Page 1

Fire Rated Partition

Document number 462103

®

INSTALLATION INSTRUCTION SUPPLEMENT

Sleeve Extensions

Refer to:

‘Installation Instructions for FD, DFD, SSFD, & KFD Models’

(Part #452763)

or

‘Installation Instructions for FSD-XXX, DFD-XXX, CFSD-XXX,

SSFSD-XXX Series Fire & Combination Fire Smoke Dampers’

(Part #461336)

or

‘Installation Instructions for FD & DFD 150X Series Curtain

Fire Dampers’ (Part #453946) for additional details.

11/2 Hour Curtain Fire Dampers and

Combination Fire Smoke Dampers

“UL CLASSIFIED (see complete marking on

product)”

“UL CLASSIFIED to Canadian safety standards

(see complete marking on product)”

Standard 555 (Listing #R13317)

Standard 555S (Listing #R13447)

FD & DFD Series

FSD Series

Application

Factory installed sleeves may need to be extended in the field. This supplement covers the following

applications:

• When the factory sleeve extends all the way through the rated barrier (Figure 1)

• When the factory sleeve ends in the plane of the rated barrier (Figure 2).

This supplemental installation instruction provides details for attachment of the sleeve extension. Consult

Authority Having Jurisdiction (AHJ) for approval.

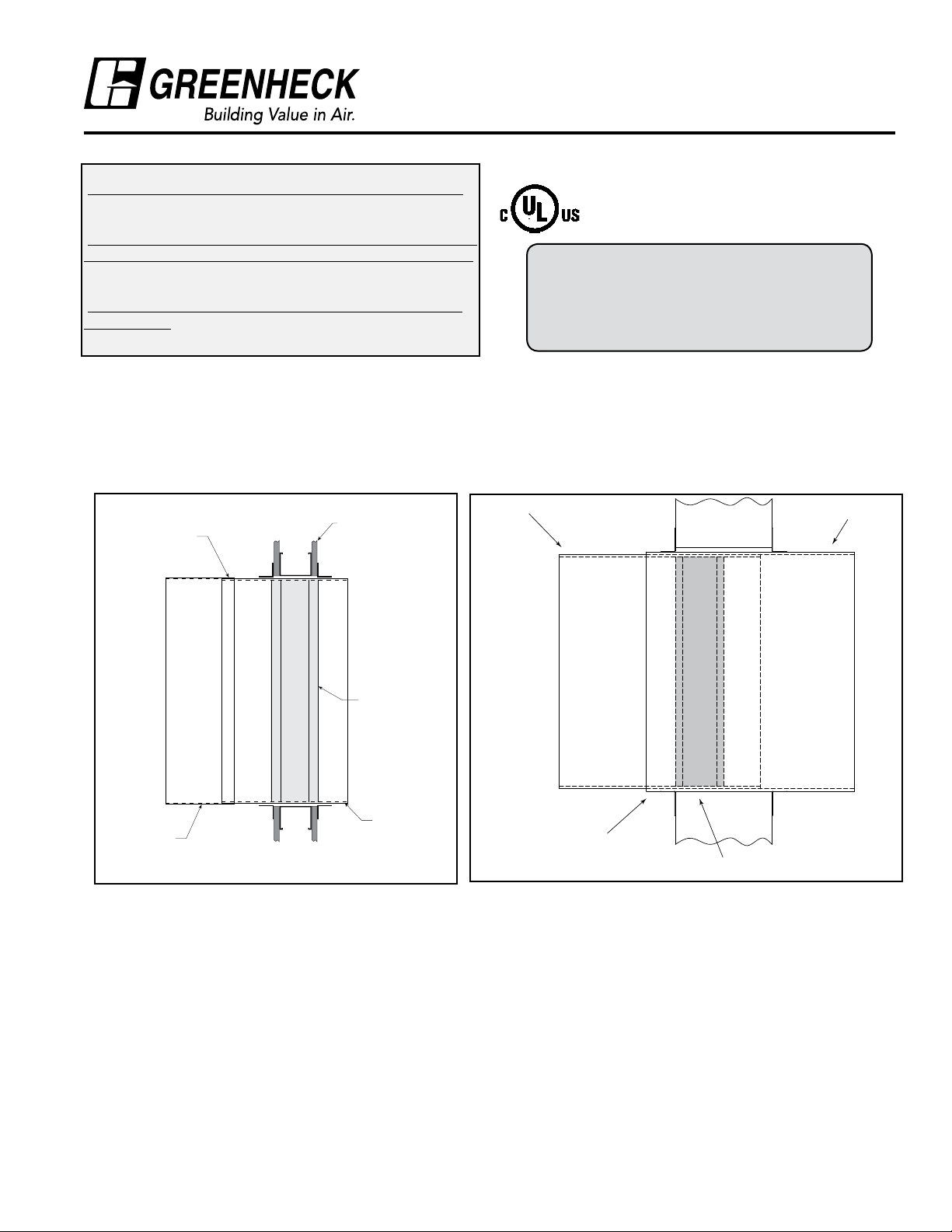

Minimum 1 in.

Overlap

Factory Sleeve

Sleeve Extension

Fire or Fire Smoke

Damper

Factory Sleeve

Sleeve

Extension

Figure 1: Factory sleeve extends all the way

through the rated barrier.

Notes

1. Sleeve extension must be same material and gage

as factory sleeve.

2. The inside dimensions of the sleeve extension must

be the same dimensions as the outside dimensions

of the factory sleeve.

3. Sleeve extension must overlap the factory sleeve a

minimum of 1 in. (25mm).

