Page 1

DESCRIPTION

The RL 147 Positioning Relay is a compact pneumatic device

designed to provide positive positioning of a pneumatic valve

or damper actuator. The positioner provides supply air

pressure against the actuator diaphragm to initiate stem or

shaft movement. The actuator spring reverses the stem or

shaft movement.

FEATURES

•

Rapid response

•

Good repeatability

•

Adjustable start point pressure

•

Adjustable span

•

Low air consumption

Technical Instruction

Document Number 155-038

RL 147-2

May, 1996

RL 147 POSITIONING RELAY

Figure 1. The RL 147 Positioning Relay mounted on a

No. 6 Damper Actuator.

SPECIFICATIONS

Operating:

Ambient Temperature Range

Storage...................................... -20 to 160°F (-29 to 71°C)

Operation .......................................35 to 160°F (2 to 71°C)

Maximum Pilot Signal Pressure .....................30 psig (207 kPa)

Maximum Supply Air Pressure.......................60 psig (413 kPa)

Start Point Adjustment Range.................3-10 psig (21-69 kPa)

Operating Span Adjustment Range.........3-12 psig (21-83 kPa)

Response.................................1/10 psi Input change (0.7 kPa)

Air Capacity @ ∆P = 2 psi (14 kPa) ............ 410 scim (112ml/s)

Air Consumption............................................. 40 scim (11 ml/s)

Table 1. Product Numbers for Positioning Relay and Mounting Kits.

Description of Actuator Type Order Numbers Reference

No. 3 Damper Actuator For actuators manufactured after 1/1/93 147-2000 147-104 7

No. 4 Damper Actuator 147-2000 147-314 7

No. 6 Damper Actuator 147-2000 147-276 8

8" Valve Actuator

For Flowrite actuators manufactured after 3/1/96

For Model 3 Flowrite actuators manufactured between 3/1/93

and 1/1/96

For Models 1 and 2 Flowrite actuators. Also order spring arm

# 147-307 for use with VF 591 5” and 6” balanced valves

12” Valve Actuator

For Flowrite actuators manufactured after 1/1/96

For Flowrite actuators manufactured between 3/78 and 1/1/96 147-2000 147-311 11

For Super Flowrite and 12” Flowrite actuators manufactured

before 3/78

PRODUCT NUMBERS

SPECIFICATIONS, Continued

Physical:

Air Connections ........................................... 1/8" (3.2 mm) NPT

Body Materials ....................................................................Zinc

Cover.......................................................... Electro Plated Steel

Dimensions .................................................................Figure 14

Shipping Weight w/Kit........................................... 2 lb. (0.9 Kg)

Positioning Relay Mounting Kit Page

599-00426

Contains both relay and mounting kit

147-2000 147-333 8

147-2000 147-277 10

599-00423

Contains both relay and mounting kit

147-2000 147-279 10

Refer to Table 1

9

9

.

Landis & Gyr, Inc.

Page 2

Technical Instruction Landis & Gyr, Inc.

RL 147-2 Page 2

APPLICATION

The Positioning Relay is recommended for damper actuator

and valve applications where rapid speed of response and/or

repeatability of stem position is needed to obtain good system

operation. It can be used to reduce the span of controlled

devices to permit sequencing. It can also be used to increase

the close-off force of a normally open actuator without

affecting its spring span. This happens because the positioner

uses full supply air pressure to position the actuator.

The spring range of the actuator does not effect the operation

of the positioner. Therefore, it is recommended that an

actuator with a high spring range, such as 8 to 13 psig (55 to

90 kPa), be selected. This combination has the high return

force of the actuator spring plus the high forward force

available from the positioner.

A positioning relay can be connected to handle up to four

identical No. 6 damper actuators or up to six identical No. 4

damper actuators provided the following conditions are met.

All actuators must operate the same damper, and no more

than 100 feet of 1/4” (6.4 mm) O.D. tube is used to connect

them. Remember all actuators connected this way must be

identical (i.e., same size, spring range, stroke, etc.).

The positioning relay is single acting and is primarily intended

for use on actuators with an integral spring to return the

actuator shaft to the normal position. Applications with a

double acting (spring-less) actuator require a reversing relay to

provide the additional control signal.

