Page 1

The IDHC series is a custom duct heater featureing much larger

sizes. The IDHC has the following standard features:

• UL 1996 certified

• 50/60 Hz compability

• A disconnecting magnetic control contactor per

stage, or each 48 amp circuit within a stage

• Zero clearance rating

• Fan interlock

• Power terminal board

• Control terminal board

• Grounding lugs

• Automatic limit switch for primary over

temperature protection

• Manual reset limit switch for secondary over

temperature protection

Capacity is dependent on voltage/phase and heater

dimensions.

Capacity : 500 kW maximum

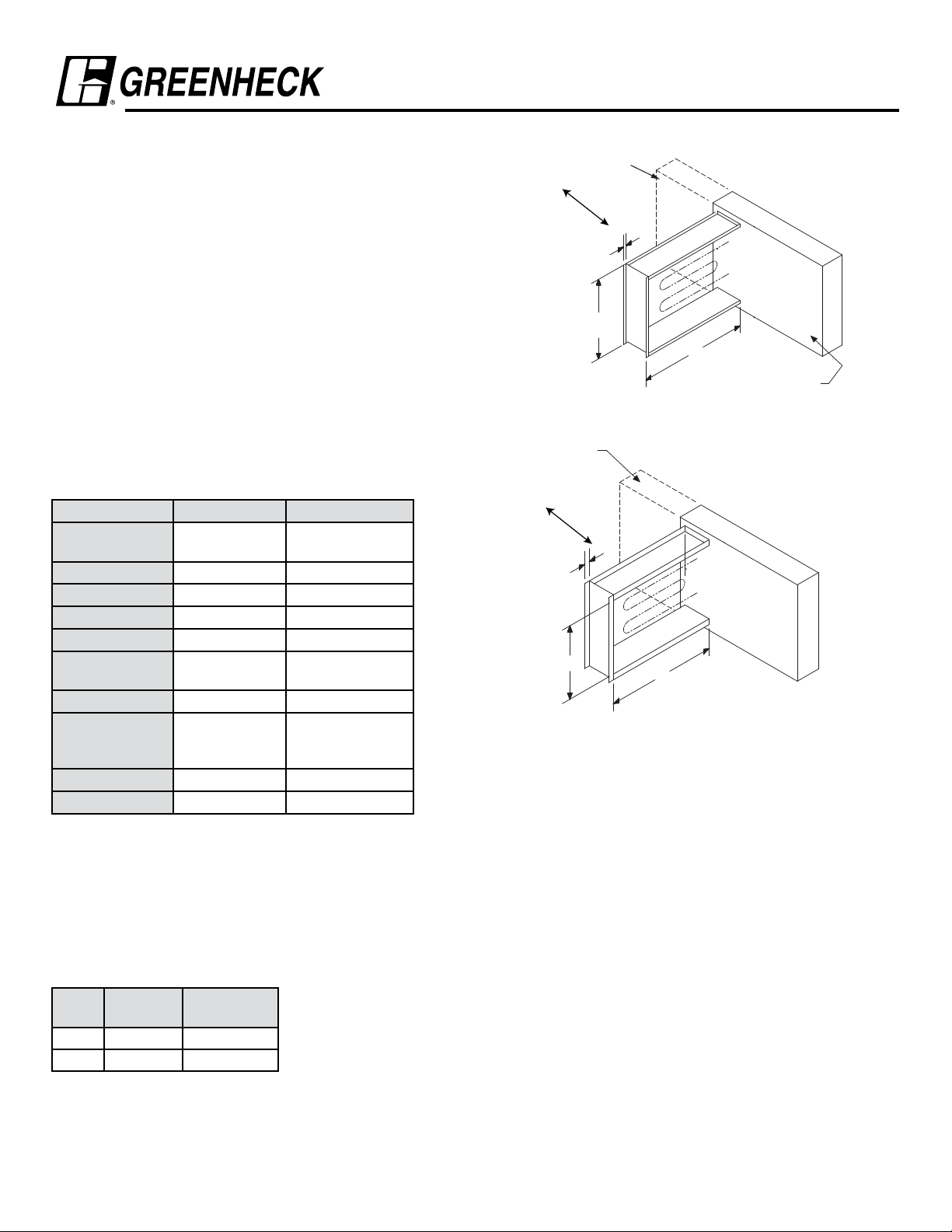

Construction Standard Optional

Airflow Direction Horizontal

bi-directional

Contactor Magnetic Mercury

Control Box Offset Left Right

Control Voltage 24V 120V

Element Wire Standard 80/20

Heater Control Stage SCR, Vernier SCR,

Heater Type Slip in Flange

Heater Voltage/

Phase

Material Galvanized Steel -

Recess None 1,2,3

Standard heater allows airflow in either direction for horizontal

duct applications.

120/1 208/1, 208/3, 230/1,

Vertical up

Pneumatic

230/3, 277/1, 460/3,

480/1, 480/3

Size Limitations

W x H

Inches 8 x 8 120 x 144

mm 203 x 203 3048 x 3658

Minimum

Size

Maximum

Size

IDHC

Duct Heaters

OFFSET RIGHT

OPTIONAL

AIRFLOW

F

H

W

W

OFFSET LEFT

STANDARD

Type F

Flange Mount

Type S

Slip- In

OFFSET RIGHT

OPTIONAL

AIRFLOW

F

H

Options available:

• Airflow switch

• Control transformer

• Disconnect switchwith door interlock

• Dust tight box with gasketed door

• PE (pressure electric) switch

• Pilot light

• Room thermostat

• Time delay relay

• Vapor barrier

• Primary power fusing

• De-rated coils

• Element wrapper recess for internally insulated ducts

• Flush mount control cabinet for tight ceiling/floor installations

• Stainless steel hardware

• Right offset control cabinet

Installation instructions available at www.greenheck.com.

