Page 1

Document Number 473325

®

RBD & RBDR Series

Remote Balancing Dampers

Installation, Operation and Maintenance Instructions

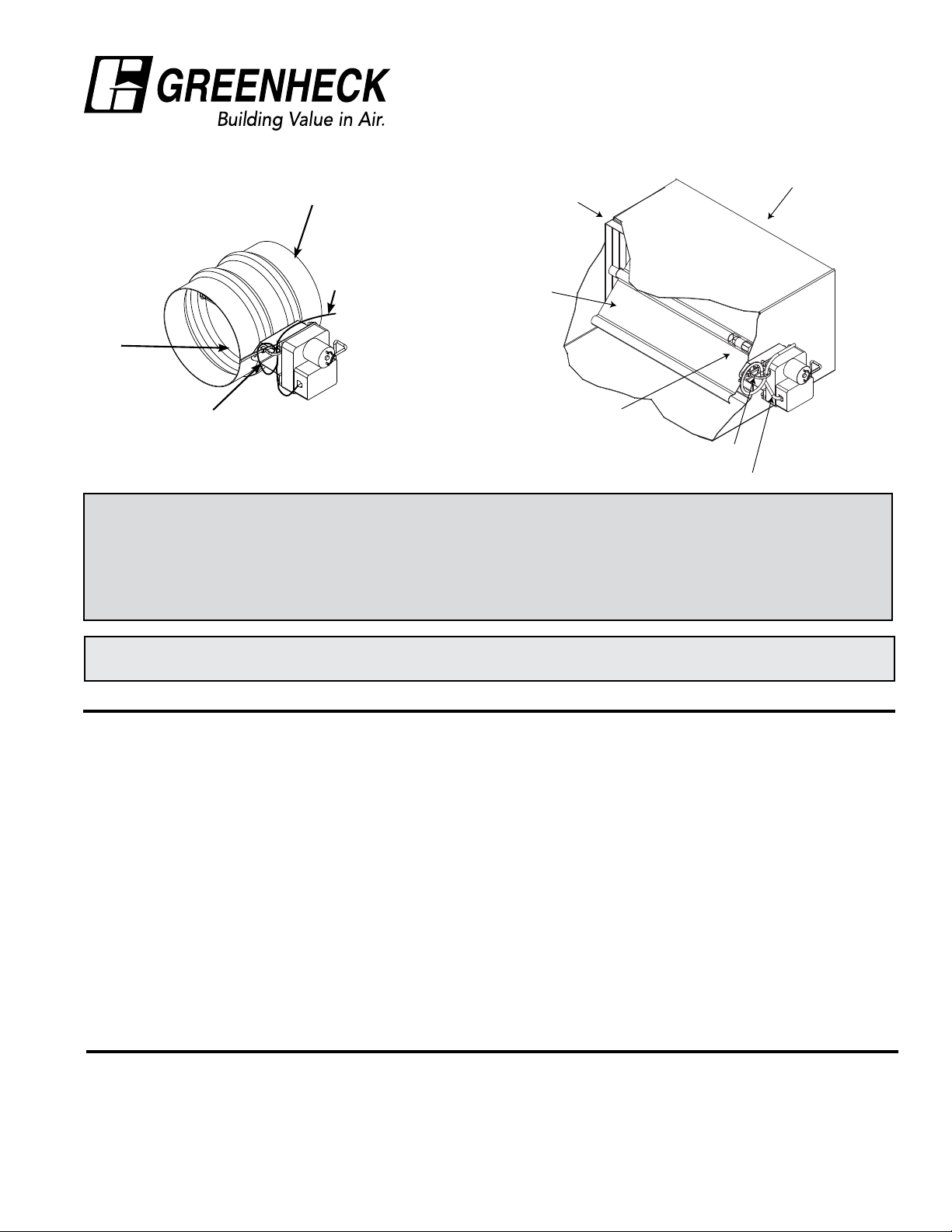

Damper

frame/sleeve

Damper

blade

wire

Standoff

bracket

Actuator

Wire tie

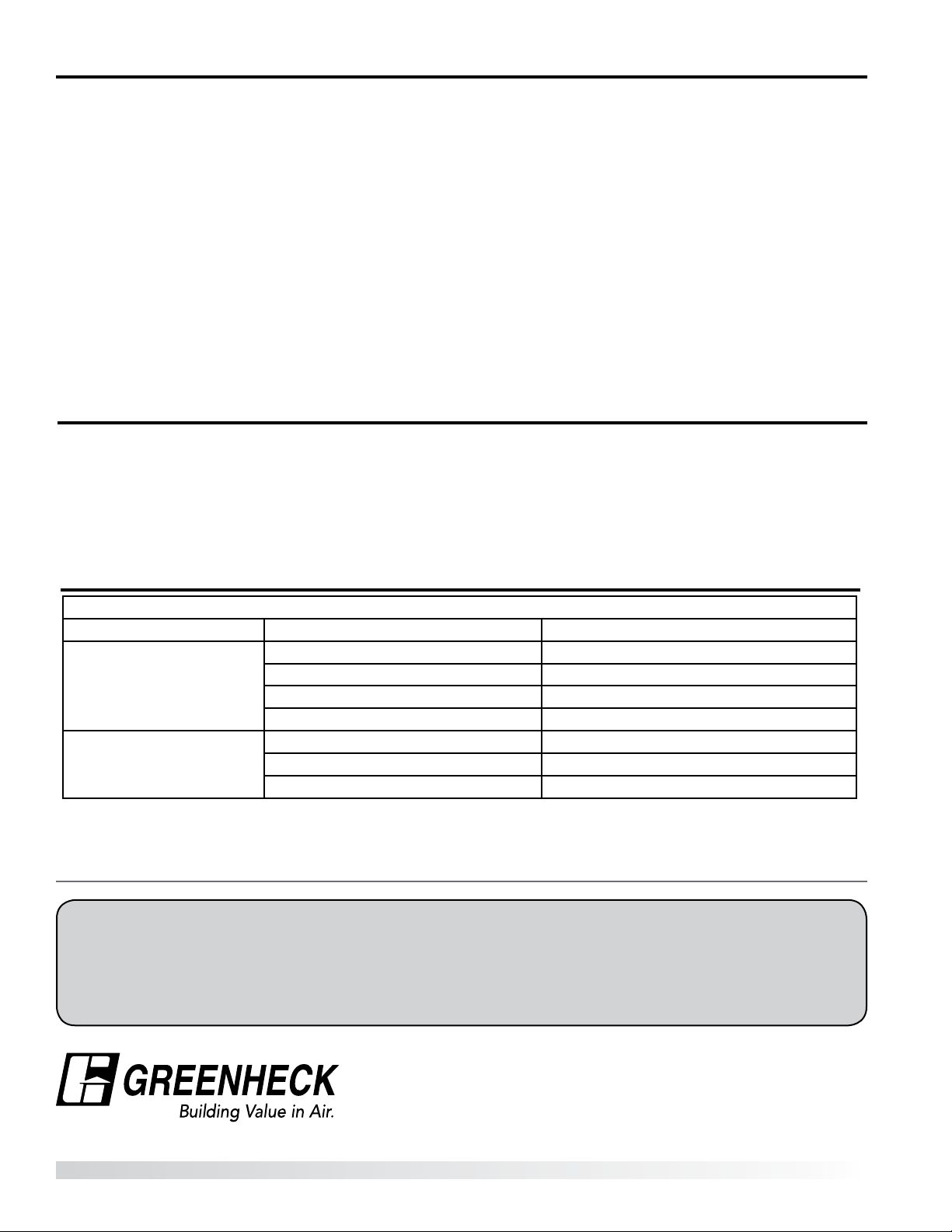

Damper

Blade

Figure 1 Figure 2

Damper

Blade

Lances

Wire

Tie

Receiving and Handling

Upon receiving dampers, check for both obvious and hidden damage. If damage is found, record all necessary information

on the bill of lading and file a claim with the final carrier. Check to be sure that all parts of the shipment, including

accessories, are accounted for.

Dampers must be kept dry and clean. Indoor storage and protection from dirt, dust and the weather is highly

recommended. Do not store at temperatures in excess of 100°F (38°C).

Duct

Wire

This manual is the property of the owner, and is required for future maintenance. Please leave it with the owner when the

job is complete.

Pre-Installation Guidelines

The basic intent of a proper installation is to secure the

remote balancing damper in the opening in such a manner

as to prevent distortion and disruption of damper operation.

The following items will aid in completing the damper

installation in a timely and effective manner.