OPERATION

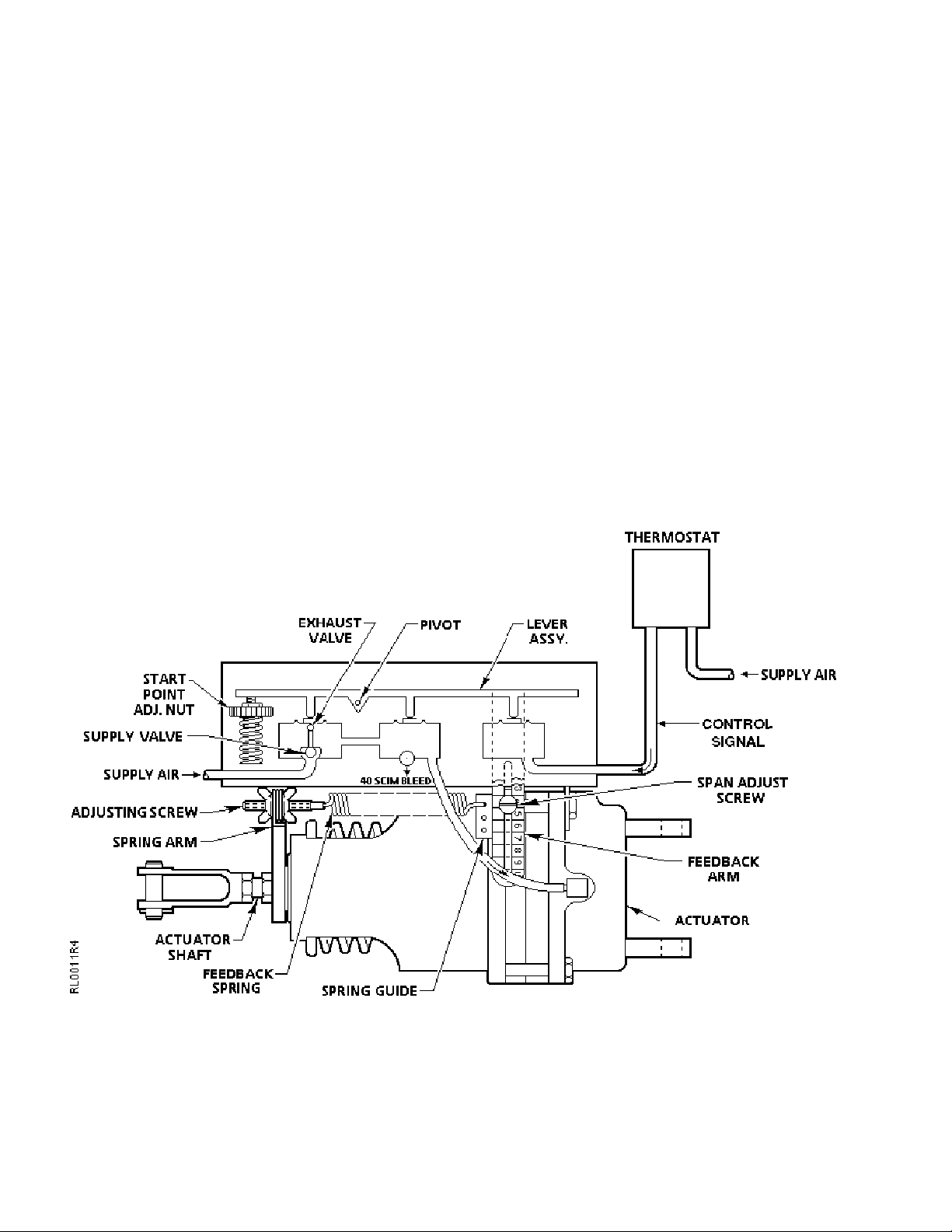

A rise in thermostat pressure will unbalance the lever

assembly. Refer to Figure 2. The shaft movement, through the

spring arm, increases tension on the feedback spring to bring

the lever assembly again into balance. A drop in thermostat

pressure will unbalance the lever assembly in the opposite

direction to exhaust air from the actuator until a new balance

position is reached.

The positioning relay start point is adjustable. The start point

adjustment nut shown in Figure 2 is used to set the start point

pressure. The span adjustment screw tab location on the

feedback arm and the feedback spring location on the spring

guide determine the span setting of the relay.

Figure 2. Operation Schematic.

