Greenheck RV-35 Installation Manual

Part #474612

®

RV/RVE

Packaged Rooftop Ventilator

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property damage!

Model RV/RVE

General Safety Information

Only qualied personnel should install and maintain this

system. Personnel should have a clear understanding of

these instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Code (NEC), the National

Fire Protection Agency (NFPA), where applicable.

Follow the Canadian Electric Code (CEC) in Canada.

2. All moving parts must be free to rotate without

striking or rubbing any stationary objects.

3. Unit must be securely and adequately grounded.

4. Do not spin wheel faster than maximum cataloged

fan RPM. Adjustments to fan speed signicantly

affect motor load. If the fan RPM is changed, the

motor current should be checked to make sure it is

not exceeding the motor nameplate amps.

5. Verify that the power source is compatible with the

equipment.

6. Never open access doors to the unit while it is

running.

WARNING

The roof lining contains high voltage wiring. To

prevent electrocution, do not puncture the interior or

exterior panels of the roof.

DANGER

• Always disconnect power before working on or near

this equipment. Lock and tag the disconnect switch

or breaker to prevent accidental power up.

• If this unit is equipped with optional gas accessories,

turn off gas supply whenever power is disconnected.

CAUTION

This unit is equipped with a compressed refrigerant

system. If a leak in the system should occur,

immediately evacuate the area. An EPA Certified

Technician must be engaged to make repairs or

corrections. Refrigerant leaks may also cause bodily

harm.

CAUTION

When servicing the unit, the internal components may

be hot enough to cause pain or injury. Allow time for

cooling before servicing.

®

Packaged Rooftop Ventilator

1

Receiving

Upon receiving the product, check to make sure all

items are accounted for by referencing the Bill of Lading

to ensure all items were received. Inspect each crate for

shipping damage before accepting delivery. Notify the

carrier if any damage is noticed. The carrier will make

notication on the delivery receipt acknowledging any

damage to the product. All damage should be noted on

all copies of the Bill of Lading which is countersigned by

the delivering carrier. A Carrier Inspection Report should

be lled out by the carrier upon arrival and led with the

Trafc Department. If damaged upon arrival, le claim

with the carrier. Any physical damage to the unit after

acceptance is not the responsibility of the manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received. If any items are

missing, report shortages to your local representative to

arrange for obtaining missing parts. Sometimes it is not

possible that all items for the unit be shipped together

due to availability of transportation and truck space.

Conrmation of shipment(s) must be limited to only

items on the Bill of Lading.

Handling

Units are to be rigged and moved by the lifting brackets

provided. This model is not designed for forklifting.

Location and number of lifting points varies by model

and size and all provided lifting brackets must be used

to properly support the unit during handling. Handle

each unit in such a way as to keep from scratching or

chipping the coating. Damaged nish may reduce the

ability of the unit to resist corrosion.

Storage

Units are protected against damage during shipment. If

the unit cannot be installed and operated immediately,

precautions need to be taken to prevent deterioration of

the unit during storage. The user assumes responsibility

of the unit and accessories during storage. The

manufacturer will not be responsible for damage during

storage. These suggestions are provided solely as a

convenience to the user.

Inspection and Maintenance During

Storage

While in storage, inspect units once per month. Keep

a record of inspection and maintenance performed. If

moisture or dirt accumulations are found on the parts,

the source should be located and eliminated. At each

inspection, rotate all moving parts by hand ten to

fteen revolutions to distribute lubricant on motor and

bearings. If paint deterioration begins, consideration

should be given to touch-up or repainting. Units with

special coatings may require special techniques for

touch-up or repair.

Machined parts coated with rust preventative should

be restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventative

coating with petroleum solvent and clean with lint-free

cloths. Polish any remaining rust from the surface with

crocus cloth or ne emery paper and oil. Do not destroy

the continuity of the surfaces. Wipe clean thoroughly

with Tectyl® 506 (Ashland, Inc.) or the equivalent. For

hard to reach internal surfaces or for occasional use,

consider using Tectyl® 511M Rust Preventative or

WD-40

® or the equivalent.

Product Overview

A horizontally congured High Percentage Outdoor

Air unit designed for installation either indoors or

outdoors. Each unit has multiple options for cooling

and/or heating. The unit is designed to replace air that

is exhausted from the building and also heat and cool,

as needed. The air volume produced by the unit is

constant, but can be optionally modulated to provide a

variable air volume (VAV) and recirculation is also offered

as an option.

Cooling

Units have the following cooling options available:

• Packaged DX

• Split DX

• Chilled water coil

Units with packaged DX are shipped fully charged with

refrigerant and are ready for operation upon arrival.

Heating

There are three different optional heat sources that can

be ordered for this unit:

• Indirect gas-red furnace with one or two sets of

heat exchangers

• Electric heat with innitely variable SCR control

• Hot water coil

Airflow Arrangement

The unit is capable of Constant Air Volume (CAV),

Variable Air Volume (VAV), 100% Outdoor Air and have

recirculating air options.

Safety Listing

Models are listed per ANSI/UL 1995, Heating and

Cooling Equipment and are ETL Certied.

Supplemental Installation, Operation and

Maintenance Manuals

Refer to the following Greenheck Installation, Operation

and Maintenance Manuals for additional information:

• Indirect Gas-Fired Heat Modules

• PCO3 DDC Controller Operating Manual

• Housed Plenum Array, Plug and Plenum

Models and Capacities

The packaged rooftop ventilator is built on three

different platform sizes.

