Greenheck VAB Installation Manual

Document 452954

Vane Axial

®

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Models VAB and VABS - Belt Drive

Models VAD and VADS - Direct Drive

Table of Contents

General Safety Information ....................1

General Information

Receiving ...............................2

Unpacking ...............................2

Handling ................................2

Storage - Indoor / Outdoor ..................2

Inspection and Maintenance during Storage . . 2-3

Installation .................................3

Electrical Connection ........................3

Controlling Vibration

Vibration Isolators .........................4

Flexible Duct Connectors ...................4

Effects of Installation on Performance ......... 4-5

Unit Start-Up ..............................6

Routine Maintenance

Motors ..................................6

Variable Frequency Drives ..................6

Shaft Bearings ...........................7

V-Belt Drives

Belt Tension .............................7

V-Belt Replacement .......................8

Blade Pitch Adjustment for Belt and Direct Drive . . 8

Troubleshooting ......................... 9-10

Maintenance Log ..........................11

Our Commitment ................... Backcover

General Safety Information

Only qualified personnel should install this fan. Personnel

should have a clear understanding of these instructions

and should be aware of general safety precautions.

Improper installation can result in electric shock, possible

injury due to coming in contact with moving parts, as

well as other potential hazards. Other considerations

may be required if high winds or seismic activity are

present. If more information is needed, contact a licensed

professional engineer before moving forward.

1. Follow all local electrical and safety codes, as well as

the National Electrical Code (NEC), the National Fire

Protection Agency (NFPA), where applicable. Follow

the Canadian Electrical Code (CEC) in Canada.

2. The rotation of the impeller is critical. It must be free

to rotate without striking or rubbing any stationary

objects.

3. Motor must be securely and adequately grounded.

4. Do not spin fan impeller faster than max cataloged

fan rpm. Adjustments to fan speed significantly

effects motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

6. Verify that the power source is compatible with the

equipment.

7. Never open access doors to a duct while the fan is

running.

DANGER

Always disconnect power before working on or near a

fan. Lock and tag the disconnect switch or breaker to

prevent accidental power up.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

®

Vane Axial Fans

1

Receiving

Upon receiving the product check to make sure all items

are accounted for by referencing the bill of lading to

ensure all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notification on the delivery receipt acknowledging any

damage to the product. All damage should be noted on

all the copies of the bill of lading which is countersigned

by the delivering carrier. A Carrier Inspection Report

should be filled out by the carrier upon arrival and the

Traffic Department. If damaged upon arrival, file claim

with carrier. Any physical damage to the unit after

acceptance is not the responsibility of Greenheck Fan

Corporation.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Manually rotate the impeller to detect any interference

between the impeller blades and the fan housing.

Handling

The fan should not be removed from its shipping crate

before being moved to its final location.

Vane axial fans should be lifted by

installing a clevis in the top hole

of each flange (Fig. 1), or by the

wooden skid if a forklift is used.

Handle in such a manner to avoid

scratching or chipping. Special

care must be taken to avoid

causing damage from stress or shock. Damaged finish

may reduce ability of the fan to resist corrosion.

Fans should never be lifted by the fan housing, motor or

accessories.

Fig. 1

Storage

Fans are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the fan and accessories while in storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

All accessories must be stored indoors in a clean, dry

atmosphere. Belts are to be stored flat to keep them

from warping and stretching. Fans—stored indoors or

outdoors—are to be placed in a vibration-free location.

The impeller should be blocked to prevent free-spinning.

During the storage period, rotate the impeller monthly

and energize the motor every three months. If storage

will be in a clean environment and will extend beyond

three months, purge grease prior to storage and every

three months thereafter. If fan is stored in a humid, dusty

or corrosive atmosphere, purge the grease prior to

storage and monthly during the storage period.

INDOOR - The ideal environment for the storage of

fans and accessories is indoors, above grade, in a

low humidity atmosphere which is sealed to prevent

the entry of blowing dust, rain, or snow. Temperatures

should be evenly maintained between 30°F

110°F

(43°C)

(wide temperature swings may cause

condensation and “sweating” of metal parts). All

accessories must be stored indoors in a clean, dry

atmosphere.

Remove any accumulations of dirt, water, ice or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts, allow cold parts to reach

room temperature. To dry parts and packages use a

portable electric heater to get rid of any moisture build

up. Leave coverings loose to permit air circulation and

to allow for periodic inspection.

The unit should be stored at least 3½ in. (89 mm) off the

floor on wooden blocks covered with moisture proof

paper or polyethylene sheathing. Aisles between parts

and along all walls should be provided to permit air

circulation and space for inspection.

