Page 1

Direct Drive Mixed Flow Fans

Model QEID

Sound & Air Performance Supplement

• Motor Information

• Engineering Information

• Air/Sound Performance

• Dimensional Data

Greenheck Fan Corpor ation certifies that the

Model QEID Mixed Flow Inline fans shown herein are

licensed to bear the AMCA seal. The ratings shown

SOUND

and

R

AIR

MOVEMENT

AND CONTROL

ASSOCIATION

®

INTERNATIONAL, INC.

are based on tests and procedures performed

AIR

PERFORMANCE

in accordance with AMCA Publication 211 and

Publication 311 and comply with the requirements

of the AMCA Certified Ratings Program.

®

January

2010

Page 2

Direct Drive Model Selection

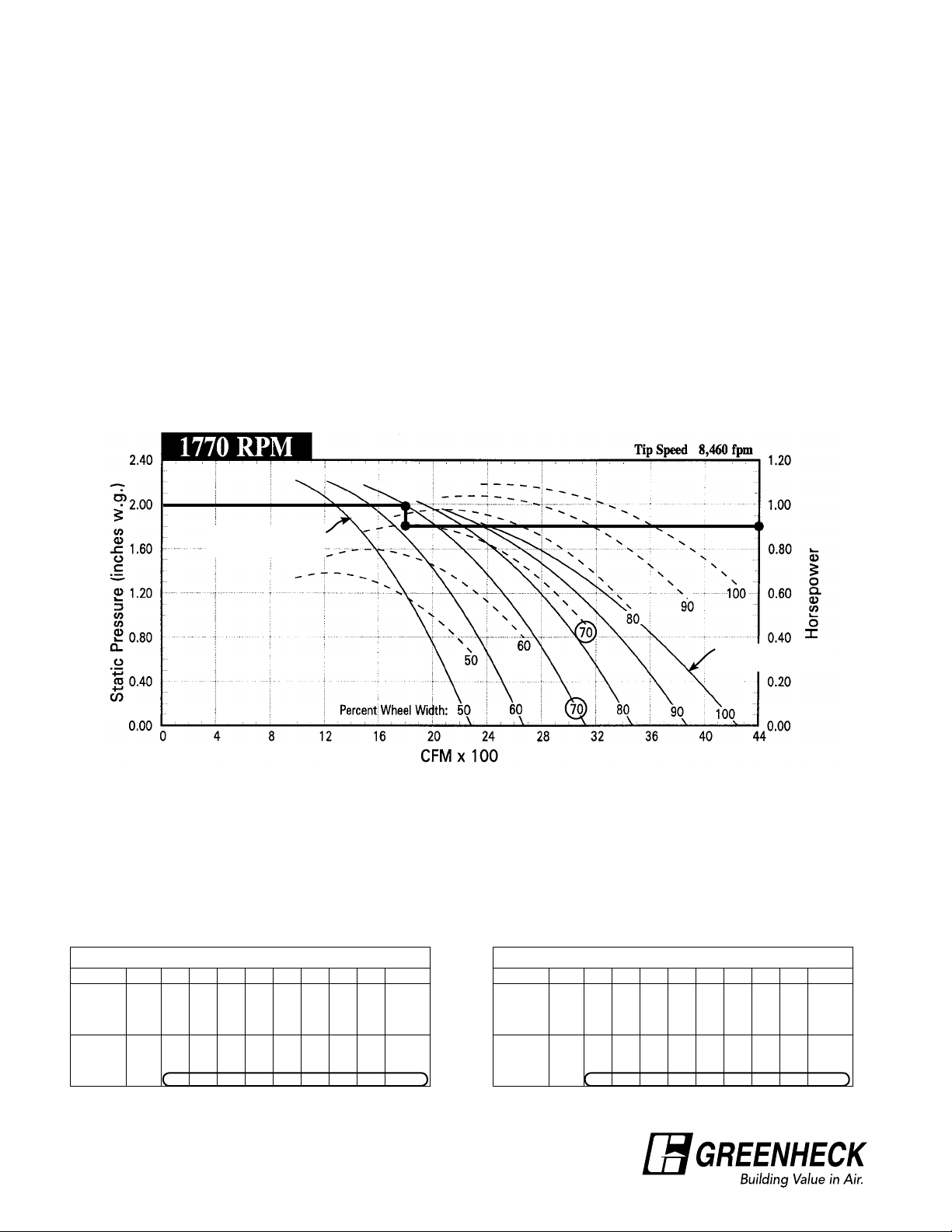

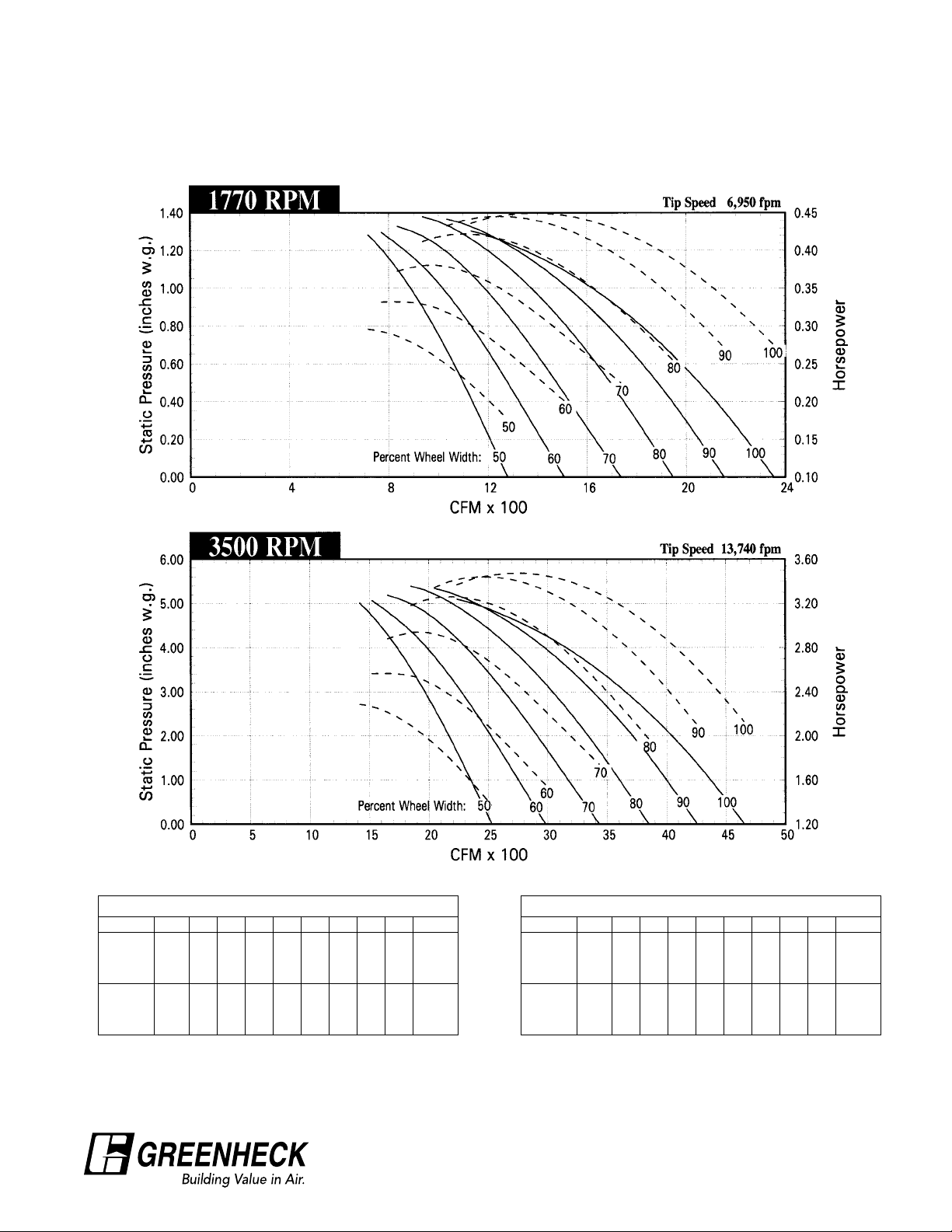

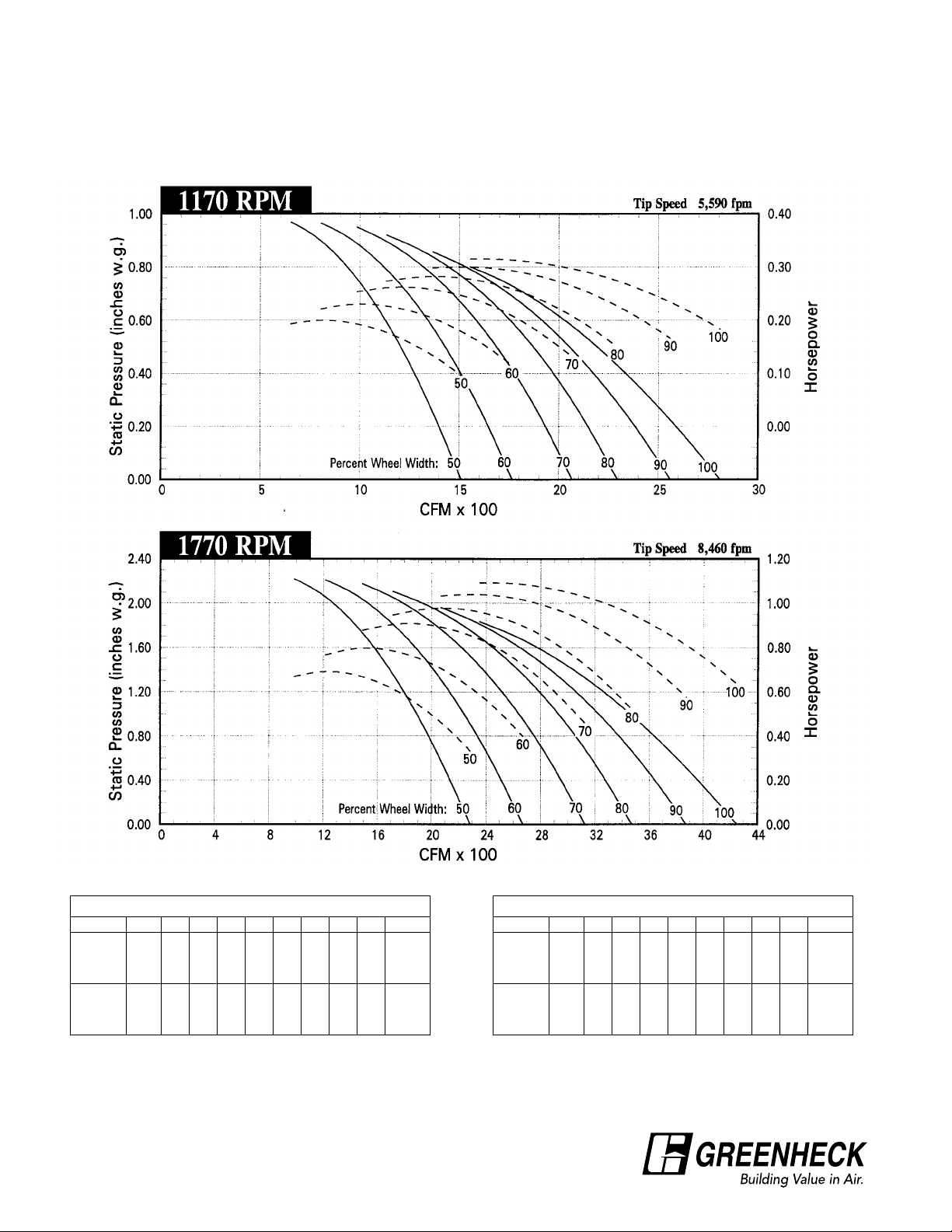

The following performance charts are for the selection of QEID mixed flow inline fans. All charts are organized

by fan size and nominal motor RPM. Within each chart, there are a series of solid black lines with corresponding

dashed lines. The solid black lines represent the fan curves for each fan and are broken down by partial wheel

widths. Minimum, maximum, and 10 percent intervals are shown. The dashed lines are brake horsepower (Bhp)

curves and are also labeled by percentage wheel width.

Example Selection: 1,700 cfm @ 2.0 inches Ps wg.

To make a selection, start by finding a size and RPM that will attain the design static pressure (Ps). Next, scan for

fan sizes and RPMs that meet the CFM requirement at the design pressure. The intersection point of the static

pressure and CFM needs to be between the minimum and maximum percent wheel width for each fan.

To determine the partial wheel width and brake horsepower, start at 2.0 inches Ps and move across the graph

until intersecting the next percent wheel width beyond the required 1,700 cfm, point A. For this example, the next

largest percent wheel width is 70. Draw a vertical line from point A that crosses the 70 percent Bhp curve. In this

case, slide vertically downward from A to point B. From point B, read the Bhp on the right vertical axis of the

chart. The Bhp for this point of operation is 0.9 Bhp. Note: If the operating point falls between two partial wheel

width curves, select the next larger wheel width at the same pressure. This will result in more CFM as compared

to the original design requirements. Wheels are available in 5% partial width increments.