Model Cooling Capacity

RV-35/RVE-35 5 to 15 tons

RV-50/RVE-50 10 to 25 tons

RV-80/RVE-80 15 to 29 tons

Packaged Rooftop Ventilator

2

®

Table of Contents

General Safety Information ...................1

Receiving, Handling, Storage .................2

Product Overview

Cooling ....................................2

Heating ....................................2

Airflow Arrangement .........................2

Safety Listing ...............................2

Supplemental Installation, Operation and

Maintenance Manuals .......................2

Models and Capacities .......................2

Subassemblies

Blower ....................................4

Coils ......................................4

Compressors ...............................4

Dampers ...................................4

Optional Barometric Relief Damper ..............4

Electric Heater ..............................4

Filters .....................................4

Indirect Gas-Fired Furnace ....................4

Packaged DX System ........................4

Split DX ...................................4

Vestibule ...................................4

Installation

Typical Unit Weights and Dimensions ............5

Service Clearances ...........................5

Additional Clearances for Packaged DX ..........6

Handling Concerns for Units with Package DX .....6

Lifting .....................................6

Roof Curb Mounting .........................7

Optional Piping Vestibule ......................7

Ductwork Configurations ......................7

Rail Mounting and Layout .....................8

Recommended Electrical and

Gas Supply Entry Locations ..................8

Gas Supply Piping ...........................8

Gas Connections ............................8

Electrical Information ........................9

Determine the Size of Main Power Lines ........9

Determine the Size of Electric Heater Wiring .....9

Provide the Opening(s) for the Electrical

Connections ..............................9

Connect the Power Supplies ..................9

Wire the Optional Convenience Outlet ..........9

Connect Field-Wired Low Voltage Components ...9

Field-Provided Disconnect ....................9

Plumbing / Piping Overview

Split DX / Water Coil Connections ..............10

Condensate Drain Trap ......................10

Control Center Components

Main Control Center .........................11

Optional Indirect Gas-Fired Furnace ............11

Component Operation

Phase Monitor .............................12

Variable Frequency Drive .....................12

Supply Fan VFD Sequence ...................12

Optional Exhaust Fan VFD Sequence ...........12

Factory-Installed Refrigeration System

Components ..............................13

Start-Up – Unit

Model and Serial Number ....................14

Pre-Start-Up Checklist .......................15

Special Tools Required ......................15

Start-Up Procedure .........................15

Voltage Imbalance ..........................15

Start-Up Checklist ..........................16

Start-Up – Components

Fan ......................................17

Supply Fan (Plenum Type) ....................17

Fan Wheel Rotation Direction .................17

Supply/Exhaust Fan .........................17

Vibration ..................................17

Discharge Air Temperature Sensor .............17

Optional Energy Wheel

Start-Up ..................................18

Drive Belt .................................18

Adjust the Air Seals .........................18

Sequence of Operation ......................18

Maintenance ...............................19

Inspection .................................19

Wheel Disassembly .........................19

Cleaning ..................................19

Reassembly ...............................19

