Greenheck SAF Installation Manual

MOTOR

L1

115/208-230/60/1

J-BOX

SUPPLY VOLTAGE

L2

Part #468410

®

Model SAF

Centrifugal Roof Supply Air Fan

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

SAF

The SAF roof mounted supply air fan designed to provide

non-tempered, filtered make-up air. Belt drive in

five sizes.

Pre-Starting Checks

1. Inspect for any damage that may have occurred

during transit.

2. Shipping damage claim must be filed with carrier.

3. Check all bolts, screws, set-screws, etc. for looseness

that may have occurred during transit. Retighten as

required. Rotate wheel by hand to be sure it turns freely.

Always use all four lifting holes when using a sling.

In United States, to reduce the risk of injury to persons,

General Safety Information When

Installing or Servicing the Fan

Do not depend on any switch as the sole means of

disconnecting power when installing or servicing the fan.

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power source

can result in fire, shock or serious injury. Motor will

restart without warning after thermal protector trips.

Do not touch operating motor, it may be hot enough to

cause injury.

Do not place any body parts or objects in fan, motor

openings or drives, while motor is connected to

power source.

Do not use this equipment in explosive atmospheres!

1. Read and follow all instructions and cautionary markings.

Make sure electrical power source conforms to

requirements of equipment and local codes.

2. Ventilators should be assembled, installed and serviced

by a qualified technician. Have all electrical work

performed by a qualified electrician.

3. Follow all local electrical and safety codes in the United

States and Canada, as well as the National Electrical

Code (NEC), the Occupational Safety and Health Act

(OSHA), and the National Fire Protection Association

(NFPA) Bulletin 96 in the United States. Ground motor in

accordance with NEC Article 250 (grounding). Follow the

Canadian Electric Code (CEC) in Canada.

4. Motor and fan must be securely grounded (bare metal) to

a suitable electric ground, such as a grounded water pipe

or ground wire system.

NOTE: Refer to Figure 1 for connection wiring diagram.

OSHA compliant guards are required when fan is installed

within 7 feet of floor or working level.

In Canada, to reduce the risk of injury to persons CSA

compliant guards are required when fan is installed within

2.5 meters (8.2 feet) of floor or grade level.

5. Do not kink power cable or allow it to come in contact

with sharp objects, oil, grease, hot surfaces or chemicals.

Replace damaged cords immediately.

6. Make certain that the power source conforms to the

requirements for the equipment.

7. Never open access door to a duct with the ventilator

running.

8. Motor must be securely and adequately grounded. This

can be accomplished by wiring with a grounded, metalclad race way system by using a separate ground wire

connected to the bare metal of the motor frame, or other

suitable means.