Page 3

RL 147 POSITIONING RELAY Technical Instruction

155-038 Page 3

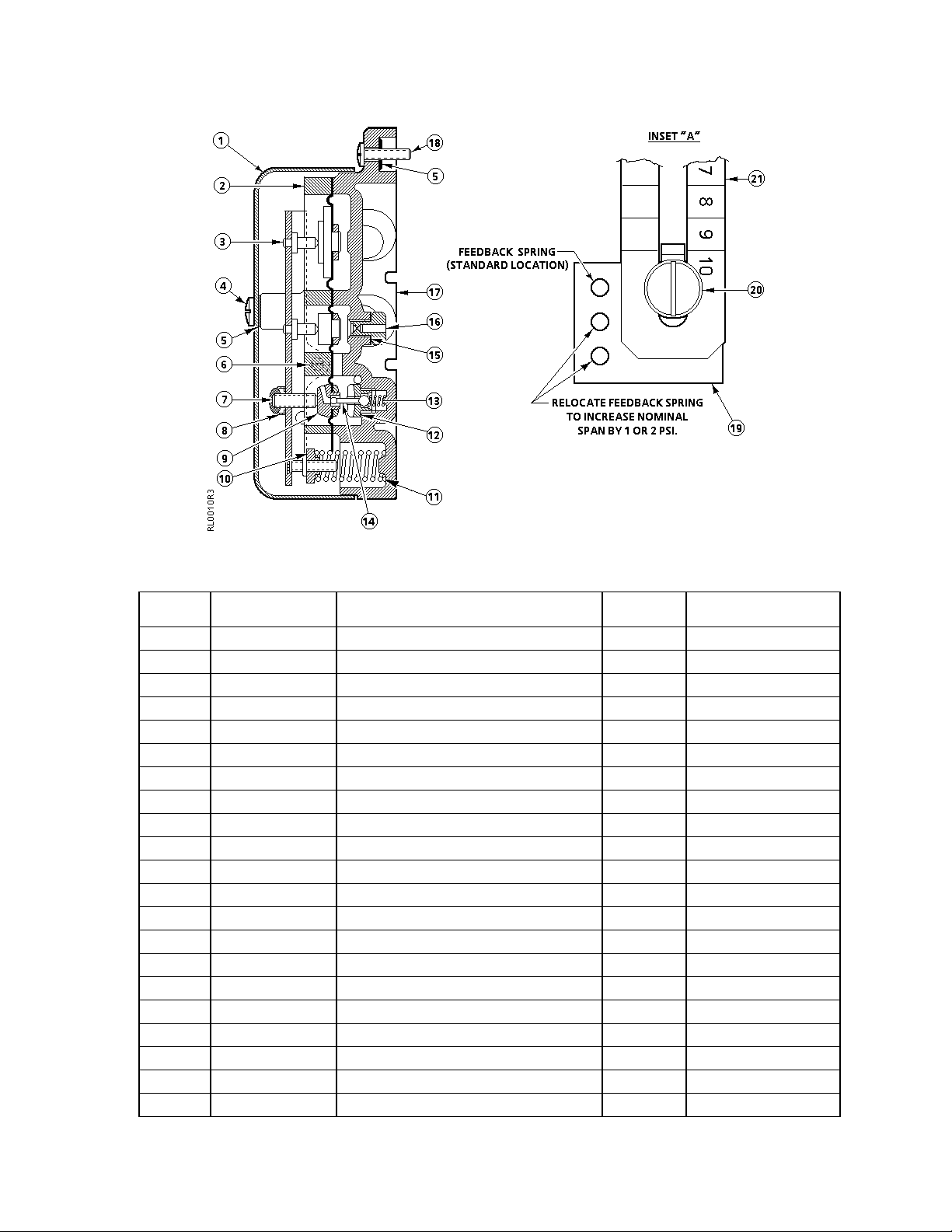

Figure 3. Construction of the RL 147 Positioning Relay.

Item

1 147-255 Cover 1 Steel

2 – Plate 1 Zamac Die Casting

3 – Lever Assembly 1

4 – #8-32 Cover Screw 1 Steel

5 – Washer 1 Rubber

6 147-273 Pivot Screw 2 Stainless Steel

7 – #8-32 x 1/2 “ Lg. Dual Pt. Set Screw 1 Steel

8 – #8-32 Palnut 1 Steel

9 – Diaphragm Assembly 1

10 – Start Point Adjustment Nut 1 Brass

11 – Start Spring 1 Music Wire

12 – Supply Valve Seat 1 Brass

13 – Supply Valve Spring 1 Phosphor Bronze

14 – Ball Assembly 1 Stainless Steel

15 – Gasket 1 Fairprene

16 – Bleed Port 1 Brass

17 – Base 1 Zamac Die Casting

18 034-048 #6-32 x 5/8” Lg. Bind Hd Screw 2 Brass

19 147-297 Spring Guide 1 Steel

20 034-067K Span Adjustment Screw 1 Steel

21 – Feedback Arm 1 Steel

Replacement

Part No.

Description

No.

Req’d

Material

Page 4

Technical Instruction Landis & Gyr, Inc.

