Page 1

Application and Design

Model HTD-636 is a heavy duty flanged frame style

industrial control damper qualified for use in tunnel and

transit systems. The airfoil blades, mechanically fastened

silicone blade seals and stainless steel jamb seals meet

the demanding requirements for strength, leakage, and

operability to standards such as NFPA-130, 502, and

UL555S.

HTD-636 has been tested in accordance with BS476 to

4 hours at Warrington Fire, UK, and is approved for fire

partitions of 4 hours or less where British Standards are

required.

Standard Construction

Frame Depth 12 in. (305mm)

Flange Width 2 in. (51mm)

Frame Material Galvanized (ASTM A653)

Frame Material Thickness 12 ga. (2.7mm)

Blade Type Fire rated double skin airfoil

Blade Material Galvanized (ASTM A653)

Blade Skin Thickness 16 ga. (1.5mm)

Axle Type Stub

Axle Diameter 0.75 in. (19mm)

Axle Material Zinc plated steel

Bearing Stainless steel sleeve

Linkage External industrial type, zinc plated steel

Blade Action Parallel

Axle Seal None

Blade Seal Mechanically fastened silicone

Jamb Seal Compression type, stainless steel

Blade Deflection L/180

HTD-636

Steel Airfoil Blades

Tunnel Transit Damper

Ratings

Fire: BS476, Four hours

Pressure: 24 in. wg (6 kPa)

Velocity: 4000 fpm (20.3 m/s)

Temperature: 482°F (250°C) for 2 hours (NFPA 130, 502)

Fatigue Cycles: 8 million reverse cycles at 24 in. wg

(6 kPa)

H*

W* **

Size Limitations

The following table provides minimum and maximum

single section size. Multiplie sections can be linked

together to create larger damper assemblies.

Single Section Size

Minimum 12 in. W x 12 in. H

(305mm x 305mm)

Maximum 48 in. W x 96 in. H

(1219mm x 2438mm)

Installation instructions available at www.greenheck.com.

* Actual Inside Dimension

** The W dimension is ALWAYS parallel with the damper blade

length.

Options

• Wide range of electric and pneumatic actuators available

• Limit Switches

• Multiple panel assemblies

• Mounting holes in anges

• Other materials and frame congurations are available.

Consult factory with your specic requirements.