Energy Recovery Wheel Belt ..................19

Energy Recovery Wheel Bearings ..............19

Energy Recovery Wheel - Troubleshooting .......20

Troubleshooting

Alarms

DDC Controller ..........................20

Phase Monitor ............................20

Variable Frequency Drive ...................20

Optional FX05 Furnace Controller ............20

Optional Digital Scroll Compressor Controller ...20

Unit ......................................21

Refrigeration Circuit ......................22-25

Routine Maintenance

Monthly ..................................26

Semiannually ..............................26

Annually ..................................26

Units with Packaged DX, Semiannually ..........26

Maintenance Procedures

Lubrication ................................26

Dampers ..................................26

Gas Furnace ...............................26

Fan Motors ................................27

Fan Wheel and Fasteners ....................27

Internal Filter Maintenance ...................27

Outdoor Air Filters ..........................27

External Filter Maintenance ...................27

Coil Maintenance ...........................27

Maintenance Log ....................Backcover

Warranty ...........................Backcover

®

Packaged Rooftop Ventilator

3

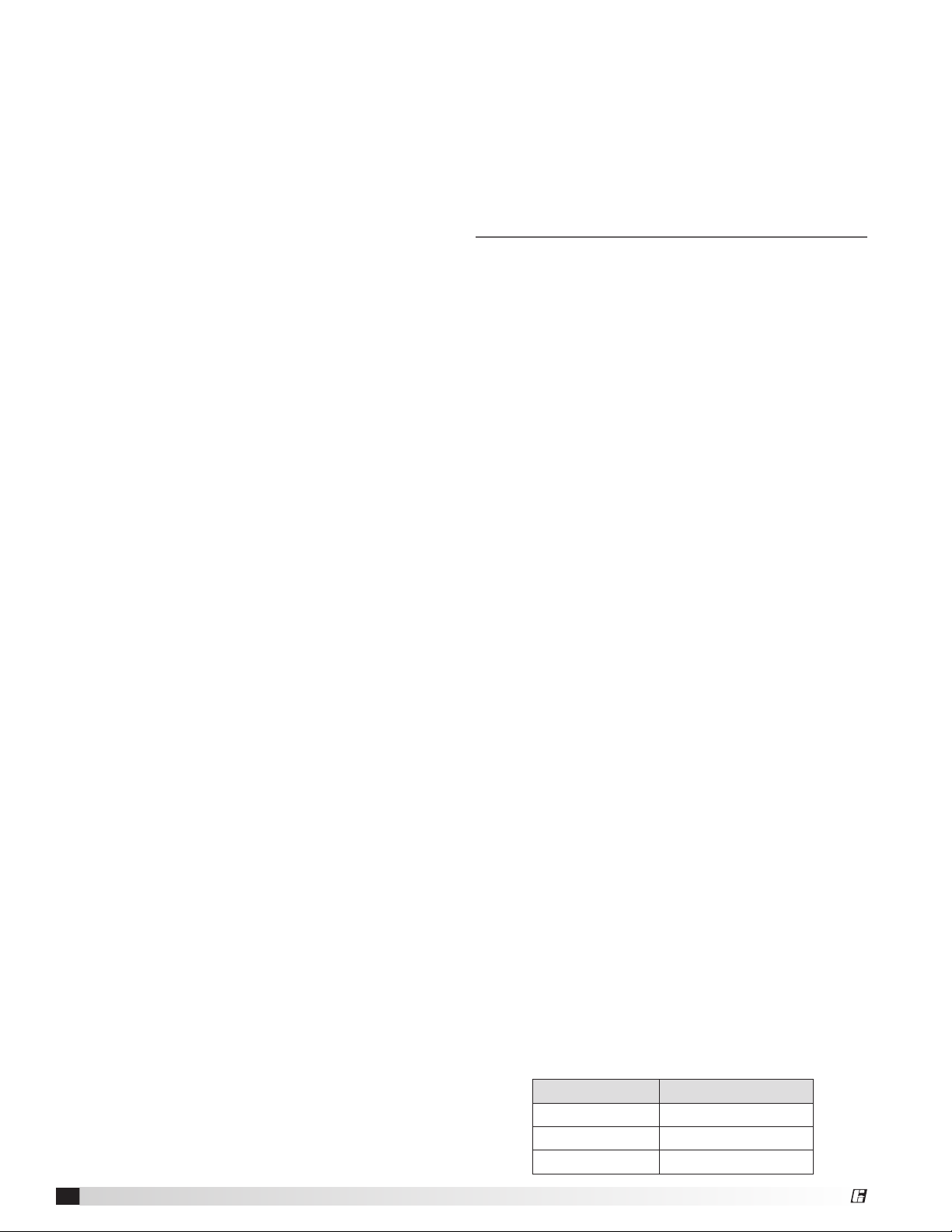

Subassemblies

Blower

Either one or two plenum-type fans. All units are

equipped with a plenum fan for Supply Air and a second

may be selected for Exhaust (Relief) Air.

Coils

Evaporator coil (optional)

Condenser coil (optional, packaged DX only)

Water coil (optional)

Reheat coil (optional)

Compressors

Each unit having packaged DX will have either one

or two refrigerant compressors. Optionally, one the

compressors may be a digital scroll type compressor.

Dampers

Motorized intake air damper, motorized recirculating

damper. Optional return air damper. Optional gravitytype exhaust damper.

Optional Barometric Relief Damper

Used during economizer mode of the unit when building

pressure increases, relief damper will open due to over

pressurization.

Electric Heater

An SCR controlled electric heater (not shown) is

available on the units. It requires a separate power

supply and has its own control panel. See unit-specic

wiring diagram.

Filters

Two-inch thick metal mesh lters in the optional

Outdoor Weatherhood air intake, 2-inch thick pleated

paper MERV 8 (standard) or MERV 13 lters in the

airstream. Optional 4-inch thick lter bank with 2-inch

thick MERV8 and 2-inch thick MERV 13 pleated paper

Final Filters.

Indirect Gas-Fired Furnace

The optional model PVG furnace is available on housing

sizes 35 and 50. Housing size 80 uses the optional

model PVF furnace.

Packaged DX System

Any unit may be ordered with a packaged DX system.

It will include either one or two compressors, a

condenser coil(s) and evaporator coil(s) and all needed

components. Units that have packaged DX are charged

with R-410A refrigerant. Do not use tools or parts

designed for other refrigerants on these units.

Split DX

The unit may be ordered with a split DX system for

connection to a building cooling system.

Vestibule

Some units may be ordered with a factory-assembled

vestibule that is to be eld-attached to the side of the

unit. See lifting instructions.

Condenser Coils

(optional)

Packaged DX

Compressors

(optional)

Furnace Vest Plate

and

Furnace Control Center

(optional)

Open view of Model RVE showing optional condenser coil, fans and enthalpy wheel.

Condenser Fans

Main Control

Center

(optional)

Indirect Gas-Fired Furnace

(optional)

Energy Wheel (RVE)

(optional)

Plenum-Type

Supply Air Blower

Final Filters

(on coil face)

Intake Air

Damper

Plenum-Type

Exhaust Air Blower

Recirculating

Damper

Coils

(optional)

Weatherhood Filters

(metal mesh)

