Page 1

ICD-44

Thermally Broken Blade

Application and Design

Insulated Control Damper

The ICD-44 is a low leakage thermally insulated damper with extruded

airfoil blades. ICD-44 features thermally broken blade to eliminate the

transfer of heat or cold penetration and reduced condensation. Its also

IECC (International Energy Consumption Code) compliant with a leakage

rating of 3 cfm/ft

2

@ 1 in. wg (55 cmh/m2 @ .25 kPa) or less.

Ratings

Pressure: Up to 8.0 in. wg (2 kPa) pressure

differential

Velocity: 2500 to 4000 fpm (12.7 m/s - 20.3 m/s)

Leakage: 3 cfm/ft2@ 1 in. wg at -40°F

(54.8 cmh/m

6 cfm/ft2 @ 4 in. wg at -40°F

(110 cmh/m

Temperature: -70°F to 200°F (-56°C to 93°C)

Standard Construction Optional Construction

Frame Material Aluminum -

Frame Material

.125 in. (3.2mm) -

Thickness

Frame Type 5 in. x 1 in.

(127mm x 25mm)

Hat Channel

Blade Action Opposed Parallel

Blade Material Extruded Aluminum -

Blade Type Thermally Broken Airfoil -

Linkage Plated Steel Out of

Airstream

Axle Bearings Dual Bearing With Acetal

Inner Sleeve, Flanged

Outer Bearing

Axle Material Plated Steel 304SS

Blade Seals Silicone -

Jamb Seals 304SS Silicone

2

@ .25 kPa at -40°C)

2

@ 1 kPa at -40°C)

Single Flange

Reverse Flange or

Quick Connect

304SS

-

1/2 in.

(13mm)

1/2 in.

(13mm)

1/2 in.

(13mm)

1/2 in.

(13mm)

Size Limitations

in. (mm)

W x H

Blade Action Parallel Opposed Parallel Opposed Parallel Opposed

Internal

Minimum

Sizes

Maximum

Sizes

Installation instructions available at www.greeenheck.com

Mount

External

Mount

Single

Section

Multi-

Section

Channel Quick Connect Single or Reverse Flange

12 x 7

(305 x 178)

8 x 7

(203 x 178)

144 in. W x 148 in. H

(3658mm x 3759mm)

12 x 12

(305 x 305)

8 x 12

(203 x 305)

Frame Type

12 x 6

(305 x 152)

8 x 6

(203 x 152)

(1219mm x 1880mm)

96 in. W x 148 in. H

(2438mm x 3759mm)

(305 x 254)

(203 x 254)

48 in. W x 74 in. H

12 x 10

8 x 10

12 x 7

(305 x 178)

8 x 7

(203 x 178)

144 in. W x 148 in. H

(3658mm x 3759mm)

12 x 12

(305 x 305)

8 x 12

(203 x 305

Thermal

Isolation

Break

5 in.

(127mm)

Parallel

Blade

5 in.

(127mm)

