Greenheck IDHB Installation Manual

Document Number 478052

®

IDHB & IDHC Series

Duct Heaters

Installation Instructions

IDHB Series

The information and instructions in this sheet apply to duct heater models for zero clearance installation in

ducts. They are approved for use with heat pumps, air conditioners, or other forced air systems and may be

controlled by contactors, relays, sequencers or solid state devices.

The duct heaters are prewired, have voltage ratings to 600 volts, both single phase and three phase.

The duct heaters are furnished with integral controls.

IDHB and IDHC series are intended for

installation in accordance with electric heaters

requirements established by:

National Fire Protection Association

NFPA Standards 90A and 90B

NFPA Standard 70

Receiving and Handling

Inspect heater for any possible shipping damage.

Check all insulators for breakage and inspect heater

element wire for any deformation that could cause a

short circuit or ground. Make sure all fasteners are

tight.

Electrical connections such as pressure terminals

should be checked for tightness.

IDHC Series

“UL Listed (see complete marking on product)

ANSI/UL Standard 1996 (File E366239)

Safety Warning

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, injury

or death. Read the installation, operating, and

maintenance instructions thoroughly before installing

or servicing this equipment.

Due to continuing research, Greenheck reserves the right to change specifications without notice.

This manual is the property of the owner, and is required for future maintenance. Please leave with the owner

when the job is complete.

Table of Contents

FIG. 2

FLANGE HEATER

WRAPPER

TERMINAL OR

CONTROL BOX

HEATING

ELEMENTS

1"

1"

DOUBLE

LIP

Category Pages

Installation ....................................................................................................................................................................2

Electrical Requirements ...............................................................................................................................................3

Minimum Air Velocities .................................................................................................................................................4

Insulated Duct Installation ...........................................................................................................................................5

Heaters with SSR or Electronic Step Controllers ........................................................................................................6

Troubleshooting Guide ............................................................................................................................................. 6-8

Installation -

Failure to follow instructions will void all warranties.

For safe operation and best performance, the following installation procedures must be adhered to.

Heaters may be installed in the sides of either horizontal or vertical ducts but never in the top or bottom of a

horizontal duct. Heaters installed in vertical ducts are tested and approved for up airflow only!

1. Install heater a minimum of (4) feet from heat

pumps or central air conditioners.