Packaged Rooftop Ventilator

4

®

Installation

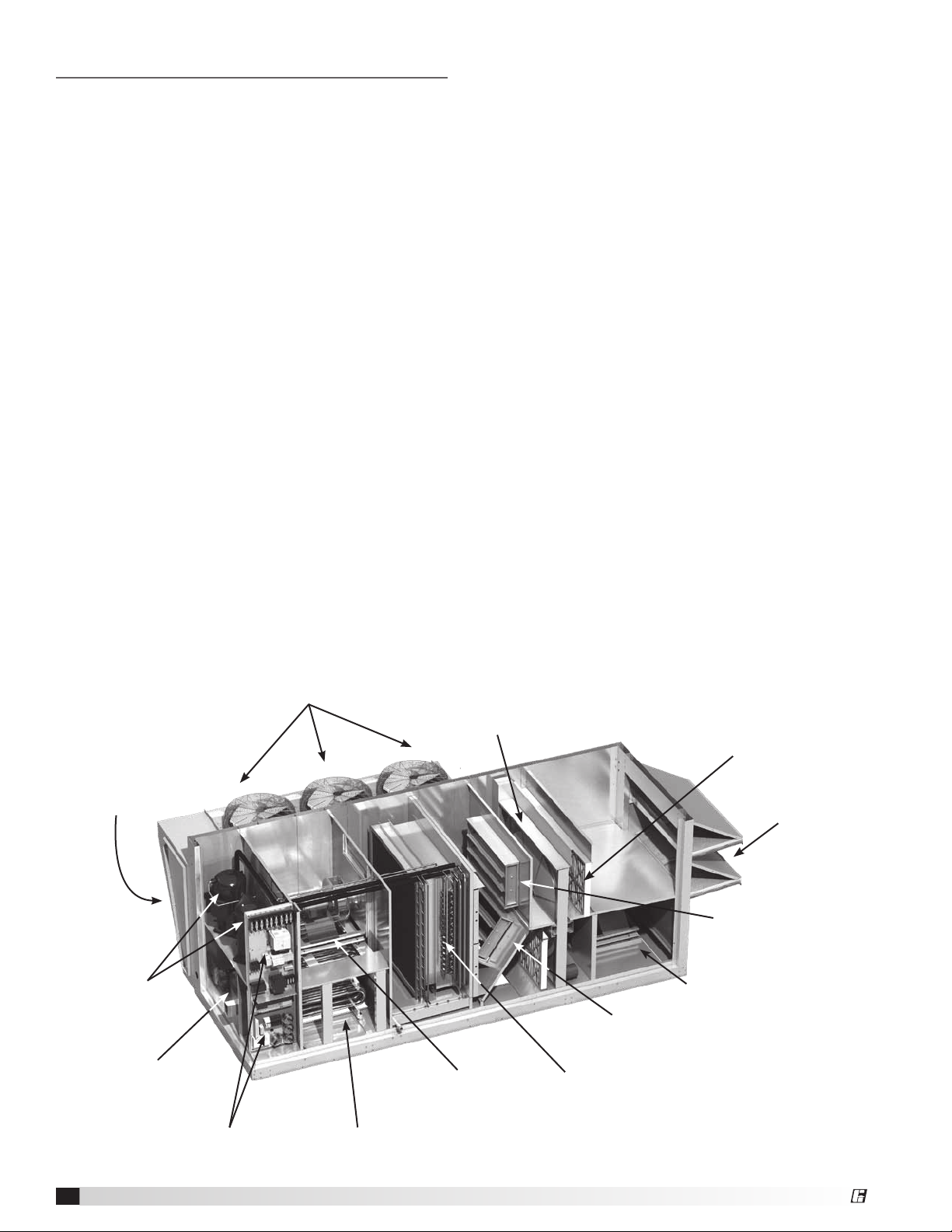

Typical Unit Weights and Dimensions

PLAN VIEW ELEVATION

LA

Supply Filters

DX Coil

Length Width

Control

Center

Supply Air

Discharge

Condensing

Section

H

Recirc

Damper

Optional

Piping Vestibule

Outdoor Air

Damper

Height

Indirect Gas

Heater

Weight

Unit

Outdoor Air

Weatherhood

W

J

Unit

Size

Return Air Inlet

A L W J J H

Outdoor Air

Weatherhood

RV-35 21.5 95.6 52.5 28.8 26.0 58.2 2,600 20x20

RV-50 21.5 108.8 64.0 32.0 26.0 70.5 3,600 20x25

RV-80 26.5 117.0 68.0 30.0 26.0 82.0 4,500 20x25

RVE-35 21.5 147.5 52.5 28.8 26.0 58.2 3,000 20x20

RVE-50 21.5 163.1 64.0 32.0 26.0 70.5 4,100 20x25

RVE-80 26.5 178.3 68.0 30.0 26.0 82.0 5,100 20x25

All dimensions are shown in inches. Weight is in pounds.

Note: If RV unit is ordered with optional exhaust (relief) fan, corresponding RVE dimensions will apply.