RL 147-2 Page 4

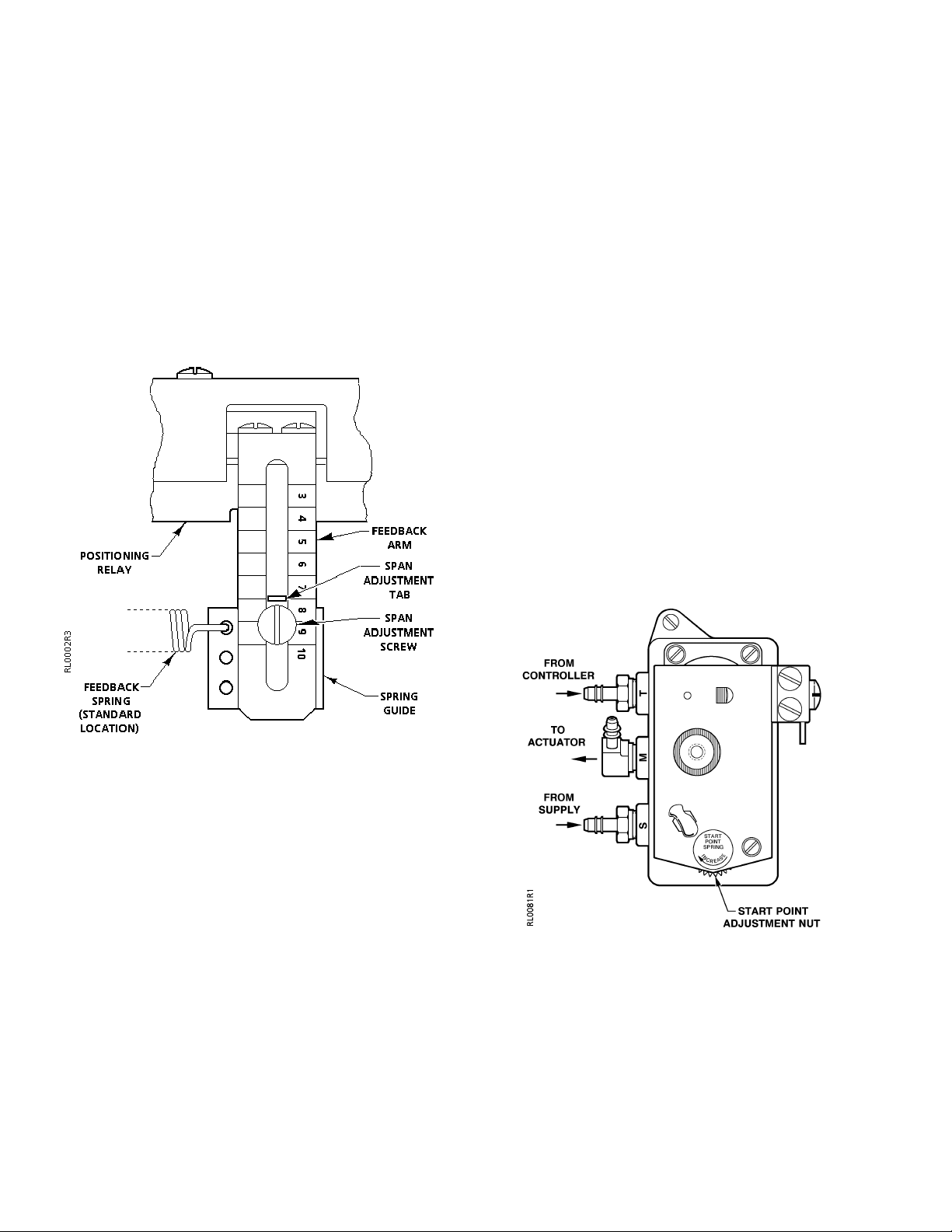

For spans of 11 psig or 12 psig (76 or 83 kPa)

CALIBRATION

Complete calibration instructions are included with each

positioning relay.

1. Check that you have the correct feedback spring(s)

attached.

2. Identify the desired operating span and the start point

pressure.

NOTE: In some cases, the actuator stem travel or stoke

is not identical to the nominal value of the relay feedback

spring. Refer to Calculating the Span Setting on page 5

to determine the span setting on the feedback arm.

1. Move the span adjustment tab to the 10 setting on the

feedback arm. Follow steps 2 and 3 above.

2. Move the feedback spring one hole away from the

standard location for a span of 11 psig (76 kPa) and two

holes away from the standard spring location for a 12 psig

(83 kPa) span. Refer to Figure 4.

3. Follow steps 4 and 5 above.

Adjusting the Start Point. Refer to Figure 6.

