Page 1

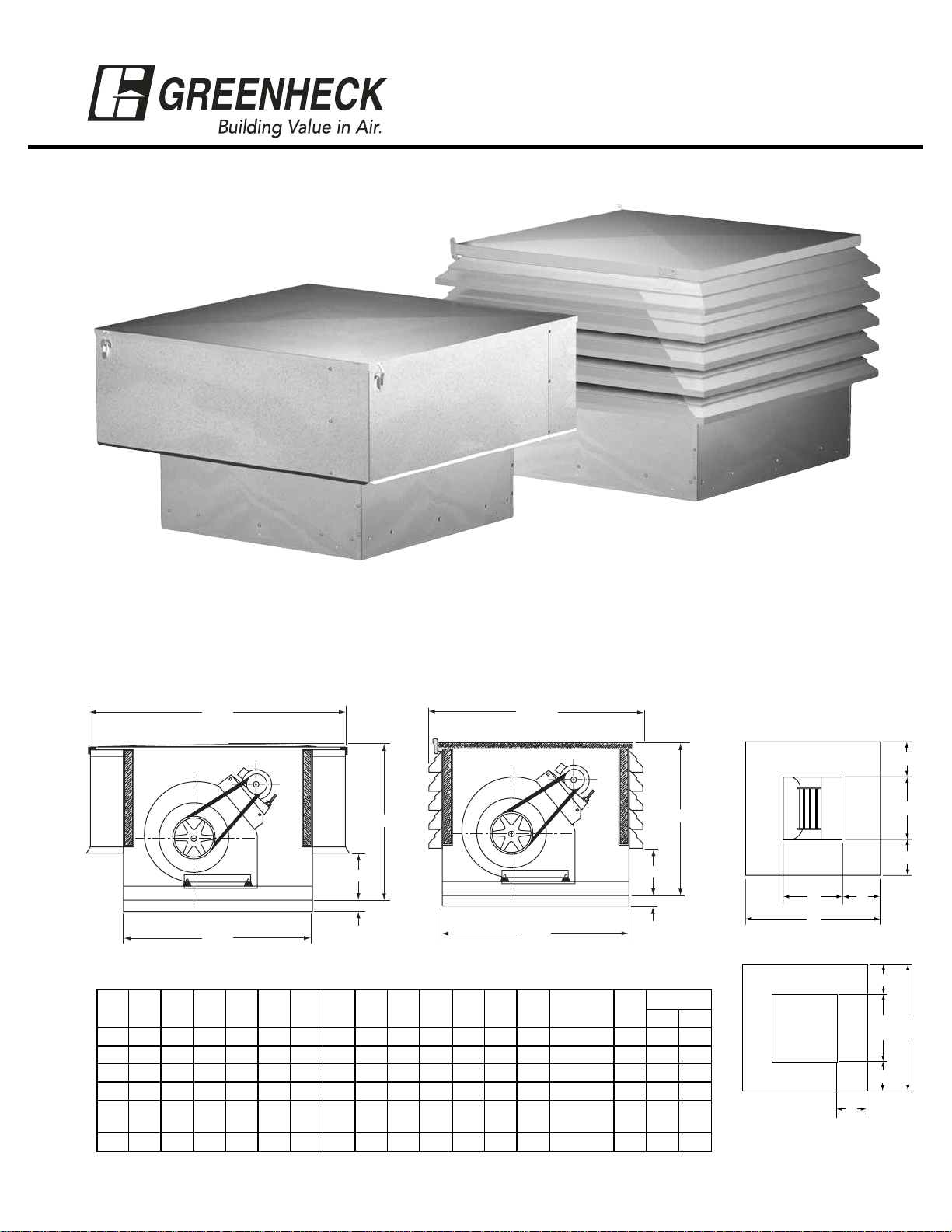

Model RSF

Model RSFP

READ AND SAVE THESE INSTRUCTIONS

Roof Supply Fans

Models RSF and RSFP

PN 453148

Installation, Operation and Maintenance Manual

Greenheck Model RSF and RSFP fans are thoroughly inspected and test run at the factory, however damage

may occur during handling and shipping. Consequently, it is important to inspect the unit for visible and

concealed damage before beginning installation. Report any damage to the shipper immediately. In addition,

assure all accessory items are accounted for.

Dimensional Data

1

RSF

RSFP

BASE OF UNIT

OPTIONAL DUCT ADAPTER

Fan

SizeASQ.BSQ.BLSQ.

