Page 1

The

High

Performance

Company

SERIES 73

ELECTRIC ACTUATOR

OPERATION AND MAINTENANCE MANUAL

Page 2

Page 3

Table Of COnTenTs:

page

Safety inStructionS: DefinitionS of termS................................................................. 2

introDuction

principle of operation.............................................................................................. 3

electrical operation................................................................................................ 3

mechanical operation.............................................................................................. 3

inStallation

pre-inStallation Storage......................................................................................... 3

mounting to valve.................................................................................................... 4

manual overriDe operation..................................................................................... 4

electrical inStallation............................................................. .............................. 5

multiple actuator wiring......................................................................................... 6/7

travel limit Switch aDjuStment............................................................................... 8

fielD or factory inStallable optionS

heater........................................................................................................................ 8

auxiliary SwitcheS.................................................................................................... 9

typical Single phaSe & Dc wiring DiagramS.......................................................... 10

appenDix a

baSic toolS................................................................................................................ 11

appenDix b

actuator troubleShooting chart........................................................................... 12

for information on thiS proDuct anD other bray proDuctS

pleaSe viSit uS at our webpage - www.bray.com

Page 4

BRAY Series 73 Electric Actuator

!

!

!

Operation and Maintenance Manual

1.0 safeTy InfOrmaTIOn - DefInITIOn Of Terms

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE used without the safety alert symbol indicates a potential situation which,

if not avoided, may result in an undesirable result or state, including

property damage.

1.1 HazarD-free use

This device left the factory in proper condition to be safely

installed and operated in a hazard-free manner. The notes

and warnings in this document must be observed by the

user if this safe condition is to be maintained and hazardfree operation of the device assured.

Take all necessary precautions to prevent damage to the

actuator due to rough handling, impact, or improper storage.

Do not use abrasive compounds to clean the actuator, or

scrape metal surfaces with any objects.

ground, tag and lock electrical circuits and equipment in

• accordance with established safety practices

• Is trained in the proper use and care of personal pro-

tective equipment (PPE) in accordance with established

safety practices

• Is trained in rst aid

• In cases where the device is installed in a potentially

explosive (hazardous) location – is trained in the operation, commissioning, operation and maintenance of

equipment in hazardous locations

The control systems in which the actuator is installed

must have proper safeguards to prevent injury to personnel, or damage to equipment, should failure of system

components occur.

1.2 QualIfIeD PersOnel

A qualied person in terms of this document is one who is

familiar with the installation, commissioning and operation of

the device and who has appropriate qualications, such as:

• Is trained in the operation and maintenance of electric

equipment and systems in accordance with established

safety practices

• Is trained or authorized to energize, de-energize,

2

WARNING

The actuator must only be installed, commissioned, oper-

ated and repaired by qualied personnel.

The device generates large mechanical force during normal

operation.

All installation, commissioning, operation and maintenance

must be performed under strict observation of all applicable

codes, standards and safety regulations.

Reference is specically made here to observe all applicable safety regulations for actuators installed in potentially

explosive (hazardous) locations.

Page 5

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

Part nuMbering systeM reference chart

Part nuMber tOrque sPeed, 1/4 turn suPPly suPPly

(In.Lbs) (Seconds) (Volts AC) (Volts DC)

73-010Y-113ZV-536 100 2/5/10 120/240 NA

73-030Y-113ZV-536 300 5/10/15 120/240 12/24

73-060Y-113ZV-536 600 5/10/15/30/60 120/240 12/24

Y - DESIGNATES THE SPEED S

Y = 0 1 2 3 4 5

SEC = 2 5 10 15 30 60

Z - DESIGNATES DRIVE TYPE

Z=

TYPE=

Use this chart as a guide to interpret the S73 electric actuator part number.

D S

DOUBLE D STAR

InTrODuCTIOn

The Bray Series 73 is a quarter turn electric actuator with

manual override for use on any quarter turn valve requiring

up to 600 Lb-In of torque. Operating speeds vary between

2 to 60 seconds. Adjusting two cams sets the open and

close travel limit switches. These cams can be adjusted to

allow rotational travel anywhere from 45° to 300°. Standard

Factory setting allows for 90° reversible rotation.

