Page 1

Document 476251

Vari-Flow Air Management System

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Vari-Flow Air Management System

General Safety Information

Only qualified personnel should install this unit.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces, or chemicals.

Replace cord immediately if damaged.

3. Verify that the power source is compatible with the

equipment.

®

WARNING

Electrical shock hazard. Can cause equipment

damage, personal injury or death. Service must only

be performance by personal that are knowledgeable

in the operation of the equipment being controlled.

DANGER

Always disconnect power before working on or near a

unit. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the unit, variable frequency drives

may be hot enough to cause pain or injury. Allow

motor to cool before servicing.

CAUTION

It is the responsibility of the installer to make sure

both electrical and gas appliances shut down in

the event of a fire or in the event of a power loss to

the building when this sequence is required by the

authority having jurisdiction.

Vari-Flow Air Management System

1

Page 2

Table of Contents

Receiving and Handling

Receiving and Handling ........................2

Installation

Control Box Mounting ........................3

Resistive Temperature Detector ................3

Pneumatic Static Pressure Kit ...................4

Keypad Mounting .............................4

Touchscreen Mounting .........................5

Electrical Connections

Power for Vari-Flow Control ...................5

Power for Lights ............................5

Variable Frequency Drives (VFD) ................6

Vari-Green® Motor ..........................6

VFD Provided by Others ......................6

Make-Up Air VFD in Vari-Flow Wiring ............7

Make-Up Air VFD in Make-Up Air Wiring .........7

Auto Tempering .............................7

Fire System Microswitch ......................7

Resistive Temperature Detector(s) ..............8

Temperature Sensors ........................8

Keypad ...................................8

Touchscreen ...............................8

Remote Enable .............................8

Shunt Trip .................................9

Electric Gas Valve with Gas Reheat .............9

Spare Fire Relay Contacts ....................9

High Temperature Alarm Contacts ..............9

Airflow Proving .............................9

Wash Interface ..............................9

Vari-Flow Connection Checklist .................10

Sequence of Operation .......................11

System Optimization ..........................12

Controller Setup and Tutorial ................ 13-14

Menus

A.

B.

C.

D.

G.

H.

Keypad Navigation and Information ..............24

Touchscreen Navigation .................... 25-26

General Information .........................26

Settings ............................... 26-27

Configuration ..............................28

Information ...............................29

Troubleshooting .............................30

Maintenance Log .............................31

Our Commitment .............................32

On/Off Unit ........................15

Setpoint ..........................16

Clock/Scheduler ....................17

Input/Output .......................17

Service ........................18-21

Manufacturer ................... 21-23

Receiving

Upon receiving the product, check to make sure all

items are accounted for by referencing the bill of lading

to ensure all items were received. Notify the carrier if

any damage is noticed. The carrier will make notification

on the delivery receipt acknowledging any damage to

the product. All damage should be noted on all of the

copies of the bill of lading which is countersigned by the

delivering carrier. If damaged upon arrival, file a claim

with the carrier. Any physical damage to the unit after

acceptance is not the responsibility of the manufacturer.

Unpacking

Verify that all required parts and the correct quantity of

each item have been received. If any items are missing,

report shortages to your local representative to arrange

for obtaining missing parts.

Storage

If a kitchen fan control center must be stored prior to

installation, it must be protected from dirt and moisture.

Indoor storage is highly recommended. For outdoor

storage, cover the control package with a tarp to keep it

clean, dry, and protected from UV (ultraviolet) radiation

damage.

NOTE

Improper storage which results in damage to the unit

will void the warranty.

Handling

Make sure the equipment does not suffer any heavy

vibration or knocks.

Vari-Flow Air Management System

2

®

Page 3

Installation

Control Box Mounting

1. Locate an area with enough space to mount the

control box and fasten to the wall.

NOTE

Control Box may be factory mounted. If so, continue

to the next section.

NOTE

If the Vari-Flow system is equipped with static

pressure controls it will be located in the Vari-Flow

cabinet, therefore this control box should be mounted

in the space to be controlled. If the control box is

mounted outside of this space, please refer to the

Pneumatic Static Pressure Kit Installation Instructions.

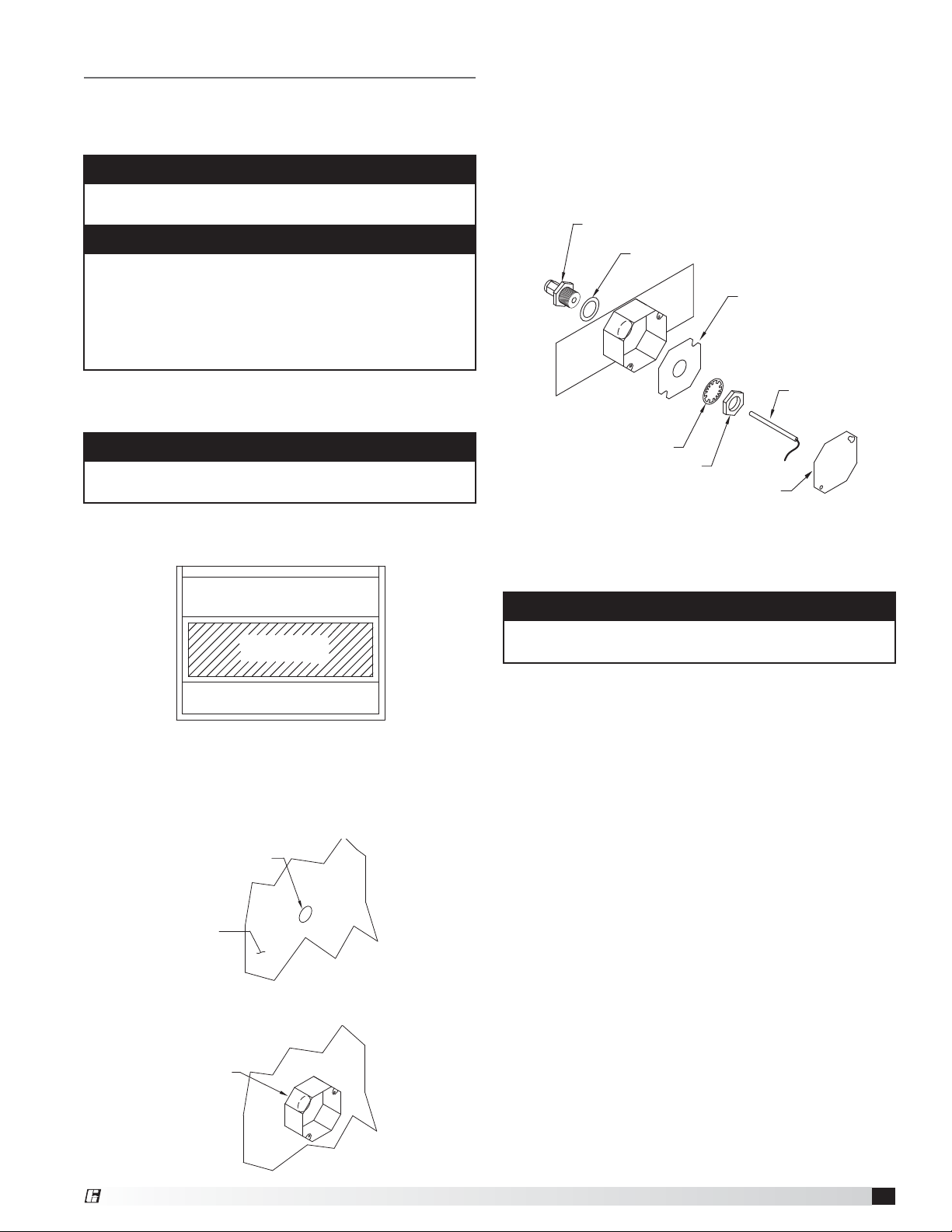

4. Insert the compression seal into the hole from

the inside of the hood making sure the gasket is

placed on the fitting before inserting it into the hole.

Place the octagon box and J-box plate provided

over the fitting on the top of the hood, keeping the

fitting centered in the box. Install the lock washer

and 1-1/2inch nut on the threaded portion of the

compression seal and tighten securely.

1/4 inch Compression Seal

Gasket

J-Box Plate

Resistive Temperature Detector(s)

(RTD) Mounting

NOTE

Resistive temperature detector(s) may be factory

installed. If so, continue to the next section.

1. Locate flat area(s) at the top interior of the hood in

front of the filters, towards the front of the hood.

Exhaust Area

Sensor Install

Cut Out Area

Supply Area (optional)

Top View of Exhaust Hood

2. Cut a 3/4-inch diameter hole into the top of the

capture tank. Make sure the resistive temperature

detector(s) will not interfere with fire system nozzles

and is not within 12 inches of light fixtures.

Temperature

Sensor

Lock Washer

Nut

Octagon Cover

5. Insert the resistive temperature detector (RTD) into

compression seal and tighten to 35 ft-lbs.

6. Place octagon cover onto J-box plate and fasten it.

NOTE

All field installation and wiring of electrical equipment

must be done to meet NEC and local codes.

.75 to .875 inch

diameter hole

Hood

Surface

3. Center the octagon extension over the hole on the

hood surface.

Octagon

Extension

®

Vari-Flow Air Management System

3

Page 4

Pneumatic Static Pressure Kit

- if equipped

NOTE

The Vari-Flow system may not be provided with the

static pressure controls, if not move onto the next

section.

1. Locate the Dwyer static pressure sensor outside of

the building in a secure location free from as many

obstructions as possible.

2. Refer to the instruction manual with the static

pressure sensor for installation and operation details.

3. Once the static pressure probe is mounted, run vinyl

tubing from the probe back to the control panel and

coil the excess tubing. Do not kink or trim the tubing.

4. If the control panel is located in the space to be

controlled, go to the next section. If the control panel

is mounted remotely from the space to be controlled,

continue to step 5.

5. Run 1/4 inch virgin poly tubing (by others) from the

sensor in the control panel to a secure location in the

space to be controlled.