Opposed

Thermal

Isolation

Break

Page 2

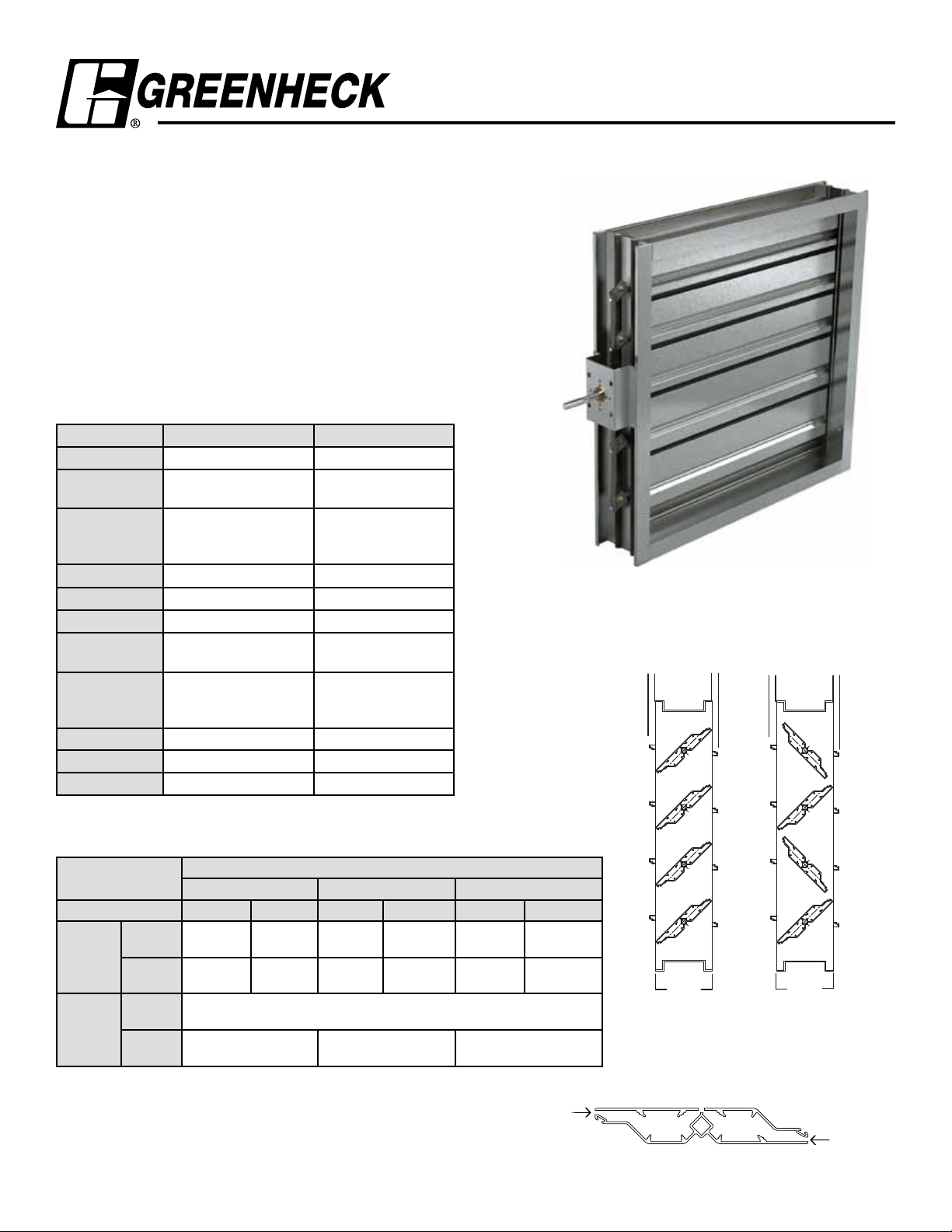

Frame Type Options ICD-44

Channel Frame

Reverse Flange

Opening

Width

Opening

Height

* Width and height is based on outside

dimension. W & H dimensions furnished

approximately 1/4 in. (6mm) undersize.

* Width and height is based on outside

dimension. W & H dimensions furnished

approximately 1/4 in. (6mm) undersize.

Single Flange

* Width and height is based on outside

dimension. W & H dimensions furnished

approximately 1/4 in. (6mm) undersize.