PrinciPle Of OPeratiOn

The Series 73 actuator is basically divided into two internal

sections; the power center below the switchplate, and the

control center above the switchplate. Below the switchplate the spur geartrain drives an output coupling. The

override mechanism for manual operation is also located

here. Above the switchplate are components requiring

customer adjustment. The indicator shaft assembly, limit

switches, terminal strips, heater, capacitor and motor are

all placed here for easy access. External to the unit are a

highly visible valve position indicator, the unique manual

override shaft and two 1/2” NPT conduit entry ports. The

external nish is a high quality polyester powder coating,

which has exceptional UV as well as chemical resistance.

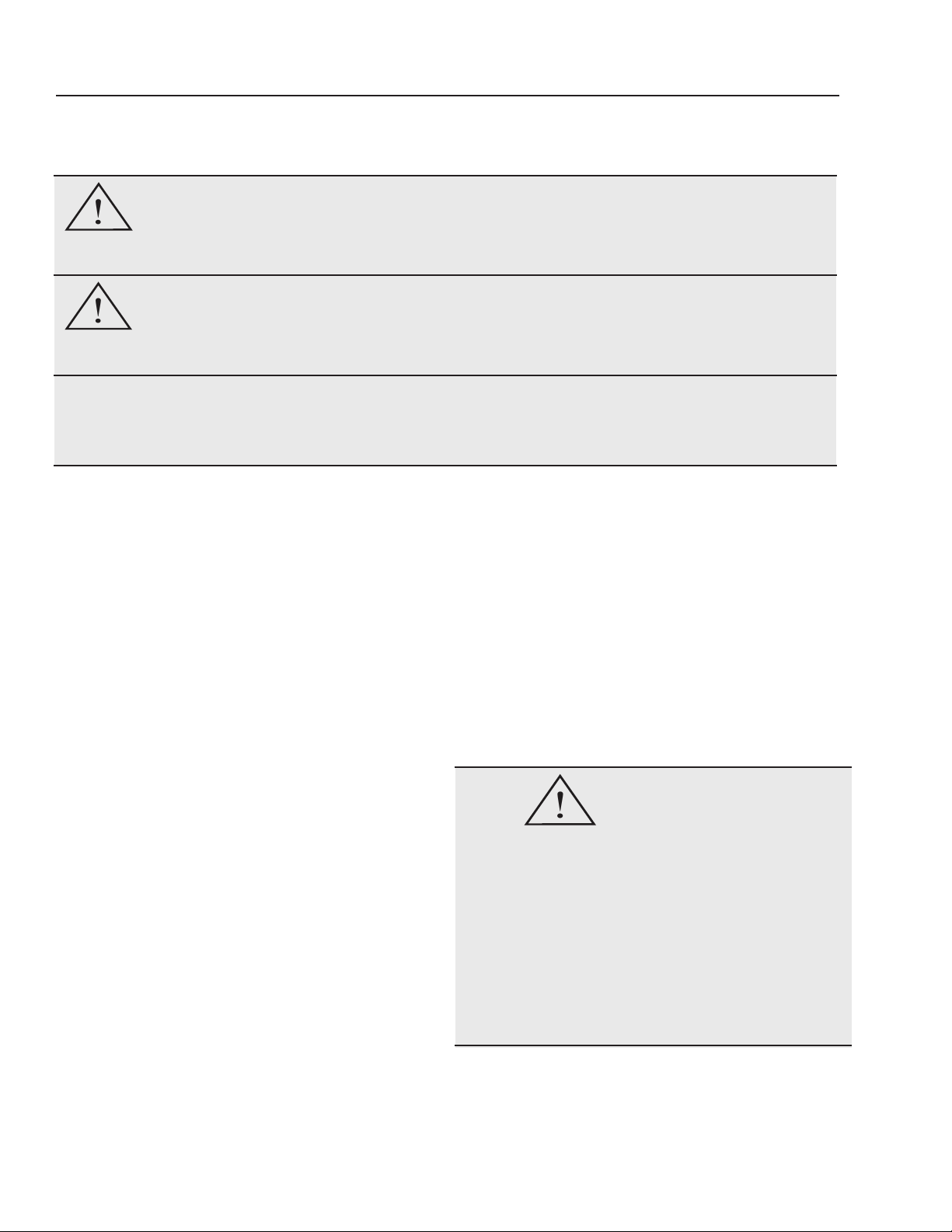

electrical OPeratiOn

The motor used in the Bray Series 73 is a permanent

induction split capacitor design (single phase AC power).

