Page 1

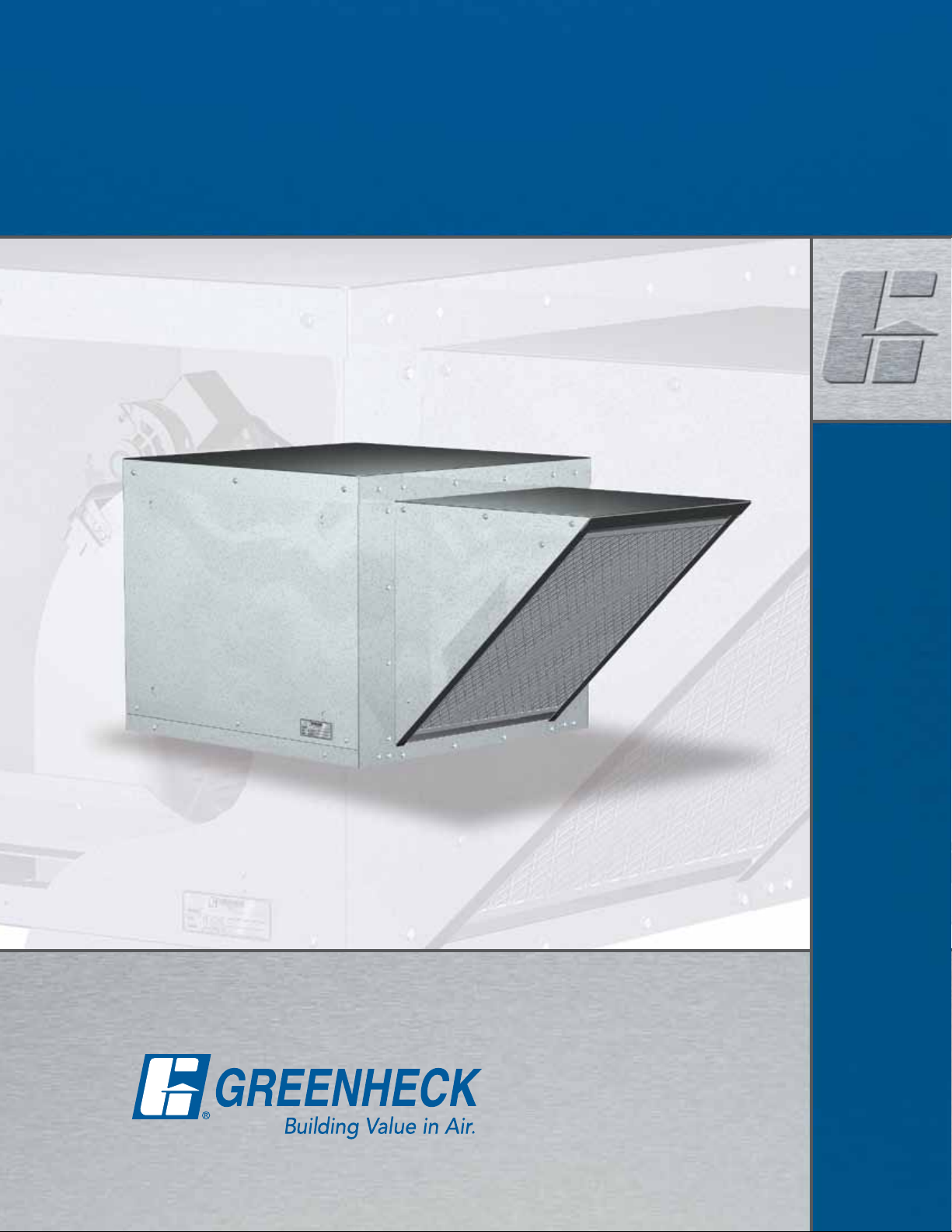

Centrifugal Roof Supply Fan

Model SAF

Belt Drive

BUILDING VALUE IN AIR.

July

2010

Page 2

Model SAF - Supply Air Fan

Greenheck’s Model SAF is a roof mounted supply

air fan designed to provide non-tempered, filtered

make-up air. These belt drive fans are available in

five sizes.

• Double-width forward-curved centrifugal wheel

results in high efficiency and low sound levels.

• Performance ranging from 820 cfm (1,393 m3/hr)

to 14,000 cfm (23,786 m3/hr) with up to 3.5 in. wg

(869 Pa) of static pressure.

• Permanent washable aluminum filters result in

many years of reliable use.

• Performance as cataloged is assured. All fan

sizes have been tested in an AMCA Accredited

Laboratory and are licensed to bear the AMCA

Sound and Air Performance Seal.

• Fan components are subjected to extensive life

testing, assuring you the fans will provide many

years of reliable performance.

SAF models are Listed for

electrical (UL/cUL 705)

File No. E40001.

Greenheck Fan Corporation certifies that the model SAF

fans shown herein is licensed to bear the AMCA seal.

The ratings shown are based on tests and procedures

performed in accordance with AMCA Publication 211 and

AMCA Publication 311 and comply with the requirements

of the AMCA Certified Ratings Program. The certified

ratings for model SAF are shown on pages 7 thru 11.