(-1°C)

and

OUTDOOR - Roads or aisles for portable cranes and

hauling equipment are needed.

The fan should be placed on a level surface to prevent

water from leaking into the fan. The fan should be

elevated on an adequate number of wooden blocks so

that it is above water and snow levels and has enough

blocking to prevent it from settling into soft ground.

Locate parts far enough apart to permit air circulation,

sunlight, and space for periodic inspection. To minimize

water accumulation, place all fan parts on blocking

supports so that rain water will run off.

Do not cover parts with plastic film or tarps as these

cause condensation of moisture from the air passing

through heating and cooling cycles.

Improper storage which results in damage to the fan will

void the warranty.

Inspection & Maintenance during Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. At each

inspection, rotate the impeller by hand ten to fifteen

revolutions to distribute lubricant on motor. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust occur.

Immediately remove the original rust preventive coating

with petroleum solvent and clean with lint-free cloths. Polish

any remaining rust from surface with crocus cloth or fine

Vane Axial Fans

2

®

emery paper and oil. Do not destroy the continuity of the

surfaces. Wipe clean thoroughly with Tectyl® 506 (Ashland

Inc.) or the equivalent. For hard to reach internal surfaces

or for occasional use, consider using Tectyl® 511M Rust

Preventive or WD-40

® or the equivalent.

Removing from Storage

As fans are moved from storage to be installed in their

final location, they should be protected and maintained

in a similar fashion until the fan equipment goes into

operation. Purge grease before putting fan into service.

