A 100 feet (30.5m)

Conduit Fittings

Connections - A stepped drill bit can be used to create

openings in the conduit fittings. Take care to not

damage the components inside the housing

when drilling.

Pressure Probes

A duct static, room static, 2-piece pitot tube and AMS

are available from Greenheck. Other pressure probes

may be used as well.

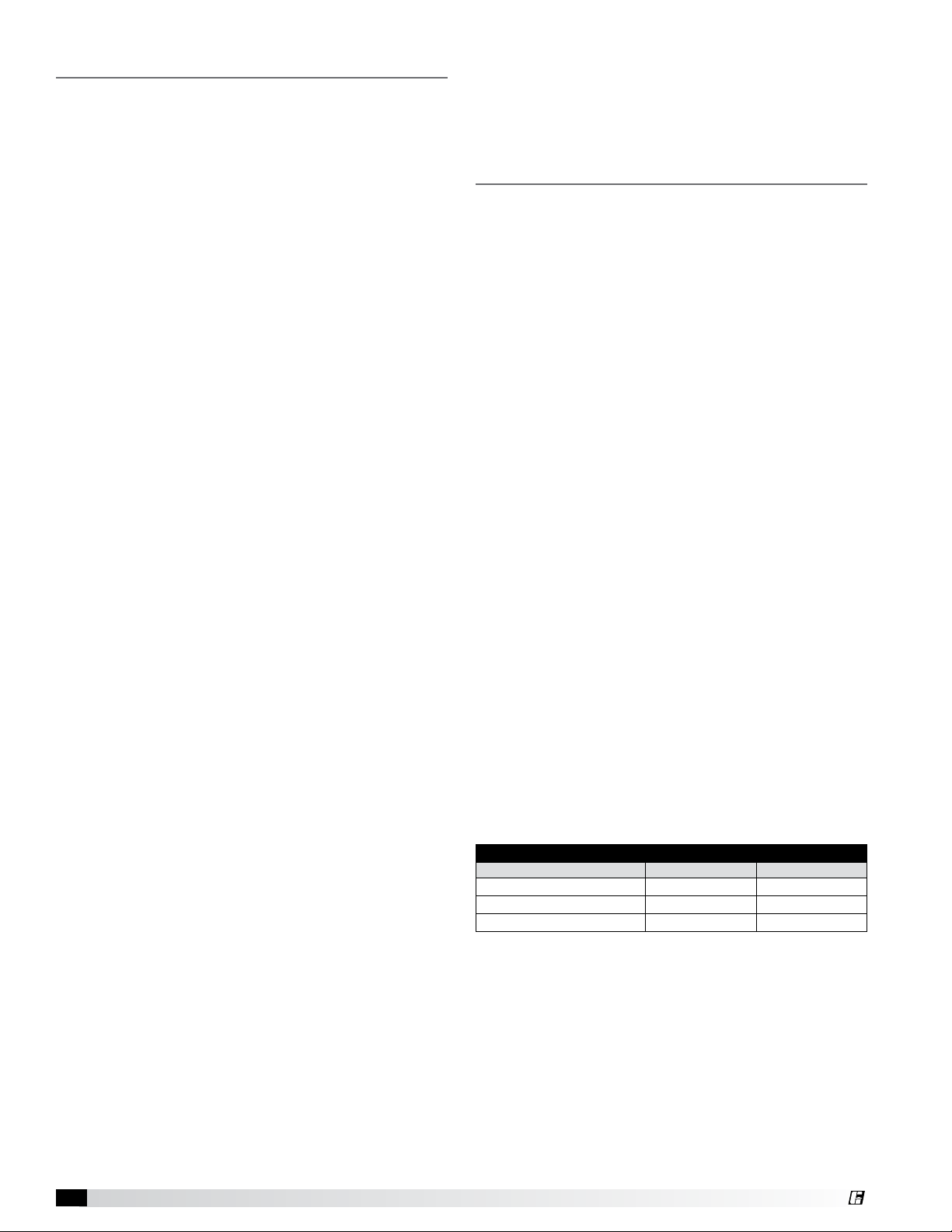

Duct Static Probe (FIG. 1)

The duct static probe must be located in the duct where

Constant Pressure Control2

Page 3

FIG. 1

you intend to control the static

pressure. It should be located

a minimum of 10’ away from

the inlet/outlet of the fan/

damper to ensure stable

operation.

The duct static probe is always

connected to the “H” port

of the control/transducer.

The “L” port is the reference

port and can remain open to

atmosphere or plumbed to another location.