Leading

Outstanding

Customer Service

Your local Greenheck representative has a wealth

of industry and product knowledge to answer

your questions. Our representatives receive the

latest product information and can have orders

processed directly to our factory. With our direct

order processing system, we can ship orders as

fast as the next business day. With Greenheck’s

experienced staff, we can answer questions and

provide solutions.

Table of Contents

Standard Construction Features .......... 3

Options and Accessories ................ 4

Typical Installation ..................... 4

Commercial Kitchen Ventilation ........... 5

Fan Sizing ............................ 5

NFPA Considerations ................... 5

Service ............................... 6

Model Number Code.................... 6

Belt Drive Performance................7-11

Typical Specifications .................. 12

Warranty ............................ 12

2

Edge

Technical

Support

When product and IOM (Installation, Operation and

Maintenance Manual) information is needed, our

products are supported by the industry’s best product

literature, electronic media and Computer Aided

Product Selection (CAPS) program. You’ll also find this

information on our website at www.greenheck.com

Our national and international representative

organizations provide personal service and

expertise. To locate your nearest Greenheck

representative, call 715-359-6171 or visit our

website at www.greenheck.com

Greenheck’s Quick Delivery

Program provides many

options to help you meet

your project’s schedule.

Stocking warehouses and

distribution centers around

the world ensure sameday pickup and same-day

shipment for orders in by

2 p.m. (CST). Hundreds

of custom products can be manufactured through

Quick Build in just days.

The Greenheck Stock & Quick Build Catalog is a

great resource for specific options and accessories

available with QD and QB fans.

Page 3

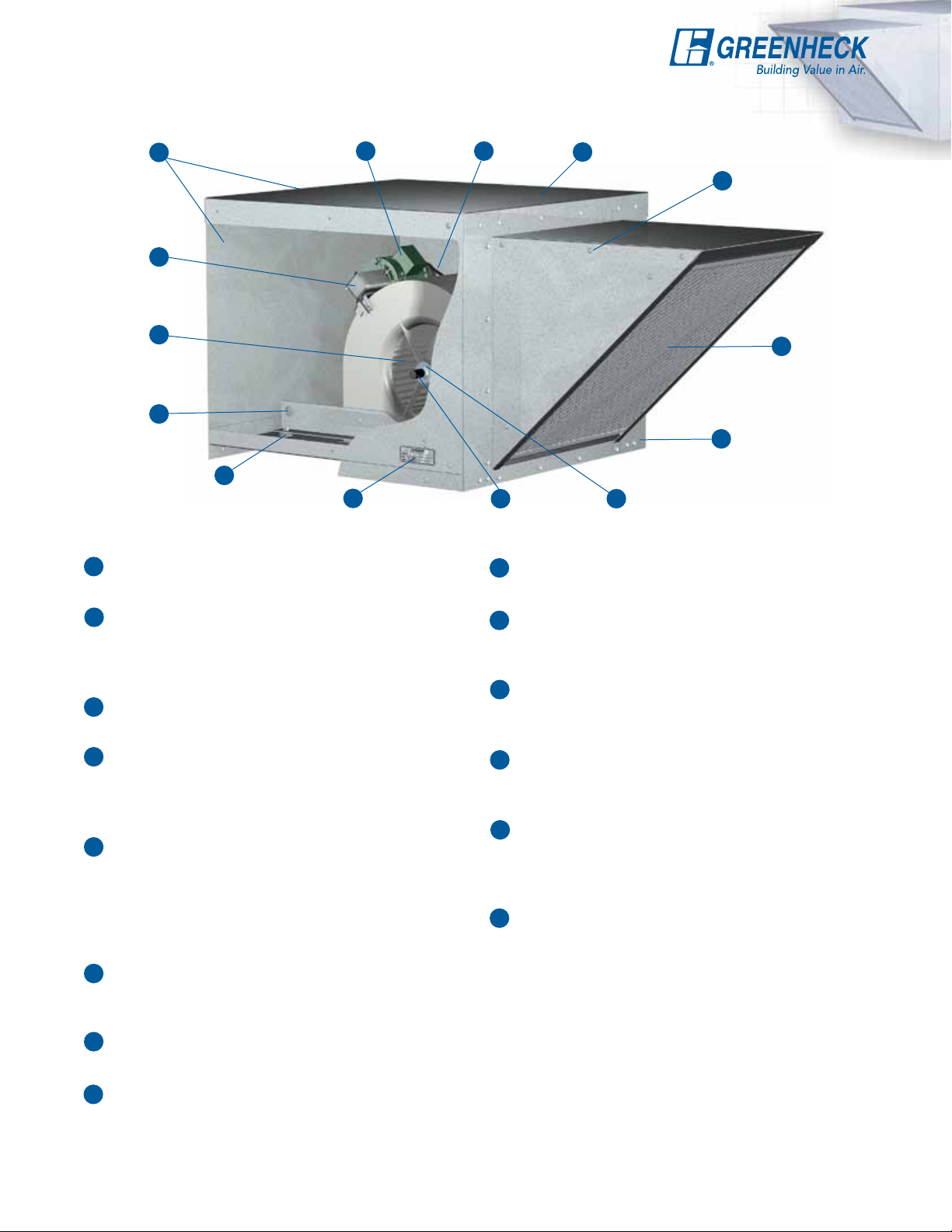

Standard Construction Features

6

5

4

3

2

1

Nameplate - Permanent stamped aluminum

plate for exact model and serial identification.