Supply

Blower

Compressors

Final Filter

Size

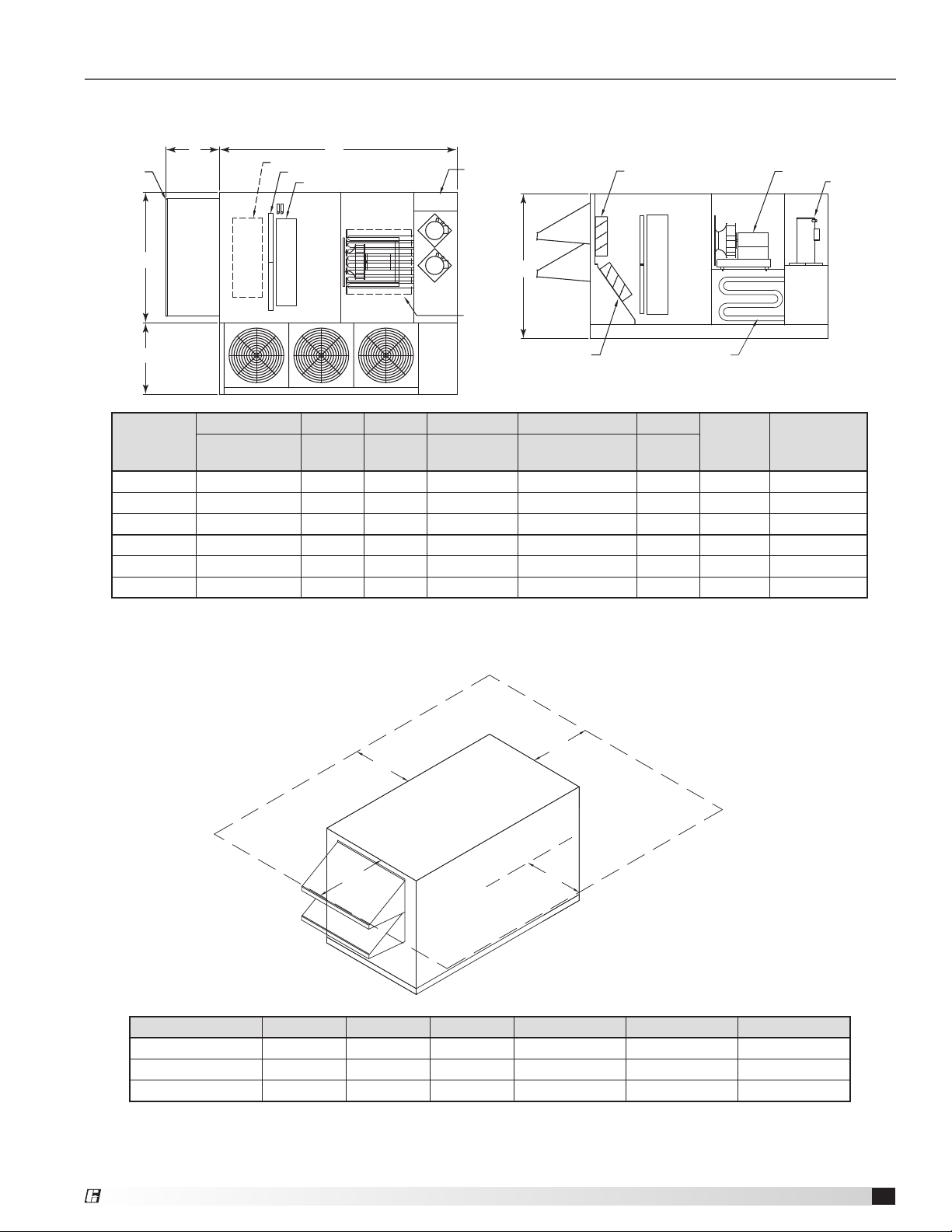

Service Clearances

Clearance

Unit Size ACS CC End OA End *NA from Unit *NA from CS *NA from Vest

RV-35/RVE-35 36 36 42 24 42 30

RV-50/RVE-50 36 36 42 24 42 30

RV-80/RVE-80 36 36 52 24 42 30

All dimensions are shown in inches.

*NA from Unit = no condensing section or piping vestibule

*NA from CS = condensing section

*NA from Vest = piping vestibule

OA End

CC End

ACS

Clearance

NA

ACS = Access

CC = Control Center

NA = Non-Access

OA = Outdoor Air Weatherhood

®

Packaged Rooftop Ventilator

5

Additional Clearances for

Packaged DX Units

Packaged DX units require additional clearance

because they must have unrestricted air movement

around the condenser coil and condenser fans. Hot air

is being discharged from the condenser fans during

operation. Enough clearance must be provided to

avoid recirculation or coil starvation. When equipped

with condenser coils, the unit should never be placed

under an overhang or inside a building. A minimum of

48inches above the condenser fans is acceptable, but

unobstructed is strongly recommended.

Minimum 48 inches clearance

Condenser Fans

Minimum 42 inches

clearance

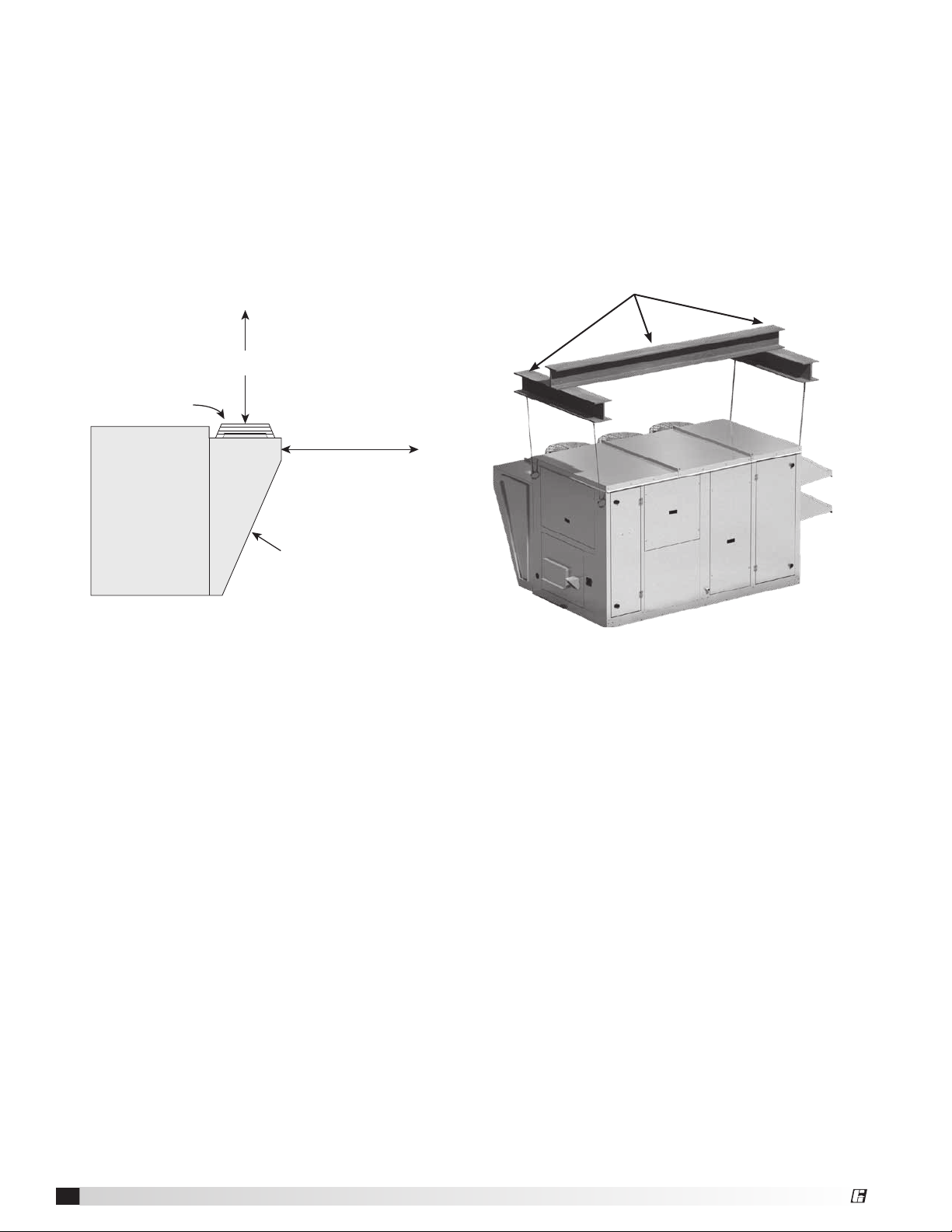

Lifting

1. Before lifting, be sure that all shipping materials

have been removed from unit.