General Operation

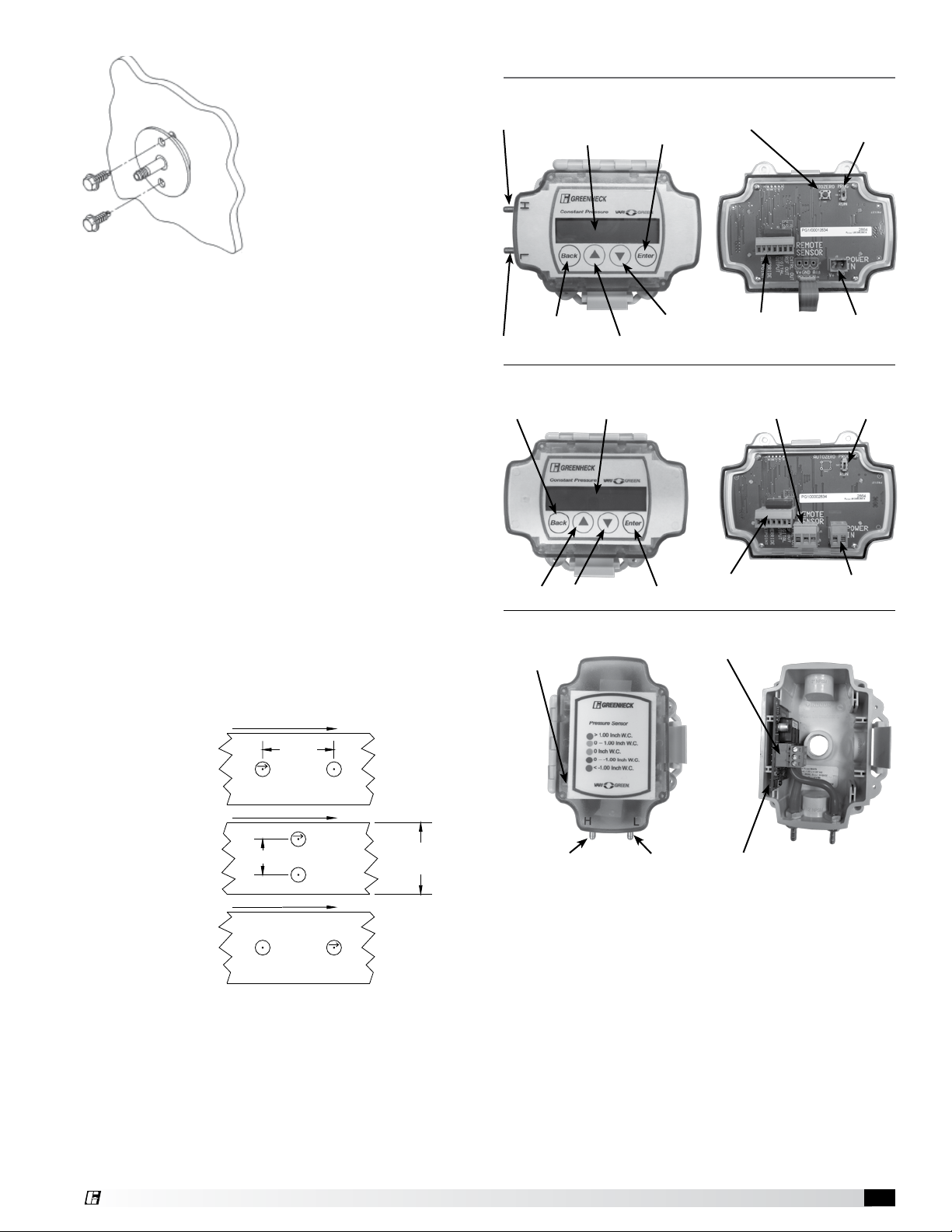

Controller with Integral Transducer

H Pressure Port

Display

Enter Button

Auto Zero Button

PROG/RUN Switch

Room Static Probe

The room static probe is used to sample the pressure in

an open space such as a room or hallway. The pressure

controlled room must be connected to the “H” port. The

“L” port is the reference port and can remain open to

atmosphere or plumbed to another location.

Alternatively, if the controller/transducer is mounted

in the space in which the pressure is to be controlled,

the “H” port can remain open and the “L” port must be

plumbed to another location for reference.

2-Piece Pitot Tube

The 2-piece pitot tube consists of a total pressure (PT)

probe and a static pressure (PS) probe. These probes

should be mounted in a straight section of ductwork

located away from elbows or transitions. The total

pressure probe can be identified by a 45deg. cut at the

end and the arrow identifying airflow direction on the

mounting flange.

Examples for mounting the probes are shown in FIG. 2

(A, B, C).

AIR FLOW

(102-203mm)

PT S

AIR FLOW

4-8 in.

P

(A)

FIG. 2

CORRECT

Back Button

L Pressure Port

Controller with Remote Transducer

Up Arrow

Remote Transducer

Status LED

Down Arrow Enter Button

Pressure

Down Arrow

Up Arrow

DisplayBack Button

Control Wiring

Connector

Romote Transducer

Wiring Connector

Control Wiring

Connector

Wiring Connector

Power Wiring

Connector

PROG/RUN

Switch

Power Wiring

Connector

(B)

(C)

INCORRECT

CORRECT

2-4 in.