7 8

1

9

10

11

12

1314

Housing - Fan housing and cover are

9

constructed of heavy gauge galvanized steel.

2

Vibration Isolation - Isolators support the drive

frame and blower assembly for long life and

minimal sound transmission into

the building.

3

Lifting Lugs - Various lifting points located on

the drive frame to provide easy lifting.

4

Steel Wheel - Double-width/double-inlet

forward-curved wheel is statically and

dynamically balanced and constructed of heavy

gauge galvanized steel.

5

Disconnect Switch - NEMA-1 switch is factory

mounted and wiring is provided from the motor

as standard (other switches are available.) All

wiring and electrical components comply with

the National Electric Codes (NEC) and are

either UL Listed or recognized.

Access Panels - Cover and side access

6

panels are easily removed for access to motor

compartment and drive assembly.

7

Motor - Carefully matched to the fan load to

provide years of trouble-free operation.

8

Drive Assembly - Belts, pulleys and keys

are oversized 150% of driven horsepower.

Machined cast pulleys are adjustable for final

system balancing. Belts are static free and

oil resistant.

Fasteners - Galvanized weather resistant

10

fasteners are used to secure both top and side

access panels.

Filters - Permanent, washable aluminum

11

one-inch filters are standard. Filter racks are

designed to allow filters to slide out easily.

Curb Cap - Curb cap has prepunched mounting

12

holes to ensure correct attachment to the

roof curb.

Bearings - Bearings are permanently sealed and

13

lubricated, 100% factory tested and designed

specifically for air handling applications with a

minimum L

Fan Shaft - Fan shaft is precision ground,

14

polished and sized so the first critical speed is

at least 25% over maximum operating speed.

Blower Outlet - Blower outlet is flanged to

provide built-in duct adapter for mounting of

ductwork directly to the fan base.

Belt Tension - Pivoting mount with screw

adjustment is provided on the drive frame for

ease of maintaining belt tension.

life in excess of 200,000 hours.