A

Minimum Percent

Wheel Width

B

Maximum Percent

Wheel Width

Sound data values are provided for both the inlet and outlet of the fan and are based on 100 percent wheel

widths. Values shown in the tables are based on the design static pressure. If the design static pressure is not

listed in the table, the sound power levels need to be interpolated from the values found on either side of the

design static pressure. If the design static pressure exceeds the maximum pressure listed in the table, then the

maximum values in the table should be used.

Example: 1,700 cfm @ 2.0 inches Ps wg. with 1770 fan RPM

Since 2.0 inches Ps exceeds the maximum static pressure in the table, the sound power levels for the maximum

static pressure should be used. Sound power levels should be interpolated for pressures between those listed.

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

0.00 71 79 75 72 75 70 59 50 78

0.40 70 75 72 70 73 65 55 46 75 0.40 80 78 71 73 76 66 56 45 78

0.60 69 74 70 69 72 62 53 45 74 0.60 79 77 69 71 76 64 54 44 77

0.80 69 73 68 66 71 59 50 44 72 0.80 82 76 68 70 75 60 51 43 76

0.00 76 77 85 83 82 81 77 63 87

0.90 75 75 84 80 79 78 71 61 84 0.90 83 80 80 82 82 78 71 59 86

1.40 75 75 82 78 78 76 69 60 83 1.40 84 79 78 80 81 76 68 58 84

1.83 76 74 78 75 76 73 65 59 80 1.83 87 79 78 78 78 73 64 57 81

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

[dB ref 10

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

0.00 82 81 75 76 78 71 60 48 81

0.00 85 82 83 86 85 81 77 62 89

Wo

-12

watts]

2

®

Page 3

Effect of Air Density - Temperature and Elevation

Ratings in the fan performance tables and curves of this catalog are based on standard air (clean, dry air with a

density of .075 pounds per cubic foot, barometric pressure at sea level of 29.92 inches of mercury, temperature of

70°F). Selecting a fan to operate at conditions other than standard air requires an adjustment to both static pressure

and brake horsepower.

A cubic foot of air has a constant volume regardless of temperature or elevation. However, air density changes with

non-standard temperature or elevation. Therefore, when selecting a fan to operate at a non-standard air density

using standard air density tables and curves, corrections must be made to parameters affected by air density.

These parameters are static pressure and brake horsepower.

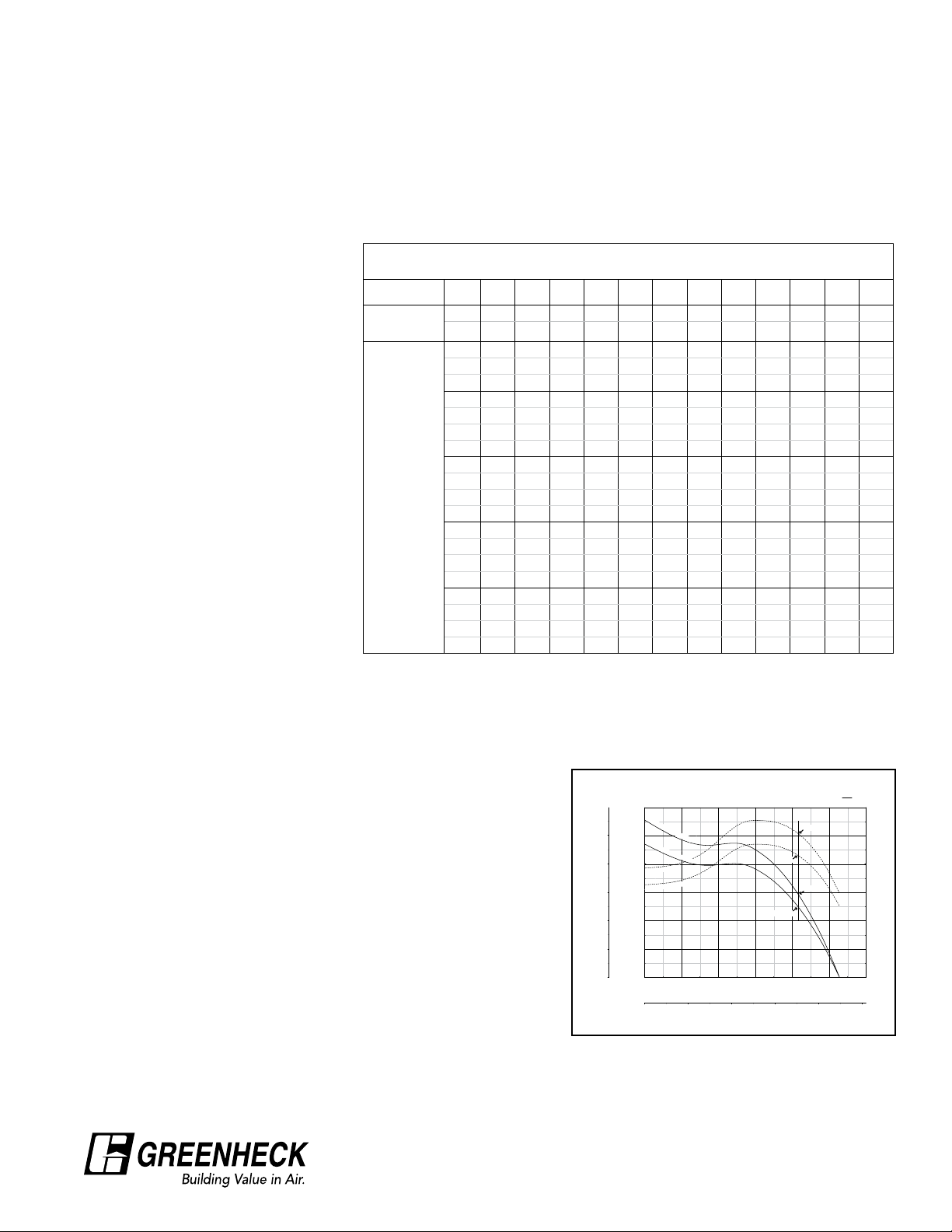

For example, a size 30-QEID mixed

flow fan is to deliver 20,000 CFM at

5.0in. static pressure. Elevation is

3000 feet, temperature is 100°F.