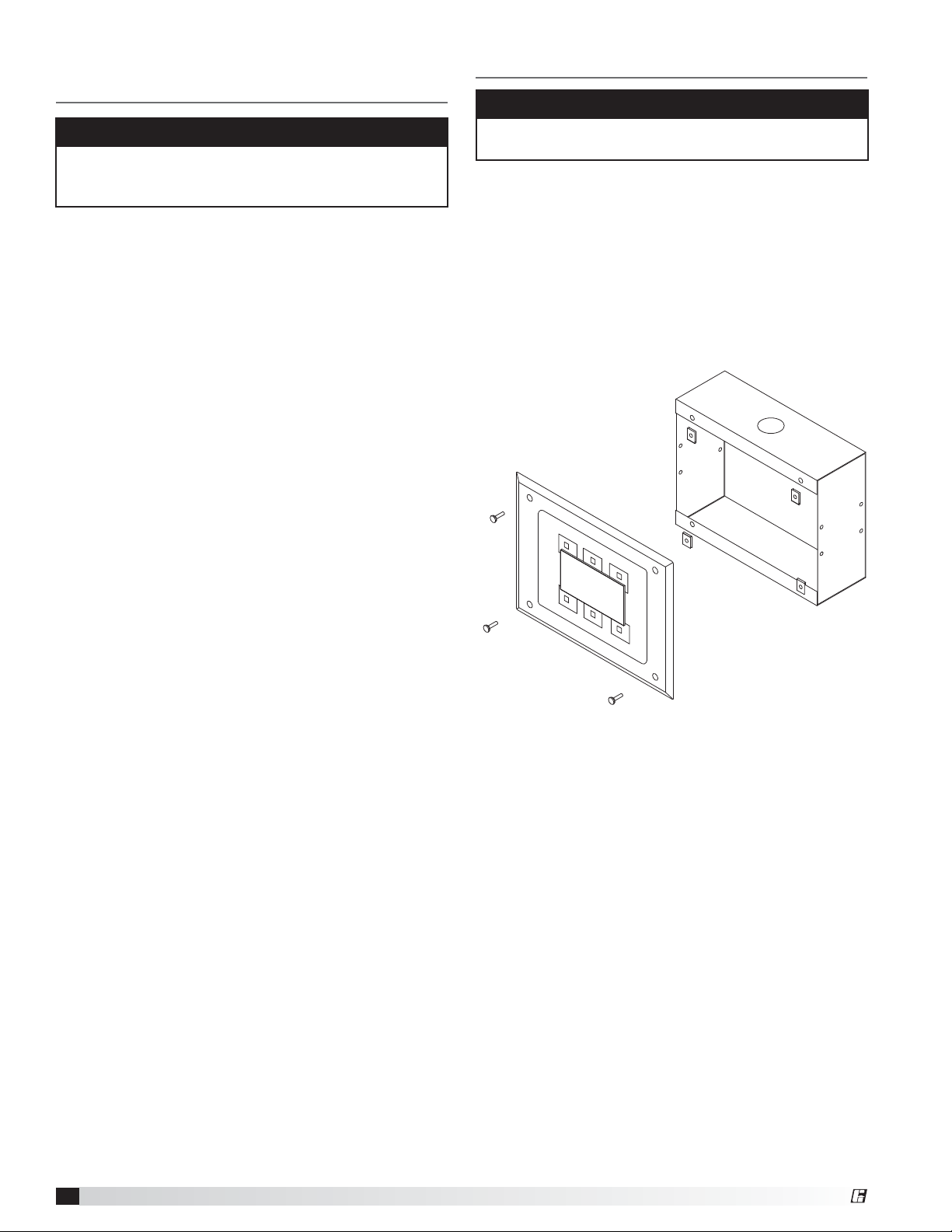

Keypad Mounting

NOTE

The keypad may be factory mounted. If so, continue

to the Electrical Connections section.

1. For systems with remote controls or keypad, a 35,

75, or 150 foot RJ25 cable is supplied to connect

the keypad to the controls. The cable is plenum

rated and does not need to be run through conduit

unless required by local codes. If the keypad is to be

mounted further away than the cable that is received,

additional cable will be needed. Additional cable is

available at the lengths mentioned above.

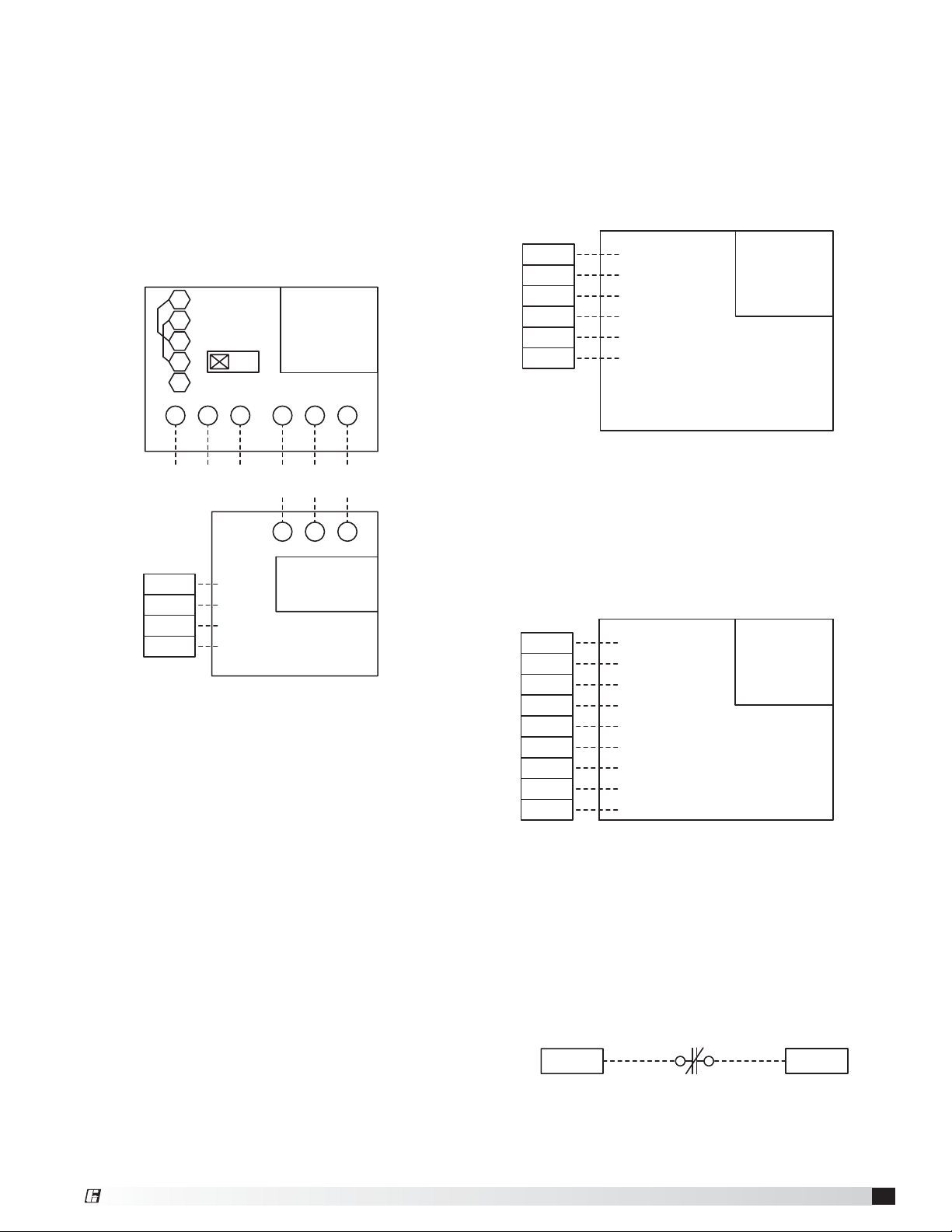

Keypad Mounting Diagram

Vari-Flow Air Management System

4

®

Page 5

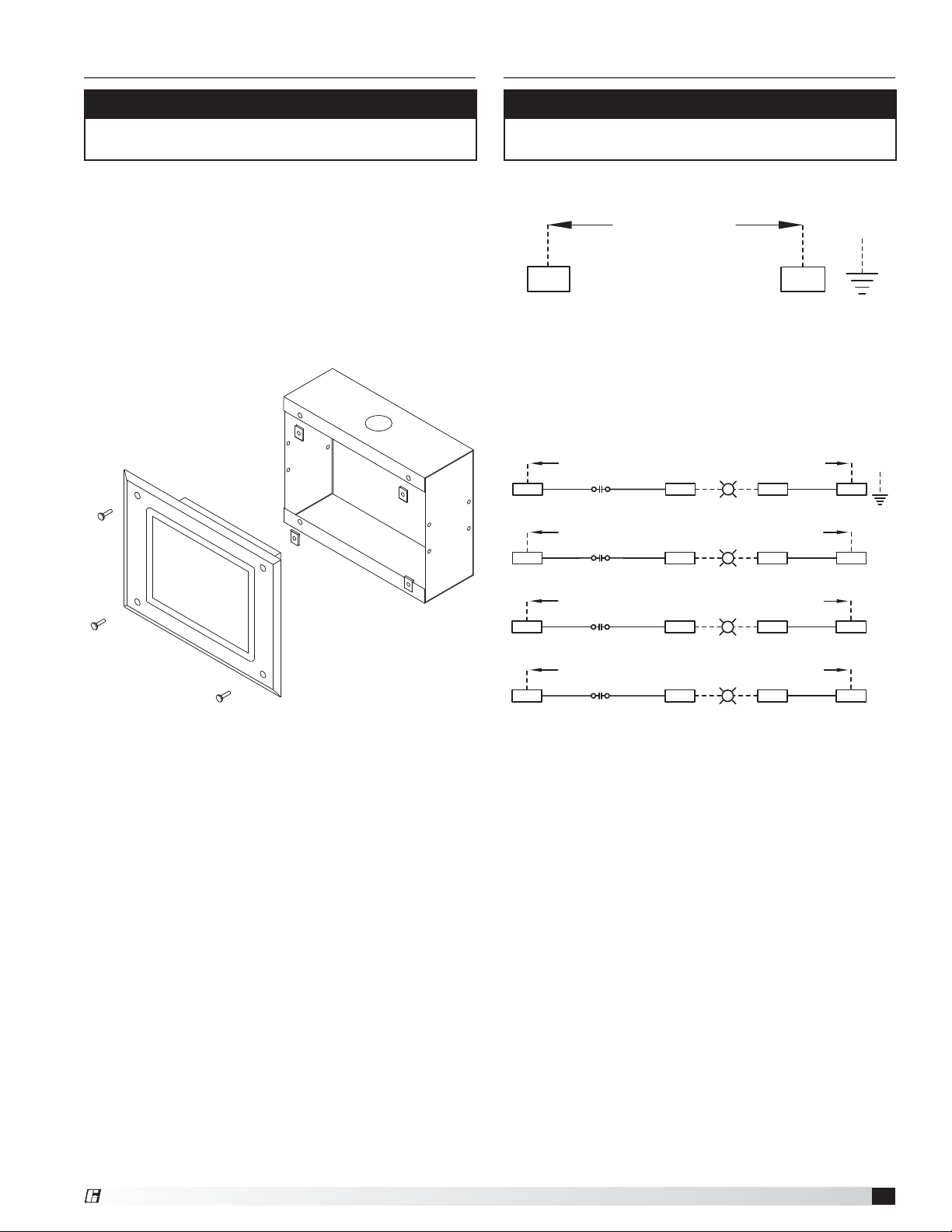

Touch Screen Mounting - if equipped

Electrical Connections

NOTE

The touch screen may be factory mounted. If so,

continue to the Electrical Connections section.

1. For systems with remote controls or touch screen,

two 35, 75, or 150 foot sets of cables are supplied to

connect the touch screen to the controls. The cables

are plenum rated and do not need to be run through

conduit unless required by local codes. If the keypad

is to be mounted further away than the cable that is

received, additional cable will be needed. Additional

cables are available at the lengths mentioned above.

Touch Screen Mounting Diagram

NOTE

All wiring of electrical equipment must be done to

meet NEC and local codes.