CCLD F G H J

K

SQ.LSQ.

M

Louver

Tiers

RSFP

Nominal

Filter

Weights

RSF RSFP

90 26 351/8 317/8 231/4 253/8 101/4 121/4 103/4 75/8 67/8 241/2 121/4 61/8 (4) 12x20 3 145 126

100 30 41

1

/8 357/8 231/4 253/8 101/4 135/8 117/8 91/16 83/16 281/2 141/4 71/8 (4) 12x25 3 173 146

120 34 47

1

/8 397/8 271/4 293/8 101/4 161/8 137/8 101/16 815/16 321/2 181/4 71/8 (4) 16x25 4 225 180

150 40 53

1

/8 457/8 311/4 333/8 101/4 191/8 161/2 111/4 107/16 381/2 201/4 91/8 (8) 16x20 5 336 250

180 46 61

1

/8 517/8 341/4 353/8 121/4 221/2 191/2 101/8 113/4 441/2 261/4 91/8

(4) 16x20

5 400 285

(4) 20x20

200 52 731/8 583/16 391/4 403/8 121/4 231/4 251/4 133/8 143/8 501/2 301/4 101/8 (8) 20x25 6 620 431

All dimensions are in inches.

®

B SQ.

C

D

2 1/2 in.

SQ.

A

BL SQ.

SQ.

A

D

2 1/2 in.

CL

G

A

M

H

M

L

SQ.KSQ.