The 5.0 in. static pressure refers to

Altitude, (Z) ft. -1000

Barometric

Pressure

( p

the static pressure at the operating

air density, in this case at 3000 feet,

100°F. Intuitively, we realize that

at higher than standard elevations

and temperatures, air density will be

lower than standard. Therefore, we

must determine what static pressure

at standard air density will equate

to 5.0 in. static pressure at our

Temperature °F

operating density. Since standard air

density is greater than operating air

density in this case, we would expect

the static pressure after applying

the correction to be greater than the

original operating static pressure.

The table gives air density

correction factors for non-standard

temperatures and elevations.

Adapted from AMCA Standard 99-09, section 0200, Charts and Tables, with written permission from Air Movement

and Control Association International, Inc.

The example below shows the

relationship of fan performance at sea level and at 3000 ft. elevation and 100°F.

EXAMPLE

The following example shows how to properly select the fan described above:

1. Since the air volume delivered by the fan is not affected by

density, airflow remains 20,000 CFM.

2. Determine correction factor from chart for an elevation of 3000

feet and air temperature of 100°F. The correction factor is 0.848

3. Divide the specified operating static pressure by the correction

factor to determine the standard air density equivalent static

pressure (Corrected static pressure = 5.0 in. ÷ 0.848 = 5.9 in. Ps).

4. Refer to the fan performance table for a 30-QEID.

At 20,000 CFM and 5.9 in. Ps: Fan RPM = 1770, Percent Wheel

Width = 70, Actual Volume 20,800 CFM, Bhp = 31.

5. Since the horsepower selected refers to standard air density,

this must be corrected to reflect actual Bhp at the lighter

operating air. Operating Bhp = standard Bhp x 0.848, or 31 x

0.848 = 26.3 Bhp. 30 HP motor would meet requirements.

If a fan is selected to operate at high temperatures, the motor must be of sufficient horsepower to handle the

increased load at any lower operating temperature where the air is more dense. Assume the air entering the 30

QEID fan at start-up is 0°F. For 0°F and 3000 feet elevation the air density correction factor is 1.033. Bhp at 0°F = 31

x 1.033 = 32, therefore, a 40 HP motor is required.

Dry Air Density Correction Factor (I-P)

Multiply Standard Air Density, 0.075 lbm / ft3 by the Factor to obtain Density at Condition p

Sea

1000 2000 3000 4000 5000 6000 7000 8000 9000 10000

Level

in. Hg 31.02 29.92 28.85 27.82 26.82 25.84 24.89 23.98 23.09 22.22 21.39 20.58

in. wg 421.71 406.75 392.21 378.20 364.61 351.29 338.37 326.00 313.90 302.07 290.79 279.78

)

b

-40 1.309 1.262 1.217 1.174 1.131 1.090 1.050 1.012 0.974 0.937 0.902 0.868

0 1.195 1.152 1.111 1.071 1.033 0.995 0.959 0.924 0.889 0.856 0.824 0.793

40 1.099 1.060 1.022 0.986 0.950 0.915 0.882 0.850 0.818 0.787 0.758 0.729

70 1.037 1.000 0.964 0.930 0.896 0.864 0.832 0.801 0.772 0.743 0.715 0.688

100 0.981 0.946 0.913 0.880 0.848 0.817 0.787 0.759 0.730 0.703 0.677 0.651

150 0.901 0.869 0.838 0.808 0.779 0.750 0.723 0.696 0.670 0.645 0.621 0.598

200 0.832 0.803 0.774 0.747 0.720 0.693 0.668 0.644 0.620 0.596 0.574 0.552

250 0.774 0.746 0.720 0.694 0.669 0.645 0.621 0.598 0.576 0.554 0.534 0.513

300 0.723 0.697 0.672 0.648 0.625 0.602 0.580 0.559 0.538 0.518 0.498 0.480

350 0.678 0.654 0.631 0.608 0.586 0.565 0.544 0.524 0.505 0.486 0.468 0.450

(t)

400 0.639 0.616 0.594 0.573 0.552 0.532 0.513 0.494 0.475 0.458 0.440 0.424

450 0.604 0.582 0.561 0.541 0.522 0.503 0.484 0.467 0.449 0.432 0.416 0.401

500 0.572 0.552 0.532 0.513 0.495 0.477 0.459 0.442 0.426 0.410 0.395 0.380

550 0.544 0.525 0.506 0.488 0.470 0.453 0.436 0.420 0.405 0.390 0.375 0.361

600 0.518 0.500 0.482 0.465 0.448 0.432 0.416 0.401 0.386 0.371 0.357 0.344

700 0.474 0.457 0.440 0.425 0.409 0.394 0.380 0.366 0.352 0.339 0.327 0.314

800 0.436 0.420 0.405 0.391 0.377 0.363 0.350 0.337 0.324 0.312 0.301 0.289

900 0.404 0.390 0.376 0.362 0.349 0.336 0.324 0.312 0.301 0.289 0.278 0.268

1000 0.376 0.363 0.350 0.337 0.325 0.313 0.302 0.291 0.280 0.269 0.259 0.250

Standard Air 70°F, Sea Level

Corrected Air 100°F, Altitude of 3000 ft.

12

S

t

a

n

d

a

r

d

A

i

r

,

1

7

7

25

20

15

10

Static Pressure (Pa x 100)

5

0

0

10

Static Pressure (in. wg)

R

P

M

C

o

r

r

e

c

t

e

d

A

i

r

,

1

7

7

0

R

P

M

8

6

4

2

0

0 5 10 15 20 25 30

0 10 20 30 40 50

p

h

B

,

r

i

A

d

r

a

d

n

a

t

S

p

h

B

,

r

i

A

d

e

t

c

e

r

r

o

C

Volume (cfm x 1000)

Volume (m

5.0 in. wg

3

/hr x 1000)