Page 3

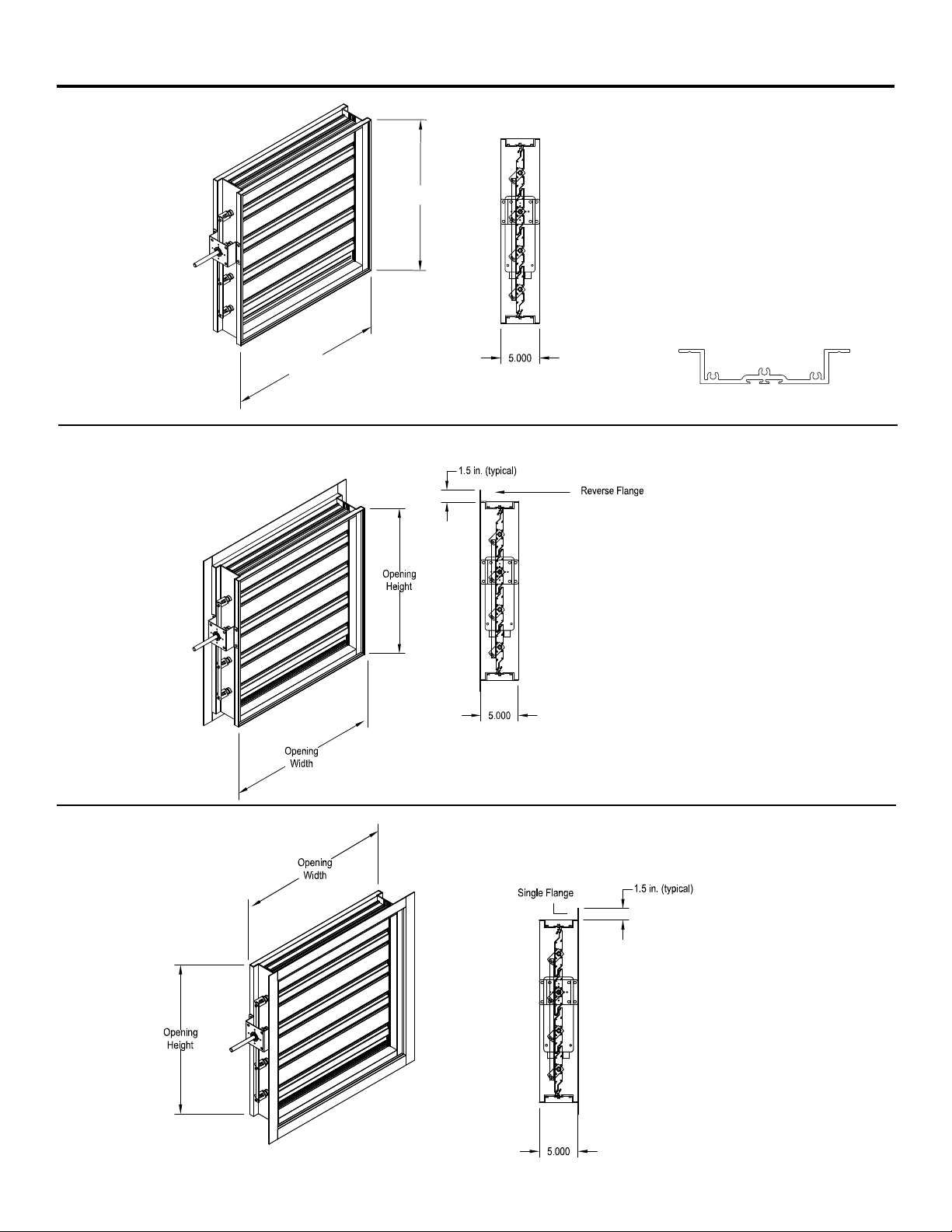

Frame Type Options ICD-44

Quick Connect

1 3/8 in.

Ductmate,

TDC or TDF

Duct

Cleat

Quick

Connect

Frame

Note: When ordering the Quick Connect Frame, size is based on

duct size (or inside dimension of the damper frame). Quick Connect

frame is actual size.

There are applications that require mounting an ICD-44 into a

plenum wall. This illustration depicts how to mount an ICD-44 into a

plenum wall.

1 3/8 in.

Page 4

Pressure Drop Data ICD-44

5D 6D

5D

D

4 (W) (H

)