M

J

F

J

Page 2

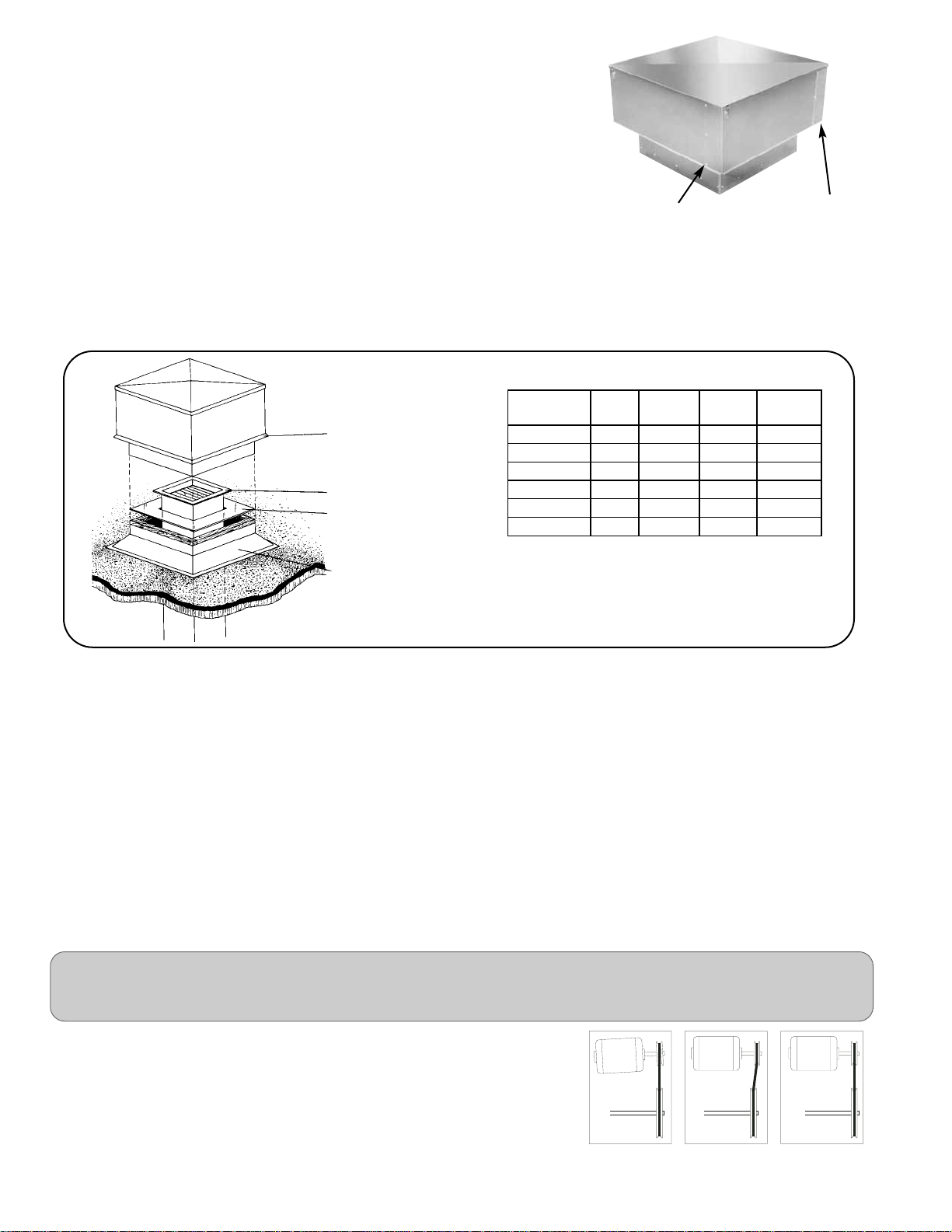

2

Lifting

Lifting the RSF and RSFP model fans must be done with care to avoid

damaging the housing. For Model RSF attach four lifting devices under the

outer housing, each device beneath the vertical row of fasteners (Fig. 1).

Lifting devices should be a minimum of 3 in. wide to avoid damaging the

sheet metal housing. Do not lift Model RSF near the center of the outer

housing.

For Model RSFP attach a minimum of four lifting devices under an exterior

louver panel, each device near the corner of the louvered housing.

Installation

Move the fan to its intended location and fasten it securely through mounting holes provided in the fan base. Shims may be

necessary depending upon thickness of the roofing material. For ducted applications, an optional duct adapter (if provided)

is attached and holds the ductwork in place prior to installing the unit. The following diagram shows a typical installation

with prefab roof curb and ductwork.

Access to the motor compartment is made by releasing four latches which secure the cover. The cover should be placed in

an area where wind will not blow it off the roof.

Electrical Connection

The electrical supply must be compatible with the fan motor with regard to voltage, phase and amperage capacity.

Moreover, the electrical supply line must be properly fused and conform to local and national electrical codes.

Electrical lead-in wires should be routed through the pre-punched hole in the optional duct adapter (if provided) and the

punched hole in the bottom of the fan housing. Electrical wires must be located so as not to rub on moving components.

The electrical supply line is connected to the optional safety disconnect switch (if provided) or wired directly to the motor.

Pre-Starting Checks

Note: For units shipped with motor and drives separate, refer to the Motor Mounting Instructions included in the hardware

bag.

Check all fasteners and set screws for tightness. Rotate the fan wheel by hand

to assure it turns freely and is centered between the inlets. Check pulleys and

belts for proper alignment to avoid premature belt wear, noise, vibration and

power loss. Motor and fan pulleys must be parallel and in line (Fig. 2).

The adjustable motor pulley is set at the factory for the fan RPM specified. Fan

speed can be increased by closing or decreased by opening the adjustable

motor pulley. Two groove variable pitch pulleys must be adjusted an equal

Fig. 1

Lift Here

Lift Here

TYPICAL INSTALLATION

RSF unit with prepunched

mounting holes and 21/2 inch

skirt to aid in installation.

Ductwork (by others)

Duct adapter (optional) allows

ductwork to be completed

prior to setting unit on curb.

Roof Curb

Fan

Curb

Size*

Recom.

Roof

Opening

Duct

Size

ID

Nominal

Damper

Size

RSF/RSFP- 90 24

1

/2 15 12 12 x 12

RSF/RSFP- 100 28

1

/2 17 14 14 x 14

RSF/RSFP- 120 32

1

/2 21 18 18 x 18

RSF/RSFP- 150 38

1

/2 23 20 20 x 20

RSF/RSFP- 180 44

1

/2 29 26 26 x 26

RSF/RSFP- 200 50

1

/2 33 30 30 x 30

All dimensions are in inches.

Note: In cases where extreme snow depths may be

encountered, extended base may be required to raise unit

or condensation pans may be required in ductwork.

*Recommended curb size shown is outside curb

dimension without roofing and flashing.

WARNING!

DISCONNECT AND SECURE TO THE “OFF” POSITION ALL ELECTRICAL POWER TO THE FAN PRIOR TO INSPECTION OR

SERVICING. FAILURE TO COMPLY WITH THIS SAFETY PRECAUTION COULD RESULT IN SERIOUS INJURY OR DEATH.