The positioning relay can be adjusted to start actuator movement at pressures between 3 and 10 psig (21 and 69 kPa).

1. Remove the relay cover.

2. Attach tubing with a pressure gauge and squeeze bulb to

the "T" port. Supply air should be attached to the "S" port.

The "M" port should be attached tot he connector on the

actuator.

3. Using the squeeze bulb, apply pressure to the relay.

Watch the valve stem or actuator shaft to see when it

begins to move. Check your pressure gauge; this is your

start point pressure.

4. If this is not the desired start point pressure, turn the start

point adjustment nut (Figure 5) clockwise to increase the

start point pressure and counterclockwise to decrease the

pressure.

5. Repeat steps 3 and 4 until the stem or shaft begins to

move at the desired pressure.

Figure 4. Span Adjustment.

Shown at Span Setting 8.

Setting the Span. Refer to Figure 4.

The positioning relay operating span can be set for spans of

3 psig through 12 psig (21 kPa to 83 kPa).

For spans of 3 psig through 10 psig (21 to 69 kPa)

1. Check that the feedback spring is attached to the spring

guide in the hole across from the span adjustment screw.

This is identified as the standard location in Figure 4.

2. With a screwdriver, loosen the span adjustment screw.

Move the spring guide on the feedback arm until the span

adjustment tab is at the desired span setting reference

number.

NOTE: The line to the left of the number is the setting.

3. Tighten the span adjustment screw.

4. The feedback spring must be parallel to the actuator shaft

or valve stem. Use open end wrenches to loosen the hex

nuts holding the spring arm in position on the shaft or

stem. Align the feedback spring and tighten the hex nuts.

5. The feedback spring should have no slack or no stretch in

it. Adjust the wing nuts and adjustment nut, if necessary

Figure 5. Start Point Adjustment.

Adjusting the Span

1. Using the squeeze bulb, apply pressure to the relay. Note

the pressure at which the stem or shaft begins to move.

2. Continue to apply pressure until the stem or shaft

completes its full stroke. Note the pressure.

3. The difference between the two pressures is the span.

4. If the span is not the desired span, move the spring guide

to a higher reference number to increase the span or

lower number to decrease the span. Refer to Figure 4.

5. Repeat steps 1 through 4 until you get the desired span.

Page 5

RL 147 POSITIONING RELAY Technical Instruction

155-038 Page 5

6. If you have moved the spring guide, you will need to

adjust the spring arm so that the spring is parallel to the

stem or shaft.

7. Check the feedback spring. There should be no slack or

no stretch in it. Adjust the wing nuts and adjustment nut, if

necessary.

8. Fasten the relay cover. Fill in the information on the

calibration label.

Calculating the Span Setting

1. Identify the valve stem from Table 2 or 4. If the stroke of

the No. 6 damper actuator has been changed from the

factory setting refer to Table 7.

2. If your stem travel matches the nominal spring travel listed

in Table 2 there is no need to calculate a new span

setting.

3. If your stem travel does not match the nominal spring

travel listed in Table 2, choose the spring(s) whose

maximum allowable travel is equal or greater than your

actual stem travel.

4. Calculate the span setting with the formula below.

Formula for Span Setting

Span

Setting

= Desired span X

Nominal spring travel

Actuator stroke

Example:

Determine the span setting for a valve having desired

span of 5 psig and 5/16" stroke.

Table 2. Spring Selection.

Spring Travel Range Recommended Springs

Nominal

in. (mm)

Max. Allowable

in (mm)

Part No. Size & Color

5/32 (5.0) 1/4 (6.4) 147-298 Small Green

1/4 (6.4) 3/8 (9.5) 147-289 Small Cadmium Plate

3/8 (9.5) 1/2 (13) (2)147-298 Small Green

3/4 (19) 1 (25) 147-290 Small Red

1 (25) 1-1/4 (32) 147-291 Long Green

1-1/4 (32) 1-5/8 (41)

147-289

plus

147-291

Small Cadmium Plate

plus

Long Green

1-1/2 (38) 2 (51) (2) 147-290 Small Red

1-3/4 (44) 2-1/4 (57)

147-290

plus

147-291

Small Red

plus

Long Green

2 (51) 2-1/2 (64) (2) 147-291 Long Green

2-3/8 (60) N/A 147-105 2” Red

3 (76) 3-1/4(83) 147-292 Long Cadmium Plate

3-3/4 (95) 4 (102) 147-301 3” Red

4 (102) 4-1/4 (108) 147-293 Blue

4 (102) 6 (152) 147-313 Zinc Pl. or Yell. Chr.