AIR FLOW

(51-102mm)

SP

PT

SP

PT

12 in.

(305mm)

OR GREATER

Connect the total pressure probe to the “H” port of the

control/transducer and the static pressure probe to the

“L” port.

AMS (Airflow Measuring Station)

The AMS should be mounted away from elbows and

transitions. Connect the “HIGH” port of the AMS to the

“H” port and the “LOW” port of the AMS to the “L” port

of the control/transducer.

H Pressure Port L Pressue Port

Auto Zero Button

Display

The 2-line multi character display is backlit and is

used to read the status of the control as well as setting

parameters during programming.

Touch Buttons

The buttons on the front of the control are touch

sensitive, similar to the touch screen of a smartphone.

Gloves must be removed to ensure it senses your finger.

In RUN mode, the arrow buttons can be used to display

different process variables. In PROG mode, the arrow,

enter and back buttons are used to navigate the menus

and set parameters. When using the arrows to set

parameters, holding the button down will increase the

scrolling speed.

Constant Pressure Control 3

Page 4

LED Status

Output: XX.X%

Flow: XXXXX CFM

Dp: X.XX in WC

Flow: XXXXXX CFM

If control mode=

Constant

Pressure

If control mode=

Constant Airflow

Vel: XXXXX FPM

Flow: XXXXXX CFM

If control mode=

Constant Airflow

A status LED exists on the control and remote pressure

transducer.

Control:

Transducer:

Pressure Transducer Auto Zero

The integral and remote pressure transducer includes

an auto zero function. There is an auto zero button on

the inside of the enclosure. If the controller is already

installed, remove field tubing and connect the “H” and

“L” port of the pressure transducer together with a

short piece of tubing (Fig. 3). Press the auto zero

button inside the

enclosure. When

the LED stops

flashing, remove

the tubing and

reconnect the

existing field

tubing.

Inputs/Outputs

The controller contains the following inputs/outputs:

Inputs:

Outputs:

Green = Normal Operation

Pink = Programming/manual mode

Flashing Yellow = Cutout timer is active

Solid Yellow = Cutout mode is active

Red = Override active

Red = >1.00 in.WC (>249Pa)

Green = 0 —1.00 in.WC (0-249Pa)

Yellow = 0 in.WC (0Pa)

Blue = 0 — -1.0 in.WC (249Pa)

Pink = < -1.00 in.WC (249Pa)

FIG. 3

Pressure tubing connected for auto zero

Remote Override (digital, dry contact)

• Activating this input will force the Fan Speed

output to a fixed % (adjustable)

Remote Setpoint (analog, 0-10V or 2-10V)

• A voltage signal can be sent to the control to

remotely adjust the setpoint.

Remote Transducer (analog, 0-10V)

• Not available on controller with integral

transducer.

Fan Speed (analog, 0-10V, 2-10V)

Pressure/Airflow Reference (analog, 0-10V)

• The output will send the actual pressure/airflow

value to another device, such as BMS.

Relay (digital, 0.5A rating)

• The relay output will close when the Fan Speed

output is above a set % (adjustable). Common

uses are to signal a dirty filter in airflow mode or

signal another device that the fan is being called

to run.