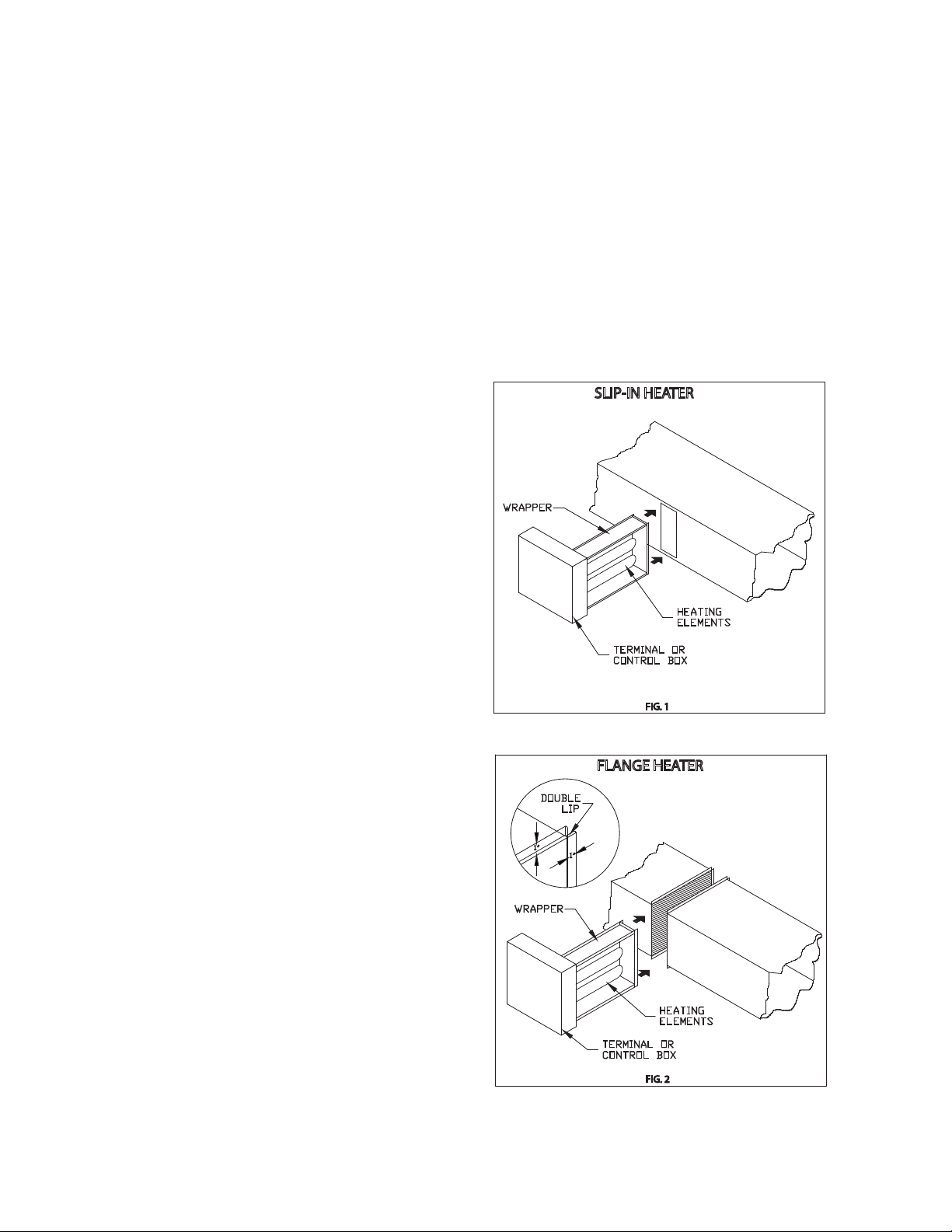

SLIP-IN HEATER

2. At least 4 feet downstream from an air

handler.

3. At least 2 feet either side of an elbow or

turn.

4. At least 4 feet from any canvas duct

connector or transition section for change in

WRAPPER

duct size.

5. At least 4 feet downstream from an air filter.

6. At least 4 feet upstream from a humidifier.

Refer to the back of this sheet for duct, electrical and

air velocity requirements.

To install a slip-in heater (FIG.1), cut an opening as

required in the side of the duct. Slide heater in the

TERMINAL OR

CONTROL BOX

HEATING

ELEMENTS

duct using the control box as template to mark the

mounting screw holes. Remove unit and drill mounting

holes. Mount unit to duct with sheet metal screws.

FIG. 1

Connect high and low voltage supplies along with

fan interlock circuit (if no airflow switch is furnished).

Larger heaters may require hangers.

To install a flange type heater (FIG.2), insert heater

between two sections of flanged duct, and bolt in

DOUBLE

FLANGE HEATER

LIP

place. For additional strength, the duct flange should

be doubled as shown in the figure. Large heaters may

1"

1"

require hanger straps. Connect high and low voltage

supplies along with fan interlock circuit (if no airflow

switch is furnished).

The air duct should be installed in accordance with

the Standards of the National Fire Protection Agency

WRAPPER

for the Installation of Air-Conditioning and Ventilating

Systems (Pamphlet No. 90A) and Warm-Air Heating

and Air-Conditioning Systems (Pamphlet No. 90B).

Do not “bank” heaters (side by side). If greater

capacity is required, proportion smaller heaters in

separate runouts.

Heater control boxes must be completely accessible

TERMINAL OR

CONTROL BOX

HEATING

ELEMENTS

FIG. 2

and located to provide ventilation at all times.

2

WATTS PER SQUARE FOOT, DUCT AREA

Electrical Requirements

Refer to attached wiring diagram and wiring diagram

on inside of cover. Make sure line and control voltage

of system matches that noted on wiring diagram.

Wire in accordance with N.E.C. and any existing

local codes. Check tightness of all factory and field

electrical connections. Make sure fan interlock is

wired in if the Duct Heater does not have an air flow

switch.

Use 90°C (194°F) copper wire.

Control must be wired for N.E.C. Class 1 unless

otherwise specified.

When heater has integral transformer for control

voltage to thermostat, use thermostat with isolating

contacts to prevent interconnection of Class 2

outputs.

Disconnect all electrical power before servicing.

When servicing heater, make sure all components are

repositioned in the proper location and reconnected

per the wiring diagram.

Replacement parts must be identical to the original

components. Contact factory for replacement parts.