2. To assist in determining rigging requirements,

weights are provided in the Unit Weights &

Dimensions section of this manual.

3. Unit must be lifted by all lifting lugs provided at top

of unit.

4. Spreader bars must span the unit to prevent

damage to the cabinet by the lift cables.

Use spreader bars to prevent damage to cabinet.

Condenser Coil

End view of roof top unit with Packaged DX

Handling Concerns for Units with

Packaged DX

Units having packaged DX have a system that is

pressurized with refrigerant and if it is damaged,

the refrigerant could leak into the atmosphere or

cause bodily harm due to the extreme cold nature of

expanding refrigerant. Use protective equipment such

as gloves and safety glasses to minimize or prevent

injury in case of a system leak during installation.

Before Lifting - Vestibule

Determine whether or not the unit has a vestibule that

must be eld-attached to the side of the unit. Vestibules

are shipped assembled but detached from the unit.

They have lifting lugs on them so they can also be lifted

by crane, but the installed location of the unit may make

it preferable to install the vestibule on the unit prior to

lifting.

Before Lifting - Field Power Access

Determine where high voltage and low voltage wiring is

to be brought into the cabinet. If wiring is to be brought

into the cabinet through the oor, see Alternate Supply

Entry Locations in this manual. If unit is to be installed

on a roof, cut access openings in the roof deck as

needed.

5. Always test-lift the unit to check for proper balance

and rigging before hoisting to desired location.

6. Never lift unit by weatherhood.

7. Never lift units in windy conditions.

8. Preparation of curb and roof openings should be

completed prior to lifting unit to the roof.

9. Check to be sure that gasketing (supplied by others)

has been applied to the top of the curb prior to

lifting the unit and setting on the curb.

10. Do not use fork lifts for handling unit.

Packaged Rooftop Ventilator

6

®

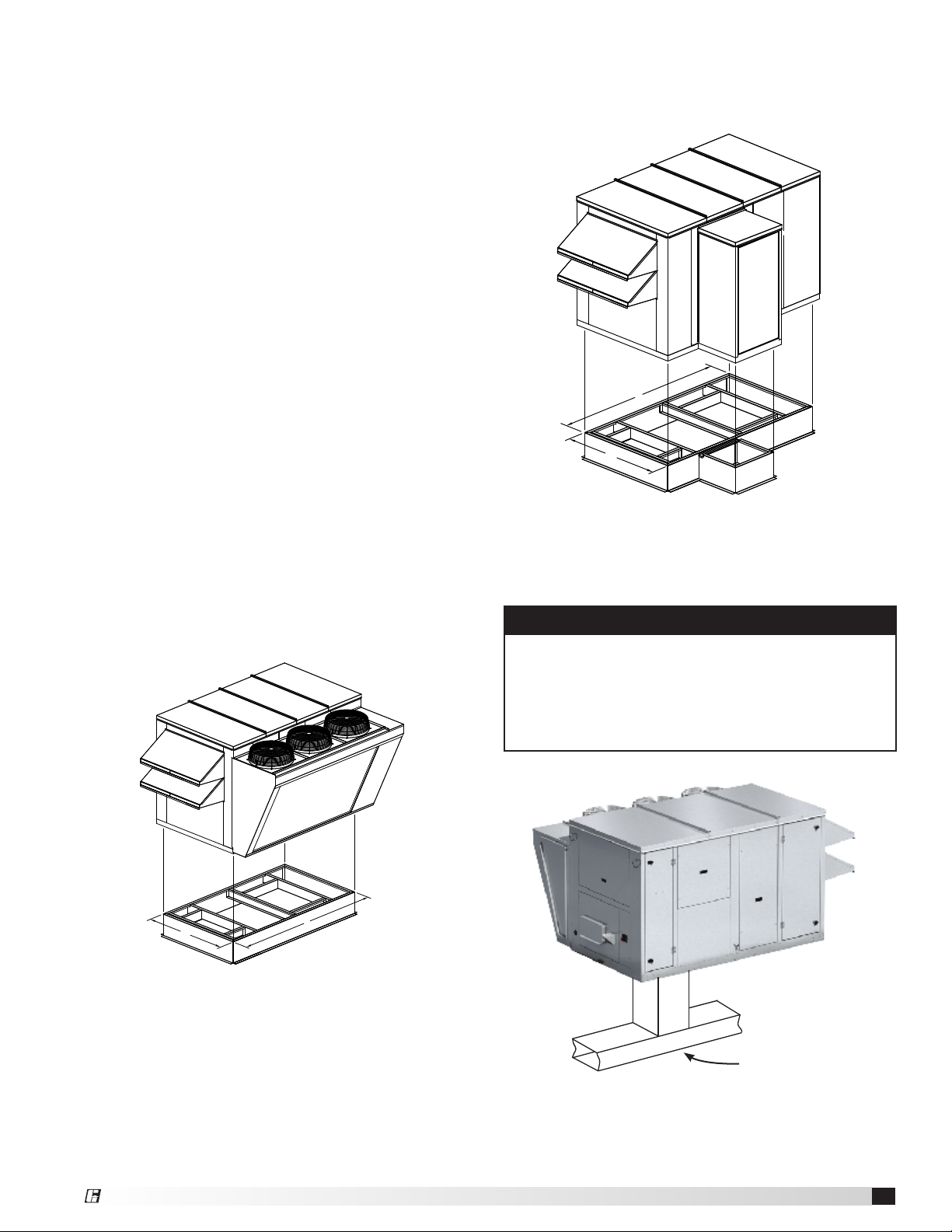

Roof Curb Mounting

Roof curb details, including duct locations and

dimensions, are to be found in the roof curb assembly

instructions.

