Page 1

Penthouse

Elevator Vent

Application and Design

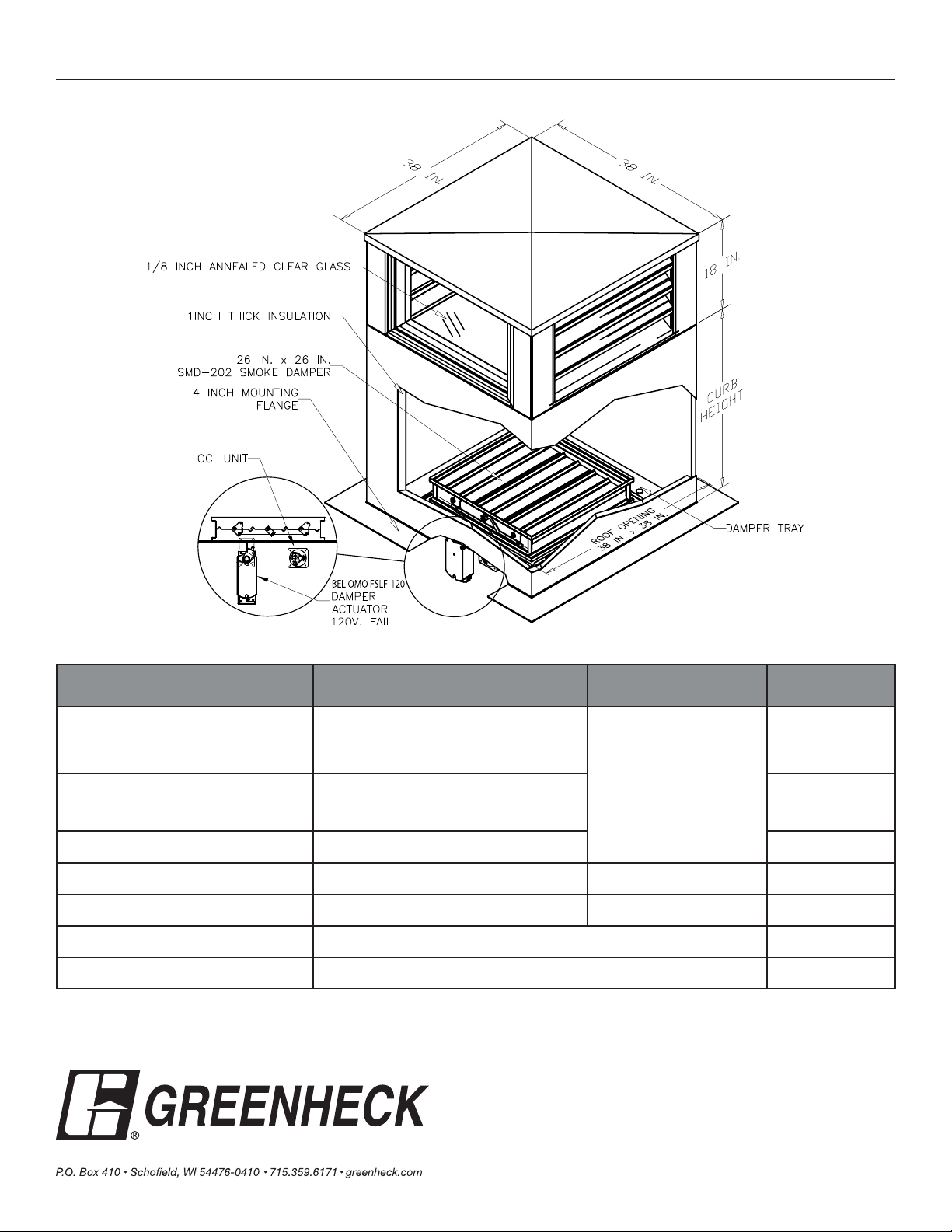

The PEV-400 Penthouse Elevator Vent is a gravity ventilator

penthouse with three sides fabricated of Greenheck’s ESJ401 stationary louver model. A smoke damper with a 120

volt actuator and OCI (Open Closed Indicator) is located

in the throat of the unit. The unit is shop assembled and

shipped attached to the curb with the damper installed in

the curb.