7 (178) 12-1/4 (311) 147-330 Zinc Plate

Select a spring with a maximum allowable range equal to or

larger than the stroke. Use the 1/4" spring with a 3/8"

maximum allowable travel range. Refer to Table 2.

Span

Setting

= 5 X

0.25

0.312

= 4

Set the span adjustment tab to line 4 on the feed back arm to

provide a 5 psig span for this valve.

Table 3. Stem Travel for VP 591 Bronze Body Valves.

Line Size Stem Travel inches (mm)

in. (mm) Single

Double Seat WM

Seat

1/2 (13) 3/8 (9.5) — 1/8 (3.2)

3/4 (19)

3/4 (19)

— 3/16

(4.8)

1 (25)

1-1/4 (32)

3/4 (19)

1 (25)

3/16 (4.8) 1/4 (6.4)

1/4 (6.4) 5/16

(7.9)

1-1/2 (38)

1 (25)

1/4 (6.4) 5/16

(7.9)

2 (51) 5/8 (16) 3/8 (9.5) NO.

5/16 (7.9) N.C.

5/16

(7.9)

Page 6

Technical Instruction Landis & Gyr, Inc.

RL 147-2 Page 6

Table 4. Stem Travel listed by 591 or 593 Flowrite Valve Product Number.

Flowrite

Product

Number

591-6480 5/8 (16)

591-6490 3/4 (19)

591-6540 5/8 (16)

591-6600 1/8 (3.2)

591-6610 3/16 (4.8)

591-6620 1/4 (6.4)

591-6630 5/16 ((7.9)

591-6640 5/16 ((7.9)

591-6650 5/16 ((7.9)

591-6720 5/8 (16)

591-6730 3/4 (19)

591-6740 1 (25)

591-6840 3/8 (9.5)

591-6850 9/16 (14)

591-6860 9/16 (14)

591-6870 5/16 ((7.9)

591-6880 9/16 (14)

591-6890 9/16 (14)

591-6900 1/4 (6.4)

591-6910 1/4 (6.4)

591-6920 5/16 (7.9)

591-6930 9/16 (14)

591-6940 3/16 (4.8)

591-6950 1/4 (6.4)

591-6960 1/4 (6.4)

591-6970 3/8 (9.5)

591-6980 3/16 (4.8)

591-6990 1/4 (6.4)

591-7000 1/4 (6.4)

591-7010 5/16 ((7.9)

591-7020 3/16 (4.8)

591-7030 1/4 (6.4)

591-7040 1/4 (6.4)

591-7050 3/8 (9.5)

591-7060 3/8 (9.5)

591-7070 9/16 (14)

591-7080 9/16 (14)

591-7090 3/16 (4.8)

591-7100 5/16 ((7.9)

591-7110 9/16 (14)

591-7870 3/4 (19)

Stem

Travel

in. (mm)

Flowrite

Product

Number

591-7871 3/4 (19)

591-7872 1 (25)

591-7873 1 (25)

591-7874 1 (25)

591-7875 3/4 (19)

591-7876 3/4 (19)

591-7877 1 (25)

591-7878 1 (25)

591-7879 1 (25)

591-7971 3/8 (9.5)

591-7972 3/4 (19)

591-7973 3/4 (19)

591-7974 1 (25)

591-7975 1 (25)

591-7976 1 (25)

591-7977 3/8 (9.5)

591-7978 3/4 (19)

591-7979 3/4 (19)

591-7980 1 (25)

591-7981 1 (25)

591-7982 1 (25)

591-8016 5/8 (16)

591-8017 5/8 (16)

591-8018 3/4 (19)

591-8019 3/4 (19)

591-8020 1 (25)

591-8021 1 (25)

591-8028 5/8 (16)

591-8029 3/4 (19)

591-8030 1 (25)

591-8071 3/8 (9.5)

591-8072 3/4 (19)

591-8073 3/4 (19)

591-8074 1 (25)

591-8075 1 (25)

591-8076 1 (25)

591-8077 3/8 (9.5)

591-8078 3/4 (19)

591-8079 3/4 (19)

591-8080 1 (25)

Stem

Travel

in. (mm)

Flowrite

Product

Number

591-8081 1 (25)

591-8082 1 (25)

591-8330 5/8 (16)

591-8331 5/8 (16)

591-8332 3/4 (19)

591-8336 5/8 (16)

591-8337 5/8 (16)

591-8338 3/4 (19)

591-8339 3/4 (19)

591-8340 1 (25)

591-8341 1 (25)

591-8342 1-1/2 (38)