50

3

Page 4

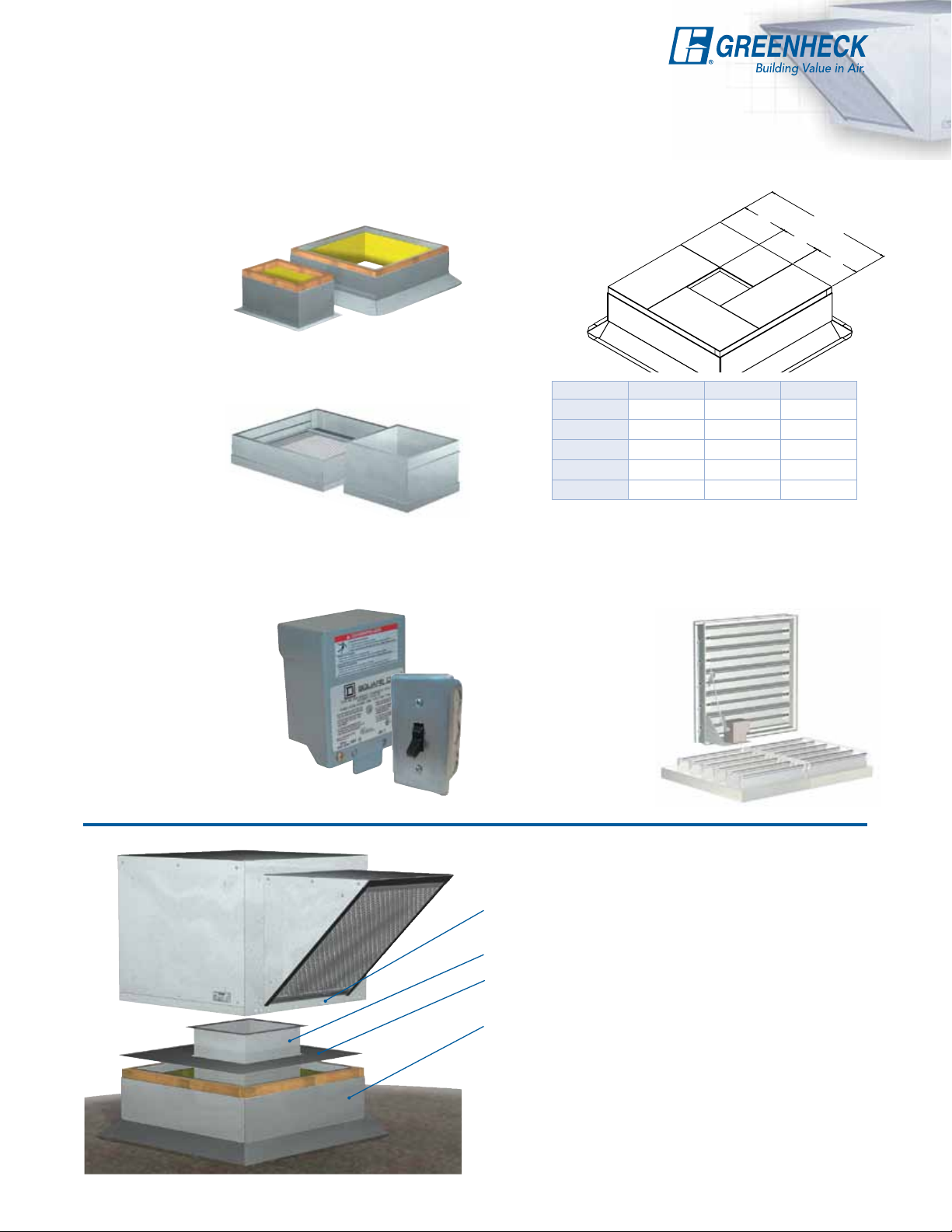

Options and Accessories

A sq.

C

C

B

Roof Curbs

Prefabricated roof curbs reduce installation time

and costs by ensuring compatibility between

the fan, the curb and roof opening. All curbs

are insulated. A wide variety of

roof curbs are available,

including: flanged,

pitched and soundabsorbing.

Curb Extension

Extensions raise the fan discharge above the roof

line and provide an accessible mounting location

for dampers. Insect screen bases, constructed

with a removable

fine mesh, are

recommended for

applications where

insect entry must

be prevented.

Curb Seal

Rubber seal between fan and curb is available to

ensure proper sealing when attached to a curb.

Disconnect Switches

A wide selection of

NEMA rated switches

are available for positive

electrical shutoff and

safety, including: general,

dust-tight, rainproof

and corrosion-resistant.

Optional switches ship

loose with unit.

Duct Adapters

Duct adapters fit over the roof curb and support the

top of the duct allowing ductwork

to be completed before the fan

is set in place. Duct adapters

also limit performance

losses by directing

airflow into

the duct.

Fan Size A B C

110 28

112 32

115 32

118 38

120 44

All dimensions in inches(millimeters).

1

⁄2 (724) 141⁄4 (362) 71⁄8 (181)

1

⁄2 (826) 181⁄4 (464) 71⁄8 (181)

1

⁄2 (826) 241⁄4 (616) 41⁄8 (105)

1

⁄2 (978) 301⁄4 (768) 41⁄8 (105)

1

⁄2 (1130) 361⁄4 (921) 41⁄8 (105)

Dampers

Designed to prevent outside air from entering back

into the building when fan is off. Flangeless intake

dampers are designed for horizontal mounting

inside ductwork. Includes

either gravity or motorized

dampers. Damper sizes

are shown on each

performance data page.

Typical Installation

Prepunched mounting holes and 21⁄2 inch skirt to

aid in installation

Ductwork (by others)

Duct adapter (optional) allows ductwork to be

completed prior to setting unit on curb

Roof curb

Roof opening dimensions can be found with the

4

dimensional data on the performance pages.

Note: In cases where extreme snow depths may be

encountered, a curb extension may be required to

raise unit or condensation pans may be required

in ductwork.

Page 5

Commercial Kitchen Ventilation

10 ft. min.

(3 m min.)

(914 mm min.)

Supply Air Fan

This drawing shows

a typical commercial

kitchen ventilation

system that consists

of a roof mounted

upblast exhaust fan

and a supply fan.

Exhaust fan variations

include sidewall exhaust

fan (also shown) when

penetrating the roof is not

practical. A utility blower is

recommended when higher

static pressure capability

is required to pull exhaust

through long duct runs

(typically 3 stories or more).

Model SAF

Outside Supply Air

Replacing Exhausted Air

Centrifugal Upblast Exhaust Fan

Model CUBE

Vented Curb

Model GPFV

Exhaust Hood

Model GHW

Centrifugal Exhaust

Sidewall Fan Option

Model CWB

Fan Sizing

Exhaust

When not specified by local codes,

the following guidelines may be used

to determine the minimum kitchen hood exhaust cfm.

Some local codes require 100 cfm/ft2 of hood area for

wall style hoods.

Supply

Recommended supply airflow is 90%

of exhaust cfm. The remaining 10%

of supply air will be drawn from areas

adjacent to the kitchen, which helps

prevent undesirable kitchen odors

from drifting into areas such as the

dining room.

Duty Level Type of Cooking Equipment cfm/ft2 of Hood

Light Oven, Range, Kettle 50

Medium Fryer, Griddle 75

Heavy Charbroiler, Electric Broiler 100

Static pressure typically ranges from 0.625 to 1.0 in. for one story buildings.