Travel limit switches are mechanical form C (SPDT) are

rated at 10 amp (0.8 PF), 1/2 HP 125 VAC and 3/4 HP

250 VAC. In situations where the torque capacity of the

unit is exceeded to the point where the motor stalls and

overheats, a thermal protector switch built into the motor

windings will automatically disconnect the motor power.

Once the motor cools sufciently the thermal switch will

V - DESIGNATES VOLTAGE

V=

VOLTAGE

3 4 5 6

12VDC 24VDC 120VAC 220VAC

reset. The motor has a spring loaded brake that activates

when power is removed from the unit. The brake prevents

the spur gears from being back driven.

General Electrical Schematic

(Note: the schematic below is for reference only. The actual wiring

diagram for each specic unit is placed inside the actuator cover).

Mechanical OPeratiOn

Mechanically, the ratio of the gearmotor determines the

speed of the unit. The gearmotor utilizes high efciency

spur gears with various ratios for the actuation speeds.

Positioning is determined by an indicator-camshaft linked

to the output coupling.

Pre-installatiOn stOrage

Units are shipped with two metal conduit entry plugs to

prevent foreign matter from entering the unit.

nOTICe

To prevent condensation from forming inside these units,

maintain a near constant external temperature and supply power to the optional heater internal to the unit.

3

Page 6

Open Travel

Switch

Close Travel

Switch

Gear With

Square

Drive Hole

(Cutaway)

Switch Plate

(Cutaway)

Spring

Valve Stem

Gear With

Square

Drive Hole

(Cutaway)

Switch Plate

(Cutaway)

Double D Drive End

of Indicator Shaft

Actuator Drive

Coupling

Valve Stem

Double D Drive End

of Indicator Shaft

Actuator Drive

Coupling

Indicator Shaft

Spring

Snap Ring

Open Travel

Switch

Close Travel

Switch

Open Cam

Close Cam

Square Drive

of Indicator

Shaft

Square Drive

of Indicator

Shaft

Snap Ring

Indicator Shaft

Using an Adjustable

Wrench, Push Down

and Rotate the Indicator

Shaft to Manually Drive

the Actuator & Valve

Series 73 Under Normal

Electrical Operating

Conditions

Open Cam

Close Cam

BRAY Series 73 Electric Actuator

!

Operation and Maintenance Manual

WARNING Turn off all power and lock out service panel before installing or modifying any

electrical wiring.

InsTallaTIOn

MOunting tO a ValVe

All Bray Series 73 electric actuators mount directly to Bray

buttery valves. With proper mounting hardware, the S73

actuator can be installed onto other quarter-turn valves or

devices. For horizontal installation, the standard mounting position aligns the actuator parallel and upright to the

pipeline. If the actuator is to be mounted on a vertical

pipe, it is recommended that the unit be positioned with

the conduit entries on the bottom to prevent condensation from entering the actuator through the conduit. In

all cases, the conduit should be positioned to prevent

drainage into the actuator.

manual OverrIDe OPeraTIOn

1. Ensure that electrical power to the unit is off.

2. Press valve position indicator down, then release a

few times to ensure ease of movement.

3. Remove the valve position indicator pointer.

4. Using an adjustable wrench, 6” or 12” depending

on actuator size, push down on indicator shaft to

disengage it from output gear, then turn shaft to

required position. Open and Close lettering and a

The actuator should be mounted to the valve as follows:

1. Manually operate the actuator until the output shaft of

the actuator is in line with the valve stem. If possible,

use an intermediate position (i.e. valve disc/stem and

actuator half open).

2. Place the proper adapter, if required, onto the valve

stem. It is recommended that a small amount of grease

be applied to the adapter to ease assembly.

3. Mount the actuator onto the valve stem. It may be

necessary to manually override the actuator to align

the bolt patterns.

4. Install the furnished mounting studs by threading

them all the way into the actuator base.

5. Fasten in place with the furnished hex nuts and lock

washers.

direction of travel arrow are molded into the housing for easy reference and permanent position

indication. The double D ats on the indicator shaft

are in alignment with the valve disc position.

5. Return to electrical operation by turning power

on to the unit. The shaft will re-engage the

output gear when electrical power is applied to

the actuator.

6. Replace the valve position indicator pointer.

4

Page 7

electrical installatiOn

SERIES

73

TORQUE

VOLTAGE

SPEED

[N m]

In. lbs.

TAG

sec.

DUTYF.L.C.

XXX

INT.O.4

120VAC

100 10

Amps

1 /4

turn

C US

!