26 Bhp

b

QEID-30

31 Bhp

5.9 in. wg

70º pitch

Density 0.075

RPM

36

30

24

18

12

6

0

Brake Horsepower

®

3

Page 4

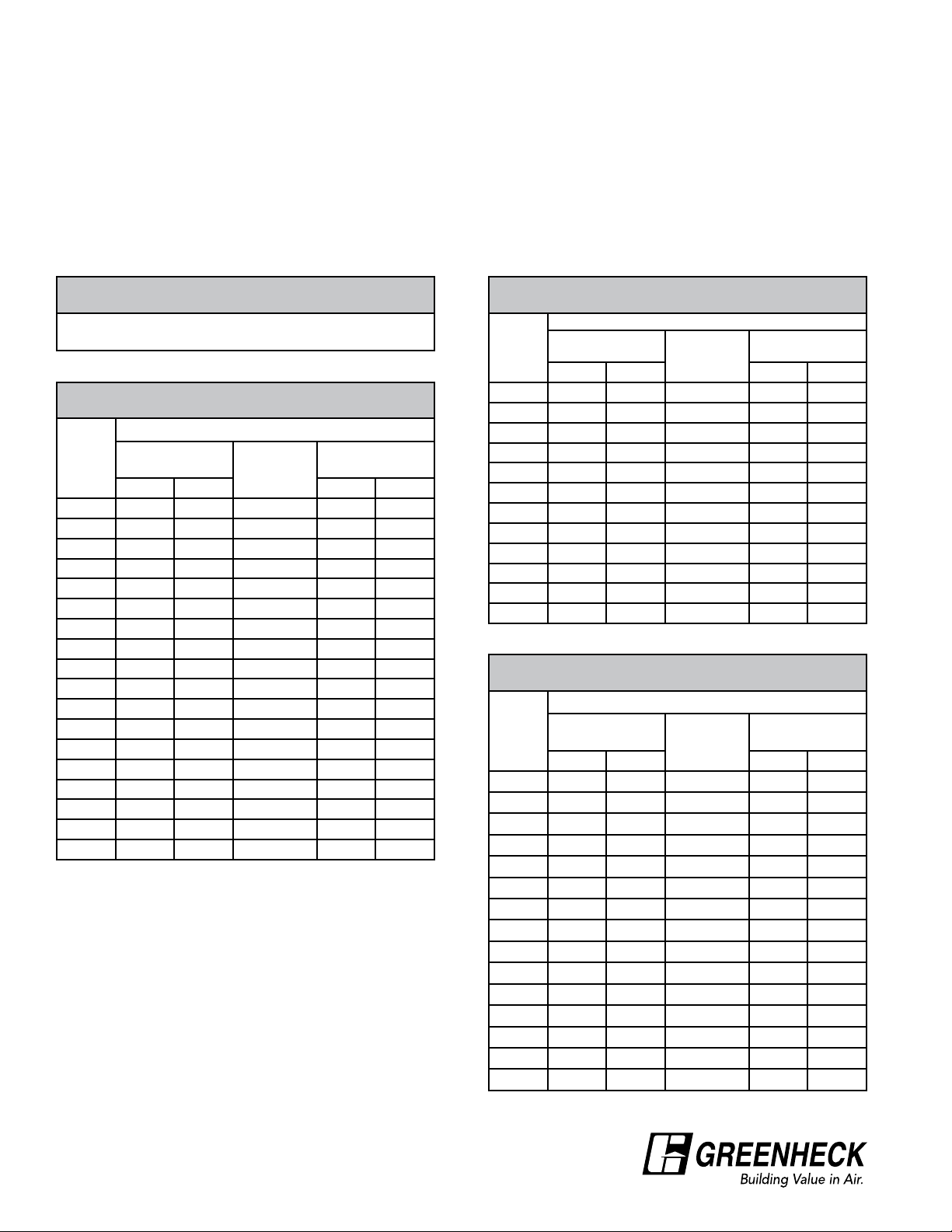

Motor Data

Greenheck QEID mixed flow fans can be supplied with any cast iron motor that is commercially available and

is appropriate for the fan size and performance required. The tables show motor frame sizes corresponding to

readily available 230/460 volt 3-phase 60 Hz motors. Consult factory (CF) for motor frame sizes on motors with

larger horsepower, 50 Hz, or different voltages. See the listed maximum and minimum motor frame size for each

fan size found on individual performance pages.

Notes:

1. Open Drip-Proof and Totally Enclosed motors have a 1.15 service factor.

2. Energy Efficient motors are in compliance with Energy Policy Act of 1992 (EPAct)

3. Premium Efficient motors meet NEMA Premium and CEE efficiency levels

690 RPM MOTORS

All 690 RPM motors are build-ups. Consult factory for motor

frame sizes.

1170 RPM MOTORS

Single Speed

HP

3/4 143T 143T CF 143T 143T

1 145T 145T 145T 145T 145T

1 1/2 182T 182T 182T 182T 182T

2 184T 184T 184T 184T 184T

3 213T 213T 213T 213T 213T

5 215T 215T 215T 215T 215T

7 1/2 254T 254T 254T 254T 254T

10 256T 256T 256T 256T 256T

15 284T 284T 284T 284T 284T

20 286T 286T 286T 286T 286T

25 324T 324T 324T 324T 324T

30 326T 326T 326T 326T 326T

40 364T 364T 364T 364T 364T

50 365T 365T 365T 365T 365T

60 404T 404T 404T 404T 404T

75 405T 405T 405T 405T 405T

100 444T 444T 444T 444T 444T

125 445T 445T 445T 445T 445T

Standard

Efficient

Open TE Open TE

Explosion

Resistant

Premium

Efficient

870 RPM MOTORS

Single Speed

HP

5 254T 254T CF 254T 254T

7 1/2 256T 256T CF 256T 256T

10 284T 284T CF 284T 284T

15 286T 286T CF 286T 286T

20 324T 324T CF 324T 324T

25 326T 326T CF 326T 326T

30 364T 364T CF 364T 364T

40 365T 365T CF 365T 365T

50 404T 404T CF 404T 404T

60 405T 405T CF 405T 405T

75 444T 444T CF 444T 444T

100 445T 445T CF 445T 445T

Standard

Efficient

Open TE Open TE

Explosion

Resistant

Energy

Efficient

1770 RPM MOTORS

Single Speed

HP

1 143T 143T CF 143T 143T

1 1/2 145T 145T 145T 145T 145T

2 145T 145T 145T 145T 145T

3 182T 182T 182T 182T 182T

5 184T 184T 184T 184T 184T

7 1/2 213T 213T 213T 213T 213T

10 215T 215T 215T 215T 215T

15 254T 254T 254T 254T 254T

20 256T 256T 256T 256T 256T

25 284T 284T 284T 284T 284T

30 286T 286T 286T 286T 286T

40 324T 324T 324T 324T 324T

50 326T 326T 326T 326T 326T

60 364T 364T 364T 364T 364T

75 365T 365T 365T 365T 365

Standard

Efficient

Open TE Open TE

Explosion

Resistant

Premium

Efficient

4

®

Page 5

QEID-12

Wheel Diameter 15.00 in.