Power for Vari-Flow Cabinet

• 115 VAC, power for controls (Terminals H and N)

CONTROL INPUT:

115 VAC, 15 AMPS FROM BREAKER

H

N

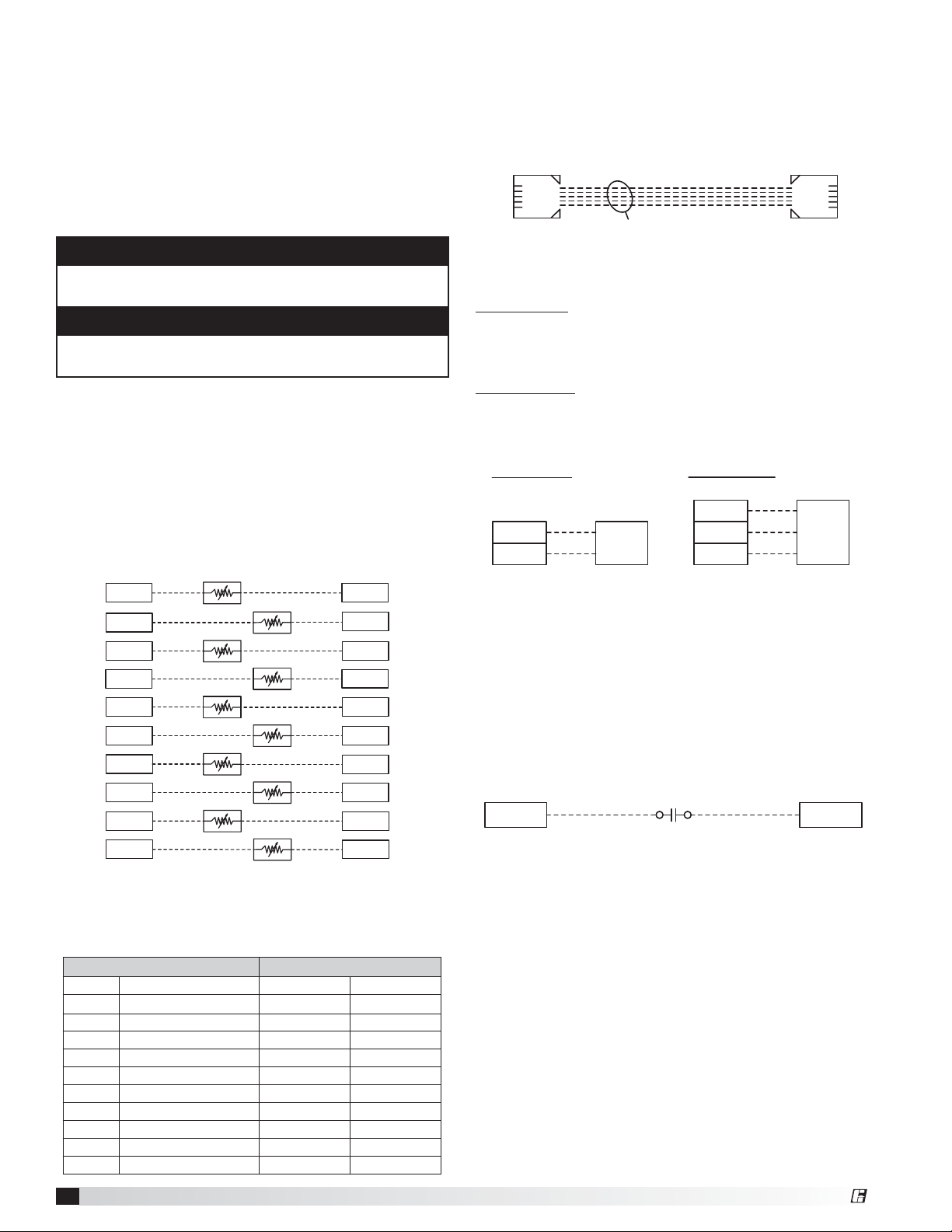

Power for Lights

• 115 VAC, power for hood lights, one per light circuit

(Terminals H1, N1 | H2, N2 | H3, N3 | H4, N4)

• 115 VAC, power to lights, one per light circuit

(Terminals B1, W1 | B2, W2 | B3, W3 | B4, W4)

EACH CANOPY LIGHTING CIRCUIT MUST NOT EXCEED 15A TOTAL CURRENT

LIGHT CIRCUIT 1: 115 VAC, 15 AMPS FROM BREAKER

R1

11

H1 W1B1

BK 14GA

H2 B2 N2W2

14

HOOD LIGHT

RELAY 1

LIGHT CIRCUIT 2: 115 VAC, 15 AMPS FROM BREAKER

R2

11

14

HOOD LIGHT

RELAY 2

HOOD LIGHT(S)

HOOD LIGHT(S)

WH 14GABK 14GA BK 14GA

WH 14GABK 14GA

G

N1

G

LIGHT CIRCUIT 3: 115 VAC, 15 AMPS FROM BREAKER

R3

11

BK 14GA BK 14GA

H3 B3 N3W3

BK 14GA BK 14GA

H4 B4 N4W4

14

HOOD LIGHT

RELAY 3

LIGHT CIRCUIT 4: 115 VAC, 15 AMPS FROM BREAKER

R4

11

14

HOOD LIGHT

RELAY 4

HOOD LIGHT(S)

HOOD LIGHT(S)

WH 14GA

WH 14GA

®

Vari-Flow Air Management System

5

Page 6

Variable Frequency Drives (VFD) - if equipped

NOTE

If electrically commutated motors are being used,

VFDs will not be needed.

1. Bring power to the input of each VFD from a

dedicated power source using conduit to the

NEMA-1 enclosure on the bottom of the drive. Each

power source shall be of the same voltage as the

respective fan and of a high enough amp rating to

handle the full load amp draw of the respective fan.

NOTE

The VFD motor overload parameter (E2-01) need to

be set to the motor nameplate FLA. Refer to the Quick

Start Guide from Yaskawa (pages 83-89) for setting

these parameters on the Yaskawa drive.

NOTE

Be sure to use appropriately sized wire for the full load

amp draw.

2. To avoid interference between the conductors,

separate conduit from the VFD output to the input

power of the fan must be used for each fan.

Vari-Green® Fan Wiring - if equipped

• 24 VAC from Vari-Flow to Vari-Green motor control

wire, black (Terminal E__-24)

• 0-10 VDC Speed Reference from Vari-Flow to

Vari-Green motor control wire, red (Terminal E__S+)

• Common from Vari-Flow to Vari-Green motor control

wire, white (Terminal E__S-)

E1-24

E1-S+

E1-S-

24 VAC RUN (BLACK)

SPEED REF. + (RED)

SPEED REF. - (WHITE)

G

NH

NOTE: POWER FOR THE

VARI-GREEN FAN GOES

DIRECTLY T O FAN

VFD-F1-E

MARK: VG

115/1

0.75 HP

VARI-GREEN

VARI-GREEN MOTOR

LINE

This is an example of Exhaust Fan 1 provided with a Vari-Green motor.

R+

RS+

S2

SIG

OFF

L3

L2L1

LINE

Each variable frequency drive must have the

LINE and LOAD wiring in separate conduit

VFD-F1-E

MARK: FAN MARK

VOLT/HP

MODBUS VFD

ADDRESS: X

T2T1

LOAD

T3

VFD Provided by Others, Control Wiring - if equipped

• Fault command from Vari-Flow to VFD provided by

• Run command from Vari-Flow to VFD provided by

• Speed reference from Vari-Flow to VFD provided by

MODBUS VFD

• Line power to VFD

• Load power from VFD to fan

This is an example of Exhaust Fan 1 provided with a VFD by others.

others (Terminal E__-FA, E__-FB)

others (Terminal E__-RA, E__-RB)

others (Terminal E__S+, E__S-)

E1-FA

E1-FB

E1-RA

E1-RB

E1-S+

E1-S-

NORMALLY OPEN

FAULT CONTACT

COMMON

RUN COMMAND

RUN COMMAND

SPEED REFERENCE +

SPEED REFERENCE -

L3

L2L1 T3T2T1

VFD BY OTHERS

LINE LOAD

VFD-F1-E

MARK: VFD BY

OTHERS

VOLT/PH

HP

VFD BY OTHERS

Vari-Flow Air Management System

6

®

Page 7

Make-Up Air VFD in Vari-Flow Wiring - if equipped

• 24 VAC run command from Vari-Flow to make-up air

unit (Terminals S__-42, S__-43)

• Tempering status from Vari-Flow to make-up air unit

(Terminals S__-44, S__-45)

• Line power to VFD input, bottom left of VFD

(Terminals L1, L2, L3)

• Load power from VFD output, bottom right of VFD to

make-up air disconnect (Terminals T1, T2, T3)

Make-up air unit requires separate 115 VAC control

power circuit.

THIS LAST VFD IN

R+

MODBUS LINE MUST

HAVE THE END OF

R-

LINE RESISTOR

SWITCHED ON

S+

S2

S-

ON

IG

L2L1

L3

VFD-F2-S

MARK: MUA - VFD

VAV

VOLT/PH

HP

MODBUS VFD

ADDRESS: X

T3

T2T1

MODBUS VFDMUA UNIT

Make-Up Air VFD in Make-Up Air Wiring - if equipped

• 24 VAC run command from Vari-Flow to make-up air

unit (Terminals S__-42, S__-43)

• Tempering status from Vari-Flow to make-up air unit

(Terminals S__-44, S__-45)

• 0-10 VDC speed reference from Vari-Flow to

make-up air unit (Terminals S__-46, S__-47)

Power for make-up air goes directly to make-up air unit.

S1-42

S1-43

S1-44

S1-45

S1-46

S1-47

24 VAC RUN

24 VAC COM

TEMPERING STATUS

TEMPERING STATUS

SPEED REFERENCE +

SPEED REFERENCE -

NOTE: CONTROL POWER FOR

MUA GOES DIRECTLY FROM

BREAKER PANEL TO MUA.

MARK: MUA - VFD

VFD IN MUA UNIT

(0-10 VDC)

VFD-F2-S

MUA

VOLT/PH

HP

MUA - VFD IN UNIT

S2-42

S2-43

S2-44

S2-45

LINE

RUN

24 VAC

COM

TEMPERING STATUS

TEMPERING STATUS

SEPARATE CONTROL POWER

TO UNIT REQUIRED

LOAD

DISCONNECT IN UNIT

MAKE UP AIR UNIT

CONTROL WIRING

MARK: MUA - VFD

VAV

F2-S

This is an example of Supply Fan 1 being a

make-up air with VFD in the Vari-Flow.

being a make-up air with VFD in the make-up air unit.

This is an example of Supply Fan 1

Auto Tempering - if equipped

• Auto Heat/Cool enable

(Terminals S1-R, S1-W1, S1-Y1)

S1-42

S1-43

S1-44

S1-45

S1-46

S1-47

S1-R

S1-W1

S1-Y1

24 VAC RUN

24 VAC COM

TEMPERING STATUS

TEMPERING STATUS

SPEED REFERENCE +

SPEED REFERENCE CONTROL COMMON

HEAT

COOL

NOTE: CONTROL POWER FOR

MUA GOES DIRECTLY FROM

BREAKER PANEL TO MUA.

This is an example of Supply Fan 1 with auto tempering.