!

1. Check the actuator’s nametag for conrmation of:

Torque Rating, Quarter Turn Time, Duty Rating and

Power Supply. Example ‘A’ below is shown for S73

PN: 73-0102-113D5-536

2. Suitably rated wire should be used for actuator voltage

and current rating. 18AWG, 300V minimum, insulated

wire is recommended for all sizes.

3. Field control scheme (supplied by others) should be

compatible with the operation of actuator motor (AC

or DC).

NOTE: Do not parallel wire multiple actuators - refer

to explanation on parallel wiring.

CAUTION

Do not reverse motor instantaneously when it is still

running - Reversing direction to actuator motor when

it is running can cause damage to motor, switches and

gearing. Directional control switching can be done by

PLC in 20ms or by a small relay in 45ms. Therefore

time delay of 1s has to be incorporated into the control

scheme to avoid damage.

NOTICE

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

CAUTION

Do not reverse motor instantaneously when it is still

running - Reversing direction to actuator motor when

it is running can cause damage to motor, switches and

gearing. Directional control switching can be done by

PLC in 20ms or by a small relay in 45ms. Therefore

time delay of 1s has to be incorporated into the control

scheme to avoid damage.

Figure A

Correct

18 AWG minimum wire is recommended for all eld wiring

4. Actuator must have its eld wiring terminated as shown

in the supplied wiring diagram (diagram attached to

inside of cover). Wiring diagrams (AC or DC) show

remote (customer supplied) typical control switching

devices. Refer to customers/eld wiring for details of

the specic control devices.

The conduit connections must be properly sealed to maintain the weatherproof integrity of the actuator enclosure.

Example A:

NOTICE

Incorrect

5

Page 8

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

Multiple Actuator (Parallel) Wiring

A voltage is present on both motor windings, these voltages

are out of phase and different in magnitude. If these windings

are connected to one another as shown in the INCORRECT

diagrams, this will interfere with the motor performance. Use

a multiple pole switch as shown in the CORRECT diagram.

incOrrect cOnnectiOns

A. No supply on terminal L.

B. Control switch in “Open Run Position”

C. Both actuators in a mid-travel position. i.e. Their open

& close travel switches are closed, allowing them to

operate in an open or close travel direction.

*The following three diagrams show progressive

result of parallel wiring.

D. 120VAC source applied, both motors start to run “open”.

(Shows current ow)

E. #1 actuator runs fully open and its travel limit switch

opens circuit. This actuator stops (perhaps only for a

short time!). #2 actuator continues to run open.

(Shows current ow)

F. The other “Back Feeding” current path existing between

the actuators is shown.

G. Though actuator #1 had come to rest (full open), it can

and does get current owing through its close travel leg

via this “Back Feeding” current from #2 actuator.

This causes actuator #1 to run a couple of degrees in the

closed direction, #2 actuator will then reach its fully open

position. If left running for a “good” period, both actuators end

up driving each other OPEN-CLOSED at strange positions.

(Shows current ow)

(Shows other “Back Feeding” current ow)

6

Page 9

cOrrect cOnnectiOns

To eliminate this “BACK FEEDING PARALLEL” driving, we suggest separate contacts for each actuator.

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

If we redraw the diagram for the #1 actuator having

reached its fully open travel position and having tripped

its open travel limit switch. You can see that the #2

actuator would still run on, until it reached its fully open

position. The #2 actuator when running open can not

“BACK FEED”, the rst actuator’s closed travel motor

winding (as it did in G). on the previous page).

(Shows current ow)

7

Page 10

BRAY Series 73 Electric Actuator

!

!

Operation and Maintenance Manual

traVel liMit switch caM adjustMent

Each cam has two tapped holes with one setscrew that

may be placed at either location for easy access.

Cams are innitely adjustable by using a 5/64” hex key.

Standard factory setting allows for 90 degrees reversible

rotation between open and close positions.

The bottom of the cam must be aligned with the bottom of

the travel limit switch button to allow the switch to function

properly during manual override.

Correct positioning of cam & switch are shown in the illustration below, when in motor/automatic drive condition.

heater

To prevent condensation from forming inside the actuator,

Bray offers an optional heater. The heater is a PTC (Posi-

tive Temperature Coefcient) type, which has a unique

temperature - resistance characteristic. The heater selfregulates by increasing its electrical resistance relative

to its temperature. The heater does not require external

thermostats or switches to control its heat output. It is

constructed of a polycrystalline ceramic, sandwiched

between two conductors, and wrapped inside a thermally

conductive electrical insulator.