Outlet Area 1.56 ft

2

Minimum Frame Size 143T

Maximum Frame Size 184T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 70 71 74 75 73 73 71 57 79

0.60 71 69 72 71 71 71 65 55 76 0.60 79 73 75 73 76 73 66 55 79

1770

1.00 71 69 72 69 69 69 64 55 75 1.00 82 71 74 70 73 70 65 55 77

1.30 83 74 74 70 69 68 63 55 74 1.30 98 85 78 75 75 70 65 56 80

0.00 89 78 83 87 88 87 84 85 93

2.50 80 78 82 87 86 86 82 79 91 2.50 92 88 86 89 88 89 86 80 94

3500

4.00 82 80 80 84 85 85 81 79 90 4.00 97 90 87 91 88 90 87 80 95

5.00 86 84 84 89 87 86 82 77 92 5.00 98 94 90 91 87 89 84 78 94

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 81 76 79 77 78 75 71 57 82

1770

0.00 97 87 89 91 89 89 86 85 95

3500

[dB ref 10

Wo

-12

watts]

5

5

Page 6

QEID-15

Wheel Diameter 18.25 in.

Outlet Area 2.32 ft

2

Minimum Frame Size 143T

Maximum Frame Size 145T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 71 79 75 72 75 70 59 50 78

0.40 70 75 72 70 73 65 55 46 75 0.40 80 78 71 73 76 66 56 45 78

0.60 69 74 70 69 72 62 53 45 74 0.60 79 77 69 71 76 64 54 44 77

0.80 69 73 68 66 71 59 50 44 72 0.80 82 76 68 70 75 60 51 43 76

0.00 76 77 85 83 82 81 77 63 87

0.90 75 75 84 80 79 78 71 61 84 0.90 83 80 80 82 82 78 71 59 86

1.40 75 75 82 78 78 76 69 60 83 1.40 84 79 78 80 81 76 68 58 84

1.83 76 74 78 75 76 73 65 59 80 1.83 87 79 78 78 78 73 64 57 81

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

6

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 82 81 75 76 78 71 60 48 81

0.00 85 82 83 86 85 81 77 62 89

[dB ref 10

Wo

®

-12

watts]

Page 7

QEID-16

Wheel Diameter 20.00 in.

Outlet Area 2.79 ft

2

Minimum Frame Size 143T

Maximum Frame Size 145T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 74 82 78 75 78 72 61 53 81

0.50 74 78 75 73 76 68 58 49 78 0.50 82 81 74 76 79 69 59 48 81

1170

0.70 72 77 73 71 75 65 56 48 77 0.70 82 79 72 74 78 66 56 47 80

0.95 73 76 71 69 74 61 53 46 75 0.95 85 79 71 73 78 63 54 45 79

0.00 80 80 88 86 84 84 80 66 90

1.15 79 79 87 82 82 81 74 64 87 1.15 86 83 82 85 85 81 74 62 89

1770

1.60 79 78 85 81 81 79 72 63 85 1.60 86 82 81 83 84 79 71 61 87

2.17 80 77 81 78 78 76 68 61 82 2.17 90 82 81 81 81 75 67 60 84

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 85 84 78 79 81 74 63 51 83

1170

0.00 88 85 86 89 88 84 80 65 92

1770

[dB ref 10

Wo

-12

watts]

7

Page 8

QEID-18

Wheel Diameter 22.25 in.

Outlet Area 3.45 ft

2

Minimum Frame Size 143T

Maximum Frame Size 184T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 75 79 79 76 73 74 64 56 80

0.70 73 76 75 73 71 70 62 54 76 0.70 78 76 74 76 75 71 62 53 79

1.00 72 73 73 71 70 67 60 53 75 1.00 78 75 73 74 74 68 60 52 77

1.35 73 72 71 69 68 64 57 54 72 1.35 85 77 74 74 73 65 58 52 76

0.00 80 79 89 86 84 81 83 68 90

1.60 76 74 85 83 81 78 75 66 86 1.60 85 79 85 84 85 80 77 66 88

2.30 74 72 82 81 79 77 72 65 84 2.30 85 78 82 82 83 79 73 64 86

3.10 76 74 78 78 77 75 70 65 81 3.10 87 80 82 81 81 76 70 64 84

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

8

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 82 78 78 79 77 75 66 56 82

0.00 90 84 90 88 88 83 84 69 92

[dB ref 10

Wo

®

-12

watts]

Page 9

QEID-20

Wheel Diameter 24.50 in.

Outlet Area 4.14 ft

2

Minimum Frame Size 143T

Maximum Frame Size 215T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 79 83 82 79 76 77 67 58 83

0.90 76 79 78 76 74 73 64 57 79 0.90 81 78 77 79 78 74 65 56 82

1170

1.25 76 77 76 74 73 70 63 56 78 1.25 81 77 76 77 77 71 63 55 80

1.65 77 75 74 72 71 67 60 56 75 1.65 88 80 77 77 76 68 60 55 79

0.00 84 82 92 89 87 84 86 71 93

2.10 80 78 88 86 84 81 78 68 89 2.10 88 82 87 87 88 83 80 69 91

1770

2.90 78 76 85 84 82 80 75 68 87 2.90 88 81 85 85 86 81 76 67 89

3.78 80 77 81 81 80 77 72 68 84 3.78 90 83 85 84 84 79 73 67 87

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 85 81 81 82 80 78 68 58 85

1170

0.00 93 86 93 91 91 86 87 72 95

1770

[dB ref 10

Wo

-12

watts]

9

Page 10

QEID-22

Wheel Diameter 27.00 in.

Outlet Area 5.12 ft

2

Minimum Frame Size 182T

Maximum Frame Size 215T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 75 84 83 80 78 77 74 61 84

1.10 72 81 80 78 76 72 66 59 81 1.10 77 80 79 82 80 74 68 59 84

1.60 71 80 79 76 75 70 64 59 79 1.60 76 78 78 80 79 73 66 58 82

2.10 73 78 76 74 73 69 64 62 77 2.10 77 78 76 77 76 70 64 59 79

0.00 83 87 92 92 90 86 87 75 95

2.50 80 82 90 89 88 83 79 71 92 2.50 83 84 91 92 91 85 81 72 95

3.70 79 81 89 87 86 82 77 71 90 3.70 82 83 90 90 90 84 78 70 93

4.81 83 83 86 84 83 79 75 72 88 4.81 84 85 87 88 87 81 76 70 91

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

10

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 81 84 83 84 81 78 75 61 86

0.00 88 89 94 95 93 88 88 77 98

[dB ref 10

Wo

®

-12

watts]

Page 11

QEID-24

Wheel Diameter 30.00 in.