Figure 1 - Typical Wiring Diagram

MOTOR

SUPPLY VOLTAGE

115/208-230/60/1

J-BOX

L1

L2

MOTOR

J-BOX

SUPPLY VOLTAGE

208-230/460/60/3

L1

L2

L3

Centrifugal Roof Supply Air Fans

®

®

Centrifugal Roof Supply Air Fans

1

1

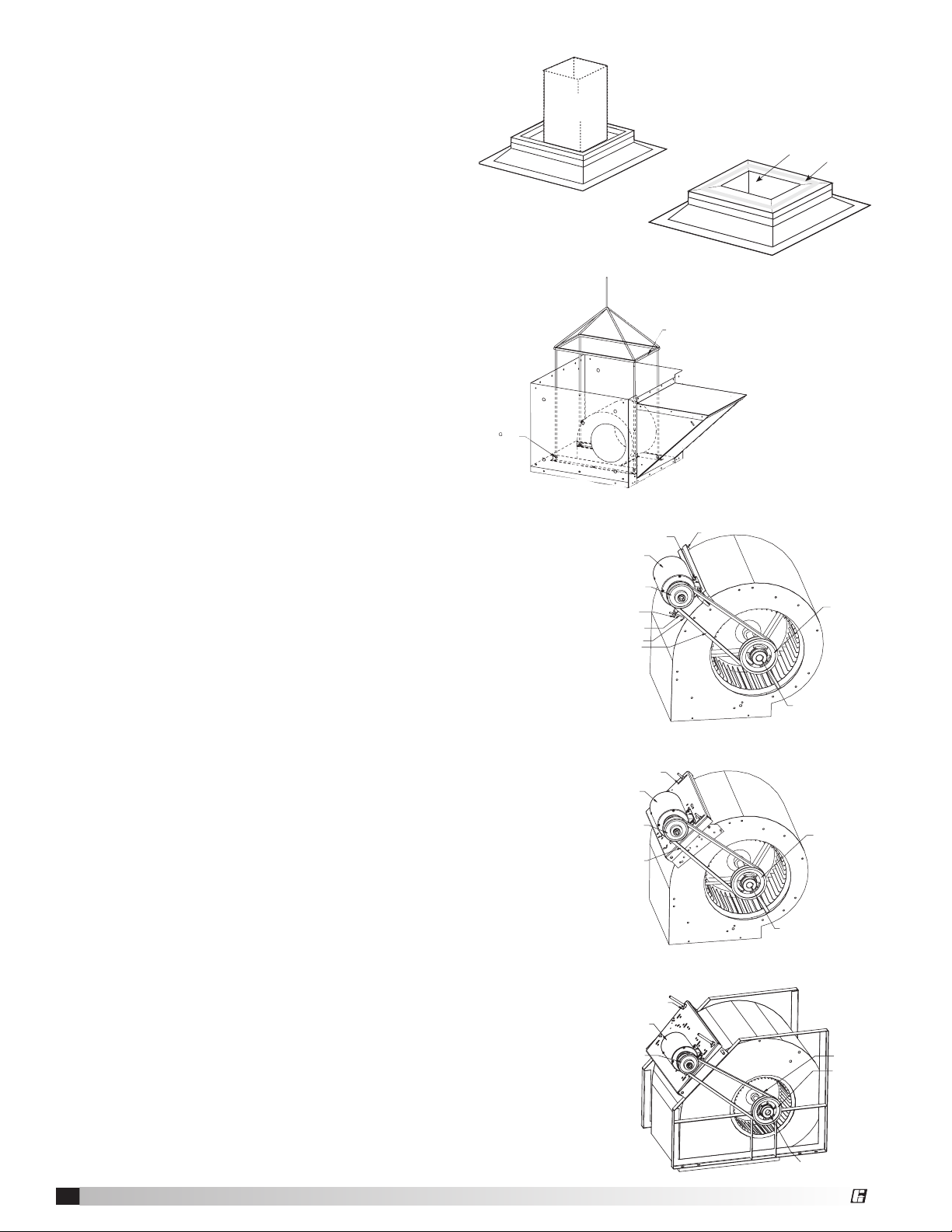

Installation

SPREADER BARS

Supply

Ductwork

by Others

Roof Mounting

Installation, troubleshooting and parts replacement is to

be performed only by a qualified personnel. Consult and

follow NFPA 96 recommendations. NFPA 96 instructions

supersede this document.

NOTE: Refer to motor nameplate for wiring procedures.

Refer to switch manufacturer for installation and

wiring procedures.

1. Cut an appropriate sized hole in the roof surface. Follow

curb manufacturer’s installation instructions. Caulk and

flash curb to ensure a water tight seal.

2. Position curb/equipment support(s) on the roof.

3. Good duct practices should be followed in accordance

with SMACNA and AMCA guidelines, NFPA 96 and any

local codes. The ductwork should extend far enough

above the roofline to meet the supply unit once it is

installed. See Figure 2.

4. Before installing supply unit, apply a sealant around

the perimeter of the supply duct to isolate the fan and

minimize vibration. See Figure 3.

5. Use a crane and set of spreader bars hooked to the

factory lifting holes (as shown in Figure 4) to lift and

center the unit on the curb. Use self-tapping sheet metal

screws to fasten unit to the curb.

NOTE: The use of all lifting holes and set of spreader

bars is mandatory when lifting unit.

6. For unassembled units, or when motor and drive is

shipped loose, install the motor and drive package as

shown in Figures 5, 6 and 7.

MODELS 110, 112, 115 and 118 - Figure 5

(Motor Frame Sizes 56 and Smaller)

MODELS 110, 112, 115 and 118 - Figure 6

(Motor Frame Sizes 143T and Larger)

a. Install blower sheave and motor sheave.

NOTE: On some units, a bushing may be required on

blower sheave.

b. Bolt the belt tensioning bracket to the motor using one

square head bolt and nut. Snap the rubber cap onto

the head of the tensioning screw. Thread the screw

through the tapped hole on the belt.

c. Slide the remaining two square head bolts down the

U-channel attached to the blower housing.

d. Align the slots/holes of the motor base plate with the

two square head bolts, attach the motor with remaining

two nuts.

e. Refer to page 3 for Motor and Pulley mounting

MODELS 120 - Figure 7

a. Install blower sheave and motor sheave.

NOTE: On some units a bushing may be required on

blower sheave.

b. Align the motor with the appropriate holes in the motor

mounting plate. Bolt the motor to the motor mounting

plate using the four bolts and nuts provided. Make

certain to align the sheaves properly.

c. Refer to page 3 for Motor and Pulley mounting

instructions.

Figure 2 -

Installing Ductwork

Figure 4 -

Lifting Unit

Figure 5 - Drive

Package Assembly

Figure 6 - Drive

Package Assembly

Figure 7 - Drive

Package Assembly

SQUARE HEAD

BOLT/NUT (2)

MOTOR

MOTOR SHEAVE

BELT

TENSIONING

BRACKET

TENSIONING

SCREW

RUBBER CAP

BELT

ADJUSTMENT

MOTOR

MOTOR SHEAVE

BELT

ADJUSTMENT

MOTOR

MOTOR SHEAVE

Figure 3 -

Applying Sealant

U-CHANNEL

SLOTS

SLOTS

Ductwork with duct

adapter installed

BUSHING

BLOWER SHEAVE

BUSHING

BUSHING

Sealant

BLOWER SHEAVE

BELT

BLOWER

SHEAVE

Centrifugal Roof Supply Air Fans

2

®®

Loading...

Loading...