Page 1

Type 1 and V-Bank Hoods

Model PHEV

Hoods Designed for Pizza Ovens

April

2006

Page 2

Pizza Hood Design Challenges

A pizza oven’s large size plus the heat and smoke they generate make effective

coverage a design challenge. Adding to this challenge are high production ovens

with “forced air baking.” These ovens can force hot air out of conveyor openings

and into the kitchen if the hood is not designed

correctly. Poor capture means higher energy

consumption.

Design Testing

Greenheck’s design engineers went to Architectural Energy’s Commercial

Kitchen Ventilation Lab to do testing to ASTMF1704 with Schleiren Flow

Visualization Technology. Schlieren imaging is an invaluable tool that allows us

to see airflow and heat transfer. Because we can see and identify what works

and what doesn’t we can design to provide optimum capture and

containment. Schleiren imaging is what led us to our design for the pizza hood.

Greenheck’s Pizza Hood

Our single island exhaust only canopy hood has a modified design to meet the unique requirements

of the pizza oven. We turned the filter bank perpendicular to the pizza oven. This allows for capture

and containment at both ends of the oven - creating a more comfortable working environment and

reducing energy costs.

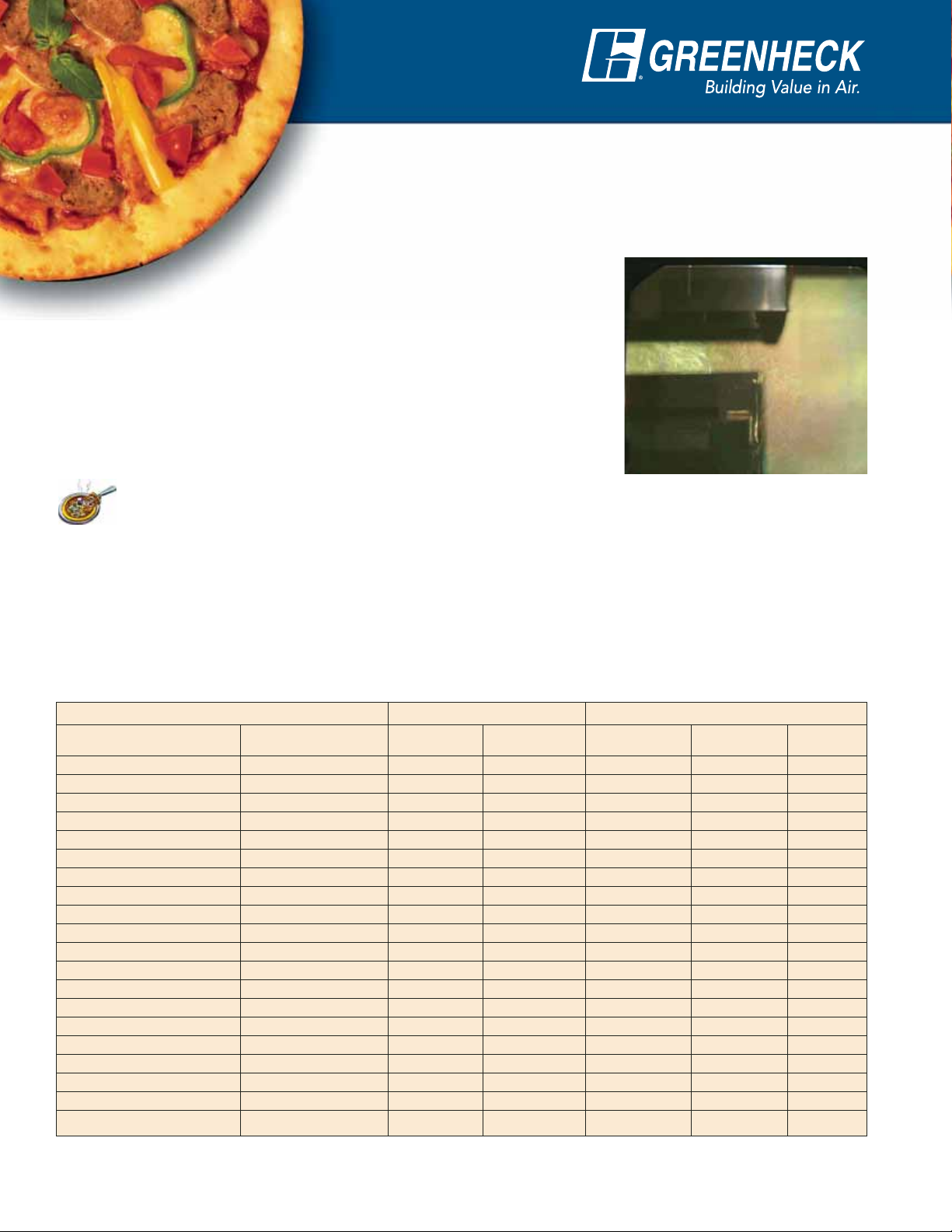

Hood Size* Exhaust Airflow

Oven Make Model Wall Island

Single Double Triple

Deck Deck Deck

Lincoln Impinger X2 3240-2 101x72 101x84 1444 1765 -

3270-2 130x72 130x84 1988 2429 -

Lincoln Impinger I All 102x69 102x81 1389 1698 -

Lincoln Impinger II All 79x64 79x52 800 840 1069

Lincoln Low Profile All 102x71 102x83 1439 1758 2237

Bakers Pride Conveyor EC 120x47 120x59 1050 1283 1633

APC 87x42 87x54 700 722 919

Blodgett Conveyor MT1828 74x47 74x59 750 750 851

SGT3240 101x65 101x77 1275 1559 1984

MT3855 115x71 115x83 1678 2051 2610

MT3870 130x74 130x86 2054 2510 3195

Middleby Marshall Conveyor PS225 / 200 / 220FS 104x62 104x74 1250 1528 -

PS220-R 120x58 120x70 1125 1322 -

PS360 / 360WB 114x67 114x79 1322 1616 -

PS360WB70 130x67 130x79 1822 2227 -

PS360EWB 114x75 114x87 1772 2166 -

PS314 95x51 95x63 865 1058 -

PS536 100x55 100x67 1020 1250 -

PS555 115x76 115x88 1820 2225 2830

PS570 130x66 130x78 1790 2180 2780

The following chart shows some of the industries most popular conveyor ovens with the Greenheck

recommended hood size and cfm. For optimal performance Greenheck used a 12 inch overhang on all sides

that do not have a wall.

*Hood model PHEV (L) X (W)

Page 3

2

4

1

3

5

18 gauge type 304 or 430 stainless steel

#4 finish available

Filter bank perpendicular to the oven for

improved capture

PEL - Performance Enhancing Lip helps

direct air to the filter and improves

capture and containment

Full length, fully welded concealed