591-8344 1-1/2 (38)

591-8350 1-1/2 (38)

591-8351 1-1/8 (29)

591-8352 1-1/8 (29)

591-8353 1-1/8 (29)

591-8354 1-1/8 (29)

591-8355 1-1/8 (29)

591-8356 1-1/8 (29)

591-8357 1-1/8 (29)

591-8358 1-1/4 (32)

591-8359 1-1/8 (29)

591-8360 1-1/2 (38)

591-8362 1-1/2 (38)

591-8364 1-1/8 (29)

591-8365 1-1/8 (29)

591-8366 1-1/8 (29)

591-8367 1-1/8 (29)

591-8368 1-1/8 (29)

591-8369 1-1/8 (29)

591-8370 1-1/8 (29)

591-8371 1-1/8 (29)

591-8372 1-1/4 (32)

591-8373 1-1/4 (32)

591-8374 1-1/2 (38)

591-8376 1-1/2 (38)

591-8378 1-1/4 (32)

591-8379 1-1/4 (32)

591-8380 1-1/4 (32)

Stem

Travel

in. (mm)

Flowrite

Product

Number

593-8381 1-1/4 (32)

593-8382 1-1/2 (38)

593-8383 1-1/2 (38)

593-8388 3/4 (19)

593-8389 3/4 (19)

593-8390 3/4 (19)

593-8391 3/4 (19)

593-8392 1-1/8 (29)

593-8393 1-1/8 (29)

593-8394 1-1/4 (32)

593-8395 1-1/4 (32)

593-8396 1-1/4 (32)

593-8397 1-1/4 (32)

593-8398 1-1/4 (32)

593-8399 1-1/4 (32)

593-8400 1-1/4 (32)

593-8401 1-1/4 (32)

593-8402 1-1/2 (38)

593-8403 1-1/2 (38)

593-8404 1-1/4 (32)

593-8405 1-1/4 (32)

593-8406 1-1/4 (32)

593-8407 1-1/4 (32)

593-8410 1-1/2 (38)

593-8411 1-1/2 (38)

593-8412 1-3/8 (35)

593-8413 1-3/8 (35)

593-8415 1 (25)

593-8416 1 (25)

593-8419 1 (25)

593-8420 1 (25)

593-8421 1-3/8 (35)

593-8422 1-3/8 (35)

593-8423 1-3/8 (35)

594-8343* 1-1/2 (38)

594-8345* 1-1/2 (38)

594-8361* 1-1/2 (38)

594-8363* 1-1/2 (38)

594-8375* 1-1/2 (38)

594-8377* 1-1/2 (38)

Stem

Travel

in. (mm)

* RL 147 is standard with the

product.

Page 7

RL 147 POSITIONING RELAY Technical Instruction

155-038 Page 7

Table 5. Mounting Kit 147-104

for the No. 3 Damper Actuator.

Item Description Q'ty

1 Mounting Bracket 1

2 Feedback Spring (for 2-3/8" stroke) 1

3 Adjusting Screw 1-3/4" (44 mm) long 1

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 3/8-24 Hex Nut 1

9 Clevis 1

Figure 6. Positioning Relay Mounted on the

No. 3 Damper Actuator.

#10-16 1/2" (13 mm) Slotted Hex

10

Screw

11 90° Elbow Connector 1

2

Figure 7. Positioning Relay Mounted on the

No. 4 Damper Actuator.

Table 6. Mounting Kit 147-314

for the No. 4 Damper Actuator.

Item Description Q'ty

1 Mounting Bracket 1

2 Feedback Spring 1

3 Adjusting Screw 1-3/4" (44 mm) long 1

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 3/8-24 Hex Nut 2

9 Clevis 1

#10-16 1/2" (13 mm) Slotted Hex

10

Screw

1

Page 8

Technical Instruction Landis & Gyr, Inc.

RL 147-2 Page 8

Figure 8. Positioning Relay Mounted

on the No. 6 Damper Actuator.

Table 7. Spring Selection for Adjustable Stroke

of the No. 6 Damper Actuator.

Actuator

Stroke

3-1/4 to 4

(82 to 102)

2-29/32 to

3-1/4

(74 to 82)

Item Description Q'ty

1 Mounting Bracket 1

2

3

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 3/8-24 Hex Nut 2

9 90° Elbow Connector 1

Feedback Spring

Color Nominal Max

Blue 4 (102)

Cadmium 3 (76) 3-1/4

Table 8. Mounting Kit 147-276

for the No. 6 Damper Actuator.

Feedback Spring

4" (102 mm) stroke (blue)

Feedback Spring

3" (76 mm) stroke (Cad.)