MARK: MUA - VFD

VFD IN MUA UNIT

(0-10 VDC)

VFD-F2-S

VOLT/PH

MUA

HP

MUA - VFD IN UNIT

Fire System Microswitch

• Fire system microswitch common to Vari-Flow

(Terminal C1)

• Fire system microswitch normally closed contact to

Vari-Flow (Terminal NC1)

C1 NC1

®

Vari-Flow Air Management System

7

Page 8

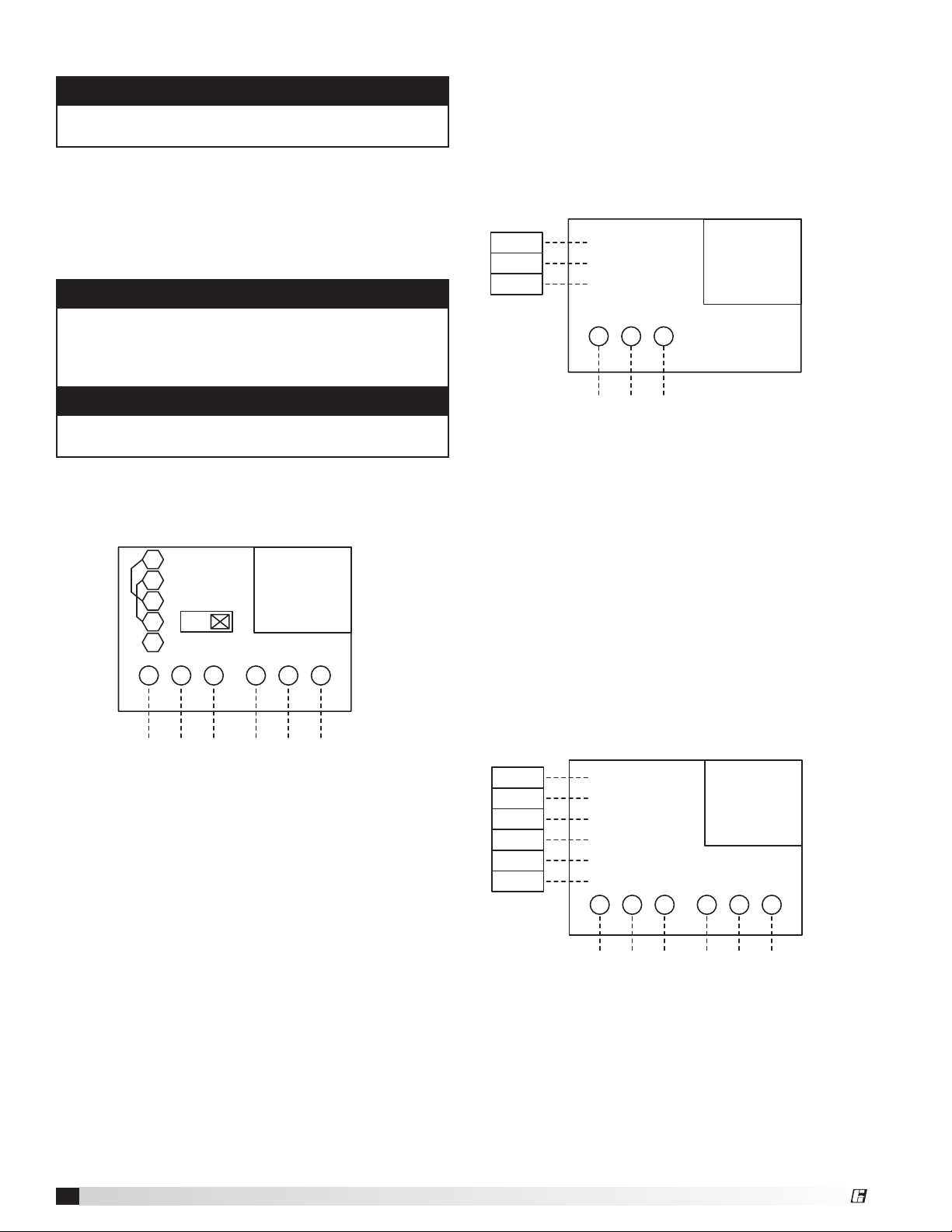

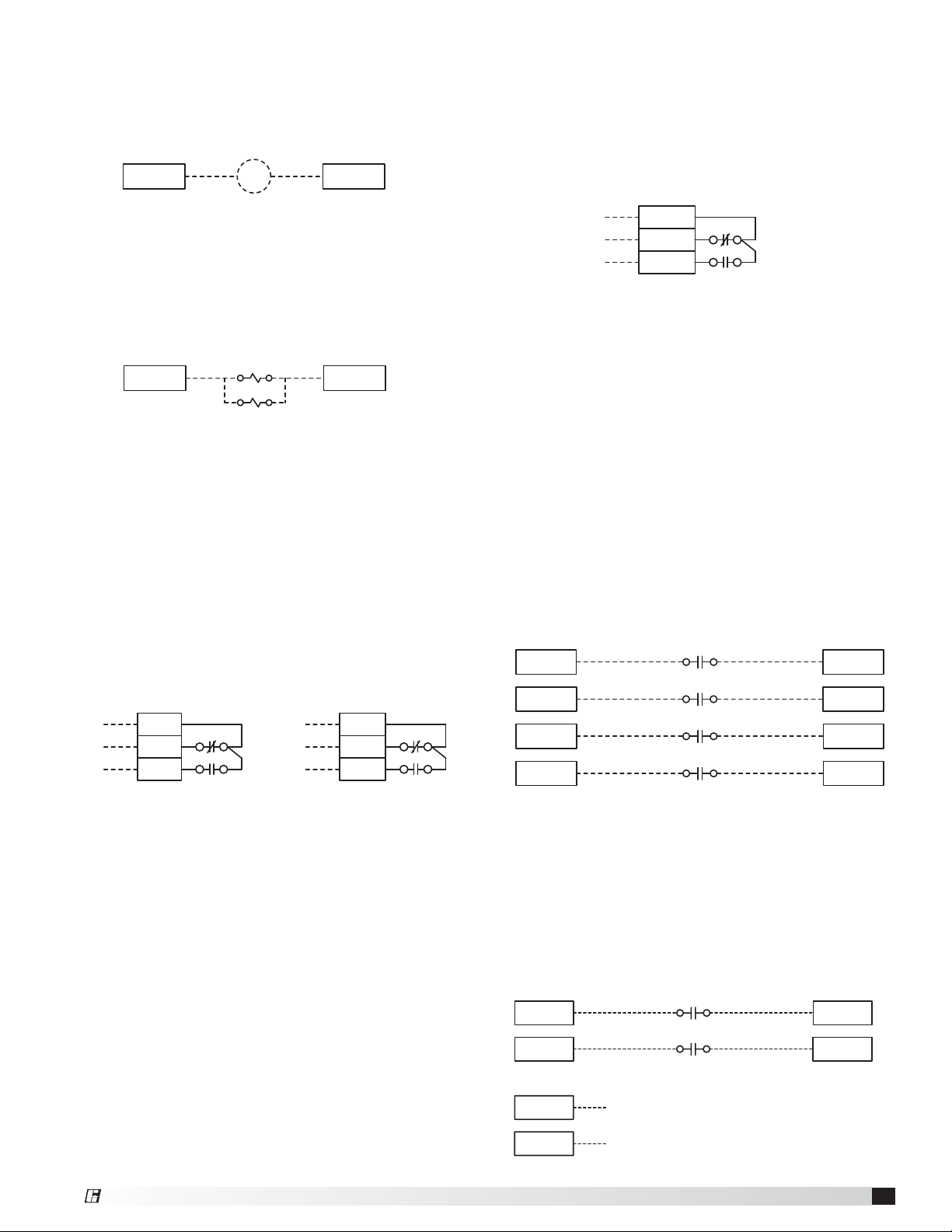

Resistive Temperature Detectors (RTD)

Wire the two leads of the sensors to be designated

terminals in the control panel as shown below. This is

determined by the number of temperature sensors on

the job (1-10 sensors). The two wires of the sensor are

not polarity sensitive. If more than one hood is being

controlled, be sure that the appropriate sensor is wired

to the appropriate terminals as depicted on the job

specific wiring diagram.

NOTE

The RTD’s should not be exposed to direct flame. The

RTD’s are rated up to 250°F

CAUTION

Exposing the sensor to direct flame may render the

sensor inoperable and will void the warranty.

Temperature Sensors* - installed in hood

• Temperature Sensor T1 to Vari-Flow

(Terminals T1-A, T1-B)

Refer to table (example below) to cross reference the

temperature sensor and the hood mark.

*Repeat based on the number of temperature sensors.

(Terminals T2-A, T2-B | T3-A, T3-B | T4-A, T4-B | T5A, T5-B | T6-A, T6-B | T7-A, T7-B | T8-A, T8-B | T9-A,

T9-B| T10-A, T10-B)

T1

T1-A T1-B

T2-A

T3-A

T4-A T4-B

T5-A T5-B

T6-A

T7-A

T8-A

T9-A

T10-A

T3

T5

T7

T9

T2

T4

T6

T8

T10

T2-B

T3-B

T6-B

T7-B

T8-B

T9-B

T10-B

Keypad - if equipped

• Connect provided cable from back of keypad to

CAREL® PCO5+ controller (Terminal J10)

CONNECT FACTORY PROVIDED RJ25 CABLE

TO J10 ON PCO5+ AND BACK OF KEYPAD

PCO5+ J10 KEYPAD

35 Foot Cable Provided

75 or 150 Foot Cable is Optional

Touchscreen - if equipped

Power Wiring

• Connect provided 2-wire cable from Vari-Flow

(Terminals 24H, 24C) to touch screen

(Terminals G, GO)

Control Wiring

• Connect provided 3-wire cable from Vari-Flow

(Terminals -, +, GND) to touch screen

(Terminals -, +, GND)

Power Wiring

24C

24H

TOUCH

SCREEN

GO

G

Control Wiring

-

+

GND

TOUCH

SCREEN

-

+

GND

Remote Enable - if used

• Connect remote enable common and normally open

from BMS to Vari-Flow (Terminals RE-1A, RE-1B)

A closed contact will turn on all fans.

An open contact will turn off all fans.

NOTE: Temperature interlock will override the remote

enable input.

RE-1A RE-1B

NOTE: The Vari-Flow job specific temperature sensor

table is found in the wiring diagram located on the VariFlow panel door. This table is an example, do not use

for your specific job.

Sensors (Field Wiring) Related Fans

Sensor Hood Mark Exhaust Fans Supply Fans

T1 Hood Mark Name 1 F1-E F11-S

T2 Hood Mark Name 2 F2-E F11-S

T3 Hood Mark Name 3 F3-E F12-S

T4 Hood Mark Name 4 F4-E F12-S

T5 Hood Mark Name 5 F5-E F12-S

T6 Hood Mark Name 6 F6-E F13-S

T7 Hood Mark Name 7 F7-E F13-S

T8 Hood Mark Name 8 F8-E F14-S

T9 Hood Mark Name 9 F9-E F14-S

T10 Hood Mark Name 10 F10-E F14-S

Vari-Flow Air Management System

8

®

Page 9

Shunt Trip - if used

• 115 VAC from Vari-Flow to shunt trip breaker coil

(provided by others) (Terminals STH, STN)

Voltage across STH, STN when in fire will be 115 VAC

Voltage across STH, STN when not in fire will be 0 VAC

STH STN

STB

Electric Gas Valve with Gas Reset - if equipped

• 115 VAC from Vari-Flow to gas solenoid

(Terminals SVH, SVN)

Voltage across SVH, SVN when in fire will be 0 VAC

Voltage across SVH, SVN when not in fire and turn on

will be 115 VAC

SVH SVN

SV1

SV2

Spare Fire Relay Contacts - if equipped

• Power to common (Terminal C3)

• Power out, normally open, closed in fire

(Terminal NO3)

• Power out, normally closed, open in fire

(Terminal NC3)

• Power to common (Terminal C4)

• Power out, normally open, closed in fire

(Terminal NO4)

• Power out, normally closed, open in fire

(Terminals NC4)

(Can be used for shunt trip, alarms, etc.)

C3

A

B

NO3

NC3

121411

R6

A

B

C4

NO4

NC4

222421

R6

High Temperature Alarm Contacts - if equipped

• Power to common (Terminal HT-C)

• Power out, normally closed, open in high

temperature alarm (Terminal HT-NC)

• Power out, normally open, closed in high

temperature alarm (Terminal HT-NO)

(Can be used for shunt trip, alarms, etc.)

HT-C

A

B

A: Closed with power at H & N and high temperature

alarm inactive, closed with no power

B: Open with power at H & N and high temperature

alarm active, open with no power

HT-NC

HT-NO

222421

R13

Airflow Proving Switch(es) (provided by others) - if

equipped

• Common and normally open from supply fan 1 air

proving switch to Vari-Flow (Terminals AP-1A, AP-1B)

• Common and normally open from supply fan 2 air

proving switch to Vari-Flow (Terminals AP-2A, AP-2B)

• Common and normally open from supply fan 3 air

proving switch to Vari-Flow (Terminals AP-3A, AP-3B)

• Common and normally open from supply fan 4 air

proving switch to Vari-Flow (Terminals AP-4A, AP-4B)

NOTE: Airflow proving switch(es) are not provided with

the Vari-Flow system.