Constant Pressure Control4

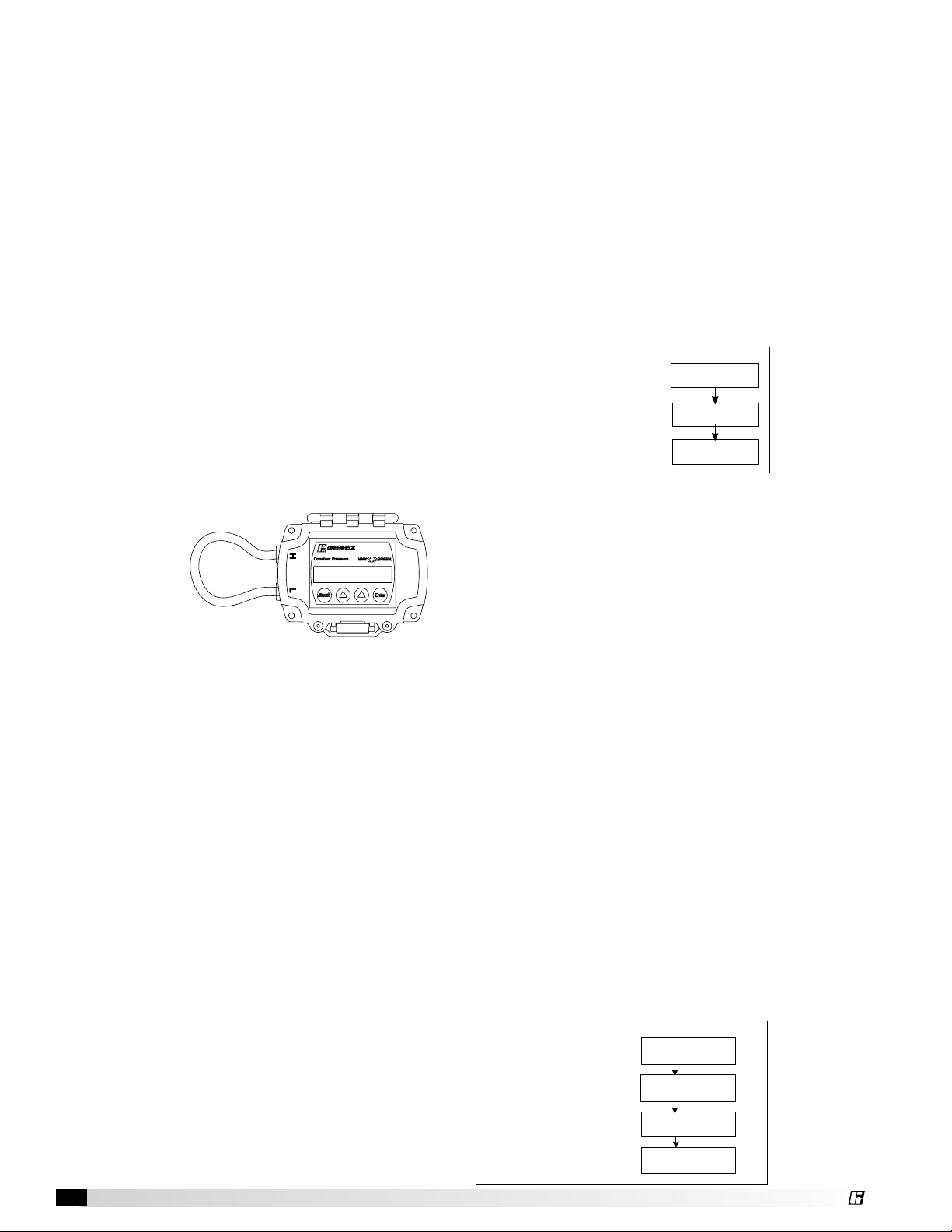

RUN/PROG Mode

Run and Program mode are set using the selector

switch on the inside of the control. Open the control

enclosure to access the switch.

RUN Mode

This control has two major functions – constant

pressure mode and constant airflow mode.

(Set using initial set up menu. pg. 6 & 7)

Constant Pressure Mode - the control will

automatically adjust the speed of the fan to maintain a

constant static pressure in a duct or room.

The display will show the following variables

(touch the arrow buttons to change the display):

Static Pressure Reading

Output %

Pressure Setpoint

Cutout Threshold %

Cutout – The following definitions will be used to

provide clarity in the explanation of the cutout feature.

Primary Fan:

The controller is connect to this fan.

Secondary Fan:

Any fan, other than the primary fan, that

influences the pressure in the system

The cutout feature is available to turn the primary fan off

in times of no demand from the secondary fans.

There are three parameters related to the cutout

function: Cutout %, Cutout Delay Time and Return from

Cutout Pressure Setpoint.

Cutout mode is activated when the fan speed

output % is less than the cutout % setpoint. After the

Cutout Delay Time has elapsed, the control will turn the

output OFF.

A change in system pressure is needed to turn the

output back ON. This value is adjustable to prevent false

pressure fluctuations from turning the fan back on.

Constant Airflow Mode – the control will automatically

adjust the speed of a fan to maintain a constant airflow

rate in a duct.

The display will show the following variables(touch the

arrow buttons to change the display):

Airflow Reading

Output %

Differential Pressure

Reading

Velocity Reading

Airflow Setpoint

Ps: -X.XX in WC

Output: XX.X%

Ps: -X.XX in WC

Set: -0.10 in WC

Ps: -X.XX in WC

Cutout: 20.0%

Flow: XXXXX CFM

Output: XX.X%

Flow: XXXXXX CFM

Dp: X.XX in WC

Flow: XXXXXX CFM

Vel: XXXXX FPM

Flow: XXXXX CFM

Set: XXXXX CFM

Page 5

Wiring Diagrams Overview

Note: These diagrams show connections when using a

Vari-Green® motor and transformer. Other inputs/

outputs on the control are not shown for clarity.

See Pg. 10 for more details.

Integral Transducer:

Remote Transducer:

Constant Pressure Control 5

Page 6

PROG Mode:

IF

Setpoint = Local

AND

Control Mode = Constant Pressure

IF

Setpoint = Local

AND

Control Mode = Constant Airflow

Pressure Setpnt

-0.010 in

WC

Cutout Setpoint Fan

Speed: 20.8%

30 Seconds

Cutout Delay

Airflow Setpoint

5000 CFM

IF

Setpoint = Remote

IF

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Setpoint Edit

Enter to

select

Set the control to program mode to

adjust initial settings and setpoints.