Standard Construction

Louvered

Perimeters . . . . .Heavy gauge extruded 6063-T5

aluminum, 4 in. x 0.081 in.

nominal wall thickness

Birdscreen � � � � �3/4 in. x 0.051 in. flattened expanded

aluminum in removable frame,

inside mount (rear)

Finish � � � � � � � � � Mill

Size . . . . . . . . . .38 in. x 38 in. x 18 in., sits on a standard

36 in. high curb or optional

12 in. or 24 in. high curb

Curb � � � � � � � � �12 ga. cold rolled steel, 4 in.

mounting flange, welded construction,

permatector paint finish

Hood � � � � � � � � �0.100 formed aluminum with

0.5 in. insulation

Boxed Corner � �0.100 formed aluminum

Glass � � � � � � � � �0.125 in. annealed clear

Weight � � � � � � � �495 pounds (with curb)

Roof Opening � �38 in. x 38 in.

PEV-400

Louver

Model � � � � � � � �ESJ-401

Size � � � � � � � � � �30 in. x 18 in. (3 total)

Free Area � � � � � �4.44 sq. ft. (total)

Damper

Model � � � � � � � �SMD-202

Size � � � � � � � � � �26 in. x 26 in.

Actuator � � � � � � 120V, GGD, Fail open

Free Area � � � � � �3.071 sq. ft.

Options (at additional cost)

• A variety of bird and insect screens

• A variety of architectural finishes

including:

Clear anodize

Integral color anodize

Baked enamel paint

Kynar paint

Page 2

PEV-400PRODUCT DETAILS

Elevator Vent

Penthouse

FINISHES

Finish Type Description/Application Color Selection

2-coat 70% KYNAR 500®/HYLAR 5000® AAMA 2605 –

Dry film thickness 1�2 mil� (AKA: Duranar®, Fluoropon®,

Trinar®, Flouropolymer, Polyvinylidene Fluoride, PVDF2)

2-coat 50% KYNAR 500®/HYLAR 5000® AAMA 2604

– Dry film thickness 1�2 mil� (AKA: Acroflur®, Acrynar®)

Baked Enamel AAMA 2603 – Dry film thickness 0�8 mil�

(AKA: Acrabond Plus®, Duracron®)

Integral Color Anodize AA-M10C22A42 (>0�7 mil)

Clear Anodize 204 R-1 AA-M10C22A31 (0�4-0�7 mil)

Industrial coatings

Mill

“Best.” The premier finish for extruded aluminum� Tough,

long-lasting coating has superior color retention and

abrasive properties� Resists chalking, fading, chemical

abrasion and weathering�

“Better.” Tough, long-lasting coating has excellent color

retention and abrasive properties� Resists chalking, fading,

chemical abrasion and weathering�

“Good.” Provides good adhesion and resistance to

weathering, corrosion and chemical stain�

“Two-step” anodizing is produced by following the normal

anodizing step with a second, colorfast process�

Clear, colorless and hard oxide aluminum coating that resists

weathering and chemical attack�

Greenheck offers a number of industrial coatings such as Hi-Pro Polyester, Epoxy, and Permatector®�

Consult a Greenheck Product Specialist for complete color and application information�

Materials may be supplied in natural aluminum or galvanized steel finish when normal weathering is

acceptable and there is no concern for color or color change�

Finishes meet or exceed AAMA 2605, AAMA 2604, and AAMA 2603 requirements. Please consult www.greenheck.com for complete information on standard and

extended paint warranties. Paint finish warranties are not applicable to steel products.

Standard Colors: Any of the 24

standard colors shown can be

furnished in 70% or 50% KYNAR

500®/HYLAR 5000® or Baked Enamel�

2-Coat Mica:

Greenheck offers 9 standard 2coat Mica colors� Other colors are

available� Consult Greenheck for

possible extra cost when selecting

non-standard colors or special

finishes�

Medium or Dark Bronze 5 years

Clear 1 Year

Copyright © 2011 Greenheck Fan Corporation

Standard Warranty

(Aluminum)

10 Years

(Consult Greenheck for

availability of extended

warranty)

5 Years

1 Year

Consult Greenheck

n/a

PEV-400

April 2011 Rev� 1

Greenheck Fan Corporation reserves the right

to make product changes without notice�

Loading...

Loading...