AP-1A AP-1B

AP-2A AP-2B

AP-3A AP-3B

AP-4A AP-4B

AIR PROVING SUPPLY FAN 1

AIR PROVING SUPPLY FAN 2

AIR PROVING SUPPLY FAN 3

AIR PROVING SUPPLY FAN 4

A: Open with power at H & N and fire system armed closed on

fire or no power

B: Closed with power at H & N and fire system armed open on

fire or no power

®

Wash Interface - if equipped

• Wash input from waterwash control panel (WWCP) to

Vari-Flow (Terminals WI-1A, WI-1B)

• Wash output from Vari-Flow to Grease Grabber H

O

2

or WWCP (Terminals WO-1A, WO-1B)

• Low detergent input from Grease Grabber H

O or

2

WWCP to Vari-Flow (Terminals WD-1A, WD-1B)

WASH FAN ENABLE/DISABLE

WI-1A WI-1B

WD-1A WD-1B

WO-1A

WO-1B

WASH DETERGENT

WASH OUTPUT

Vari-Flow Air Management System

9

Page 10

Vari-Flow Connection Checklist

Power for Vari-Flow Cabinet

Connect 115 VAC power for controls (Terminals H, N)

Connect 115 VAC power for hood lights, one per light

circuit (Terminals H1, N1 | H2, N2 | H3, N3 | H4, N4)

Connect 115 VAC power to lights, one per light circuit

(Terminals B1, W1 | B2, W2 | B3, W3 | B4, W4)

Power to Variable Frequency Drives (VFD)*

Line power to VFD input, bottom left of VFD

(Terminals L1, L2, L3)

Load power from VFD output, bottom right of VFD

(Terminals T1, T2, T3)

Vari-Green® Fan Wiring* - if equipped

24 VAC from Vari-Flow to Vari-Green motor control wire,

black (Terminal E__-24)

0-10 VDC Speed Reference from Vari-Flow to Vari-Green

motor control wire, red (Terminal E__S+)

Common from Vari-Flow to Vari-Green motor control wire,

white (Terminal E__S-)

VFD Provided by Others, Control Wiring* - if equipped

Fault command from Vari-Flow to VFD provided by others

(Terminal E__-FA, E__-FB)

Run command from Vari-Flow to VFD provided by others

(Terminal E__-RA, E__RB)

Speed reference from Vari-Flow to VFD provided by others

(Terminal E__S+, E__S-)

Line power to VFD

Load power from VFD to fan

Make-Up Air VFD in Vari-Flow Wiring* - if equipped

24 VAC run command from Vari-Flow to make-up air unit

(Terminals S__-42, S__-43)

Tempering status from Vari-Flow to make-up air unit

(Terminals S__-44, S__-45)

Line power to VFD input, bottom left of VFD

(Terminals L1, L2, L3)

Load power from VFD output, bottom right of VFD to make-

up air disconnect (Terminals T1, T2, T3)

Make-Up Air VFD in Make-Up Air Wiring* - if equipped

24 VAC run command from Vari-Flow to make-up air unit

(Terminals S__-42, S__-43)

Tempering status from Vari-Flow to make-up air unit

(Terminals S__-44, S__-45)

0-10 VDC speed reference from Vari-Flow to make-up air

unit (Terminals S__-46, S__-47)

Auto Tempering - if equipped

Auto Heat/Cool enable

(Terminals S1-R, S1-W1, S1-Y1)

Fire System Microswitch

Fire system microswitch common to Vari-Flow (Terminal C1)

Fire system microswitch normally closed contact to

Vari-Flow (Terminal NC1)

* Wiring repeated based on the number of

fans of that type. This is based on the job

specific Vari-Flow wiring diagram.

Resistive Temperature Sensors* - installed in hood

Temperature Sensor T1 (Terminals T1-A, T1-B)

If more than one temperature sensor is used, wire the

following if applicable:

Temperature Sensor T2 (Terminals T2-A, T2-B)

Temperature Sensor T3 (Terminals T3-A, T3-B)

Temperature Sensor T4 (Terminals T4-A, T4-B)

Temperature Sensor T5 (Terminals T5-A, T5-B)

Temperature Sensor T6 (Terminals T6-A, T6-B)

Temperature Sensor T7 (Terminals T7-A, T7-B)

Temperature Sensor T8 (Terminals T8-A, T8-B)

Temperature Sensor T9 (Terminals T9-A, T9-B)

Temperature Sensor T10 (Terminals T10-A, T10-B)

Keypad - if equipped

Connect provided RJ25 cable from back of keypad to

CAREL® PCO5+ (Terminal J10).

Touch Screen - if equipped

Connect provided 2-wire cable from Vari-Flow

(Terminals 24H, 24C) to touch screen (Terminals G, GO)

Connect provided 3-wire cable from Vari-Flow

(Terminals -, +, GND) to touch screen (Terminals -, +, GND)

Remote Enable- if used

Connect remote enable common and normally open from

BMS to Vari-Flow (Terminals RE-1A, RE-1B)

Shunt Trip - if used

115 VAC from Vari-Flow to shunt trip breaker coil (provided

by others) (Terminals STH, STN)

Electric Gas Valve with Gas Reset - if equipped

115 VAC from Vari-Flow to gas solenoid

(Terminals SVH, SVN)

Spare Fire Relay Contacts - if equipped

Power to common (Terminal C3)

Power out, normally open, closed in fire (Terminal NO3)

Power out, normally closed, open in fire (Terminal NC3)

Power to common (Terminal C4)

Power out, normally open, closed in fire (Terminal NO4)

Power out, normally closed, open in fire (Terminal NC4)

High Temperature Alarm Contacts - if equipped

Power to common (Terminals HT-C)

Power out, normally closed, open in high temperature alarm

(Terminal HT-NC)

Power out, normally open, closed in high temperature alarm

(Terminal HT-NO)

Air Proving Switch(es) (provided by others) - if equipped

Common and normally open from supply fan 1 air proving

switch to Vari-Flow (Terminals AP-1A, AP-1B)

Common and normally open from supply fan 2 air proving

switch to Vari-Flow (Terminals AP-2A, AP-2B)

Common and normally open from supply fan 3 air proving

switch to Vari-Flow (Terminals AP-3A, AP-3B)

Common and normally open from supply fan 4 air proving

switch to Vari-Flow (Terminals AP-4A, AP-4B)

Wash Interface - if equipped

Wash input from waterwash control panel (WWCP) to

Vari-Flow (Terminals WI-1A, WI-1B)

Wash output from Vari-Flow to Grease Grabber H

O or

2

WWCP (Terminals WO-1A, WO-1B)

Low detergent input from Grease Grabber H

O or WWCP to

2

Vari-Flow (Terminals WD-1A, WD-1B)

Vari-Flow Air Management System

10

®

Page 11

Sequence of Operation

Normal Operation

1. Press the fans on/off button on the Vari-Flow keypad

or touch screen to turn the fans on (manual mode).

a. Vari-Flow will turn on all exhaust and supply fans.

b. The Vari-Flow system starts the fans at idle

speed and automatically adjusts exhaust fan

speeds between the low speed setpoint (50%

default) and high speed setpoint (100% default)

based on actual cooking loads as sensed by

the temperature sensors mounted in the hood

capture area. This is determined by the low

temperature setpoint (90°F default) and high

temperature setpoint (115°F default).

c. The Vari-Flow system adjusts the supply speed

based on a weighted average of the exhaust

fan speed. *If static pressure sensor is used for

supply airflow control it will adjust the supply

speed based on static pressure.

2. Press the fans button on the Vari-Flow keypad or

touch screen again to turn off the fans.

a. The Vari-Flow system may go into auto mode if

conditions 3.a-3.c are met.

3. Temperature interlock mode (auto mode).

a. If the temperature in the hood goes above the

temperature interlock on setpoint (115°F default)

and the fans are currently off, the Vari-Flow will

automatically turn on the associated exhaust

and/or supply fans.

b. If the temperature in the hood goes below the

temperature interlock off setpoint (90°F default)

and the fans are not currently turned on manually

the fans will turn off after the temperature

interlock off delay time setpoint (10 minute

default).

c. If the fans were turned on manually and the

user attempts to turn off the fans with the hood

temperature not meeting condition b the fan(s)

will remain on until such conditions are met.

4. With the fan(s) on via manual or auto mode, the

100% override button will force the exhaust fan(s)

that are currently on to full speed for the 100%

override off delay setpoint. The supply fan will adjust

speed the same as 1.c.

5. Pressing the 100% override button on the Vari-Flow

keypad or touch screen again will turn the 100%

override off and return the fans to the speed as

discussed in 1.b.

6. Pressing the hood lights on/off button on the VariFlow keypad or touch screen will turn on the hood

lights.

7. Pressing the hood lights on/off button on the VariFlow keypad/touch screen again will turn off the

hood lights.

Fire Operation:

1. With the fire system microswitch wired to terminal

C1 and NC1 and the fire system in a fire state, the

following will occur:

a. System fault will appear on keypad or touch

screen.

b. Vari-Flow will force the exhaust fan(s) to full

speed.

c. Vari-Flow will force the supply fan(s) off.

d. Vari-Flow will send 115 VAC signal to shunt trip

breaker coil (breaker provided by others).

e. Vari-Flow will force the lights off (if selected with

lights out in fire).

f. Vari-Flow will force the electric gas valve off (if

selected with gas valve reset option).

Fault Operation:

1. Temperature sensor fault.

a. System fault will appear on keypad or touch

screen.

b. Associated fan(s) will be turned on and forced to

full speed until fault is rectified.

2. Exhaust VFD fault.

a. System fault will appear on keypad or touch

screen.

b. All fans will be turned on and forced to full speed.

It will remain this way until the fault is rectified.

3. Supply VFD fault.

a. System fault will appear on keypad or touch

screen.

b. All fans will be turned on and forced to full

speed (for the event that if the fault clears it will

automatically run the fans at full speed). It will

remain this way until the fault is rectified.

4. Supply airflow proving fault - if equipped.

a. System fault will appear on keypad or touch

screen.

b. Exhaust fans will not turn on until supply airflow

has been proven. It will remain this way until the

fault is rectified.

5. Pressure sensor fault - if equipped.

a. System fault will appear on keypad or touch

screen.

b. Supply fan speed will automatically be controlled

via weighted average until the fault is rectified.

6. High temperature alarm - if equipped.

a. System fault will appear on keypad or touch

screen.

b. Vari-Flow will send 115 VAC signal to shunt trip

breaker coil (breaker provided by others).

c. Vari-Flow will force the electric gas valve off (if

selected with gas valve reset option).

®

Vari-Flow Air Management System

11

Page 12

System Optimization

Low Temperature Set Point (90°F default)

Record the kitchen ambient temperature ___________

Set the low temperature set point 5°F above the

ambient kitchen temperature

Setting the Low Temperature Set Point

NOTE: If the system is provided with a keypad, press

the Prg button (

menu.

1. Go to Setpoints menu.

2. Go to Exhaust Fan Setup on page 16.

3. Adjust the Low Temp Setpoint to the previously

recorded value.

High Temperature Set Point (115°F default)

1. Turn the fans on by pressing the ‘FAN’ button on the

keypad.

2. Turn on all cooking appliances and allow them to

reach normal cooking temperatures.

3. Record the temperature in the hood by looking at the

temperature in the main menu. __________

4. Set the high temperature set point 5°F below the

previously recorded temperature.