Installation

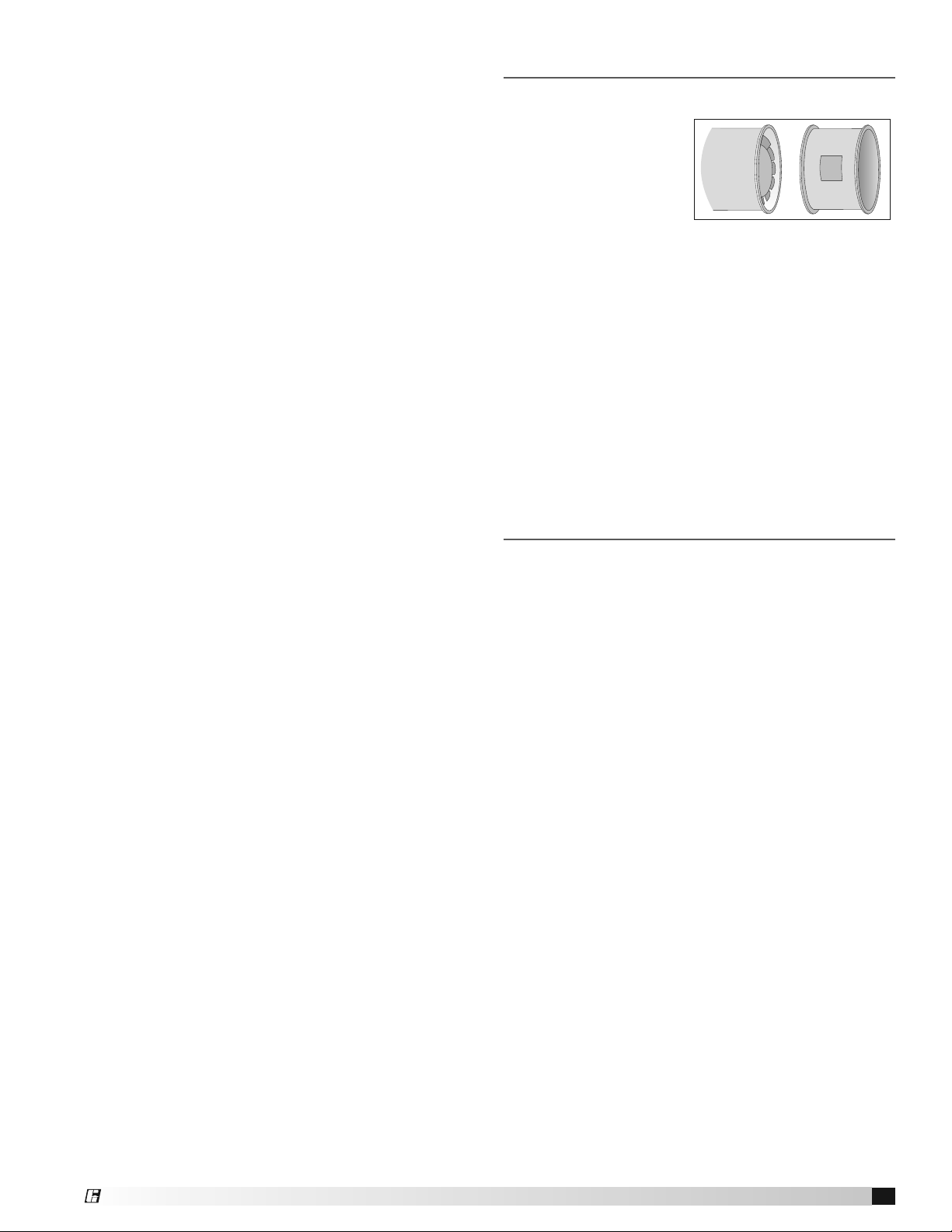

Service Access - Greenheck recommends all vane axial

installations be provided

with a means for service

access. This access may

be in the form of access

doors in the duct system,

removable duct sections,

inlet and outlet cones or

an optional inspection

section (Fig. 2).

Service access is necessary to inspect and repair

internal fan components, both at the inlet and outlet

ends of the fan. Fans installed without consideration

for service access can result in time consuming and

expensive removal of connected ductwork.

Airflow Direction - Airflow through a vane axial fan

enters at the impeller end and is exhausted out the end

of the fan containing the motor (direct drive) or drive

components (belt drive). Additionally, an arrow decal is

affixed to the fan indicating direction of airflow.

Fig. 2 Inspection section

for service access

Electrical Connection

Electrical connections are made to wires located in

the junction box located on the fan housing for direct

drive fans or in the junction box located on the motor

for belt drive fans. The electrical supply must be

compatible with the motor with regard to voltage, phase

and amperage capacity. The electrical supply must be

provided with a lockable disconnect switch, proper

fusing and comply with local and national electric

codes.

Greenheck recommends a vibration switch be installed

in the electrical circuit to disable the fan in event of

abnormal vibration. These switches are available

through your nearest Greenheck representative.

®

Vane Axial Fans

3

Controlling Vibration

Vibration Isolators

Although vane axial fans are typically very smooth

running fans, any residual vibration will be transmitted

and amplified through flooring, ceilings and ductwork.

To prevent a small amount of vibration from becoming

a large amount of noise, vibration isolators are

recommended for floor mount or ceiling hung

installations.

The most common isolators are:

Isolator Type Application

Free-Standing Spring Permits radial and axial vibration

dampening.

Housed Spring Permits radial and axial vibration

dampening where less motion can

be tolerated.

Restrained Spring Used where large weight changes

or high wind loads occur. Upward

vertical movement is prevented by

mechanical restraints.

Seismic Control Restricts movement of supported

equipment during earthquakes

while providing isolation.

Spring Hanging Provides vibration isolation of

suspended equipment. Threaded

suspension rods typically are

supplied by the installer.

Rubber-in-Shear Neoprene isolators are highly

effective for relatively small fans

with speed of 1800 RPM and over.

