Greenheck M9185D Installation Manual

INSTALLATION INSTRUCTIONS

Honeywell Modutrol IV Series Actuators

UL Listed Electric Actuators with Two Position Control

These instructions apply to the external field installation of

Honeywell actuators on Greenheck model VCD Control Dampers

when they are duct mounted or sleeved.

Honeywell M9185D actuators is a modulating actuator that spring

returns to the fail position when power is interrupted.

Part #454200

Models M9185D

Tools Required:

Wrenches:

(1)3/8 in., (2)1/2, (1) 9/16 in. , (1)7/16, and (1) 5/16 in.

(1) Hammer

Note: These actuator models require field

calibration for the zero and span setting.

Part Number Quantity Description

1 1 Actuator

2 1 Mounting Bracket

3 1 Mounting Plate

4 4

5 4

6 10

7 2

8 2

9 2

10 1 1 in. Crankarm

11 1

1

/4 -20 x 1/2 in. Threadstud

1

/4 -20 x 3/4 in. Threadcutting Screw

1

/4 -20 Spinlock Nut

1

/2 in. Crankarm

5

/16 -18 x 11/2 in. Bolt

5

/16 -18 Spinlock Nut

3

/8 -16 x 21/2 in. Carriage Bolt

Part Number Quantity Description

12 1

13 2 Linkage Adjustment Pin

14 2

15 1 Drive Link

16 1 Stand Off Bracket

17 4 #14 - 3/4 in. TEK Screw

19 1 221455A Crankarm

20 4

3

/8 -16 Spinlock Nut

1

/4 in. E-Ring

1

/4 in. -20 x 1/2 in. Hex Bolt

Instructions:

14

15

19

6

13

14

13

7

8

9

11

10

12

A

A

These installation instructions assume the damper is already

mounted in a duct or sleeve with the damper shaft extending

beyond the sleeve or duct 6 inches.