Setting the High Temperature Set Point

NOTE: If the system is provided with a keypad press

the Prg button (

menu.

1. Go to Setpoints menu.

2. Go to Exhaust Fan Setup on page 16.

3. Adjust the High Temp Setpoint to the previously

recorded value.

4. Press ESC until you reach the keypad indicators on

the LCD screen.

) for 5 seconds to enter the main

) for 5 seconds to enter the main

Vari-Flow Air Management System

12

®

Page 13

Controller Setup and Tutorial

When the user interface is a keypad, the user will need

to press the

When the user interface is a touch screen, the user

will see the main menu without having to press the

button.

Within the programmable logic controller, factory set

points can be modified to configure the system for

specific functions if necessary. All parameters are

shown in this section.

button to enter the main menu.

Keypad Navigation

Escape Allows the user to exit the current menu, jumping to the Main Menu.

Some of the menus require the user to enter a password

in order to enter the menu. The service password is

1000 and is entered by pressing the

The DDC controller is located in the unit control panel.

The face of the controller has six buttons, allowing the

user to view unit conditions and alter parameters. The

DDC controller is pre-programmed with easy to use

menus.

To change the display contrast, hold the Enter and

Escape button while pressing the up and down arrows.

A keypad also connects via the J10 port. A RJ25 cable

is needed.

A complete listing of all settings within the Controller

U1 are provided in this Installation, Operation and

Maintenance Manual.

and buttons.

Up | Down

!

Ì

Exhaust Fan 1 Setup

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

Exhaust Fan 1 Setup

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

Alarm

Enter

Program Pressing the Program button allows the user to enter the Main Program Menu.

The arrow buttons allow the user to scroll through different screens and adjust

parameters.

Button will blink red, indicating an alarm condition. Press to review current alarms. To

review previous alarms, access the DATA LOGGER through the main menu.

A. In screens with adjustable parameters, pressing the Enter button moves the cursor

from the upper left corner of the screen to the parameter. The arrow buttons can then

be used to adjust the parameter.

B. To move to the next parameter on the same screen, press the Enter button.

C. To save the change, press the Enter button until the cursor moves back to the upper

left corner of the screen.

Example of Parameter Adjustment

The cursor always begins in the upper left corner of the display and will be

blinking. Press the button to move the cursor down for parameter adjustment.

Once the cursor has reached the desired parameter, press the buttons to

adjust the value.

Exhaust Fan 1 Setup

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

®

When satisfied with the adjustment, press the button to save the parameter.

When finished, make certain the cursor is in the upper left corner. If the

cursor is not in the upper left corner, the changes will not be saved. The

cursor must be in the upper left corner to enable screen advancement.

Vari-Flow Air Management System

13

Page 14

Main Menu Overview

The Vari-Flow controller will revert to a default main menu loop. This loop includes several screens to view the

operating conditions of the unit. Scroll through the menu screens by using the

line border are dependent upon an optional accessory and may not always appear.

buttons. Screens with a dashed

TIME DATE UNIT##

Hood 1: ON Speed

XXX.X°F XXX.X%

*Exp: Offline

VFD: Offline

Status: UNIT ON

TIME DATE UNIT##

Supply 1: ON Speed

XXX.X% XXX.X%

*Exp: Offline

VFD: Offline

Status: UNIT ON

If an alarm occurs, the

Alarms

Press DOWN to review

current alarm(s).

Press ESC to exit.

Press ALARM to reset.

EXHAUST FAN #1 S TATU S:

The temperature on this screen displays real-time conditions from the sensors

located in the hood. The speed on this screen displays the real-time conditions of

the fan.

The “*Exp: Offline” only appears if the system is equipped with an expansion

controller, but the DDC controller sees it as off the network. The “VFD: Offline”

only appears if the DDC controller is not connected to the drive.

If there are additional exhaust fans, the display on the screen will be the same

besides the fan number.

S

UPPLY FAN # 1 STATUS. (IF EQUIPPED)

If equipped with supply fan, this screen will display the airflow percentage (left)

and the supply fan speed signal.

If there are additional supply fans the display on the screen will be the same

besides the fan number.

Example of Alarms

button will glow red on the controller and the remote display (if installed).

To view alarm, press the button once. This will display the most recent alarm.

Press the

the cause of the alarm has not been fixed. Press the buttons to view any

additional occurring alarms.

button again to reset the alarm. If the alarm cannot be cleared,

This is an example of a hood temperature sensor failure.

Hood Temperature

Sensor B01 Failure

Alarms

No active alarm

Press ENTER

to DATA LOGGER

This screen appears if there are no active alarms.

To view all saved alarms, press the

button to enter the DATA LOGGER. For

more information, see the Data Logger menu.

Type List of Possible Alarms Description Type

Exhaust VFD Fault Failure of an exhaust VFD Alarm only

Supply VFD Fault Failure of a supply VFD Alarm only

Hood Temperature Sensor Failure Failure of a hood temperature sensor Alarm only

Hood High Temperature Alarm Indicates a high hood temperature Alarm only

Pressure Sensor Failure Indicates a pressure that is out of range Alarm only

Supply Airflow Indicates a loss of airflow in the supply fan Alarm only

Fire Alarm Indicates a fire Alarm only

VFD Communication Alarm Indicates a loss of communication to the VFD failure Alarm only

BMS Communication Alarm Indicates a loss of communication to the BMS Alarm only

Vari-Flow Air Management System

14

®

Page 15

Menus

The controller is equipped with several menus to help guide users with altering program parameters. The following

menus can be accessed by pressing the

A. On/Off Unit

The On/Off Unit menu allows the user to view the detailed On/Off status of the

controller.

button. To enter the desired menu, press the

button.

On/Off Unit

Unit address: 1

Power By Display: ON

Status: UNIT ON

On/Off Exhaust

1: ON

2: ON

On/Off Light Circuits

1: ON

2: ON

3: ON

4: ON

Lights Out in Fire: ON

Status: The controller may be in following On/Off states:

a. Unit On: Unit is ON, functioning normally.

b. Off by ALARM: Unit is OFF due to an alarm. View alarms by pressing

ALARM button.

c. Off by PLAN: Unit is OFF by pLAN network.

d. Off by BMS: Unit is OFF by BMS command

e. Off by SCHEDULER: Unit is OFF by internal Clock/Scheduler.

f. Off by DIGITAL INPUT(ID4): Unit is OFF by digital input 4 (ID4).

g. Off by KEYPAD: Unit is commanded OFF by this screen.

THIS SCREEN DISPLAYS THE STATE OF THE EXHAUST FANS AND ALLOWS THE USER TO

TURN THE FAN(S) ON/OFF INDEPENDENTLY.

Exhaust: The number of fans listed is based on the number of fans for the specific

job.

THIS SCREEN DISPLAYS THE STATE OF LIGHTS AND ALLOWS THE USER TO TURN THE

LIGHT CIRCUITS ON/OFF INDEPENDENTLY.

Lights: The number of light circuits listed is based on the number of light circuits

for the specific job.

Note: If “Lights Out in Fire” is set to ON, hood lights will shut off in a fire state.

On/Off Options

Gas Valve: OFF

Wash Setup

Wash: OFF

Time: 60m

Override

Start: OFF

Full Speed: OFF

Auto Tempering

Auto Tempering: OFF

THIS SCREEN DISPLAYS THE STATE OF THE ELECTRIC GAS VALVE AND ALLOWS THE USER

TO TURN THE GAS VALVE ON/OFF. (IF EQUIPPED)

Note: In the event of a fire, the gas valve will turn off automatically. You are

required to manually turn it back on after the fire system has been reset.

THIS SCREEN DISPLAYS THE STATE OF THE WASH BUTTON AND ALLOWS THE USER TO

START A WASH.

Time: The length of time the Vari-Flow is in a wash state and will not allow the

fans to run.

THIS SCREEN DISPLAYS THE STATE OF THE FAN 100% BUTTON AND ALLOWS THE USER

TO START THE 100% OVERRIDE.

Note: When start is changed to ON it will immediately turn back to off, the full

speed status will change to ON until the override time is met or the 100% button is

pressed again. This page is used for a status of the “Fan 100” button.

THIS SCREEN DISPLAYS THE STATE OF THE AUTO TEMPERING BUTTON AND ALLOWS THE

USER TO TURN AUTO TEMPERING ON/OFF.

Auto Tempering: Enables/Disables the make-up air from automatically heating/

cooling based on the inlet air sensor.

®

Vari-Flow Air Management System

15

Page 16

B. Setpoint

The Setpoint menu allows the user to view and adjust temperature related

parameters.

Temperature Interlock

Enable: ON

Temp On: 115.0°F

Temp Off: 90.0°F

Delay Off: 600s

Exhaust Fan 1 Setup

Temp Speed

Low: 90.0°F 50.0%

High: 115.0°F 100.0%

CFM: XXXX

THIS SCREEN DISPLAYS THE CURRENT SET POINTS FOR THE TEMPERATURE INTERLOCK

FEATURE.

The user can use the default exhaust fan temperature set points or configure them

using the system optimization process. This option satisfies IMC 507.2.1.1

(Fan(s) must automatically activate when cooking operations occur.)

• Temp On Set Point: The temperature at which the fan(s) automatically turn on

based on the temperature of the associated hood. The default is 115°F and is

adjustable.

• Temp Off Set Point: The temperature at which the fan(s) automatically turn

off based on the temperature of the associated hood. It must also satisfy the

requirement of the Minimum Off Delay Set Point. The default is 90°F and is

adjustable.

• Off Delay Set Point: The amount of time the temperature must remain

below the Minimum Off Set point before the fan(s) will turn off. The default is

10minutes and is adjustable.

THIS SCREEN DISPLAYS EXHAUST FAN SETUP.

Low Temp: Temperature that the fan will start to increase in speed from the low

speed set point.

High Temp: Temperature that the fan will be at the high speed set point.

Low Speed: Minimum speed of the fan.

High Speed: Maximum speed of the fan.

Depending on the number of exhaust fans, other exhaust fan setup pages will appear.

Supply Fan 1 Setup

Design MaxSpd CFM:XXX

Min: 50.0%

Max: 100.0%

Min Tempering: 66.0%

Override

Duration: 10m

Factory Settings

Smoke Fire Stat

Exhaust Fans: 100%

High Temperature Alm

Enable: Off

Temp On: 210.0°F

Temp Off: 205.0°F

THIS SCREEN DISPLAYS THE SUPPLY FAN SETUP.

Design Max Speed: Design airflow of the supply fan.

Min: Minimum speed of the supply fan.

Max: Maximum speed of the supply fan.

Min Tempering: Minimum speed of the supply fan when it is tempering.

Depending on the number of supply fans, other supply fan setup pages will appear.

THESE PARAMETERS DICTATE THE AMOUNT TIME THE THAT THE FAN RUNS AT FULL

SPEED WHEN THE “FAN 100%” BUTTON IS PRESSED.

THIS SCREEN DISPLAYS THE SETTING FOR THE EXHAUST FANS IN THE EVENT OF A FIRE.

Once the fire inspection has been completed, this should not be changed.

THIS SCREEN DISPLAYS THE HIGH TEMPERATURE ALARM SETTINGS.

When enabled and the temperature reaches the Temp On set point the shunt trip

output will become active, forcing the electric equipment off. If there is an electric

gas valve and it is wired into the VAV system it will also turn that off. Once the

temperature is below the Temp Off set point the shunt trip output and gas valve

will return to normal state.

Remember that the shunt trip breaker will have to be manually reset as well as the

electric gas valve.

Vari-Flow Air Management System

16

®

Page 17

C. Clock/Scheduler

The Clock/Scheduler menu allows the user to view and alter the time and date.