NFPA Considerations

The National Fire Protection Association specifies

minimum distance criteria for restaurant exhaust and

supply fans:

Option A

1. Roof deck to top of exhaust fan windband:

40 inches (1016 mm) minimum

2. Roof deck to top of curb:

18 inches (457 mm) minimum

3. Supply fan intake:

10 feet (3048 mm) minimum from all exhaust fans

40 in. min.

(1016 mm min.)

18 in. min.

(457 mm min.)

Cooking

Equipment

Option A

10 ft. min.

(3 m min.)

36 in. min.

Option B

For applications where the 10 feet (3048 mm) horizontal distance

cannot be met, vertical separation between exhaust and supply

must be at least 36 inches (914 mm).

Option B

12 in.

(305 mm)

5

Page 6

Service

Filtered supply fans require regular inspection and

cleaning (or replacement) of filters to ensure high

efficiency and performance. The model SAF is

designed to provide easy access to filters and

other components through a convenient removable

hood cover.

Removable Hood Cover

Removal of the hood cover allows easy access to all

fan components for inspection, cleaning, and service.

Serviceability

The internal drive components are easy to reach

and service with the hood removed.

Weather Resistant Fasteners

Easy to remove galvanized fasteners keep the

hood cover secured.

Filter Removal

Filter racks are designed so filters can easily slide out

for cleaning or replacement.

Model Number Code

The model number system is designed to completely identify the fan. The correct code letters must be

specified to designate belt or direct drive. The remainder of the model number is determined by the size

and performance selected from the following pages.

MODEL CONFIGURATION

SAF - Belt Drive Supply

FAN SIZE

110 through 120

6

SAF - 110 - 7

NOMINAL WHEEL

DIAMETER IN INCHES

MOTOR HP

7 = 3/4 30 = 3

4 = 1/4 10 = 1 50 = 5

3 = 1/3 15 = 1

5 = 1/2 20 = 2 100 = 10

1

⁄2 75 = 71⁄2

Page 7

SAF-110

25

(635)

22

(559)

Inlet

1

(210)

4

/

30

(762)

8

1

9

/4

(235)

11

Airflow

9

16

/

(762)

30

(294)

13

(340)

3

/8

1

Damper Size = 14 x 14 (355 x 355)

Roof Opening = 161/2 x 161/2 (419 x 419)

Curb Cap Thickness = 0.052 (1)

^Approximate Unit Weight = 181 lb. (82 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

1

/16

21

(535)

1

(38)

/2

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

cfm

Model

Number

Fan

CFM

820

1000

0.125 0.25 0.375 0.5 0.625 0.75 1 1.125 1.25 1.5

RPM 432 549

BHP 0.05 0.08

Sones 11.4 11.9

RPM 476 579 672 755

BHP 0.07 0.11 0.14 0.17

Static Pressure in inches wg

MAXIMUM RPM = 1400

TIP SPEED = RPM x 2.91

MAXIMUM MOTOR FRAME SIZE = 145T

AVERAGE OUTLET VELOCITY = CFM/1.07

Sones 10.0 11.7 11.3 10.5

RPM 525 616 701 780 850

1180

BHP 0.11 0.14 0.18 0.22 0.26

Sones 10.5 11.2 11.5 11.2 11.2

RPM 577 660 736 809 878 941

1360

BHP 0.15 0.19 0.23 0.28 0.32 0.37

Sones 11.2 11.0 11.4 11.4 11.8 12.7

RPM 632 707 777 844 908 969 1082 1134 1192

1540

BHP 0.21 0.25 0.30 0.35 0.40 0.45 0.55 0.60 0.66

Sones 12.0 11.7 11.7 11.8 12.7 13.7 15.2 18.3 19.5

RPM 688 757 822 883 943 1001 1110 1162 1210 1307

1720

SAF-110

BHP 0.28 0.33 0.38 0.43 0.48 0.54 0.65 0.71 0.77 0.89

Sones 13.1 12.8 12.4 12.8 13.9 14.9 17.9 18.9 19.9 22

RPM 745 809 870 927 982 1036 1140 1189 1238 1328

1900

BHP 0.37 0.42 0.48 0.53 0.59 0.65 0.77 0.83 0.90 1.02

Sones 14.2 14.1 13.7 14.5 15.4 16.4 18.6 19.5 20 23

RPM 802 864 920 974 1026 1075 1174 1221 1266

2080

BHP 0.47 0.53 0.59 0.65 0.71 0.77 0.90 0.97 1.04

Sones 15.5 15.7 15.9 16.5 17.3 18.2 20 21 21

RPM 859 920 971 1023 1071 1119 1210

2260

BHP 0.59 0.66 0.71 0.78 0.85 0.92 1.05

Sones 16.9 17.6 18.1 18.6 19.4 21 22

RPM 918 976 1025 1073 1120

2440

BHP 0.72 0.80 0.87 0.94 1.01

Sones 18.8 19.6 20 21 22

RPM 977 1032 1080

2620

BHP 0.88 0.97 1.04

Sones 21 22 23

Performance certified is for installation type B: free inlet, ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings include the effects of a filter.

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type B:

free inlet hemispherical sone levels.