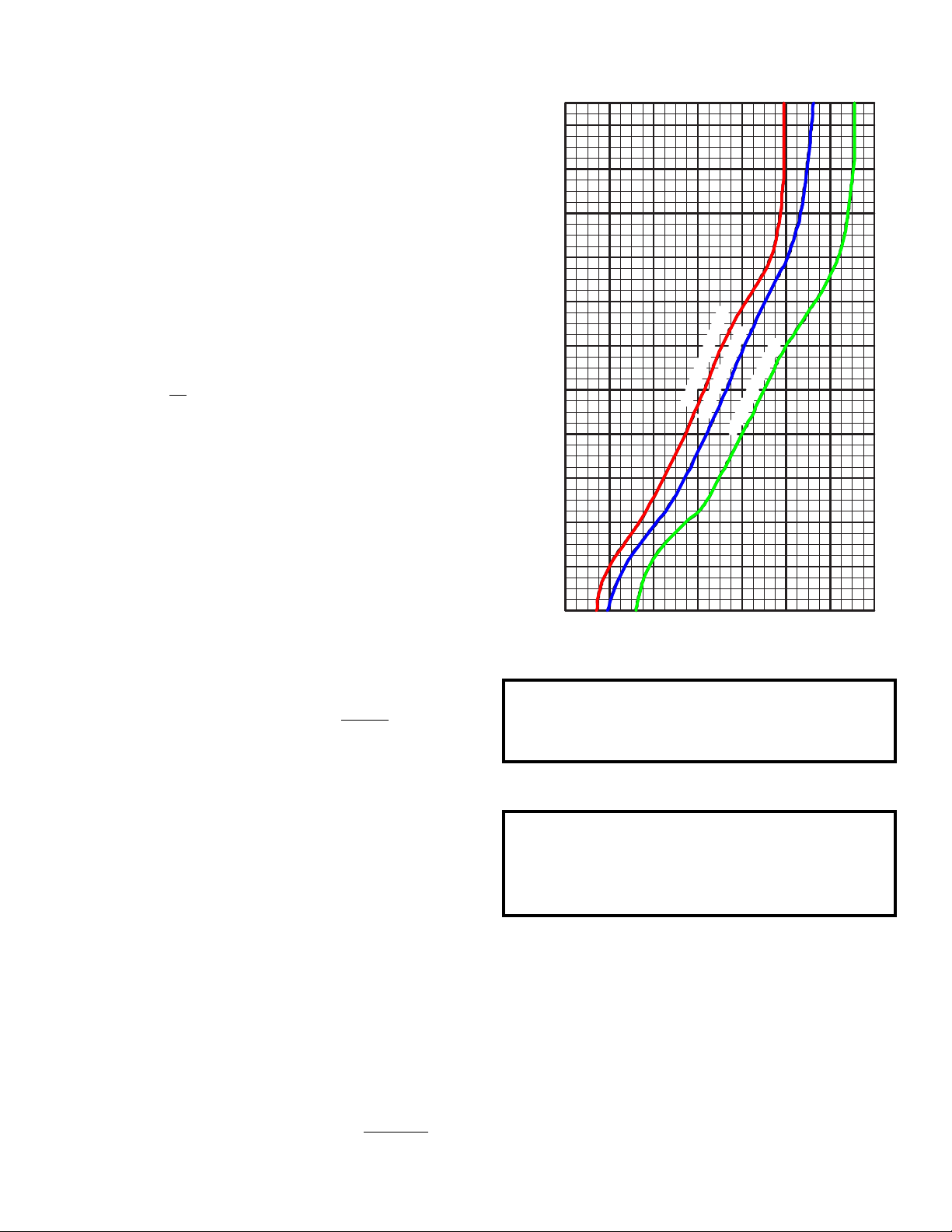

Minimum Air Velocities

The minimum uniform airflow in a duct heater

is directly related to the inlet air temperature.

Consideration must be given to both airflow across

the heater and inlet air temperature, (shown at left).

1. To calculate the watts per sq. ft. of duct

area, divide the total watts required by the

duct area.

EXAMPLE: Duct Size = 2ft. x 3ft.

Total watts = 20,000

W/Sq. Ft. = 20,000 = 3333

6

2. If the air handler equipment is expressed in

F.P.M. then a direct cross reference can be

made by comparing the temperature of the

air (as it enters the Duct Heater) to the KW

rating on the chart of rated velocity.

a. Draw a line horizontally from the Watts/

Sq. Ft. required to the inlet air temperature

being used.

b. From this point of intersection on the Inlet

Air Curve, draw a line down vertically to

establish the air velocity.

c. The velocity should never be lower than

the velocity as determined from the chart.

In cases where this is not true, the velocity

must be increased or the KW required must

be reduced.

3. In cases where the air handling equipment

is expressed in C.F.M., convert to F.P.M. by

dividing the C.F.M. by the duct area.

EXAMPLE: F.P.M. = CFM

Duct Area

Minimum Air Velocities

22,000

20,000

18,000

16,000

14,000

12,000

10,000

8,000

6,000

4,000

2,000

Note: Minimum airflow must be

maintained at any point over the face of

Note: Observe at least one complete

heating cycle to insure that cycling of

the safety limit controls does not occur

before leaving the installation.

BELOW 78°F INLET AIR

78° TO 90°F INLET AIR

91° TO 110°F INLET AIR

Minimum Air Velocity (fpm)

the heater.

1,2001,000800600400200

1,400

3

Loading...

Loading...