The user can also add up to seven schedules for occupancy requirements.

Clock

Date: MM/DD/YY

Hour: 15:30

Day: Monday

Clock

DST: Enable

Transition time: 60min

Start: LAST SUNDAY

in MARCH at 2.00

End: LAST SUNDAY

in OCTOBER at 3.00

D. Input/Output

Analog Input

Temperature 1

Input B001: 95.0°F

THE CLOCK SCREEN ALLOWS THE USER TO ADJUST THE TIME AND DATE.

THIS SCREEN ALLOWS THE USER TO ADJUST DAYLIGHT SAVINGS TIME SETTINGS.

The Daylight Savings time feature can be adjusted to meet the current daylight

savings time requirements.

The Input/Output menu allows the user to quickly view the status of the controller

inputs and outputs.

To manually control I/O values, go to the Service menu > Manual management.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all of the inputs and outputs shown. See unit wiring

diagram for your specific configuration.

Digital Input

Remote On/Off

DI 1 STATUS: Closed

Relay Output

Relay 1 STATUS: OFF

Analog Output

Output: 5.00vdc

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all of the inputs and outputs shown. See unit wiring

diagram for your specific configuration.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all of the inputs and outputs shown. See unit wiring

diagram for your specific configuration.

Similar screens appear for all controller inputs and outputs.

Your controller may not utilize all of the inputs and outputs shown. See unit wiring

diagram for your specific configuration.

®

Vari-Flow Air Management System

17

Page 18

G. Service

The Service menu allows the user to access several sub-menus regarding controller

information, controller overrides, operating hours, BMS configuration, I/O manual

management and Probe Adjustment. The user can also change the default Service

Password (1000) by accessing the Service Settings sub-menu. By accessing the

BMS Config sub-menu, the user can adjust BMS protocol settings. (BACnet®,

LonWorks®, Modbus)

G. Service

b. Information

Information

Greenheck Fan

Code:

Ver.: 1.00 03/18/13

Manual: VARI-FLOW_IOM

Bios: 6.00 04/01/02

Boot: 4.00 04/01/02

G. Service

c. VFD Status

ENTERING THE INFORMATION SUB-MENU WILL DISPLAY INFORMATION ABOUT THE

CONTROLLER AND THE PROGRAM LOADED ON THE CONTROLLER.

Manual: Reference this Installation, Operation and Maintenance Manual available

at www.greenheck.com.

The VFD Status menu is for commissioning and troubleshooting. This menu

allows the user to view the Yaskawa VFD current status. If further control is

required, the user can also manually control the controller inputs and outputs. To

access the VFD Status sub-menu, enter the service password (Default=1000).

YASKAWA V1000 1

Speed: 0.0Hz

Ref Frequency: 0.0Hz

Volts out: 0.0V

Rated Current: 0.0A

Amps out: 0.0A

Power out: 0.0kW

THIS SCREEN ALLOWS THE USER TO VIEW THE CURRENT STATUS OF THE YASKAWA

VFD. THERE WILL BE ADDITIONAL VFD SCREENS BASED ON THE NUMBER OF EXHAUST

AND SUPPLY VFDS PROVIDED WITH THE SYSTEM.

Speed: This is the actual speed of the Yaskawa VFD in Hertz.

Ref Frequency: This is the reference speed signal sent to it from the Vari-Flow

Controls.

Volts out: The voltage on the output side of the Yaskawa VFD .

Rated Current: This is the maximum rated current of the Yaskawa VFD.

Amps out: This is the current amperage that the Yaskawa VFD is providing to the

motor.

Power out: This is the current power (kW) that the Yaskawa VFD is providing to

the motor.

G. Service

e. BMS Config

BMS Configuration

Protocol: BACnet MSTP

BACnet Plugin? YES

MODBUS SETUP

Address: 1

Baudrate 9600

Vari-Flow Air Management System

18

The BMS Config menu allows the user to view and alter BMS protocol settings.

If the BMS protocol is BACnet or Modbus, additional screens allow further

configuration. See below for details. To access the BMS Config sub-menu, enter

the service password (Default=1000).

THIS SCREEN ALLOWS THE USER TO SELECT THE BMS PROTOCOL. ALL BMS

PROTOCOLS REQUIRE A COMMUNICATIONS CARD INSTALLED IN THE SERIAL CARD

PORT, LOCATED ON THE FACE OF THE CONTROLLER.

If the protocol is BACnet MSTP or BACnet IP/Eth, the user can change common

BACnet parameters via the controller. The BACnet Plugin must be set to YES.

THIS SCREEN ALLOWS THE USER TO ADJUST MODBUS PARAMETE RS.

This screen only appears if the selected BMS protocol is set to Modbus.

The address is the Modbus address of the card installed in the SERIAL CARD port

located on the face of the controller. (Factory Default Address = 1).

The Baud Rate should be set to the BMS baud rate. (Factory Default Baud Rate

is 9600).

®

Page 19

MSTP SETUP

Instance: 77000

Baudrate 38400

MAC Addr: 0

MaxMasters: 127

MaxInfoFrames: 20

THIS SCREEN ALLOWS THE USER TO ADJUST BACNET MSTP PARAMETERS.

This screen only appears if the selected BMS protocol is set to BACnet MSTP and

BACnet Plugin = YES.

If a BACnet MSTP card has been installed, the default parameters can be changed

via the controller display. Factory settings are shown in the screen to the left.

To view current parameters:

BACnet Read/Write

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view BACnet Read/Write screen.

Function: Read

Update? Yes

*Cycle unit power to confirm

write command.

3. Change Function to Read and Update? to YES.

Current BACnet MSTP parameters should now be displayed in the BACnet MSTP

SETUP screen. If all values appear to be zeros, consult the factory. (Make sure you

have allowed several minutes for the controller to initialize).

Values may appear to be zero prior to setting the Function to READ.

To change BACnet MSTP parameters:

1. Power on controller and allow several minutes to initialize.

2. Go to BMS Config menu and view MSTP SETUP screen.

3. Move cursor to desired parameter by pressing the

4. Once desired parameters have been entered, go to BACnet Read/Write

5. Reboot the controller by cycling power to the unit. Allow several minutes for

6. View MSTP parameters. If changed values did not save, contact the factory.

buttons. Press

to select the parameter to change. Press the buttons to adjust the

parameter. Press to save adjusted value.

screen. Change Function to Write and Update? to YES.

the controller to initialize.

TCP/IP SETUP

Instance: 77000

IP set by: DHCP

IP: 128.2.104.134

Subnet: 255.255.000.000

Gatewy: 128.2.0.12

THIS SCREEN ALLOWS THE USER TO ADJUST BACNET IP PARAMETERS .

This screen only appears if the selected BMS protocol is set to BACnet IP/Eth and

BACnet Plugin = YES.

If a BACnet IP card has been installed, the default parameters can be changed

via the controller display. The card is in DHCP mode from the factory. Once

communication is established, the user can enter static IP parameters.

TCP/IP SETUP

To view current parameters:

1. Power on controller and allow several minutes to initialize.

DNS 1: 193.168.001.001

DNS 2: 193.168.001.001

Type: IP

2. Go to BMS Config menu and view BACnet Read/Write screen.

3. Change Function to Read and Update? to YES.

Current BACnet IP parameters should now be displayed in the BACnet TCP/IP

SETUP screen. If all values appear to be zeros, consult the factory. (Make sure you

have allowed several minutes for the controller to initialize).

*Values may appear to be zero prior to setting the Function to READ.

BACnet Read/Write

To change BACnet TCP/IP parameters:

1. Power on the controller and allow several minutes to initialize.

Function: Read

Update? Yes

*Cycle unit power to confirm

write command.

2. Go to BMS Config menu and view TCP/IP SETUP screen.

3. Move cursor to desired parameter by pressing the

4. Once desired parameters have been entered, go to BACnet Read/Write

5. Reboot the controller by cycling power to the unit. Allow several minutes for

6. View TCP/IP parameters. If changed values did not save, contact the factory.

buttons. Press

to select the parameter to change. Press the buttons to adjust the

parameter. Press to save adjusted value.

screen. Change Function to Write and Update? to YES.

the controller to initialize.

®

Vari-Flow Air Management System

19

Page 20

G. Service

d. Service Settings

a. Balancing

b. Probe adjustment

c. Thermoregulation

d. User Save

The Service Settings menu allows the user to change the default Service

Password (1000), save and restore default parameters, and adjust probe values.

Balancing

Exhaust Fan 1

Balance: OFF

Minimum: 50.0

Maximum: 100.0

Analog Input

Input B02

Offset: 0.0°F

Value: 70.5°F

Exhaust Fan Setup

Minimum On: 10s

Minimum Off: 10s

Supply Fan Airflow

Delay: 15s

THIS SCREEN ALLOWS THE USER TO BALANCE THE EXHAUST AND SUPPLY FANS.

There will be additional fans listed based on the number of exhaust and supply

fans on this system.

Balance: When it is in the OFF position, fans will work in normal operation. When

set to MAX the fan will be forced to full speed. When set to MIN the fan will be

forced to minimum speed.

Minimum: Based on the setting of Balance, the user can adjust the minimum

speed to meet the requirements for the design of the system.

Maximum: Based on the setting of Balance, the user can adjust the maximum

speed to meet the requirements for the design of the system.

Make sure to return the mode of operation to OFF when balancing is

complete. If the mode of operation is left in either MIN or MAX, the fan

will not turn off.

THE PROBE ADJUSTMENT MENU ALLOWS THE USER TO CALIBRATE SENSOR PROBES

WITH AN OFFSET VALUE.

Similar screens are available for remaining sensor probes.

THIS SCREEN ALLOWS THE USER TO BALANCE THE EXHAUST FAN RUN SETTINGS.

Minimum On: Minimum amount of time the exhaust fan(s) will run if they are

turned on.

Minimum Off: Minimum amount of time the exhaust fan(s) will remain off if the

fans were turned off, before they can be turned on again.

Supply Fan Airflow Delay: This is only valid with the Airflow Proving option. The

amount of time that the control waits for the supply fan to prove airflow before it

goes into an airflow alarm.

User Default

Save: OFF

Restore? OFF

Enable Auto Save: ON

Alarm History Reset

This will clear the Alarm

history

Continue? OFF

Vari-Flow Air Management System

20

THIS SCREEN ALLOWS THE USER TO SAVE AND RESTORE THE DEFAULT

PARAMETE RS STORED IN MEMORY

If the user would like to save their settings, move the cursor to the SAVE position

and change to ON. This will save all of the current parameters into memory as

Service Settings. If the user would like to restore to these values at some point

in the future, moving the cursor to the RESTORE position, and selecting ON will

restore the controller to the user saved defaults

THIS SCREEN ALLOWS THE USER TO SAVE AND RESTORE THE DEFAULT

PARAMETE RS STORED IN MEMORY.

If the user would like to save their settings, move the cursor to the SAVE position

and change to ON. This will save all of the current parameters into memory as

Service Settings. If the user would like to restore to these values at some point

in the future, moving the cursor to the RESTORE position, and selecting ON will

restore the controller to the user saved defaults.

®

Page 21

G. Service

d. Manual Management

a. Analog Inputs

b. Digital Inputs

c. Relay Outputs

d. Analog Outputs

Analog Input

Temperature 1

Manual Control B001 OFF

Manual Position: 0

Value: 80.0°F

Digital Input

Remote On/Off

Manual DI 1: OFF

Manual Position: CLOSED

DI 1 Status: Closed

The Service Settings menu allows the user to change the default Service

Password (1000), save and restore default parameters, and adjust probe values.