3.14

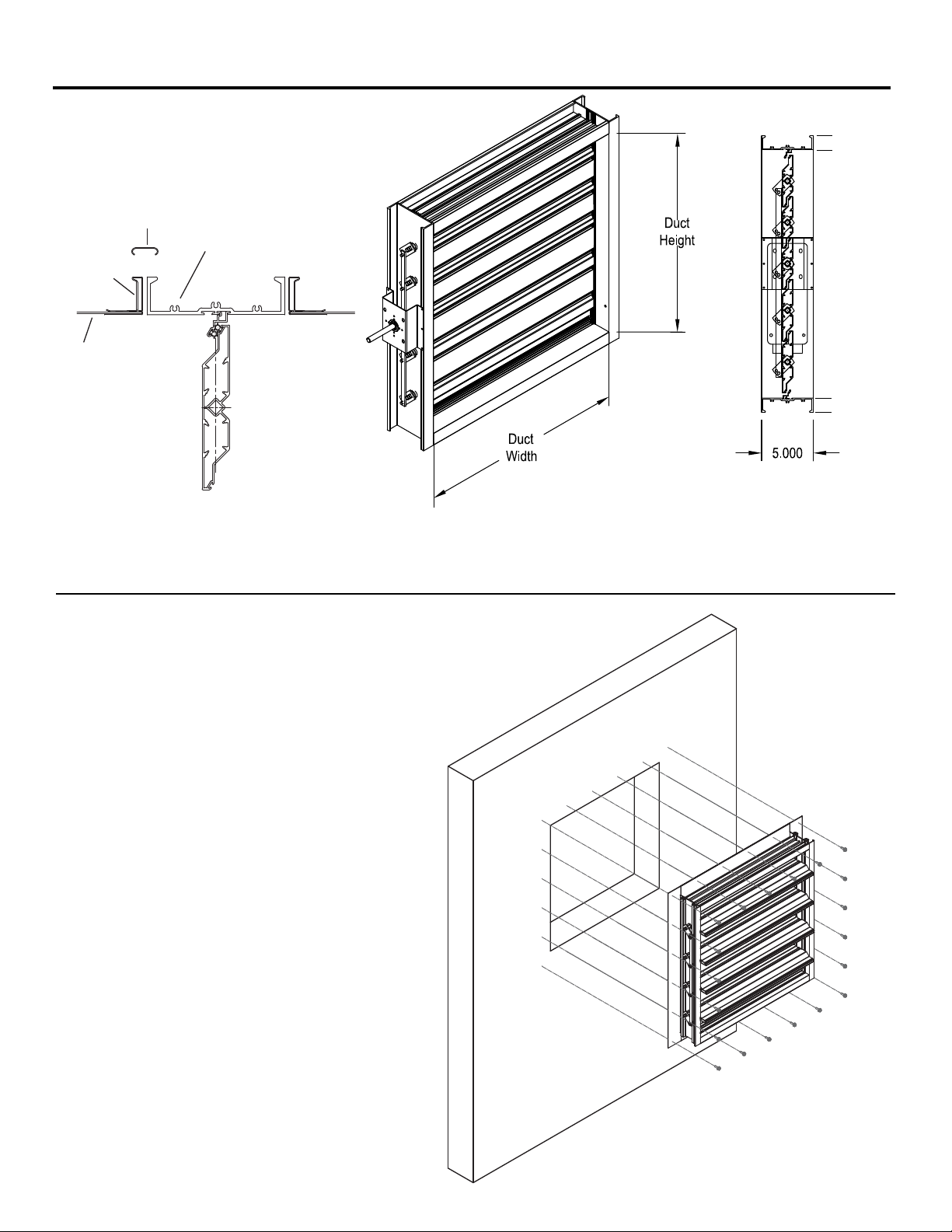

This pressure drop testing was conducted in accordance with AMCA Standard 500-D using the three configurations shown. All

data has been corrected to represent standard air at a density of .075 lb/ft3 (1.201 kg/m3).

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with an

analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given HVAC

system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This configuration has the lowest pressure drop of the three test configurations

because entrance and exit losses are minimized by straight duct runs upstream and downstream of the damper.

Figure 5.2 Illustrates a ducted damper exhausting air into an open area. This configuration has a lower pressure drop than

Figure 5.5 because entrance losses are minimized by a straight duct run upstream of the damper.

Figure 5.5 Illustrates a plenum mounted damper. This configuration has the highest pressure drop because of extremely high

entrance and exit losses due to the sudden changes of area in the system.

Page 5

AMCA 5.2 Pressure Drop ICD-44

5D 6D

D

D

=

4 (W) (H)

3.14

Figure 5.3

5D

12 x 12

12 x 12 (305mm x 305mm)

Velocity

(fpm)

500 .03

1000 .11

1500 .25

2000 .45

2500 .71

3000 1.03

3500 1.40

4000 1.83

Pressure

Drop

(in. wg)

24 x 24 (610mm x 610mm)

Velocity

(fpm)

500 .02

1000 .08

1500 .19

2000 .34

2500 .53

3000 .77

3500 1.05

4000 1.37

Pressure

Drop

(in. wg)

36 x 36 (914mm x 914mm)

Velocity

(fpm)

500 .01

1000 .05

1500 .11

2000 .21

2500 .33

3000 .47

3500 .64

4000 .84

Pressure

Drop

(in. wg)

48 x 12

36 x 36

12 x 48

24 x 24

12 x 48 (305mm x 1219mm)

Velocity

(fpm)

500 .01

1000 .06

1500 .14

2000 .25

2500 .40

3000 .57

3500 .78

4000 1.02

Pressure

Drop

(in. wg)

48 x 12 (1219mm x 305mm)

Velocity

(fpm)

500 .03

1000 .14

1500 .32

2000 .57

2500 .89

3000 1.29

3500 1.76

4000 2.30

Pressure

Drop

(in. wg)

Page 6

AMCA 5.3 Pressure Drop ICD-44

5D

6D

12 x 12 (305mm x 305mm)