7

Page 8

SAF-112

1

/16

32

(814)

29

(743)

1

/4

Inlet

1

(241)

2

/

34

(864)

9

11

10

/16

(271)

13

Airflow

11

/

16

34

(864)

(348)

15

(395)

9

/16

2

Damper Size = 18 x 18 (457 x 457)

Roof Opening = 201/2 x 201/2 (521 x 521)

Curb Cap Thickness = 0.052 (1)

^Approximate Unit Weight = 244 lb. (111 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

(51)

27

(695)

3

/8

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

ef

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Fan

CFM

1250

1500

0.125 0.25 0.375 0.5 0.625 0.75 1 1.125 1.25 1.5

RPM 390 483

BHP 0.08 0.11

Sones 12.8 12.6

RPM 422 513 590

BHP 0.11 0.15 0.20

Static Pressure in inches wg

MAXIMUM RPM = 1200

TIP SPEED = RPM x 3.30

MAXIMUM MOTOR FRAME SIZE = 145T

AVERAGE OUTLET VELOCITY = CFM/1.48

Sones 12.2 12.5 11.8

RPM 459 549 616 682

1750

BHP 0.16 0.21 0.26 0.31

Sones 12.7 12.7 12.1 14.0

RPM 503 580 652 708 766 824

2000

BHP 0.22 0.28 0.34 0.39 0.45 0.51

Sones 13.6 13.6 14.2 15.7 17.6 18.3

RPM 549 615 685 745 794 844

2250

BHP 0.30 0.36 0.43 0.49 0.55 0.61

Sones 14.6 14.9 16.6 17.8 19.1 18.9

RPM 598 653 717 779 830 874 967 1013

SAF-112

2500

BHP 0.40 0.46 0.53 0.61 0.68 0.74 0.89 0.97

Sones 15.8 17.0 18.8 19.7 19.8 19.6 20 21

RPM 647 698 753 810 865 911 990 1034 1077

2750

BHP 0.52 0.58 0.66 0.74 0.82 0.90 1.04 1.12 1.21

Sones 17.7 19.9 21 21 21 21 22 23 25

RPM 697 743 790 843 897 947 1026 1062 1098 1179

3000

BHP 0.66 0.73 0.80 0.89 0.99 1.08 1.23 1.31 1.39 1.58

Sones 20 21 23 22 22 22 24 25 26 31

RPM 748 790 833 880 928 978 1063 1098

3250

BHP 0.83 0.90 0.98 1.07 1.16 1.27 1.45 1.54

Sones 22 23 24 24 24 24 26 27

RPM 798 839 878 918 964 1009

3500

BHP 1.02 1.10 1.18 1.26 1.37 1.48

Sones 24 25 25 25 26 27

RPM 849 888 924 962

3750

BHP 1.24 1.33 1.41 1.50

Sones 26 27 27 28

Performance certified is for installation type B: free inlet, ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings include the effects of a filter.

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type B:

free inlet hemispherical sone levels.

8

Page 9

SAF-115

1

32

/16

(814)

29

(743)

1

/4

Inlet

1

(216)

2

/

34

(864)

8

9

(230)

1

/16

16

Airflow

1

/

16

34

(864)

(408)

18

(478)

13

/16

Damper Size = 24 x 24 (610 x 610)

Roof Opening = 261/2 x 261/2 (673 x 673)

Curb Cap Thickness = 0.052 (1)

^Approximate Unit Weight = 263 lb. (119 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

2 (51)

27

(695)