1) Check the schedules for proper damper locations

within the building. Visually inspect the damper for

damage.

2) Lift or handle damper using sleeve or frame. Do not lift

damper using blades or actuators.

3) Do not install screws in damper frame that will interfere

with blade linkage or prevent damper blades from

opening and/or closing.

4) Damper must be installed into duct or opening square

and free of twist or other misalignment. Damper

must not be squeezed or stretched into duct or

opening. Out of square, racked, twisted or misaligned

installations can cause excessive leakage and/or torque

requirements to exceed damper/actuator design.

5) Damper and actuator must be kept clean and protected

from dirt, dust and other foreign materials prior to and

after installation. Examples of such foreign materials

include but are not limited to:

a) Mortar dust

b) Drywall dust

c) Firesafing materials

d) Wall texture

e) Paint overspray

7) Damper should be sufficiently covered as to prevent

overspray if wall texturing or spray painting will be

performed within 5 feet of the damper. Excessive dirt

or foreign material deposits on damper can cause

excessive leakage and/or torque requirements to

exceed damper/actuator design.

Installation Instructions

Round, RBDR series, dampers are supplied from the factory

with the actuator installed see Figure 1.

Square/rectangular, RBD series, dampers are supplied with

an actuator kit that must be field installed as follows:

1) Install the RBD series damper into the ductwork with the

lanced end of the blade positioned to the side of the duct

where the actuator is to be located (see Figure 2).

2) Drill a minimum 9/16 in. (14mm) diameter hole that lines

up with the center pivot of the damper blade.

3) Insert the pointed end of the pin through the hole and into

the blade lances. Pound pin into the blade lances until the

end of the pin is ½ in. (13mm) outside of the duct surface

while the blade is centered in the damper frame.

Page 2

Installation Instructions

4) With the blade closed, install the actuator by aligning

the coupler over the end of the square pin (as shown in

Figure 2) and sliding the actuator assembly onto the pin

until the bracket is in contact with the duct surface.

5) Check the blade clearance to be sure that the blade

can move side to side in the frame and it is not pressed

against the opposite side of the damper frame. If the

blade is pressed against the opposite side, the pin may

need to be pounded a little further into the blade.

6) Connect a Greenheck EZ Balance control device to the

actuator. While holding the actuator assembly against

the duct, press and hold the “Close” button until the “full

closed” light flashes.

7) Rotate the actuator assembly to hold the blade closed

then secure the actuator to the duct using the two

supplied screws.

8) Recheck the blade clearance and damper operation by

cycling the actuator.

9) All wire connections from the wall or ceiling jack to

the damper actuator must be secured to the building

structure in such a way as to prevent strain on the wire

connections (for example: use wire ties to secure a wire

loop at each connection and intermittently between the

connections).

10) The actuator mounting bracket has a factory installed

wire tie for the purpose of providing strain relief at the

actuator. Thread the wire through the wire tie, loop

around and back through the wire tie before connecting

to the actuator box. Tighten the wire tie leaving a short

loop at the actuator.

Electrical Guidelines

RBD & RBDR Series dampers are driven by a 9 volt actuator. The 9 volt power is supplied from a Greenheck “EZ Balance”

hand held remote. The “EZ Balance” remote is plugged into a wall or ceiling jack that is wired to the damper actuator using

wire and connector assemblies.

After the damper and wiring is installed, operation of the damper and wiring circuit must be visually verified by connecting

the “EZ Balance” remote to the wall jack and power up the unit. Using the switch on the “EZ Balance” remote, run the

damper through a complete cycle from full close to full open and reverse back to closed position. Document that proper

operation has been verified.

Damper Troubleshooting

The following is a cause and correction list for common concerns with the dampers.

Symptom Possible Cause Corrective Action

Frame is 'racked' causing blades to bind Adjust frame such that it is square and plumb

Damper does not fully open

and/or fully close

Damper does not operate

Screws in damper components Locate screws and remove

Contaminants on damper Clean with a non oil-based solvent

Defective motor Replace

Remote battery is dead Replace with a 9 volt battery

Broken wire connection Check all wire connections

Broken wire Check wire for cuts, replace if necessary

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to

change specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product

area tabs and in the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

473325• RBD Rev. 5, April 2014 Copyright 2014 © Greenheck Fan Corporation

Loading...

Loading...