A manual mode also exists to

manually set the output of the

control.

Menu Structure

The structure of the program menu is

shown below. A detailed description

of the parameters follows

the diagram.

Main Menu

Control Mode

Constant Press

Setpoint

Location: Remote

Minimum Setpoint

-1.00 in WC

Maximum Setpoint

1.00 in WC

Units of Measure

Imperial

Setpoint

Location: Local

Initial Setup

Enter to Select

Units of Measure

Metric

Setpoint

Location: Remote

Minimum Setpoint

0 CFM

Maximum Setpoint

10,000 CFM

Control Mode

Constant Airflow

Setpoint

Location: Local

1-

2-

3-

4-

Initial Setup Enter to

select

Setpoint Edit Enter to

select

Factory Defaults Enter to

select

Manual Control Enter to

select

1 - Initial Setup – select this menu

to change settings related to the

application of the control, such as:

• Pressure or airflow mode

• Local or remote setpoint

• Fan inlet or outlet control

Remote Setpoint

2 to 10 VDC

Fan Control on:

Inlet

Pressure Output

0 to 10 VDC

Remote Setpoint

0 to 10 VDC

Fan Control on:

Outlet

Pressure Output

2 to 10 VDC

IF

Pressure Sensor

=

Remote

Rem Sensor Min

-1.00 in WC

Rem Sensor Max

1.00 in WC

Remote Setpoint

2 to 10 VDC

Measurement

Device: Pitot

Pitot Correction

1.00

Airflow Output

0 to 10 VDC

Pressure Sensor

SET

K = 4005

m = 0.5

IF

=

Internal

Remote Setpoint

0 to 10 VDC

Duct Area

4.00 sq ft

Measurement

Device: AMS

AMS “K” Value

2,000

AMS “m” Value

0.5000

Air Density Corr

1.00

Max Flow Output

5000 CFM

Airflow Output

2 to 10 VDC

The Setpoint Edit menu (pg. 8) is

then used to adjust the common

setpoints, such as:

• Pressure or airflow mode

• Cutout settings

• Min/max output %

• Override, digital output %

Constant Pressure Control6

Control Output

Response Time

Fast

0 to 10 VDC

Control Output

2 to 10 VDC

Startup Timer

3 seconds

Sensor Filter

0 seconds

Response Time

Medium

Save

Response Time

Slow

Page 7

1 Initial Setup Menu Parameters

Parameter Name Values Default Description

Units Imperial, Metric Imperial Units used for settings within controller

Control Mode

Setpoint Location Local, Remote Local

Min Pressure/Flow

Setpoint

Max Pressure/Flow

Setpoint

Remote Setpoint

Voltage

Fan Inlet/Outlet Inlet, Outlet Inlet

Duct Area

Measurement Device Pitot Tube, AMS Pitot Tube

AMS “K” value

AMS “m” value

Pitot Correction

Factor

Air Density Correction

Factor

Constant Pressure,

Constant Airflow

0-10V, 2-10V 0-10V

0-100 sq. ft

(0-9.29 sq. m)

0.50 to 2.00 1.00

0-5.00 1.00

Constant pressure This sets the main function of the control.

Determines where the pressure or airflow setpoint will be set.

If local, set using the setpoints menu. If remote, connect a 0-10V signal to

remotely set the setpoint.

Bottom end of pressure

transducer span

Top end of pressure

transducer span

4 sq ft

(0.37 sq. m)

This value will correspond to the minimum voltage (0 or 2V) from the

remote setpoint signal. Only available when setpoint is set to [remote].

This value will correspond to a 10V signal from the remote setpoint signal.

Only available when setpoint is set to [remote].

Change this setting based on the signal for the remote setpoint. If 0-10V,

0V refers to the minimum setpoint. If 2-10V, 2V refers to the minimum

setpoint. Only available when setpoint is set to [remote].

Set this parameter to match where the pressure probe is located in relation

to the fan the control is controlling. Only available in [pressure] mode.

Input the area of the duct where the pitot tube is located. If using an AMS,

input the area from the AMS label. Only available in [airflow] mode.

Select the measurement probe type being used. Only available in [airflow]

mode.

When AMS is used, set to “K” value on AMS label.

Only available in [airflow] mode.

When AMS is used, set to “m” value on AMS label.

Only available in [airflow] mode.

Corrects the airflow measurement for the airflow device being used.

Adjust the value if using a pitot tube by others. Only available in [airflow]

mode.

Adjust this value to match the density of the air flowing through the

system. Select the value from the table on pg. 11.