Adjusting Screw

4-1/2" (114 mm) long

Adjusting Screw

1-3/4" (44 mm) long

4-1/4

(108)

(82)

Adjusting

Screw

4-1/2 (114)

long

1-3/4 (44)

long

1

1

1

1

Figure 9. Positioning Relay Mounted on a

VP 591 8" Valve Actuator.

Table 9. Mounting Kit 147-333

for the VP 591 8" Valve Actuator.

Item Description Q'ty

Feedback Spring-Small Cad. Plate 2

Feedback Spring-Small Red 1

2

Feedback Spring-Large Green 1

Feedback Spring-Small Green 2

3 Adjusting Screw-4" (102 mm) long 1

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 2

9 90° Elbow Connector 1

Page 9

RL 147 POSITIONING RELAY Technical Instruction

155-038 Page 9

1

LEVER

ASSEMBLY

POSITIONING

RELAY

2

3

4

7

4

1

LEVER

ASSEMBLY

POSITIONING

RELAY

2

3

7

RL0088.R1

Figure 10. Positioning Relay Mounted on a

Flowrite 599 Series 8" Valve Actuator.

9

4

4

9

FEEDBACK

ARM

SPRING

GUIDE

JAM

NUT

STEM

NUT

FEEDBACK

SPRING

ARM

GUIDE

JAM

NUT

STEM

NUT

Table 10. Kit 599-00426 for the Flowrite Series 599

8" Valve Actuator.

Item Description Q'ty

RL 147 Positioning Relay 1

1 Mounting Bracket 1

2 Feedback Spring 1

3 Adjusting Screw 1

4 Wing Nut 2

7 Spring Arm 1

9 90° Elbow Connector 1

Table 11. Kit 599-00423 for the Flowrite Series 599

12" Valve Actuator.

Item Description Q'ty

RL 147 Positioning Relay 1

1 Mounting Bracket 1

2 Feedback Spring 2

3 Adjusting Screw 1

4 Wing Nut 2

7 Spring Arm 1

9 90° Elbow Connector 1

RL0091.R1

Figure 11. Positioning Relay Mounted on a

Flowrite Series 599 12" Valve Actuator.

Page 10

Technical Instruction Landis & Gyr, Inc.

RL 147-2 Page 10

Table 13. Mounting Kit for Super Flowrite and 12"

Flowrite before March 1978. Refer to Figure 12.

Item Description Q'ty

1 Mounting Bracket 1

Feedback Spring-Small Cad. Plate 2

2 Feedback Spring-Small Red 2

Feedback Spring-Large Green 1

3 Adjusting Screw-4-1/2" (114 mm)

long

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 Sure-Tite Clamp 1

9 90° Elbow Connector 1

1

Figure 12. Positioning Relay Mounted on the

Flowrite 8" Actuator (Models 1 & 2) and Super Flowrite.

Table 12. Mounting Kit 147-277*

for Flowrite 8” Valve Actuator (Models 1 & 2)

Item Description Q'ty

1 Mounting Bracket 1

Feedback Spring-Small Cad. Plate 2

2 Feedback Spring-Small Red 1

Feedback Spring-Large Green 1

Feedback Spring-Small Green 2

3 Adjusting Screw-4-1/2" (114 mm)

long

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 Sure-tite Clamp 1

9 90° Elbow Connector 1

*Also order spring arm # 147-307 for use with

VF 5915” and 6” balanced valves.

1

Page 11

RL 147 POSITIONING RELAY Technical Instruction

155-038 Page 11

Table 14. Mounting Kit 147-311 for the VP 591/3

Flowrite Valve Actuator.

Item Description Q'ty

1 Mounting Bracket 1

Feedback Spring-Small Cad. Plate 2

2 Feedback Spring-Small Red 2

Feedback Spring-Large Green 2

3 Adjusting Screw-6-1/2" (165 mm)

1

long

4 Wing Nut 2

5 Lock Washer 1

6 Flat Washer 1

7 Spring Arm 1

8 5/16-18 x 1/2 long Cap Screw 2

9 90° Elbow Connector 1

Figure 13. Positioning Relay Mounted on a

VF 591/3 Flowrite Valve Actuator.

Figure 14. Dimensions in inches (millimeters).

Information in this publication is based on current specifications. The company reserves the right to make changes

in specifications and models as design improvements are introduced.

Landis & Gyr, Inc.

Copyright © 1996 by Landis & Gyr, Inc. • Printed in the U. S. A.

• 1000 Deerfield Parkway, Buffalo Grove, Illinois 60089

Loading...

Loading...