Rooftop units require curbs to be mounted rst. The

duct connections must be located so they will be clear

of structural members of the building.

1. Factory Supplied Roof Curbs

Roof curbs are Model GKD which are shipped in a

knockdown kit (includes duct adapters) and require

eld assembly (by others). Assembly instructions are

included with the curb kit.

2. Install Curb

Locate curb over roof opening and fasten in place.

Check that the diagonal dimensions are within ± 1/8

inch of each other and adjust as necessary. For proper

coil drainage and unit operation, it is important that the

installation be level. Shim the curb as required to level.

Install gasketing on top surface of curb (provided by

others).

3. Install Ductwork

Installation of all ducts should be done in accordance

with SMACNA and AMCA guidelines. Duct adapters are

provided to support ducts prior to setting the unit.

4. Set the Unit

Lift unit to a point directly above the curb and duct

openings. Guide unit while lowering to align with duct

openings. Roof curbs t inside the unit base. Make sure

the unit is properly seated on the curb and level.

Optional Piping Vestibule

If the unit was ordered with the vestibule, the NA (NonAccess side) clearance dimension must be measured

from the vestibule.

L

W

Typical Unit with Piping Vestibule and

Factory-Supplied Curb Kit

Ductwork Configurations

NOTE

Downblast Discharge Ductwork - whenever

downblast discharge is used, the ductwork directly

beneath the unit must be connected with either a “T”

or an “L” configuration and the area directly beneath

the heat source must not have any openings such

as louvers or grates.

W

Typical Unit with Condensing Section and

Factory-Supplied Curb Kit

L

5. Install Vestibule

If unit was ordered with a vestibule and it has not yet

been attached to the unit, caulk and attach the vestibule

at this time.

®

No louvers or grates

Packaged Rooftop Ventilator

7

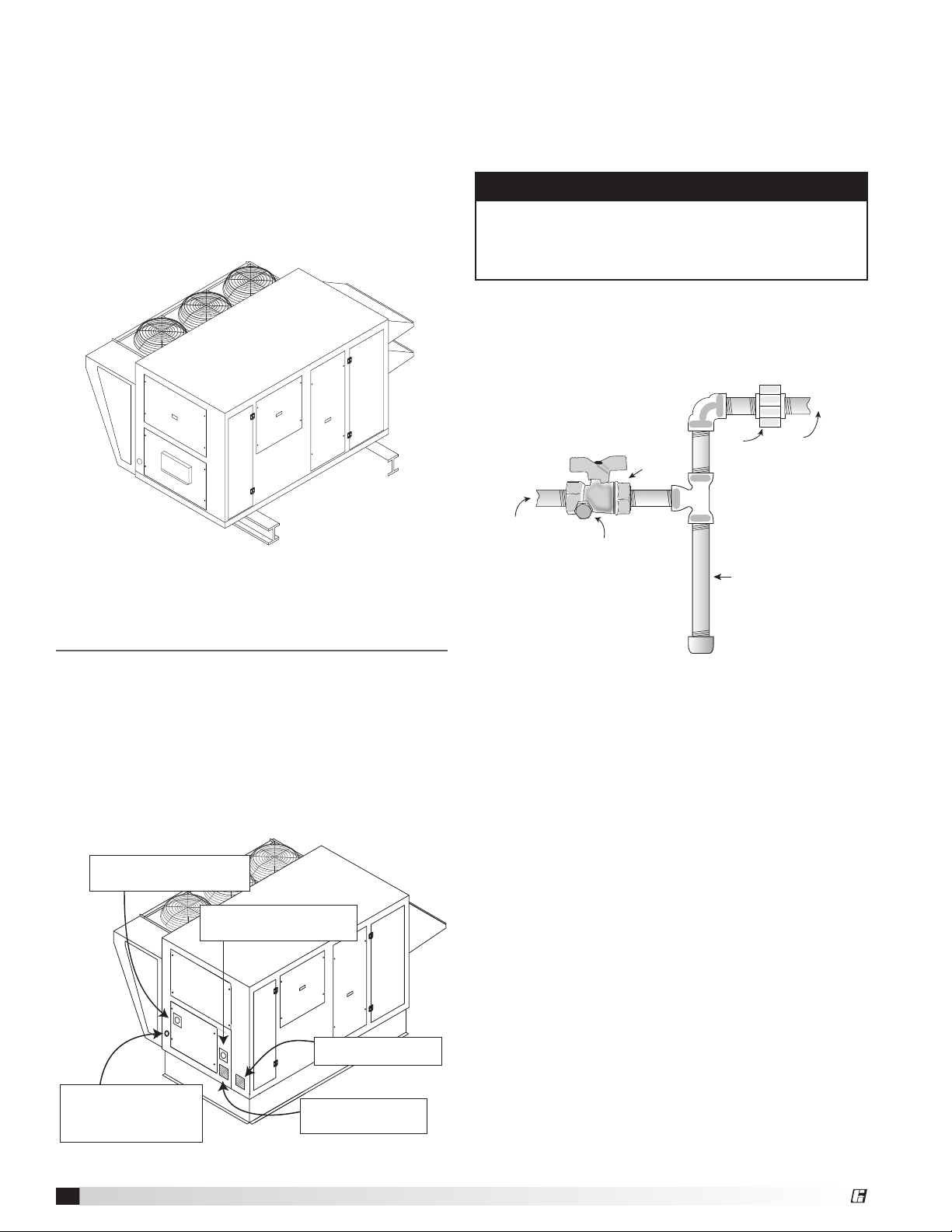

Rail Mounting and Layout

• The units may be installed on rails provided and

installed by others. Ensure that rails are designed to

handle the weight of the unit and provide proper load

distribution on building supports.