Only available in [airflow] mode

Max Flow Output

Pressure/Airflow

Output

Remote Sensor Min

Pressure

Remote Sensor Max

Pressure

Control output 0-10V, 2-10V 0-10V

Startup Timer 1-30 Seconds 3 Seconds

Sensor Filter 0-10 Seconds 0

Response Time

0-100,000 CFM

0-m3/hr 169,901

0-10V, 2-10V 0-10V This sets the span of the reference output.

Fast, Medium,

Slow

500 CFM

8495 m3/hr

-1.00 in. WC (-249Pa)

1.00 in. WC (249Pa)

Fast

Sets the top of the span for the reference output in [airflow] mode. Adjust

this setting to give more resolution to the remote airflow reading.

Set this value to the minimum pressure value of the remote pressure

transducer. Only available with remote pressure transducer model.

Set this value to the minimum pressure value of the remote pressure

transducer. Only available with remote pressure transducer model.

This value will change the span of the control output.

Vari-Green motors use 0-10V.

The control output will be set to the minimum value at startup for this

amount of time.

Adjust this value if the pressure reading is unstable.

Increasing the value increases the stability of the pressure reading.

This value adjusts the response time of the controller.

Set to Medium or Slow if the fan is unstable/oscillating.

Constant Pressure Control 7

Page 8

3 - Factory Defaults – select this to reset

Initial Setup Enter to

select

IF

Setpoint = Local

AND

Control Mode = Constant Pressure

IF

Setpoint = Local

AND

Control Mode = Constant Airflow

Pressure Setpnt

-0.010 in

WC

Cutout Setpoint Fan

Speed: 20.8%

Cut Ret Pres Set

0.010 In.

WC

30 Seconds

Cutout Delay

Airflow Setpoint

5000 CFM

20%

Minimum Output %

100%

Override Out %

100%

Maximum Output %

100%

Dig Output Set

Save

Manual Out: 50%

Ps: 0.00

in WC

IF

Setpoint = Remote

IF

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Setpoint Edit

Enter to

select

Manual Control

Enter to

select

IF

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Manual Out: 50%

Flow: 0

CFM

Exit

Manual Control Enter to

select

Factory Defaults Enter to

select

Setpoint Edit Enter to

select

Initial Setup Enter to

select

IF

Setpoint = Local

AND

Control Mode = Constant Pressure

IF

Setpoint = Local

AND

Control Mode = Constant Airflow

Pressure Setpnt

-0.010 in

WC

Cutout Setpoint Fan

Speed: 20.8%

Cut Ret Pres Set

0.010 In.

WC

30 Seconds

Cutout Delay

Airflow Setpoint

5000 CFM

20%

Minimum Output %

100%

Override Out %

100%

Maximum Output %

100%

Dig Output Set

IF

Setpoint = Remote

IF

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Setpoint Edit

Enter to

select

Manual Control Enter to

select

Factory Defaults Enter to

select

Setpoint Edit Enter to

select

IF

Setpoint = Local

AND

Control Mode = Constant Pressure

IF

Setpoint = Local

AND

Control Mode = Constant Airflow

Pressure Setpnt

-0.010 in

WC

Cutout Setpoint Fan

Speed: 20.8%

Cut Ret Pres Set

0.010 In.

WC

30 Seconds

Cutout Delay

Airflow Setpoint

5000 CFM

20%

Minimum Output %

100%

Override Out %

100%

Maximum Output %

100%

Dig Output Set

Save

IF

Setpoint = Remote

IF

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Setpoint Edit

Enter to

select

all parameters to their default values.

Factory Defaults Enter to

select

2 - Setpoint Edit Menu Structure:

The Setpoint Edit menu is then used to

adjust the common setpoints, such as:

• Pressure or airflow mode

• Cutout settings

• Min/max output %

• Override, digital output %

Restore Factory Defaults:

No

Restore Factory Defaults:

Yes

Are you sure?

YES

Exit

4 - Manual Control – select this menu to

operate the fan manually. Use the arrow

buttons to adjust speed up and down. The

display will also show the live pressure or

airflow reading (depending on setting).

Control Mode = Constant PressureIFControl Mode = Constant Airflow

Manual Out: 50%

Ps: 0.00

in WC

IF

Manual Control

select

Enter to

Exit

Manual Out: 50%

Flow: 0

CFM

Constant Pressure Control8

Page 9

2 Setpoint Edit Menu Parameters

Parameter Name Values Default Description

-1.00 to

Pressure setpoint

Airflow setpoint

Cutout %

Cutout delay time 0-300 seconds 30 seconds

Cutout return

pressure setpoint

Override

output %

Minimum

output %

Maximum

output %

Digital output

set %

*

+1.00 in WC

(-249 to +249Pa)

20 – 100% 20%

-0.250 in WC–

0.250 in WC

(-62.27 to

+ 62.27Pa)

0, 20-100% 100%

20-100% 20% Sets the minimum output value of the controller during [Run] mode.

