Greenheck IG Installation Manual

Indirect Gas-Fired Make-Up Air

Model IG

• 800 to 7,000 cfm • Up to 400,000 BTU/hr

May

2004

Multiple Furnace Control Options

Optional Evaporative Cooling

PRODUCT FEATURES

2

The Greenheck model IG features a

power vented, 80% efficient, ETL

listed, indirect gas-fired furnace.

Heating is available up to 400,000

BTU/hr (input) with air flow volumes

up to 7,000 cfm.

Units are factory assembled and

wired to minimize field installation

time and costs.

Indirect Gas-Fired Furnaces

• Power vented with post purge cycle

• ETL listed to ANSI standard Z83.8 and CGA 2.6

• 80% thermal efficiency

• Gas control options include up to 8:1 staged

turndown and up to 4:1 modulating turndown

• Aluminized steel or stainless steel heat exchanger

• Direct spark ignition system

• Easy access burner controls

• Insulated double wall construction

Control Center

The control center includes the following standard

components:

• Magnetic motor starter

with solid state overload

protection

• Control transformer with

fusing

• Disconnect switch

• Separately fused motor

• Distribution terminal strip

Premium grade control components are selected to

provide you with years of reliable operation. All

electrical components are UL Listed, recognized or

classified and factory prewired for single point power

connection.

Vibration Isolators

The entire fan and motor

assembly is mounted on

Neoprene vibration

isolators to minimize noise

transmission into the

building.

Filters

Filter options include 2-inch pleated 30% efficient

filters or 2-inch washable aluminum mesh filters.

Integrated Downturn Plenum

Greenheck’s unique indirect furnace design includes

an integrated downturned plenum, eliminating the

need for an additional section to achieve a downblast

discharge.

Durable Construction

Designed for maximum weather resistance, IG

housings are constructed of heavy gauge G90

galvanized steel. Insulated double wall construction

and lifting lugs are standard.

Reliable Fan Performance

Air performance ratings

from Greenheck’s

AMCA registered test

chamber ensure

accurate data.

Double width, double

inlet forward curved

wheels for high

efficiency and low

sound levels are constructed of heavy gauge steel.

Wheels are statically and dynamically balanced to

ensure vibration free operation.

Access Panels

Large access panels are provided for easy inspection

and maintenance of motors, drives, fan wheels,

filters, and heater controls.

Factory Wired and Tested

All units are tested prior to

shipment to ensure Greenheck’s

high level of quality. Units are

checked for proper fan, furnace

and controls operation.