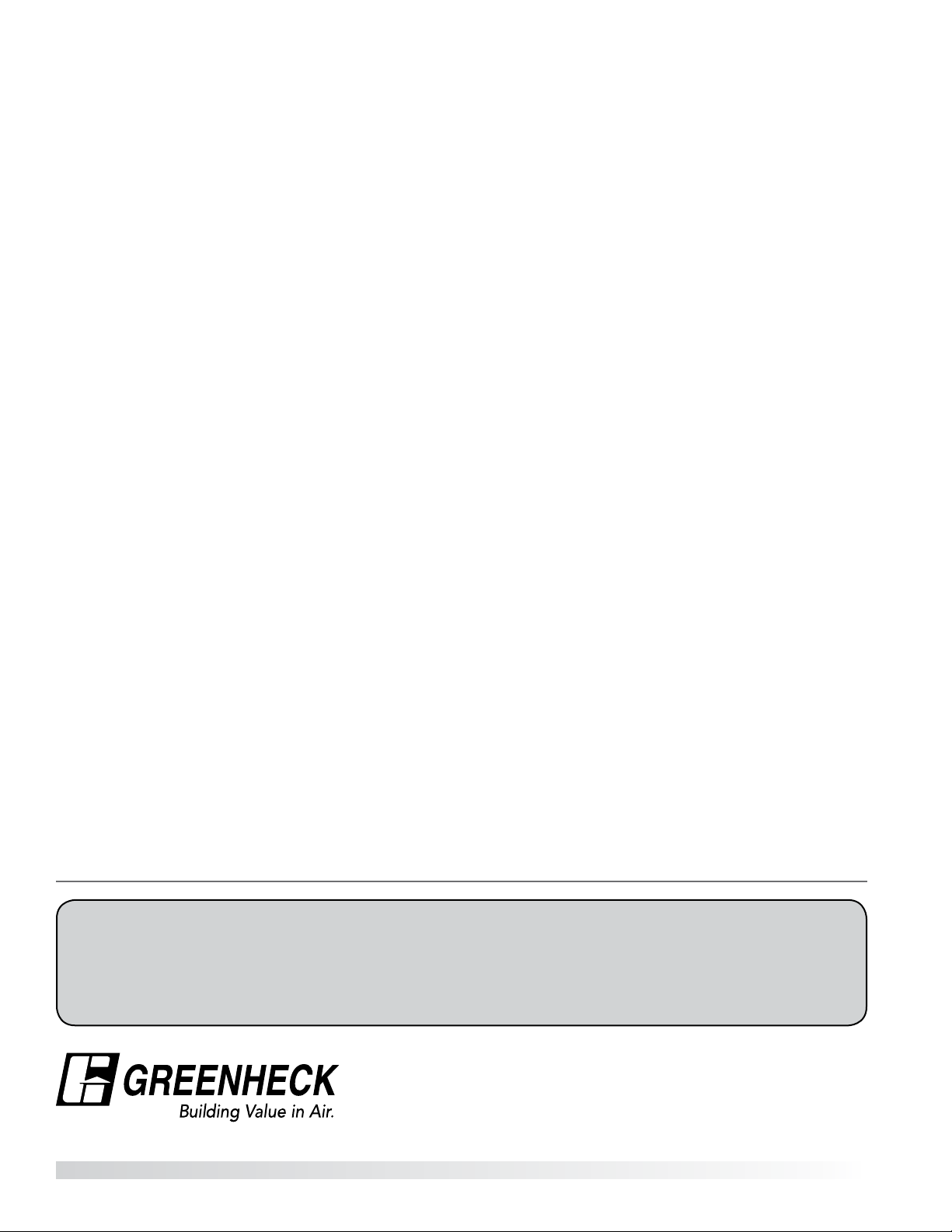

Connecting Joint of Sleeves

See notes 4,5, and 7

Figure 2: Factory sleeve ends in the plane of the rated

barrier.

Fire or Combination Fire

Smoke Damper

4. All four sides of the sleeve extension must be

attached to the factory sleeve. Attachments must

be spaced a maximum of 6 in. (152mm) on center

and a maximum of 2 in. (51mm) from corners. A

minimum of 2 attachments per side (8 per damper )

are required. One of the methods of attachment

shown below must be used.

- tack or spot welds

- #10 sheet metal screws

- 1/4 in. (6mm) bolts and nuts

- 3/16 in. (4.7mm) steel pop rivets

Page 2

5. Products with a smoke rating (FSD models) require

that the joint between the two sleeves be sealed.

Approved caulks include:

• G.E. 1200 series silicone construction

adhesive

• Component Hardware Group (QMFZ2)

silicone SLT-5000 or SLT-5200

• Silico (QMFZ2) silicone SB or CH (E224060)

• Dow Corning (QMFZ2) silicone SLT-5200

(E40195)

• Dow R/C (QMFZ2) silicone Type RTV732.

Approved duct sealants include:

• Precision PA2084T duct sealant adhesive

• Design Polymetrrics DP1010 water base duct

sealant

• Grey Pookie

• Ductmate PROseal

®

• CL Ward S seal

6. Sleeve extensions can be made to either end of

the factory sleeve. However, the total sleeve length

cannot extend more then 16 in. (406mm) on the

actuator side and not more than 6 in. (152mm) on

the non-actuator side.

7. The joint created by the factory sleeve and sleeve

extension cannot be in the plane of the partition.

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

462103• Sleeve Extension Rev. 5, April 2014 Copyright 2014 © Greenheck Fan Corporation

Loading...

Loading...