20-100% 100% Sets the maximum output value of the controller during [Run] mode.

20-100%

-0.10 in. WC

(-24.9Pa)

inlet mode:

0.01 in. WC

(2.49Pa)

outlet mode:

-0.01 in. WC

(2.49Pa)

20% (pressure

mode) 97%

(airflow mode)

Pressure setting the control will maintain. Only available in [Pressure

Mode] and when [Local Setpoint] is selected.

Airflow setting the control will maintain. Only available in Airflow mode

and when [Local Setpoint] is selected.

When the output value falls below this setting, the output will turn off

after the delay time has elapsed. This is used to turn the primary fan

off in times of no demand. Only available in [Pressure mode].

The output value must be below the cutout threshold for this amount

of time before the fan will turn off.

Only available in [Pressure mode].

This is the threshold that the secondary fan(s) output must pass for

the primary fan to turn back on while in cutout mode.

• Inlet Mode: Measured static pressure must be more positive than

the return from cutout value.

• Outlet Mode: Measured static pressure must be more negative than

the return from cutout value.

Only available in [Pressure mode].

When the digital input is closed, the fan output will be set to this value

until the digital input is opened.

The digital (relay) output will close when the fan output is above this

value. Useful as a dirty filter switch in [Constant Airflow] mode.

More Information about the cutout feature:

*

• The cutout % value is only valid for a discreet

pressure set point. If the pressure setpoint is

changed, the cutout % must be adjusted as well.

Make sure the pressure setpoint is correct before

continuing to set the cutout.

• Steps to determine cutout %:

o Verify pressure setpoint is correct and that the

entire system is in the state where it is desired

for the fan to turn off (such as no secondary fans

operating).

o While viewing the display of the control, make

sure that the Output % value is shown. If not,

touch the up/down arrow on the control until the

Output % value is shown.

o After the pressure has stabilized at the setpoint

(usually 2-3 mins), take note of the Output %.

The value will fluctuate slightly, a mental average

is adequate.

o The recommended cutout value is 1-2 percentage

points above the value noted in the previous

step.

o EXAMPLE: With no secondary fans in the system

operating, the controller is running the primary

fan at 43.5% to maintain the pressure setpoint.

The cutout value is set at 45%. Now, any time

that the output of the control drops below 45%

(after the cutout delay time has elapsed) the fan

will turn off.

• When the Output % is less than the Cutout %, the

LED on the control will flash Yellow, signaling that

the Cutout Delay Timer has started. When the

Cutout Delay Time has elapsed, the LED will turn

solid Yellow and the Output % will show OFF.

• Troubleshooting:

o If the fan will not turn off when desired, the

cutout value is set too low.

o If the fan turns off when it is not desired, the

cutout value is set too high.

o If the fan turns off as desired, but does not turn

back on when desired:

- The cutout return pressure setpoint can be

adjusted up or down to match the system

needs.

- A pressure change must be present. If there

is nothing upstream/downstream of the

fan that will force a pressure change in the

system then the fan will not come back on

and the cutout feature should not be used.

Constant Pressure Control 9

Page 10

Note: Wiring diagrams show detail of all inputs/outputs

available.

PRESSURE CONTROL DETAIL

12-32 VDC POWER INPUT

18-28 VAC

Part Number Table

Indiv.

Part No.

Description Photo

POWER

CONTROL OUT

REF OUT

DIGITAL

OUTPUT

OVERRIDE

REMOTE SET

PRESSURE CONTROL DETAIL, REMOTE TRANSDUCER

POWER

IN

POINT

IN

GND

V+

0-10 VDC, FAN RPM

0-10 VDC, PRESSURE/FLOW REF

RELAY OUTPUT

NORMALLY

OPEN INPUT

0-10 VDC, SET POINT

12-32 VDC POWER INPUT

18-28 VAC

0-10 VDC, FAN RPM

385604

385605

385606

Controller

with Integral

Transducer

(+/- 1”)

Controller

for Remote

Transducer

Remote

Transducer

(+/- 1”)

REMOTE

TRANDUCER

CONTROL OUT

REF OUT

DIGITAL

OUTPUT

OVERRIDE

REMOTE SET

POINT

0-10 VDC FROM REMOTE TRANSDUCER

POWER TO REMOTE TRANSDUCER

0-10 VDC, PRESSURE/FLOW REF

RELAY OUTPUT

NORMALLY

OPEN INPUT

0-10 VDC, SET POINT

474748

474770

475106

Duct Static

Pressure

Probe

Room Static

Pressure

Probe

Duct Total

Pressure

Probe

Constant Pressure Control10

Page 11

Duct Air

Temp

°F

(Deg. C)

0 500 1000 1500 2000 2500 3000 3500 4000 4500 5000 5500 6000

(0) (152.4) (304.8) (457.2) (609.6) (762) (914.4) (1066.8) (1219.2) (1371.6) (1524) (1676.4) (1828.8)