Velocity

(fpm)

500 .01

1000 .04

1500 .09

2000 .17

2500 .26

3000 .38

3500 .52

4000 .67

Pressure

Drop

(in. wg)

24 x 24 (610mm x 610mm)

Velocity

(fpm)

500 .01

1000 .03

1500 .08

2000 .14

2500 .22

3000 .32

3500 .43

4000 .57

Pressure

Drop

(in. wg)

36 x 36 (914mm x 914mm)

Velocity

(fpm)

500 .01

1000 .02

1500 .04

2000 .08

2500 .12

3000 .18

3500 .24

4000 .32

Pressure

Drop

(in. wg)

48 x 12

12 x 48 (305mm x 1219mm)

Velocity

(fpm)

1000 .02

1500 .06

2000 .10

2500 .17

3000 .24

3500 .33

4000 .43

12 x 48

12 x 12

24 x 24

36 x 36

Pressure

Drop

(in. wg)

500 .01

48 x 12 (1219mm x 305mm)

Velocity

(fpm)

500 .01

1000 .06

1500 .14

2000 .25

2500 .40

3000 .58

3500 .79

4000 1.03

Pressure

Drop

(in. wg)

Page 7

AMCA 5.5 Pressure Drop ICD-44

5D 6D

5D

D

4 (W) (H)

3.14

24 x 24

12 x 48

12 x 12

36 x 36

12 x 12 (305mm x 305mm)

Velocity

(fpm)

500 .05

1000 .23

1500 .52

2000 .93

2500 1.44

3000 2.08

3500 2.83

4000 3.70

Pressure

Drop

(in. wg)

48 x 12

24 x 24 (610mm x 610mm)

Velocity

(fpm)

500 .05

1000 .21

1500 .47

2000 .84

2500 1.32

3000 1.90

3500 2.59

4000 3.39

Pressure

Drop

(in. wg)

36 x 36 (914mm x 914mm)

Velocity

(fpm)

500 .03

1000 .14

1500 .33

2000 .58

2500 .91

3000 1.31

3500 1.79

4000 2.34

Pressure

Drop

(in. wg)

12 x 48 (305mm x 1219mm)

Velocity

(fpm)

500 .04

1000 .18

1500 .42

2000 .74

2500 1.16

3000 1.68

3500 2.28

4000 2.98

Pressure

Drop

(in. wg)

48 x 12 (1219mm x 305mm)

Velocity

(fpm)

500 .05

1000 .22

1500 .51

2000 .90

2500 1.41

3000 2.04

3500 2.78

4000 3.70

Pressure

Drop

(in. wg)

Page 8

Leakage & Specifications ICD-44

Leakage Data

Leakage testing was conducted in accordance with AMCA Standard 500-D and is expressed as CFM/sq. ft. of damper face area.

All data has been corrected to represent standard air at a density of .075 lb/ft3 (1.2 kg/m3).

Leakage

36 X 36

24 X 24

12 X 12

48 X 12

12 X 48

Static Pressure Difference (inches wg)

Specifications

Control Dampers meeting the following specifications shall be

furnished and installed where shown on plans and/or as described in

schedules.

Dampers shall consist of: .125 (3.2mm) aluminum channel frame;

aluminum airfoil blade internally insulated polyurethane foam and

thermally broken. Blades shall be completely symmetrical relative

to their axle pivot point, presenting identical resistance to airflow in

either direction or pressure on either side of the damper. Axle will be

1

⁄2 in. (13mm) diameter plated steel; bearings are dual bearing with

acetal inner sleeve, flanged outer bearing resulting in no metal-tometal or metal-to-plastic contact. Blade seal to be silicone rubber,

jamb seal to be 304SS, and external (out of the airstream) blade-toblade linkage.

Dampers manufacturer’s printed application and performance data

including pressure, velocity, leakage, and temperature limitations

shall be submitted for approval showing damper suitable for

pressures to 8 in. wg (2 kPa), velocities to 4000 fpm (20.3 m/s),

standard air leakage less than 6 cfm/sq. ft. @ 4 in. wg

(110 cmh/m

air performance data shall be developed in accordance with the

latest edition of AMCA Standard 500-D.

Basis of design is ICD-44.

2

@ 1 kPa) and temperatures to 200 °F (93°C). Damper

Copyright ©2010 Greenheck Fan Corporation

ICD-44 Rev. 5 August 2010

Loading...

Loading...