Outlet Area 6.21 ft

2

Minimum Frame Size 213T

Maximum Frame Size 256T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 79 88 86 83 81 80 78 64 87

1.30 75 85 84 81 79 75 69 62 84 1.30 81 83 83 85 83 78 71 62 87

1170

2.00 75 83 82 79 78 74 68 63 82 2.00 80 82 81 83 82 76 69 61 85

2.60 77 82 80 77 76 72 67 65 81 2.60 80 81 79 80 79 73 67 62 83

0.00 87 90 95 95 93 89 90 78 98

3.00 83 86 93 92 91 86 82 75 95 3.00 86 87 95 95 94 89 84 75 98

1770

4.60 83 84 92 91 89 85 80 74 93 4.60 86 86 93 94 93 87 82 74 96

5.95 86 87 89 88 86 82 78 75 91 5.95 88 88 91 91 90 84 79 74 94

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 84 87 86 87 84 81 79 65 89

1170

0.00 91 92 97 98 97 92 91 80 101

1770

[dB ref 10

Wo

-12

watts]

11

Page 12

QEID-27

Wheel Diameter 33.00 in.

Outlet Area 7.54 ft

2

Minimum Frame Size 213T

Maximum Frame Size 286T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 82 91 90 86 84 83 81 67 90

1.60 79 88 87 84 82 78 72 65 87 1.60 84 86 86 88 86 80 74 65 90

2.30 78 87 85 82 81 77 71 66 85 2.30 82 84 84 86 85 79 72 64 88

3.10 80 85 83 80 79 75 70 68 84 3.10 83 84 82 83 82 76 70 65 86

0.00 90 93 99 98 96 92 93 81 101

3.65 87 89 96 95 94 89 85 77 98 3.65 89 90 97 98 97 91 87 78 101

5.25 86 87 95 94 92 88 83 77 96 5.25 89 89 96 96 96 90 84 77 99

7.09 90 90 92 91 89 85 81 78 94 7.09 90 91 93 94 93 87 82 77 97

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

12

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 87 90 89 90 87 84 82 67 92

0.00 94 95 100 101 100 94 94 83 104

[dB ref 10

Wo

®

-12

watts]

Page 13

QEID-30

Wheel Diameter 36.50 in.

Outlet Area 9.31 ft

2

Minimum Frame Size 254T

Maximum Frame Size 326T

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 86 94 93 89 87 86 84 70 93

1.90 82 91 90 87 85 81 75 68 90 1.90 87 89 89 91 89 84 77 68 93

1170

2.90 82 90 88 85 84 80 74 69 89 2.90 86 88 87 89 88 82 75 67 91

3.80 84 88 86 83 82 78 73 71 87 3.80 86 87 85 86 85 79 73 68 89

0.00 94 97 102 101 99 95 96 84 104

4.35 90 92 99 98 97 92 88 81 101 4.35 92 93 101 101 100 95 90 81 104

1770

6.65 90 91 98 97 95 91 86 80 100 6.65 92 92 99 100 99 93 88 80 102

8.70 93 93 95 94 92 88 84 81 97 8.70 94 94 97 97 96 90 85 80 100

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 90 93 92 93 90 87 85 71 95

1170

0.00 97 98 103 104 103 98 97 86 107

1770

[dB ref 10

Wo

-12

watts]

13

Page 14

QEID-33

Wheel Diameter 40.25 in.

Outlet Area 11.27 ft

Minimum Frame Size 254T

Maximum Frame Size 365T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

1770

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 85 93 95 95 91 90 89 76 97

2.25 82 92 93 92 88 85 81 72 94 2.25 88 94 96 98 93 89 83 73 98

3.45 81 90 91 90 87 83 77 72 92 3.45 88 92 95 96 91 86 80 72 96

4.50 87 90 89 88 85 81 76 72 90 4.50 89 92 93 94 89 84 77 72 94

0.00 92 99 104 104 102 99 99 93 107

5.15 89 97 103 102 100 96 92 86 104 5.15 95 99 104 106 105 100 96 88 109

7.90 88 95 101 99 98 94 90 84 102 7.90 95 99 103 104 103 98 93 86 107

10.30 94 98 101 98 96 92 88 83 101 10.30 96 99 102 102 101 96 90 84 105

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

14

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

1770

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 89 95 98 100 95 92 90 77 101

0.00 96 100 105 108 107 103 100 94 111

[dB ref 10

Wo

®

-12

watts]

Page 15

QEID-36

Wheel Diameter 44.50 in.

Outlet Area 13.79 ft

Minimum Frame Size 254T

Maximum Frame Size 365T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 85 95 87 88 85 88 75 68 92

1.55 81 92 85 86 83 81 72 65 88 1.55 84 92 90 96 87 83 75 66 95

870

2.30 80 89 83 85 81 78 70 65 86 2.30 83 91 88 94 85 81 72 65 93

3.10 85 88 81 84 79 75 70 66 85 3.10 85 91 87 91 83 78 70 66 90

0.00 89 97 98 98 94 93 92 79 101

2.80 86 95 96 95 92 88 84 75 97 2.80 91 97 100 101 96 92 87 76 102

1170

4.20 85 93 94 93 90 86 80 75 95 4.20 91 96 98 99 94 90 83 75 100

5.55 90 93 92 91 88 84 79 76 93 5.55 92 95 96 97 92 87 80 75 97

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 86 92 92 96 89 89 79 70 96

870

0.00 92 98 101 103 98 95 93 80 104

1170

[dB ref 10

Wo

-12

watts]

15

Page 16

QEID-40

Wheel Diameter 49.00 in.

Outlet Area 16.77 ft

Minimum Frame Size 284T

Maximum Frame Size 365T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 88 98 90 91 88 91 78 71 95

1.90 84 95 88 89 86 84 75 68 91 1.90 87 95 93 98 90 86 78 69 97

870

2.80 83 92 86 88 84 80 73 68 89 2.80 86 94 91 97 88 83 75 68 96

3.75 88 91 84 87 82 78 73 69 88 3.75 88 94 90 94 85 81 73 69 93

0.00 92 100 101 101 97 96 95 82 103

3.45 90 98 99 98 94 91 87 78 100 3.45 94 100 102 104 99 95 89 79 104

5.10 89 96 97 96 93 89 83 78 98 5.10 94 98 101 102 97 92 86 78 102

6.80 94 96 95 94 91 87 82 78 96 6.80 95 98 99 100 95 90 83 78 100

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

16

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 89 95 95 99 92 91 82 72 99

870

0.00 95 101 104 106 101 98 96 83 107

[dB ref 10

Wo

®

-12

watts]

Page 17

QEID-44

Wheel Diameter 54.25 in.