Air Density Correction Factors

Elevation

Dimensions in feet and (meters)

-40 (-40) 0.79 0.81 0.82 0.84 0.85 0.87 0.88 0.9 0.92 0.93 0.95 0.97 0.99

-20 (-29) 0.83 0.85 0.86 0.88 0.89 0.91 0.93 0.94 0.96 0.98 0.99 1.02 1.04

0 (-18) 0.87 0.88 0.9 0.92 0.93 0.95 0.97 0.99 1 1.02 1.04 1.06 1.08

20 (-7) 0.91 0.92 0.94 0.96 0.97 0.99 1.01 1.03 1.05 1.07 1.08 1.11 1.13

40 (4) 0.94 0.96 0.98 1 1.01 1.03 1.05 1.07 1.09 1.11 1.13 1.16 1.18

70 (21) 1 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25

80 (27) 1.02 1.04 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25 1.27

100 (38) 1.06 1.08 1.1 1.12 1.14 1.16 1.18 1.2 1.22 1.25 1.27 1.29 1.32

120 (49) 1.09 1.11 1.13 1.16 1.18 1.2 1.22 1.24 1.27 1.29 1.31 1.34 1.37

140 (60) 1.13 1.15 1.17 1.2 1.22 1.24 1.26 1.29 1.31 1.34 1.36 1.39 1.41

160 (71) 1.17 1.19 1.21 1.24 1.26 1.28 1.31 1.33 1.35 1.38 1.4 1.43 1.46

180 (82) 1.21 1.23 1.25 1.28 1.3 1.32 1.35 1.37 1.4 1.42 1.45 1.48 1.51

200 (93) 1.25 1.27 1.29 1.32 1.34 1.36 1.39 1.42 1.44 1.47 1.49 1.53 1.55

Specifications

Input Power: Current Usage:

12-32VDC, 18-28VAC 100 mA Max

Output: LCD Display:

0-10VDC

(PID Output)

0-10VDC

(Pressure or Flow)

N.O. Digital (configurable)

Input: Airflow (CFM) (M

Override (Dry Contact) Mounting:

Setpoint Range:

-1.00" to +1.00" WC

(+/-249Pa)

0-10,000 CFM

(16.990 m

3

/hr)

Accuracy: Enclosure Rating:

+/- 1.0% FS @ 80F IP66, NEMA-4

Temperature

Compensation Range:

45 to 80ºF (7 to 26ºC) -13 to 175ºF (-25 to 79ºC)

Port Connection:

1/4 inch (6mm)Tubing

(1/8 to 3/16 inch ID)

(3 to 5mm ID)

Burst Pressure:

1.5psi (either port)

(10.342Pa)

Units:

Imperial Metric

Length In. / ft. mm / m

Flow CFM m

Pressure In. WC Pa

Velocity FPM m/hr

Pressure, CFM,

Output %

Control Modes:

Pressure

(Direct and Rev. Acting)

3

/hr)

Four Ext. holes for

#10 Screws

Enclosure Material:

UV-Resistant Polycarbonate,

UL94V-0

Environmental

Operating Range:

0-95% RH

non-condensing

3

/hr

Assembly Part Numbers

Description Assembly P/n Includes

Controller w/ Integral Transducer,

1 Duct Static Tap

Controller w/ Integral Transducer,

1 Room Static Tap

Controller w/ Integral Transducer,

2 Room Static Taps

Controller w/ Integral Transducer,

1 Duct Static and 1 Duct Total Tap

Controller, Remote Transducer,

1 Duct Static Tap

Controller, Remote Transducer,

1 Room Static Tap

Controller, Remote Transducer,

2 Room Static Taps

Controller, Remote Transducer,

1 Duct Static and 1 Duct Total Tap

872982 385604, 474748

872983 385604, 474770

872984 385604, 474770 (2)

872985

872986

872987

872988

872989

385604, 474748,

475106

385605, 385606,

474748

385605, 385606,

474770

385605, 385606,

474770 (2)

385605, 385606,

474748, 475106

Controller, Remote Transducer 872990 385605, 385606

Mounting Hole Pattern

41⁄16 in.

(103mm)

2 in.

(51mm)

7

⁄16 in.

1-

(37mm)

2-7⁄8 in.

(53mm)

Ø 7⁄8 in.

(22mm)

Note:

Four (4) #10 screws recommended with 5⁄32 in. (4mm)

pilot holes.

Constant Pressure Control 11

Page 12

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications

without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in the

Library under Warranties.

®

Phone: 715.359.6171 • Fax: 715.355.2399 • Parts: 800.355.5354 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

479653 • Constant Pressure Control, January 2015 Copyright 2015 © Greenheck Fan Corporation12

Loading...

Loading...