• Blade deection - L/360

Page 2

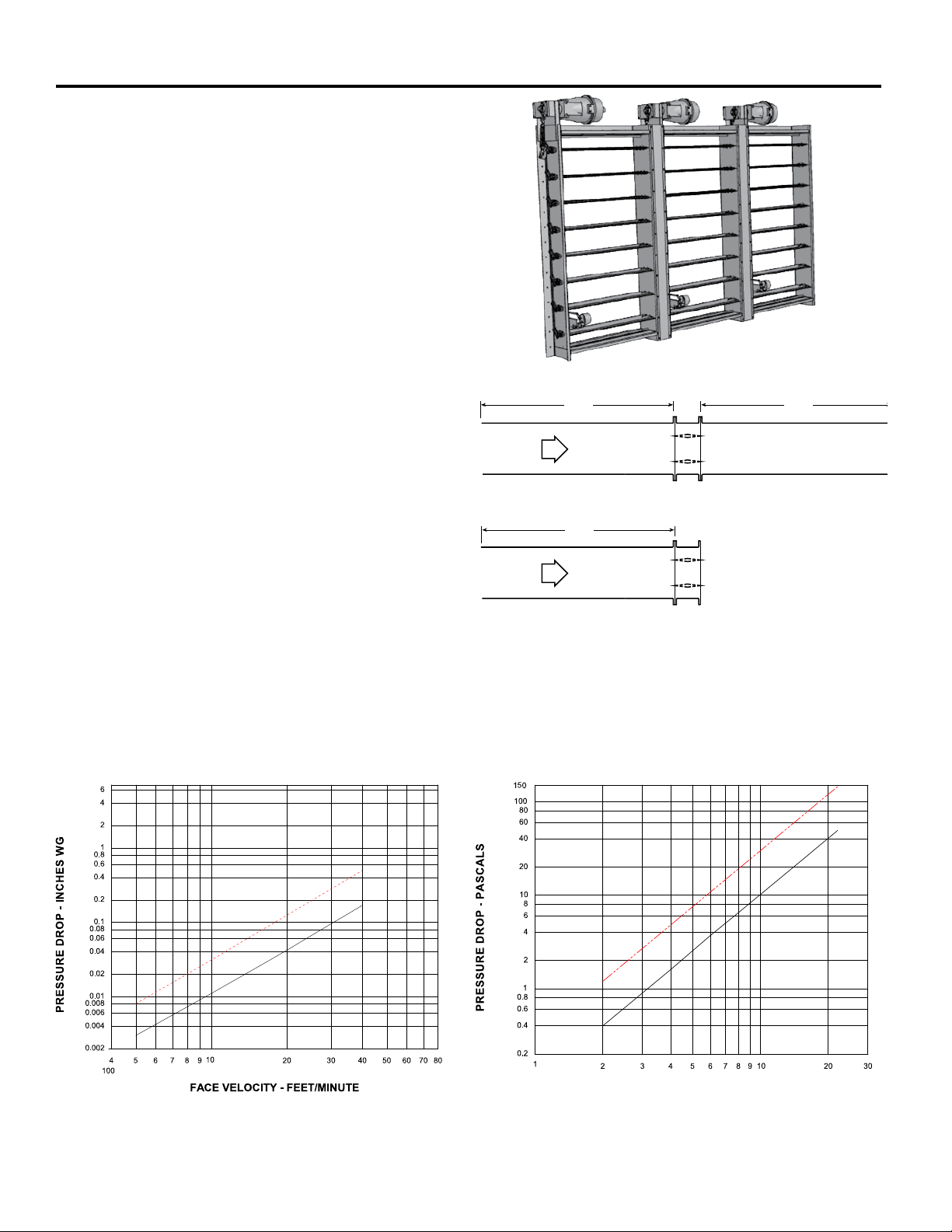

Multiple Panel Assemblies

Multiple panels can be stacked on top of each other and sideby-side to span opening that are larger than the maximum single

panel damper. Jackshafting can be added to couple multiple

panels, allowing them to be operated using a single actuator.

Consult the factory for design assistance for multiple panel

assemblies.

Pressure Drop Data

This pressure drop data was conducted in accordance with

AMCA Standard 500-D using the two configurations shown. All

data has been corrected to represent standard air at a density of

.075 lb./ft

Actual pressure drop found in any HVAC system is a combination

of many factors. This pressure drop information along with an

analysis of other system influences should be used to estimate

actual pressure losses for a damper installed in a given HVAC

system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This configuration

has the lowest pressure drop of the two test configurations

because entrance and exit losses are minimized by straight duct

runs upstream and downstream of the damper.

Figure 5.2 Illustrates a ducted damper exhausting air into an

open area.

3

(1.2 kg/m3).

HTD-636ASSEMBLIES & PERFORMANCE DATA

4D 6D

Fig. 5.3

4D

Fig. 5.2

Pressure Drop (english version)

42 in. x 42 in. (1067mm x 1067mm) Damper

AMCA 5.2

AMCA 5.3

x

Figure 5.2: Log (P) = 2*Log (V) - 7.507618

Figure 5.3: Log (P) = 2*Log (V) - 7.977296

Pressure Drop (metric version)

42 in. x 42 in. (1067mm x 1067mm) Damper

AMCA 5.2

AMCA 5.3

FACE VELOCITY - METERS/SECOND

Figure 5.2: Log (P) = 2*Log (V) - .522991

Figure 5.3: Log (P) = 2*Log (V) - .992669

Page 3

HTD-636LEAKAGE & SPECIFICATIONS

Leakage Data

Damper leakage (with blades fully closed) varies based on the type of low leakage seals applied. Leakage testing was

conducted in accordance with AMCA Standard 500-D and is expressed as CFM per sq. ft. of damper face area. All data has

been corrected to represent standard air at a density of .075 lb./ft

3

(1.2 kg/m3).

42 in. x 42 in. (1067mm x 1067mm) Damper

Leakage (english version)

Log (leakage) = 0.5 * (log (pressure) + 1.20412)

42 in. x 42 in. (1067mm x 1067mm) Damper

Leakage (metric version)

Log (leakage) = 0.5 * (log (pressure) + 4.332098)

Specifications

Industrial grade control dampers meeting the following

specifications shall be furnished and installed where shown

on plans and/or as described in schedules.

Dampers shall consist of: a 12 ga. (2.7mm) galvanized steel

channel frame with 12 in. (305mm) maximum depth and 2 in.

(51mm) flanges; double skin airfoil type blades fabricated

from two layers of 16 ga. (1.5mm) galvanized steel;

(19mm) dia. plated steel axles turning in oil impregnated

sintered stainless steel bearings press-fit into frame; and

external (out of the airstream) blade-to-blade linkage. Blade

seals shall be mechanically fastened silicone rubber and

jamb seals shall be flexible stainless steel.

3

⁄4 in.

Damper manufacturer's printed application and performance

data including pressure, velocity and temperature limitations

shall be submitted for approval showing damper suitable for

pressures to 24 in. wg (6 kPa), velocities to 4000 fpm

(20.3 m/s) and temperatures to 482°F (250°C). Testing and

ratings to be in accordance with AMCA Standard 500-D.

Dampers shall be tested in accordance with BS476 to 2 hours

and approved for fire partitions of 2 hours or less where

British Standards are required.

Basis of design is Greenheck model HTD-636.

Copyright © 2011 Greenheck Fan Corporation

HTD-636 Rev.1 February 2011

Loading...

Loading...