NOTE: The manual adjustment of these input and/or outputs should only be

adjusted in the event of troubleshooting. Change parameters to the advice of

factory personnel.

THE PROBE ADJUSTMENT MENU ALLOWS THE USER TO CALIBRATE SENSOR PROBES

WITH AN OFFSET VALUE.

Manual Control: Allows the user to override the analog input for troubleshooting.

Manual Position: The value to force the input to when in an override state.

Value: The current value of the analog input.

Similar screens appear for all additional controller analog inputs.

Manual DI: Allows the user to override the digital input for troubleshooting.

Manual Position: The value to force the input to when in an override state.

Value: The current state of the digital input.

Similar screens appear for all additional controller digital inputs.

Relay Output

Manual Relay 1: OFF

Manual Position: OFF

Relay 1 Status: OFF

Analog Output

Mode: Auto

Manual Value: 0.00vdc

Output: 5.00vdc

H. Manufacturer

a. Configuration

Configuration

Temperature Units: °F

Force Clock Enable: OFF

Clock Mode: 24h

Disable Buzzer: OFF

Startup Delay: 5s

Manual Relay: Allows the user to override the digital input for troubleshooting.

Manual Position: The value to force the output to when in an override state.

Value: The current state of the relay output.

Similar screens appear for all additional controller digital inputs.

Manual Control: Allows the user to override the analog output for

troubleshooting.

Manual Value: The value to force the input to when in an override state.

Output: The current value of the analog output.

Similar screens appear for all additional controller analog inputs.

The Configuration menu allows the user to change the units, enable Scheduling,

Holidays, expansion I/O and change Field Card settings. Users are welcome to enable

Scheduling and Holidays. However, configuration changes and expansion I/O enabling

are to be done under factory advice only!

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE UNIT SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door).

Configuration

Enable Unit On/Off

By digit input: OFF

By Supervisor: OFF

By pLAN network: OFF

By Schedule: OFF

®

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE UNIT ON/OFF SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door).

Vari-Flow Air Management System

21

Page 22

Configuration

Unit Control

Custom 1: ON

Custom 2: OFF

Custom 3: OFF

Custom 4: OFF

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE CUSTOM UNIT SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

Configuration

Analog input filtering

Enable: OFF

Input 1: 19s

Input 2: 19s

Input 3: 19s

Input 4: 19s

Input 5: 19s

Factory settings

Manual Control Reset

Enable: OFF

Time: 0m

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE ANALOG INPUT SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE MANUAL CONTROL RESET

SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

Factory settings

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE EXHAUST IN FIRE SETTINGS.

These settings have been set from the factory to operate the components selected

Smoke Fire Stat

Exhaust Fans: 100%

Scheduler

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE SCHEDULER SETTINGS.

These settings have been set from the factory to operate the components selected

Number of Schedules: 0

Optimized Start: NO

Set 1 Adjust: NO

Set 2 Adjust: NO

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door).

Holidays

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE SCHEDULER SETTINGS.

These settings have been set from the factory to operate the components selected

Number: 0

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

Factory settings

Modbus Master

Port: FieldBus 2

BaudRate: 19200

Data: 8,None,2

MODULATING SETUP

Supply Fan

Cntrl: REV PID

Band: 50.0

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE VFD COMMUNICATION

SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

THIS SCREEN DISPLAYS AND ALLOWS ADJUSTMENT OF THE SUPPLY FAN SETTINGS.

These settings have been set from the factory to operate the components selected

with the control system. When troubleshooting, refer to the wiring diagram sent

with the unit (located on the control center door). These items should not be

changed without advice from factory personnel.

Output Period: 500mS

Vari-Flow Air Management System

22

®

Page 23

H. Manufacturer

b. I/O Configuration

The I/O Configuration menu allows adjustment of all controller inputs and outputs.

This menu is similar to the Probe Adjustment menu, except that it additionally allows

adjustment of the factory default ‘normal’ states of the digital inputs and the direction

of the analog outputs. Additionally, it allows adjustment of the physical location

of each I/O. ADJUSTMENT OF I/O PHYSICAL LOCATION MUST ONLY BE DONE

UNDER FACTORY GUIDANCE! IMPROPER ADJUSTMENT MAY RESULT IN SYSTEM

Analog Input

Temperature 1

En: ON Ch: 1

Normal PT1000

Offset: 0.0°F

Value: 70.5°F

DAMAGE!

This is an example of an analog input configuration screen.

In the I/O configuration screens, the user can alter the physical location and type

of each point.

Similar configuration screens appear for the remaining I/O.

Analog Input

Temperature 1

En: ON Ch: 1

Normal PT1000

Offset: 0.0°F

Value: 70.5°F

H. Manufacturer

d. Initialization

Initialization

DEFAULT INSTALLATION

Erase user settings and install

global default values: NO

Factor y Save

Digital Input

Remote On/Off

Enable; ON Channel: 1

Action: CLOSED

Delay: 0s

Status: Open

The Initialization Menu allows the user to save and restore the controllers default

parameters. The controller can be restored with either the Manufacturer’s default

parameters from shipment, or an unconfigured factory default.

THIS SCREEN ALLOWS THE USER TO RESTORE BACK TO THE ORIGINAL FACTORY

DEFAULT PARAMETE RS.

Restoring to the original default parameters will result in a non-customized

controller. The user should not restore to these settings unless instructed by the

factory.

THIS SCREEN ALLOWS THE USER TO SAVE AND RESTORE THE FACTORY DEFAULT

PARAMETE RS STORED IN MEMORY.

The Factory Settings include the Factory default parameters and the unit setup

Save? OFF

Restore? OFF

Auto Restore? No

code. If the user would like to restore to these parameters, move the cursor to the

Restore position and change to ON.

Relay Output

Enable: ON

Channel: 1

Status: OFF

Analog Output Config

Enable: ON

Channel: 1

Action: DIRECT

Minimum: 0.0vdc

Maximum: 10.0vdc

User Save

Save? OFF

Restore? OFF

Auto Restore? No

Factory Delete

CLEAR ALL SAVED DATA

FACTORY+USER: OFF

Passwords

Insert new passwords

Service (PW1): 0000

Manufacturer (PW2): 0000

®

THIS SCREEN ALLOWS THE USER TO SAVE AND RESTORE THE USER PARAMETERS

STORED IN MEMORY.

The User Settings include the Factory default parameters. If the user would like to

restore to these parameters, move the cursor to the Restore position and change

to ON.

THIS SCREEN ALLOWS THE USER TO CLEAR ALL SAVED DATA.

THIS SCREEN ALLOWS THE USER TO CHANGE THE SERVICE (PW1) AND

MANUFACTURER PASSWORD (PW2).

Vari-Flow Air Management System

23

Page 24

Keypad Navigation and Information

TEMPERATURE

TEMPERATURE

TEMPERATURE

CLEAN HOOD

TEMPERATURE

INTERLOCK

INTERLOCK

INTERLOCK

INTERLOCK

AUTO TEMPERINGCLEAN HOOD

AUTO TEMPERING

FILL

FILL

DETERGENT

DETERGENT

FAN FAN 100%LIGHTS

FAN FAN 100%LIGHTS

FAN FAN 100%LIGHTS

FAN FAN 100%LIGHTS

SYSTEM

SYSTEM

SYSTEM

SYSTEM

FAULT

FAULT

FAULT

FAULT

The following information details the Daily Operations of the Vari-Flow System keypad buttons and their functions.

LIGHTS - Momentarily pressing the ‘LIGHTS’ button

will turn on all lights for the respective hood(s) attached

to the system. An indicator on the LCD display above

the button will display the status of the lights. Pressing

the ‘LIGHTS’ button again will turn off the lights for the

respective hood(s).

FANS - Momentarily pressing the ‘FAN’ button will

turn on all fan(s) (exhaust and supply where applicable)

for the respective hood(s) attached to the system. An

indicator on the LCD display above the button will

display the status of the fans. The fans will start at a

minimum speed and vary automatically based on heat

load generated by the appliances.

FAN 100% - Momentarily pressing the ‘FAN 100%’

button while the fans are on will send the speed to the

fans that are currently on to full speed for 10 minutes

(adjustable) or until the Fan 100% button is pressed

again. Pressing the Fan 100% button again will take the

fans out of 100% operation and return them to standard

CLEAN HOOD, if equipped – Momentarily pressing the

‘CLEAN HOOD’ button will turn off all fan(s) (exhaust

and supply where applicable) for the respective hood(s)

attached to the system. An indicator on the LCD display

below the button will display the status of the cleaning

function. It will start a wash procedure for the external

wash system.

TEMPERATURE INTERLOCK – If the fans were not

manually turned on by pressing the ‘FAN’ button and

the temperature in the hood(s) is above the temperature

interlock setpoint it will force the respective fan(s) on.

An indicator on the LCD display below the button will

display the status of the temperature interlock.

AUTO TEMPERING, if equipped – Momentarily

pressing the ‘AUTO TEMPERING’ button will enable the

make-up air unit to automatically temper the air based

on the outside air sensor. An indicator on the LCD

display below the button will display the status of the

Auto Tempering function.

operating conditions.

Vari-Flow Air Management System

24

®

Page 25

Touch Screen Navigation

L

ALL LIGHTS

F

ALL FANS

ON/O

AUTO

G

100%

O

CLEANHOODTEMP INTERLOCK

75

5

E

2

3

0

75

5

2

0

S

N

1

2

ALL LIGHTS

L

F

ALL FANSN/O

AUTO

G

TEMP INTERLOCK

10:11:57

:11:57

ALL LIGHTS

INDIVIDUAL

INDIVIDUA

LIGHT ON/OFF

LIGHT ON/OFF

100

100

75

50

0

25

25

0

0

ALL LIGHTS

INDIVIDUAL

INDIVIDUA

LIGHT ON/OFF

LIGHT ON/OFF

1

234

1

EXHAUST FAN

XHAUST FAN

ALL FANS

ON/OFF

FF

INDIVIDUAL

INDIVIDUAL

FAN ON/OFF

FAN ON/OF

4

OVERRIDE

TEMPERING

TEMPERIN

ALL LIGHTS ON/OFF - turns all lights on/

off.

INDIVIDUAL LIGHT ON/OFF - directs you

to the individual light control screen where

you can turn individual lights on or off.

100%

VERRIDE

AUTO

TEMP INTERLOCK

INDICATOR

NDICATOR

CLEAN

HOOD

TEMP INTERLOCK INDICATOR – if the

TEMP INTERLOCK

100

10

75

50

0

5

25

0

INDICATOR

INDICATOR

12

SUPPLY FAN

UPPLY FA

fan(s) were not turned on via the fan on/off

button(s) and the temperature in the hood

is above the temperature interlock setpoint

the TEMP INTERLOCK INDICATOR icon

will be lit up. The fan(s) will continue to run until it

is below the setpoint for the amount of time in the

temperature interlock settings.

ALL FANS

ON/OFF

INDIVIDUAL

INDIVIDUAL

FAN ON/OFF

FAN ON/OF

ALL FANS ON/OFF - turns all fans on/off.

FF

INDIVIDUAL FAN ON/OFF - provides

control of each individual fan allowing you

to turn individual fans on/off.

100%

OVERRIDE

VERRIDE

100% OVERRIDE - forces the fans that

are currently on to full speed. The fans will

return to the speed determined by the hood

temperature after the timer has expired

(preset to 10 minutes). Pressing the icon

when 100% OVERRIDE is on will also return the fans to

the speed determined by the hood temperature.

®

AUTO

TEMPERING

TEMPERIN

AUTO TEMPERING (if equipped) –

enables/disables the make up air unit to

automatically heat and/or cool based on

the inlet air temperature. When it is enabled

the make-up air until will heat and/or cool