3

/8

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

no

o

D

cfm

Model

Number

Fan

CFM

1300

1650

0.125 0.25 0.5 0.75 1 1.25 1.5 1.75 2 2.25

RPM 316 407 546 654

BHP 0.07 0.12 0.23 0.34

Sones 7.6 8.9 9.7 12.0

RPM 351 430 565 672 763 844

BHP 0.12 0.17 0.29 0.43 0.58 0.73

Static Pressure in inches wg

MAXIMUM RPM = 1200

TIP SPEED = RPM x 4.06

MAXIMUM MOTOR FRAME SIZE = 145T

AVERAGE OUTLET VELOCITY = CFM/2.09

Sones 6.3 9.2 10.3 13.3 15.5 16.7

RPM 387 463 586 691 781 861 934 1000

2000

BHP 0.18 0.24 0.38 0.53 0.70 0.87 1.05 1.23

Sones 6.8 9.0 11.1 14.1 15.8 17.1 18.3 19.6

RPM 432 498 610 712 800 879 952 1018 1080 1139

2350

BHP 0.26 0.34 0.48 0.65 0.83 1.03 1.23 1.44 1.64 1.85

Sones 8.5 9.7 12.2 14.9 16.3 17.5 18.8 20 21 23

RPM 479 534 642 734 821 898 970 1037 1098 1157

2700

BHP 0.38 0.45 0.63 0.80 1.00 1.20 1.43 1.66 1.89 2.12

Sones 10.3 11.2 13.9 15.7 16.9 18.0 19.3 21 22 23

RPM 528 574 676 763 843 920 989 1055

SAF-115

3050

BHP 0.52 0.60 0.80 0.99 1.19 1.42 1.64 1.89

Sones 12.9 13.9 15.6 17.4 18.1 18.6 19.9 21

RPM 577 621 712 795 870 942 1011

3400

BHP 0.70 0.79 1.00 1.21 1.43 1.66 1.91

Sones 16.0 16.5 17.9 19.1 19.9 21 21

RPM 627 669 748 830 902 968

3750

BHP 0.91 1.02 1.23 1.48 1.71 1.95

Sones 19.0 18.6 20 21 22 23

RPM 677 717 785 866 935

4100

BHP 1.17 1.29 1.50 1.78 2.04

Sones 22 21 22 23 24

RPM 729 765 830 902

4450

BHP 1.47 1.60 1.84 2.12

Sones 23 23 24 25

RPM 780 815

4800

BHP 1.82 1.96

Sones 26 26

Performance certified is for installation type B: free inlet, ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings include the effects of a filter.

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type B:

free inlet hemispherical sone levels.

9

Page 10

SAF-118

32

(813)

1

36

/16

(916)

Inlet

3

(248)

4

/

9

5

11

/16

(287)

40

(1016)

19

Airflow

Damper Size = 30 x 30 (762 x 762)

Roof Opening = 321/2 x 321/2 (826 x 826)

Curb Cap Thickness = 0.064 (2)

^Approximate Unit Weight = 494 lb. (224 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

1

(486)

8

/

40

(1016)

22

(567)

5

/16

2

(51)

31

(789)

1

/16

e

v

r

u

c

m

te

ys

s

s

i

h

t

f

o

t

f

e

l

e

th

o

t

t

c

le

e

s

t

o

n

o

D

cfm

Model

Number

Fan

CFM

2500

3100

0.125 0.25 0.5 0.75 1 1.5 2 2.5 2.75 3

RPM 294 359 466 564

BHP 0.16 0.23 0.37 0.57

Sones 6.9 9.4 9.8 11.5

RPM 334 390 488 572 654

BHP 0.26 0.34 0.51 0.70 0.93

Static Pressure in inches wg

MAXIMUM RPM = 1185

TIP SPEED = RPM x 4.85

MAXIMUM MOTOR FRAME SIZE = 215T

AVERAGE OUTLET VELOCITY = CFM/2.96

Sones 8.3 8.6 10.8 12.2 15.8

RPM 376 426 516 594 664 800

3700

BHP 0.41 0.50 0.70 0.91 1.12 1.67

Sones 10.3 10.1 11.9 13.3 17.0 24

RPM 419 466 547 621 688 807 924

4300

BHP 0.60 0.71 0.93 1.16 1.41 1.93 2.59

Sones 12.5 12.0 13.1 14.6 19.1 23 24

RPM 466 508 582 651 713 828 932 1034 1081 1127

4900

BHP 0.85 0.98 1.23 1.48 1.75 2.32 2.93 3.69 4.07 4.46

Sones 14.8 14.5 15.6 17.5 21 23 24 24 25 25

RPM 514 550 620 684 743 851 949 1042 1089 1134

SAF-118

5500

BHP 1.17 1.31 1.59 1.87 2.16 2.77 3.42 4.12 4.54 4.96

Sones 17.2 17.2 19.1 22 23 23 24 25 25 26

RPM 563 594 661 719 775 878 973 1059 1100

6100

BHP 1.57 1.70 2.03 2.34 2.64 3.31 4.01 4.73 5.08

Sones 20 20 22 24 26 25 25 26 26

RPM 613 640 702 757 810 908 998

6700

BHP 2.05 2.19 2.54 2.88 3.23 3.93 4.65

Sones 24 24 24 27 28 28 29

RPM 662 688 744 797 846 939

7300

BHP 2.61 2.78 3.15 3.53 3.89 4.63

Sones 27 27 27 31 30 30

RPM 711 737 787 839 885

7900

BHP 3.27 3.46 3.84 4.26 4.66

Sones 30 30 31 32 33

RPM 760 786 831 880

8500

BHP 4.04 4.26 4.64 5.10

Sones 33 34 35 36

Performance certified is for installation type B: Free inlet, Ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings include the effects of a filter.

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA International Standard 301. Values shown are for

installation type B: free inlet hemispherical sone levels.

10

Page 11

SAF-120

1

48

/16

(1221)

35

(910)

13

/16

Inlet

1

(281)

16

/

46

(1168)

11

7

5

/8

(149)

Airflow

25

3

(645)

8

/

46

(1168)

23

(586)

1

/16

2

Damper Size = 36 x 36 (914 x 914)

Roof Opening = 381/2 x 381/2 (978 x 978)

Curb Cap Thickness = 0.064 (2)

^Approximate Unit Weight = 716 lb. (325 kg)

All dimensions in inches (millimeters).

^Weight shown is largest cataloged Open Drip Proof motor.