• Make sure that rail positioning does not interfere with

the openings on the unit.

• Rails should run the width of the unit and extend

beyond the unit a minimum of 12 inches on each side.

• Set unit on rails.

Each installation is unique and as a result, alternate

entry locations may be eld-located. Before using any

alternate entry location, verify the suitability of the

location and ensure the use of an alternate location

does not interfere with unit wiring, components or

functionality.

WARNING

Never drill holes in the roof of the unit! There is high

voltage wiring located between the inner and outer

roof panels. Damage to the wiring could cause severe

bodily harm or death.

Gas Supply Piping

Units with indirect gas-red furnaces require eldsupplied and installed gas supply piping.

Typical Unit Installed on Rails Supplied by Others

Recommended Electrical and Gas

Supply Entry Locations

Manufacturer recommends that electrical service and

gas supply be brought into the cabinet through the

end wall, as shown below. There are three penetrations

into the cabinet that are required; one for high voltage

supply wiring, one for low voltage control wiring and one

for either gas supply or high voltage supply wiring for an

electric heater.

Alternate Supply Entry Locations

Disconnect Switch for electric heater.

Present only if electric heat is selected.

Terminate heater supply wiring here.

From Gas Supply

Gas Cock

Bleeder Valve or

1/8 in Plugged Tap

Ground

Joint

Union

8 in. Trap

Gas to

Controls

Typical Gas Supply Piping Connection

Gas Connections

If this unit is equipped with an indirect gas-red furnace,

connection to an appropriate gas supply line will be

required. For complete information on installation

procedures for the optional gas furnace, refer the

Indirect Gas-Fired Heat IOM. See also Recommended

Electrical and Gas Locations in this manual.

Optional Main Disconnect Switch

(Terminate high voltage supply wiring

here or at power distribution block).

RECOMMENDED LOCATION

for low voltage control wiring.

RECOMMENDED LOCATION:

Factory-provided opening for gas

supply. If electric heat is ordered,

use this location for high voltage

supply wiring for heater.

RECOMMENDED LOCATION

for field-supplied high voltage

supply wiring.

Recommended Gas and Electric Supply Entry Locations

Packaged Rooftop Ventilator

8

®

Electrical Information

WARNING

The roof lining contains high voltage wiring. To prevent

electrocution, do not puncture the interior or exterior

panels of the roof.

WARNING

To prevent injury or death due to electrocution or

contact with moving parts, lock disconnect switch

open.

For units with a gas furnace, if you turn off the power

supply, turn off the gas.

IMPORTANT

Before connecting power to the unit, read and

understand the following instructions and wiring

diagrams. Complete wiring diagrams are attached on

the inside of the control center door(s).

IMPORTANT

All wiring should be done in accordance with the latest

edition of the National Electric Code ANSI/NFPA70

and any local codes that may apply. In Canada, wiring

should be done in accordance with the Canadian

Electrical Code.

IMPORTANT

The equipment must be properly grounded and

bonded. Any wiring running through the unit in the

airstream must be protected by metal conduit, metal

clad cable or raceways.

CAUTION

If replacement wire is required, it must have a

temperature rating of at least 105ºC, except for an

energy cut-off or sensor lead wire which must be rated

to 150ºC.

DANGER

High voltage electrical input is needed for this

equipment. This work should be performed by a

qualified electrician.

CAUTION

Any wiring deviations may result in personal injury or

property damage. Manufacturer is not responsible

for any damage to, or failure of the unit caused by

incorrect final wiring.

Determine the Size of the Main Power

Lines

The unit’s nameplate states the voltage and the unit’s

MCA. The main power lines to the unit should be sized

accordingly. The nameplate is located on the outside of

the unit on the control panel side.

Determine the Size of Electric Heater

Wiring

An optional electric heater may require a separate

power supply. The power connection should be made

to the factory-provided electric heater disconnect and

must be compatible with the ratings on the nameplate,

supply power voltage, phase and amperage. Consult

ANSI/NFPA 70 and CSA C22.1 for proper conductor

sizing.

Provide the Opening(s) for the Electrical

Connections

Electrical openings vary by unit size and arrangement

and are eld-supplied.

Connect the Power Supplies

Connect the main power lines and electric heater power

lines to the disconnect switches or terminal blocks

and main grounding lug(s). Torque eld connections to

manufacturer’s recommendations.

Wire the Optional Convenience Outlet

The convenience outlet requires a separate 115V power

supply circuit. The circuit must include short circuit

protection which may need to be supplied by others.

Connect Field-Wired Low Voltage

Components

Most factory-supplied electrical components are

prewired. To determine what electrical accessories

require additional eld-wiring, refer to the unit-specic

wiring diagram located on the inside of the control

center access door.

The low voltage control circuit is 24 VAC and control

wiring should not exceed 0.75 ohms.

Control wires should not be run inside the same conduit

as that carrying the supply power. Make sure that

eld-supplied conduit does not interfere with access

panel operation. All low voltage wiring should be run in

conduit wherever it may be exposed to the weather.

If wire resistance exceeds 0.75 ohms, an industrialstyle, plug-in relay should be added to the unit control

center and wired in place of the remote switch (typically

between terminal blocks R and G on the terminal strip.

The relay must be rated for at least 5 amps and have a

24 VAC coil. Failure to comply with these guidelines may

cause motor starters to “chatter” or not pull in which

can cause contactor failures and/or motor failures.

Field-Provided Disconnect

If eld-installing an additional disconnect switch, it

is recommended that there is at least four feet of

service room between the switch and system access

panels. When providing or replacing fuses in a fusible

disconnect, use dual element time delay fuses and size

according to the rating plate.

®

Packaged Rooftop Ventilator

9

Loading...

Loading...