Outlet Area 20.49 ft

Minimum Frame Size 324T

Maximum Frame Size 405T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 92 101 93 94 91 94 81 74 98

2.30 88 98 91 92 89 87 78 71 94 2.30 90 98 96 102 93 89 81 72 101

870

3.45 87 95 89 91 87 84 76 71 92 3.45 89 97 94 100 91 87 78 71 99

4.60 92 94 87 90 85 81 76 72 91 4.60 91 97 93 97 89 84 76 72 96

0.00 96 103 104 104 100 99 98 85 107

4.15 93 101 102 101 98 94 90 81 103 4.15 97 103 106 107 102 98 93 82 108

1170

6.25 92 100 100 99 96 92 86 81 101 6.25 97 102 104 105 100 96 89 81 106

8.30 97 99 98 97 94 90 85 82 99 8.30 98 101 102 103 98 93 86 81 103

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 92 98 98 102 95 95 85 76 102

870

0.00 98 104 107 109 104 101 99 86 110

1170

[dB ref 10

Wo

-12

watts]

17

Page 18

QEID-49

Wheel Diameter 60.00 in.

Outlet Area 24.85 ft

Minimum Frame Size 364T

Maximum Frame Size 445T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

1170

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

0.00 95 104 97 97 94 97 84 77 101

2.70 91 101 94 95 92 90 81 74 97 2.70 93 101 99 105 96 92 84 75 104

870

4.15 90 99 92 94 90 87 79 74 95 4.15 92 100 97 103 94 90 81 74 102

5.55 95 97 90 93 88 84 79 75 94 5.55 94 100 96 100 92 87 79 75 99

0.00 99 106 107 107 103 102 101 88 110

4.90 96 105 105 104 101 97 93 84 106 4.90 100 106 109 110 105 101 96 85 111

7.50 95 103 103 102 99 95 89 84 104 7.50 100 105 107 108 103 99 92 84 109

10.10 101 102 101 100 97 93 88 85 102 10.10 101 104 105 106 101 96 89 84 106

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

[dB ref 10

Wi

18

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

1170

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 95 101 101 105 98 98 88 79 105

870

0.00 101 107 110 112 107 104 102 89 113

[dB ref 10

Wo

®

-12

watts]

Page 19

QEID-54

Wheel Diameter 66.00 in.

Outlet Area 30.46 ft

Minimum Frame Size 364T

Maximum Frame Size 445T

2

Inlet Sound Power, L

RPM Ps 1 2 3 4 5 6 7 8 L

0.00 96 100 95 94 93 90 79 73 97

2.10 92 97 92 92 89 85 76 70 94 2.10 93 98 99 100 93 87 79 71 99

690

3.20 91 95 91 91 87 82 75 70 92 3.20 93 97 97 98 90 85 77 70 98

4.20 93 93 89 89 85 80 75 72 90 4.20 94 97 95 95 88 82 76 71 95

0.00 98 107 99 100 97 100 87 80 104

3.35 94 104 97 98 95 93 84 77 100 3.35 96 104 102 107 99 95 87 78 106

870

5.10 93 102 95 97 93 89 82 77 98 5.10 95 103 100 106 97 92 84 77 105

6.70 98 100 93 96 91 87 82 78 97 6.70 97 103 99 103 94 90 82 78 102

Performance certified is for installation type B: Free inlet, Ducted outlet. Performance ratings do not include the effects of appurtenances (accessories).

The sound power level ratings shown are in decibels, referred to 10

outlet L

effects of duct end correction. Ratings for outlet sound include the effects of duct end correction. The A-weighted sound power ratings shown have been

calculated per AMCA Standard 301.

, LWoA sound power levels for full (100%) width wheels, installation type B: Free inlet, Ducted outlet. Ratings for inlet sound do not include the

Wo

®

[dB ref 10

Wi

-12

watts] Outlet Sound Power, L

A RPM Ps 1 2 3 4 5 6 7 8 LWoA

Wi

-12

watts, calculated per AMCA Standard 301. Values shown are for inlet LWi, LWiA and

0.00 95 99 100 101 96 92 83 73 102

690

0.00 98 104 104 108 101 100 91 81 108

870

[dB ref 10

Wo

-12

watts]

19

Page 20

QEID Dimensional Data

Slip-Fit

O.D.

Size

30

33

36

40

44

49

54

Slip Fit O.D. Length* Weight**

inches mm inches mm lbs. kg.

17.13 435 25.0 635 100 45

20.88 530 25.0 635 140 65

23.00 584 26.0 660 170 80

25.38 645 29.0 737 200 95

27.81 706 34.0 864 250 115

30.88 784 35.5 902 370 170

34.00 864 41.5 1054 480 220

37.44 951 45.0 1143 570 260

41.63 1057

45.75 1162 1140 520

50.56 1284 1360 620

55.75 1416 1650 750

61.63 1565 2190 995

67.75 1721 2700 1225

75.00 1905 3130 1420

Refer to

table below.

860 390

Length

Size

12

15

16

18

20

22

24

27

30

33

36

40

44

49

54

* Length of unit varies with motor frame size. See table below.

** Weight is for unit only and does not include motor.

Length — inches (millimeters)

254/6 T 284/6 T 324/6 T 364/5 T 404/5 T 444/5 T

45.5 (1156) 50.0 (1156) 50.0 (1156)

46.5 (1181) 54.0 (1372) 54.0 (1372) 54.0 (1372)

50.5 (1283) 58.0 (1473) 58.0 (1372) 58.0 (1372)

56.5 (1435) 61.0 (1549) 61.0 (1549)

64.0 (1626) 64.0 (1626) 70.0 (1778)

74.5 (1892) 74.5 (1892) 80.5 (2045)

77.0 (1956) 77.0 (1956) 83.0 (2108)

Our Warranty

Greenheck warrants this equipment to be free from defects in material and workmanship for a period

of one year from the shipment date. Any units or parts which prove defective during the warranty

period will be replaced at our option when returned to our factory, transportation prepaid. Motors are

warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck

prove defective during this period, they should be returned to the nearest authorized motor service

station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specifications without notice.

P.O. Box 410 • Schofield, WI 54476-0410 • Phone (715) 359-6171 • greenheck.com

Copyright © 2010 Greenheck Fan Corp. • QEID Supplement Rev 2 January 2010 PD (00.CVI.9005 R2 1-2010)

Prepared to Support

Green Building Efforts

®

Loading...

Loading...