Page 2

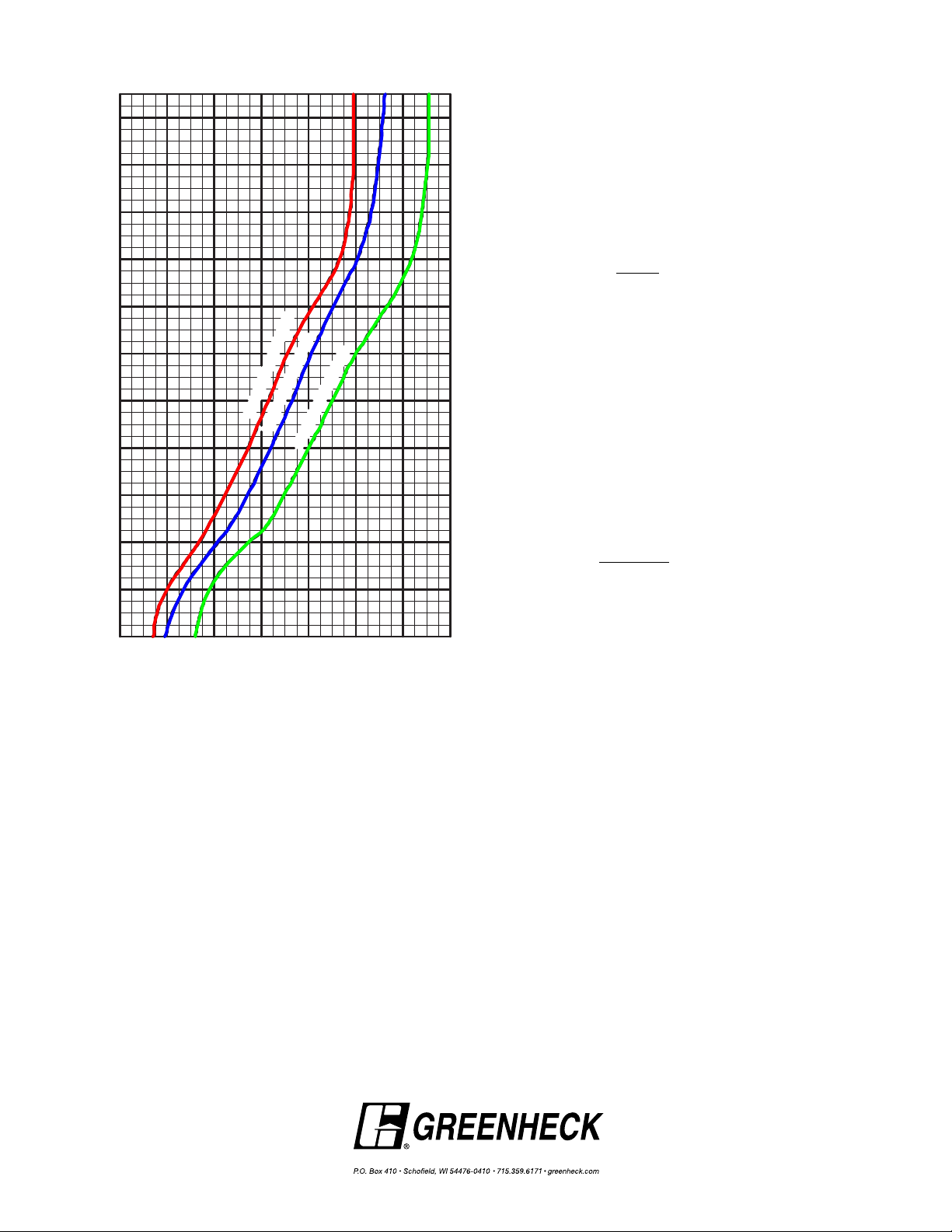

Minimum Air Velocities

WATTS PER SQUARE FOOT, DUCT AREA

22,000

20,000

18,000

16,000

14,000

12,000

10,000

8,000

6,000

4,000

2,000

BELOW 78°F INLET AIR

78° TO 90°F INLET AIR

91° TO 110°F INLET AIR

General

A. The minimum airflow through a duct heater is directly related

to the inlet air temperature. Consideration must be given to

both airflow across the heater and the inlet temperature.

B. To calculate the watts per sq. ft. (square foot) of duct area,

divide the total watts required by the duct size (Watt density

= watts/duct area (ft2).

Example: Duct size equal 2 ft. x 3 ft., total watts equal 20,000

watts per sq. ft.

20,000

= 3333

6

C. If airflow in the duct is expressed in FPM, then a direct cross

reference can be made by comparing the temperature of the

air (as it enters the duct heater) to the kW rating on the table

at the rated air velocity.

1. Draw a line horizontally from the watts per sq. ft required

to the inlet air temperature being used.

2. From this point of intersection on the inlet temperature

line, draw a line down vertically to establish the air

velocity.

3. In cases where the velocity is less than that determined

from the chart, then the velocity must be increased, the

kW required must be reduced, or both must be done.

D. In cases where the airflow is expressed in CFM, convert to

FPM by dividing the CFM by the duct area.

CFM

Duct Area(ft2)

= FPM

Minimum Air Velocity (fpm)

1,2001,000800600400200

1,400

Copyright © 2015 Greenheck Corporation

IDHC Rev. 7 August 2015

Loading...

Loading...