Connect the heater wires to the terminal strip as indicated

on the wiring diagram.

heater Kit cOnsists Of:

1. Heater with ying leads

2. Heater Mounting Bracket

3. #10 pan head screw, phillips drive

tOOls required:

• For terminal wiring Screwdriver, 3/16” tip at blade

• For heater mounting screw Screwdriver, No.1 phillips

installatiOn PrOcedure:

WARNING

Turn off all power and lock out service panel before

installing or modifying any electrical wiring.

The heater is mounted through a hole provided in the

switchplate.

1. Place the heater snugly into its mounting bracket

until approx. 1/2” is below the bracket as shown in

the illustration below.

2. Slip the heater into its mounting hole

3. Align the fastening hole in the bracket with the

threaded screw hole in the plate. Fasten the heater

to the switchplate.

4. Connect the heater wires to the terminal strip as

indicated on the wiring diagram.

WARNING

The heater surface can reach temperatures in excess

of 200 degrees Celsius.

8

Page 11

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

field install. Of auxiliary switch (es)

The maximum allowable auxiliary switch conguration is

shown in the illustrations below for each size of actuator.

auxiliary switch Kit cOnsists Of:

1. Switch with ying leads

2. Switch spacers

3. Cam with set screw

4. Cam spacers

5. Pan head screw, phillips drive

tOOls required

For terminal wiring Screwdriver, 3/16” at tip blade

installatiOn PrOcedure:

For switch mounting Screwdriver, No. 1 phillips

1. Remove switch mounting screws & discard

2. Remove switch bracket & retain for use later

3. Install auxiliary cam(s) and spacers as shown

4. Install auxiliary switch(es) and spacers as shown

5. Reinstall switch bracket

6. Install longer switch mounting screws from kit

7. Connect switch wiring to terminal strip per wiring

diagram

8. Adjust cams as required

9

Page 12

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

Typical actuator wiring diagrams shown for single phase A.C. and D.C. motorized units.

Diagrams show actuators in their fully closed positions.

10

Page 13

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

aPPenDIx a

basic tOOls required fOr installatiOn

cOMMOn tO all units

Position Indicator Knob Screwdriver, 3/4” tip at

All switches, heater kit Screwdriver, No.1 phillips

Terminal strip wiring Screwdriver, 3/16” at tip

Cam adjustment Hex key, 5/64”

Cover socket head cap screws Hex key, 9/64”

100-300 lb-in units

Switchplate socket head cap screws Hex key, 9/64”

Valve mounting nuts (small bolt circle) Wrench, 3/8”

Valve mounting nuts (large bolt circle) Wrench, 7/16”

600 lb-in units

Switchplate socket head cap screws Hex key, 7/64”

Valve mounting nuts (small bolt circle) Wrench, 7/16”

Valve mounting nuts (large bolt circle) Wrench, 1/2”

11

Page 14

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

aPPenDIx b

actuatOr trOubleshOOting chart

Problem Possible cause Solutions

Actuator does not operate Cams are depressing travel switch Adjust cams to their correct positions

Override is engaged/shaft depressed Apply electricity to cancel manual

mode

Wiring is incorrect Check wiring and power supply

Actuator has reached its thermal Allow time to cool

shutdown temperature

Actuator operates in reverse Field wiring is reversed Rewire eld wiring

directions

Actuator does not fully close valve Limit switches are tripping Readjust travel limit switches

(or open valve) Valve torque requirement is higher Manually override out of seat, try

than actuator output angle seating or t larger actuator

Voltage power supply is low Check power source

Motor hums but does not run Motor brake engaged Check that brake is not obstructed

Corrosion inside unit Condensation forming Test heater wiring, should have

constant power supply

Water leaking into the unit Check all seals and possible water

entry through conduit

12

Page 15

nOTes

BRAY Series 73 Electric Actuator

Operation and Maintenance Manual

13

Page 16

A Division of BRAY INTERNATIONAL, Inc.

13333 Westland East Blvd. Houston, Texas 77041

281.894.5454 FAX 281.894.9499 www.bray.com

Bray® is a registered trademark of BRAY INTERNATIONAL, Inc.

© 2009 Bray International. All rights reserved. OM-73-001 12-2009

Loading...

Loading...