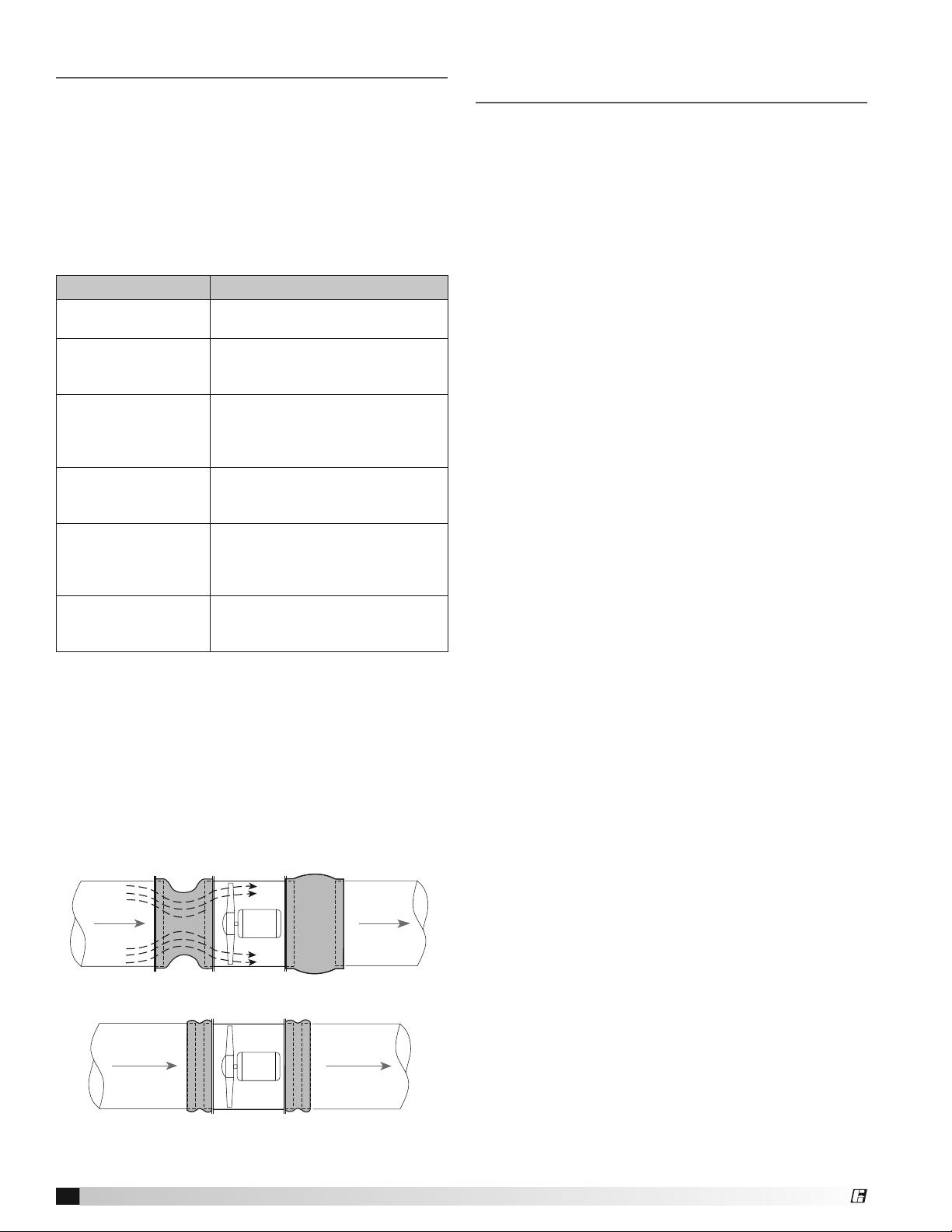

Flexible Duct Connectors

Flexible duct connectors should be taut between the fan

inlet and the connecting duct. Loose flexible connectors

will cause “necking” of the airstream when installed

on the negative pressure side of the fan. This will

create non-uniform airflow into the fan inlet and starve

the impeller blade tips of air. Therefore, the flexible

connector should not be loose and should be just long

enough for mechanical isolation. See Fig. 3 for flexible

connectors.

Poor

Effects of Installation on

Performance

System Effect - Inlet and outlet conditions greatly

affect the air performance of a vane axial fan. The Air

Movement and Control Association (AMCA) defines

system effect as “a pressure loss which recognizes the

effect of fan inlet restrictions, fan outlet restrictions,

or other conditions influencing fan performance when

installed in the system”.

System effect is very difficult to quantify and correct.

Frequently, the only means to correct the resulting poor

performance is to increase fan speed or blade pitch in

the hope of overcoming the additional pressure loss.

This may result in overloading the motor and require

motor replacement. In extreme cases, the entire fan may

need to be replaced if the system effect is severe.

The following diagrams show common inlet and outlet

conditions. Minimum recommended distances are

shown to minimize system effect on the ducted and

non-ducted installations.

Non-Ducted Inlets - Greenheck recommends inlet bells

on all non-ducted inlets. An inlet bell smooths airflow

into the impeller blade tips providing uniform impeller

blade loading. An inlet without an inlet bell creates nonuniform airflow resulting in poor performance, vibration

and noise.

Inlets in Proximity to Walls - Vane axial installations

with a non-ducted inlet too close to a wall or other

obstruction may create reduced fan performance.

Greenheck recommends a minimum of one fan diameter

between a wall and the fan inlet.

Ducted Inlets - Inlet ducts must provide smooth non

turbulent airflow into the impeller blades. Any elbows,

transitions, dampers or other disruptions close to

the fan inlet will create system effect and reduce fan

performance.

Non-Ducted Outlets - Greenheck recommends an

outlet cone be attached to all non-ducted outlets. An

outlet cone reduces velocity pressure losses resulting in

lower brake horsepower and higher efficiency.

Outlets in Proximity to Walls - Vane axial outlets

should be no closer than two fan diameters from any

wall. Fans with less than this distance will experience

significant performance losses.

Ducted Outlets - Ducted outlets require a straight,

uniform diameter length of ductwork immediately

after the fan outlet. Sharp turns or elbows close to

the outlet will create system effect losses and poor air

performance. Greenheck recommends a minimum of

three fan diameters between the fan outlet and any duct

turn.

Good

Fig. 3 Flexible Duct Connectors

Vane Axial Fans

4

®

Loading...

Loading...