Fig. 2

WRONG WRONG CORRECT

Page 3

3

number of turns open. Any increase in fan speed results in an increase in horsepower required for the motor. Motor load

amperes should always be checked and compared to nameplate rating when changing fan speed.

Direction of fan wheel rotation is critical. A fan wheel rotating in the wrong

direction will result in reduced airflow, motor overloading and possible burnout. Check wheel rotation by momentarily turning the fan on.

Rotation should be in the same direction as airflow at the outlet. See housing

and wheel examples in Fig. 3. IMPORTANT NOTE: RSF/RSFP fans should be

operated only when attached to the completed system. Without proper

static pressure loading, the motor may be overloaded and burnout may

occur.

Routine Maintenance - See WARNING Page 2

To preserve the reliability and performance designed into the fan, regularly scheduled maintenance should be performed.

Items to be checked at each maintenance interval are filters, belts, bearings, fasteners, lubrication and removal of dust and

dirt.

Filters

1 inch washable aluminum mesh filters are standard on Model RSF and RSFP fans. (Optional 2 inch filters may be supplied

on some fans). Filters should be cleaned on a regular basis for optimum efficiency.

To remove the filters, first remove the fan cover by releasing the four latches. (Place the cover in an area where wind will not

blow it off the roof). The filters can be lifted out and washed in a mild detergent solution. If desired, an adhesive spray

available at most filter distributors can be applied to increase filter efficiency.

Belts

Belt tension should be checked two times during the first 24 hours of

operation and during each scheduled maintenance thereafter. Premature belt

failures are frequently caused by improper belt tension, either too tight or

loose. The proper belt tension for operating a V-belt is the lowest tension at

which the belt will not slip at peak load conditions. For initial tensioning, belt

deflection should be 1/64 inch for each inch of belt span, determined by using

moderate thumb pressure half way between pulley centers. For example, the

belt deflection should be 1/2 inch if the belt span is 32 inches (Fig. 4).

Belt tension can be adjusted by loosening the motor plate hinge bolts and

adjusting the jack screws as required. RSF/RSFP units are supplied with

either a painted steel motor bracket or a galvanized motor plate for larger

motor frames. To adjust belt tension on units equipped with the painted steel

motor bracket, simply adjust the single jack screw.

For units equipped with a galvanized motor plate, both jack screws must be adjusted equally. Check pulley and belt

alignment after adjusting belt tension (Fig. 2).

Lubrication

Fan bearings on Model RSF and RSFP are permanently lubricated. Motor bearings equipped with grease fittings should be

lubricated in accordance with instructions on the motor nameplate. Motors without grease fittings are lubricated for life.

Cleaning

Motors and Fan Wheels require periodic cleaning to remove dust and dirt which may accumulate. Motor cleaning should be

limited to the exterior surface only. Removing dust and dirt from the motor housing assists in motor cooling and prolongs

motor life. Motors should never be sprayed with steam, water or solvents.

Fan wheels which are left to accumulate dust and dirt will have poor air performance, loss of efficiency and possible

damaging vibration due to an unbalanced condition.

Periodic cleaning is a good investment in preserving the reliability and performance designed into the fan.

Fig. 3

Fig. 4

AIRFLOW

T

O

A

R

T

I

O

N

R

O

T

A

T

I

O

N

Belt Span

Deflection =

Belt Span

64

Page 4

Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from

the purchase date. Any units or parts which prove to be defective during the warranty period will be replaced at our

option when returned to our factory, transportation prepaid.

The motor is warranted by the motor manufacturer for a period of one year. Should the motor furnished by Greenheck

prove defective during this period, it should be returned to the nearest authorized motor service station. Greenheck

will not be responsible for any removal or installation costs.

GREENHECK

RSF/RSFP IOM

#453148 Rev 2 Dec 2004

Copyright © 2004 Greenheck Fan Corp.

*Galvanized motor plate shown. Painted steel motor bracket used on units with smaller motor frame sizes.

Note: The unit serial number, located on the Greenheck name tag, should be provided when requesting parts or

information.

Filters

Shaft Pulley

Blower Mounting Angle

Shock Mounts (4)

Motor Pulley

Motor

*Motor Plate

Blower Unit

Belt

PARTS LIST

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice.

P.O. BOX 410 SCHOFIELD, WISCONSIN 54476-0410

®

PH. 715-359-6171

www.greenheck.com

Loading...

Loading...