1

/8 (54)

44

(1119)

1

/16

e

v

r

u

c

m

e

t

s

y

s

s

i

h

t

f

o

t

f

e

l

e

h

t

o

t

t

c

e

l

e

s

t

o

n

o

D

cfm

Model

Number

Fan

CFM

0.125 0.25 0.5 1 1.25 1.5 2 2.5 3 3.5

Static Pressure in inches wg

RPM 275 325 414 553 612

4000

BHP 0.32 0.41 0.64 1.15 1.41

Sones 15.0 13.2 15.0 16.8 19.2

RPM 317 363 440 570 627 679 773

5000

BHP 0.55 0.67 0.93 1.51 1.83 2.16 2.82

Sones 17.6 15.5 17.0 18.9 21 23 29

RPM 363 403 472 594 647 695 788 871

6000

BHP 0.88 1.04 1.33 2.00 2.35 2.69 3.48 4.28

Sones 17.8 19.6 17.8 21 22 25 30 39

RPM 412 446 510 620 672 719 804 885 960 1029

7000

BHP 1.35 1.52 1.86 2.59 2.98 3.40 4.20 5.12 6.05 6.97

Sones 19.8 22 20 23 25 27 31 39 53 80

RPM 462 491 550 649 698 744 828 903 975 1044

8000

BHP 1.95 2.14 2.55 3.31 3.76 4.21 5.15 6.06 7.08 8.14

Sones 23 23 24 25 28 30 33 40 51 73

RPM 513 538 591 687 728 772 853 928 995 1060

SAF-120

9000

BHP 2.72 2.93 3.38 4.27 4.68 5.19 6.20 7.27 8.3 9.38

Sones 26 26 27 29 31 32 37 41 49 66

RPM 564 588 635 726 766 803 880 952 1020

10000

BHP 3.68 3.92 4.40 5.39 5.88 6.35 7.45 8.58 9.77

Sones 30 29 30 34 35 36 41 47 51

RPM 616 638 680 765 804 840 908 979

11000

BHP 4.84 5.11 5.63 6.74 7.26 7.8 8.85 10.12

Sones 33 33 35 38 39 41 47 53

RPM 668 689 725 806 844 879

12000

BHP 6.22 6.52 7.06 8.29 8.89 9.46

Sones 38 39 40 43 45 47

13000

14000

RPM 720 740 774 848

BHP 7.85 8.18 8.78 10.07

Sones 44 45 46 49

RPM 772 791

BHP 9.75 10.11

AVERAGE OUTLET VELOCITY = CFM/4.06

MAXIMUM RPM = 1100

TIP SPEED = RPM x 5.37

MAXIMUM MOTOR FRAME SIZE = 215T

Sones 49 51

Performance certified is for installation type B: free inlet, ducted outlet. Power rating (Bhp) does not include transmission losses. Performance ratings include the effects of a filter.

The sound ratings shown are loudness values in fan sones at 5 ft. (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for installation type B:

free inlet hemispherical sone levels.

11

Page 12

Typical Specifications

Roof mounted, nontempered, filtered, makeup air units shall be of the

belt-driven, double-width/

double-inlet, forwardcurved, centrifugal blower

type.

Housing shall be of square

design and constructed of

heavy-gauge galvanized

steel. The cover shall

be adequately sized to

prevent rain and snow from

entering the building and

constructed of heavy-gauge

galvanized steel.

Curb caps shall have

prepunched mounting

holes.

Permanent washable

one-inch filters shall be

provided.

Fan wheels shall be of

the forward-curved type,

constructed of heavygauge galvanized steel, and

statically and dynamically

balanced to ensure smooth,

vibration free operation.

Motors shall be

permanently lubricated,

heavy-duty, ball bearing

type carefully matched to

the fan load and furnished

at the specified voltage,

phase and enclosure.

The fan shaft shall be

ground and polished steel

mounted in heavy-duty,

sealed ball bearings.

Bearings shall be selected

for a minimum L50 life in

excess of 200,000 hours

at maximum cataloged

operating speeds.

Pulleys shall be of the

fully machined cast iron

type, keyed and securely

attached to the wheel

and motor shafts. Motor

sheaves shall be adjustable

for final system balancing.

Drives shall be sized for a

minimum of 150% of driven

horsepower. The entire fan

and motor assembly shall

be mounted on vibration

isolators to prevent noise

transmission into the

building.

Fans shall bear the

AMCA Certified Ratings

Seal for Sound and Air

Performance.

Fans shall be model SAF

as manufactured

by Greenheck Fan

Corporation of Schofield,

Wisconsin, USA.

Building Value in Air

Greenheck delivers value

to mechanical engineers by

helping them solve virtually

any air quality challenges

their clients face with a

comprehensive selection of

top quality, innovative airrelated equipment. We offer

extra value to contractors

by providing easy-to-install,

competitively priced, reliable

products that arrive on time.

And building owners and

occupants value the energy

efficiency, low maintenance

and quiet dependable operation

they experience long after the

construction project ends.

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the shipment date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

Prepared to Support

Green Building Efforts

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2010 Greenheck Fan Corp.

00.F&V.1006 R5 7-2010 RG

Loading...

Loading...