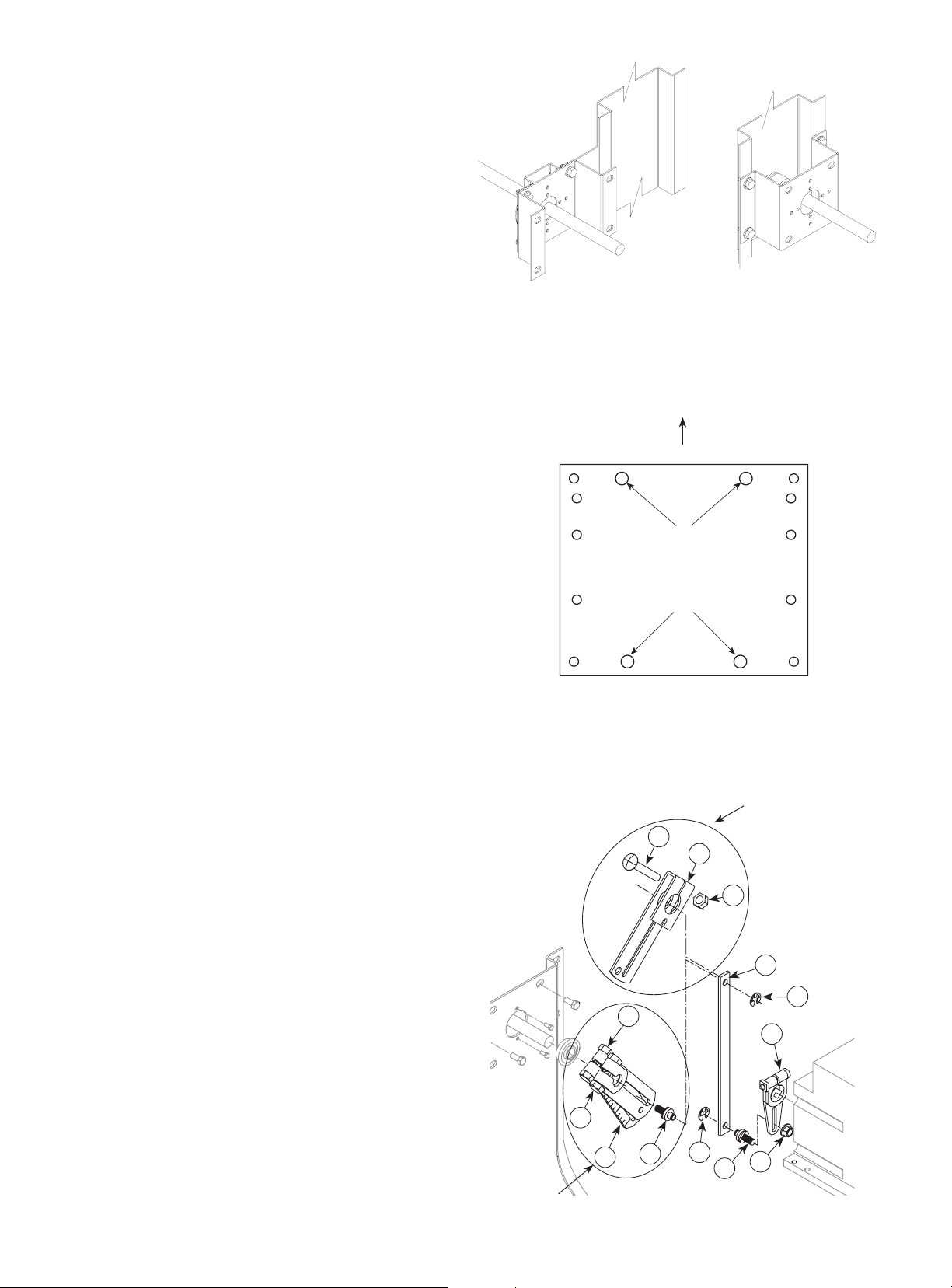

1. Install the stand off bracket (item 16).

Dampers with a jackshaft

1a. Mount the stand off bracket onto the jackshaft bracket

with (4) 1/4-20 X 1/2 in. thread cutting screws (item 17).

Use the orientation shown on this page.

Note: The bracket must be perpendicular to the damper

on the duct or sleeve and the bracket's shaft hole must be

centered on the jackshaft.

Dampers without a jackshaft (Shaft Extension)

1b. Mount the stand off bracket (item 16) spanning across the

damper frame flanges. Use the orientation shown to the

right. Fasten to the damper frame with (4) #14 Tek screws,

supplied in the field. Be sure not to run the screws into the

damper linkage, which is between the flanges.

Note: The bracket must be perpendicular to the damper

on the duct or sleeve and the bracket's shaft hole must be

centered on the shaft extension.

2. Fasten the mounting plate (item 3) to the mounting bracket

(item 2) using (4) 1/4- 20 x 1/2 in. thread studs (item 4), and

(4) 1/4-20 spinlock nuts (item 6), through the matching four

hole pattern on the mounting bracket labeled “A” on the

illustration. Note that the mounting bracket has only one

pattern that will match the mounting plate pattern.

3. Mount the mounting bracket (item 2) to the stand off

bracket using (4)1/4 -20 x 1/2 in. bolts (item 21) and (4)1/4 20 Spinlock nuts (item 6) included with this kit. Use the

outer four holes of the mounting bracket for jackshafted

models and the inner four holes for directly driven models.

4. If the damper has a 1/2 in. dia. damper shaft, mount the

ball bearing (item 18), into the mounting bracket with two

#10 Tek screws (item 20). The Tek screws are required to

keep the thrust forces from pushing the bearing out of the

mounting bracket. If the damper shaft is 1 in. in diameter

then no ball bearing is required.

5. Mount the actuator to the mounting plate in the

corresponding holes using (3 )1/4-20 x 3/4 in. thread

cutting screws (item 5). Note that the actuator must be

mounted with the shaft in the horizontal position.

6. Assemble the linkage

Parts needed for dampers with 1/2 in. shafts:

(Qty. 2) 1/2 in. crankarms (item 7)

(Qty. 2) 5/16 - 18 x 11/2 in. bolts ( item 8)

(Qty. 2) 5/16 - 18 spinlock nuts ( item 9)

(Qty. 1) Drive link (item 15)

(Qty. 2) Linkage adjustment pin (item 13)

(Qty. 2) 1/4 - 20 spinlock nuts (item 6)

(Qty. 1) Actuator crankarm (item 19)

(Qty. 2) 1/4 in. E-Ring (item 14)

Parts needed for dampers with 1 in. shafts:

(Qty. 1) 1 in. crankarm (item 10)

(Qty. 1) 3/8 -16 x 21/2 in. bolts (#11)

(Qty. 1) 3/8 -16 spinlock nut (#12)

(Qty. 1) Drive link (#15)

(Qty. 2) Linkage adjustment pin (#13)

(Qty. 2) 1/4 in. - 20 spinlock nuts (#6)

(Qty. 1) Actuator crankarm (#19)

(Qty. 2) 1/4 in. E-Ring (#14)

Orientation of Stand Off

Bracket for a jackshaft

driven damper

Steps 6a,b

for dampers with 1/2

in. shafts.

Orientation of Stand Off

Bracket for a directly driven

damper

Damper

Mounting Plate

Steps 6a,b for dampers

with 1 in. shafts

(substitute these parts in

place of 7, 8, 9, &13)

Loading...

Loading...