grease trough

Incandescent Lights

Filler Panels for wall applications

Backsplash Panels for wall applications

Heat Shield for island applications

Fire Systems: Wet Chemical; Dual Agent

Hood Mounted Switches

Utility Cabinets

Variable Volume Controls

Stainless Steel Baffle Filters

1

2

3

4

5

Pizza Hood

Features & Options

Options

Features

CUBE Roof Upblast Centrifugal Exhaust Fan...the industry standard

When you buy a Greenheck CUBE fan, you receive a fan with the industry’s best

performance and durability for general clean air, high grease, and other

contaminant applications (as found in restaurants, food service, and fume hood

exhaust). CUBE fans are specifically designed to discharge air directly away

from the mounting surface.

• Number 1 in product quality and reliability.

• Broadest performance in the industry, up to 5 in. wg and 30,000 cfm.

• UL Listed for electrical and grease.

• Greenheck pioneered leakproof construction for the entire life of the fan

utilizing a one-piece windband that is continuously welded to the curb cap.

Page 4

Project Name: Item #

APPLICATION AND SPECIFICATION:

Provide Greenheck Exhaust Hood Model PHEV as shown on plans and in accordance with the following

specification:

Kitchen ventilation hood(s) shall be Type I, exhaust canopy suitable for all types of cooking applications.

Hood(s) shall be single island canopy, exhausting two banks of filters through one central plenum. Hood(s)

to be UL 710 Listed Without (With) Fire Dampers for 600°F rated cooking appliances.

Hood(s) shall be constructed of a minimum 18 gauge type 304 or 430 stainless steel, with a #4 finish. The

hood(s) shall be constructed using the standing seam method for optimum strength. All external seams

shall be welded and/or liquid tight in accordance with NFPA #96. Lighter material gauges, alternate

material types, finishes, are not acceptable. All unexposed interior surfaces shall be constructed of a

minimum 18 gauge corrosion resistant steel including, but not limited to ducts, plenum, and brackets.

Hood(s) shall include UL 1046 Classified aluminum baffle filters, in sufficient number and sizes to ensure

optimum performance as specified by the filter manufacturer. The filter housing shall terminate in a

pitched, full-length grease trough, which shall drain into a removable grease container.

Vaporproof, UL Listed incandescent light fixtures shall be prewired to a junction box. Wiring shall conform

to the requirements of the National Electrical Code (NEC #70 - Latest Edition).

Filler Panel (Optional)

Heat Shield

(Optional)

Typical

Hanger

Bracket

W

W

L

L

Specifications

Copyright © 2006 Greenheck Fan Corp. • Universal Pizza Hood PHEV Rev. 2, April, 2006 RG

Loading...

Loading...