Model IG

Indirect Gas-Fired

Make-Up Air Unit

®

INSTALLATION OPTIONS

3

®

Kitchen Combination Package

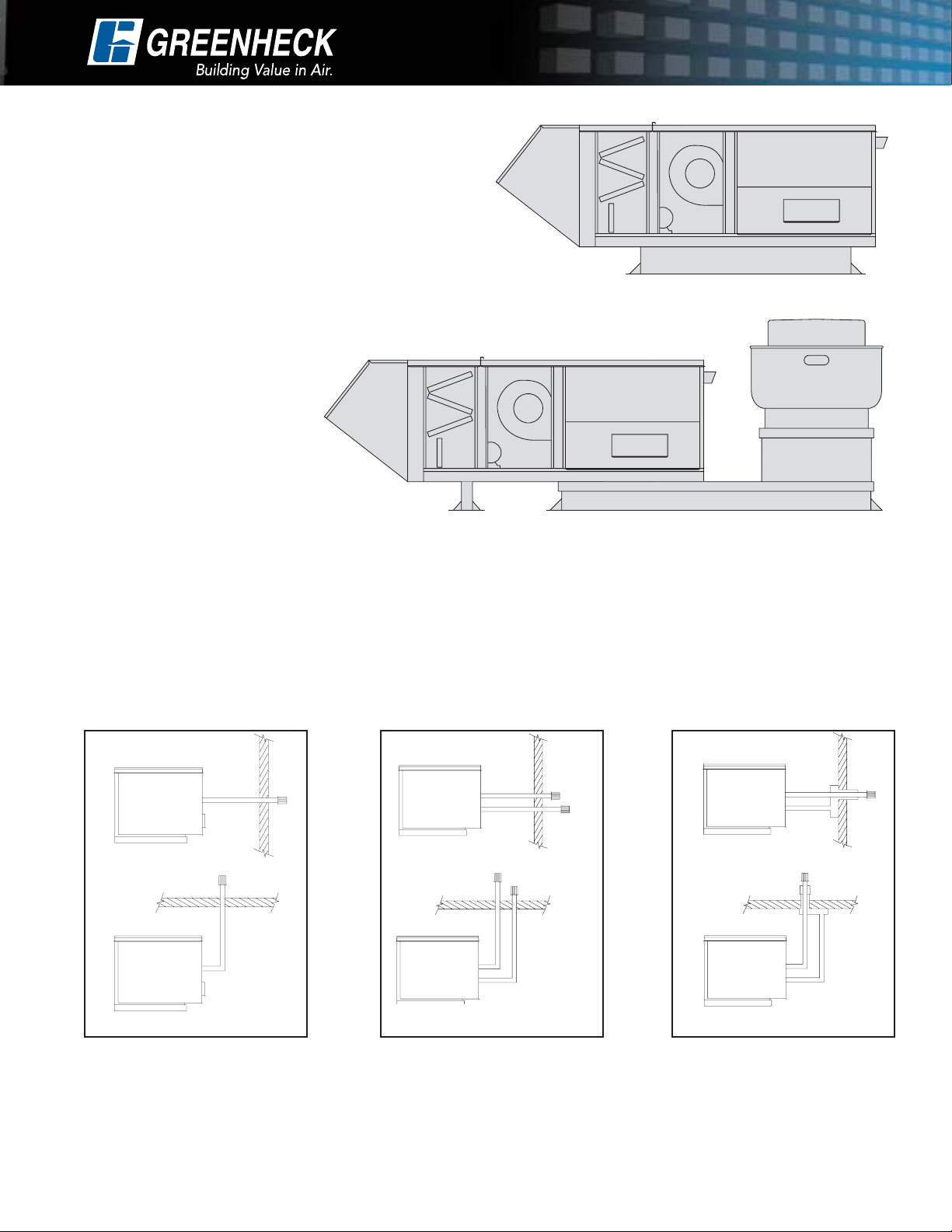

Downblast or Horizontal Discharge

Model IG is available in either downblast

(Arrangement DB) or horizontal (Arrangement HZ)

discharge. Arrangement DB utilizes Greenheck’s

integrated downturned plenum to provide you with

the most compact downturn design available.

Venting Options

When your application calls for indoor installation, Greenheck offers multiple venting options:

Basic Indoor Venting Separate 2-Pipe Venting Concentric Venting

The Greenheck combination

package (Arrangement DBC)

simplifies installation and

reduces your field labor costs.

This pre-engineered design

offers you the benefit of only

one roof penetration for both

supply and exhaust ducts, while

ensuring complete compatibility

and interface between the

supply fan, exhaust fan, curb

and combination extension.

Greenheck combination packages are specifically designed to comply with NFPA 96, which states:

• Exhaust duct must terminate at least 24 in. above the roof deck.

• Exhaust fan discharge must terminate at least 40 in. above the roof deck.

• There must be at least 10 ft. of horizontal separation between the intake and exhaust discharge.

Through WallThrough WallThrough Wall

Through Roof Through Roof Through Roof

Concentric venting uses

outdoor air for combustion

and vents combustion

byproducts outdoors through

a vent line, but offers you the

benefit of only one roof or wall

penetration.

Separate 2-pipe venting uses

outdoor combustion air and

vents combustion byproducts

outdoors through a vent line,

requiring separate roof or wall

openings for each line.

Basic indoor venting uses

indoor air for combustion and

vents combustion byproducts

outdoors through a vent line

in the wall or roof.

Loading...

Loading...