Greenheck Hooded Roof Propeller Fans User Manual

Hooded Roof Propeller Fans

Belt and Direct Drive

Exhaust, Supply and Reversible

October

2020

Hooded Roof Propeller Fans

Exhaust Supply/Reversible

Belt and Direct Drive

Table of Contents

Model Comparison ....................... 3

Standard Construction Features ...........4-5

Options and Accessories .................6-7

High Wind & Hurricane ................ 7

Seismic ............................. 7

Vari-Green® Options ...................... 8

Reversible Models ....................... 9

Dimensional Data ....................... 10

From general ventilation of factories and warehouses

to industrial duty, the range of construction and

performance capabilities offered in this catalog

represent the most comprehensive hooded propeller

roof fan line available.

Material Data .......................... 11

Model Number Code ................. 11, 18

Direct Drive ........................11

Belt Drive .......................... 18

Performance Pages ...................12-49

Typical Specifications .................50-51

Basics of Fan Selection .................. 52

Regardless of fan size, performance or duty level, all

Greenheck hooded propeller roof fans are built

to perform with the same high standards of reliability

and durability.

Exhaust, supply and reversible models are

available in belt or direct drive. Filtered supply is also

available. Propellers are available in fabricated steel,

fabricated aluminum or cast aluminum. Drive frames

and panels are constructed to match the level of duty

and the motor size.

Greenheck offers a complete line of accessories,

which include protective guards, tall bases, dampers,

disconnect switches and special coatings.

Greenheck Fan Corporation certifies that the RE2,

RCE3, RS2, RCS3, RBE, RBCE, RBS, RBCS, RBF

and RBCF models shown herein are licensed to

bear the AMCA Seal. The ratings shown are based

on tests and procedures performed in accordance

with AMCA Publication 211 and AMCA Publication

311 and comply with the requirements of the AMCA

Certified Ratings Program.

Hooded Propeller Roof Fan models

File no. E40001

*UL is optional and must be specified

are listed for electrical (UL/cUL 705)

Performance as cataloged is assured.

Enjoy Greenheck’s extraordinary service, before, during and after the sale.

Greenheck offers added value to our wide selection of top performing, energy-efficient products by providing

several unique service programs.

Our Quick Delivery program ensures shipment of in-stock products within 24 hours of

placing your order. Our Quick Build made-to-order products are manufactured in

1-3-5-10-15 or 25-day production cycles, depending upon its complexity.

Greenheck’s free computer aided product selection program CAPS®, rated by many as the

best in the industry, helps you conveniently and efficiently select the right products for the

challenge at hand.

Our 3D service allows you to download, at no charge, easy-to-use AutoDesk® Revit®

3D drawings for many of our ventilation products.

Find out more about these special services at greenheck.com

2

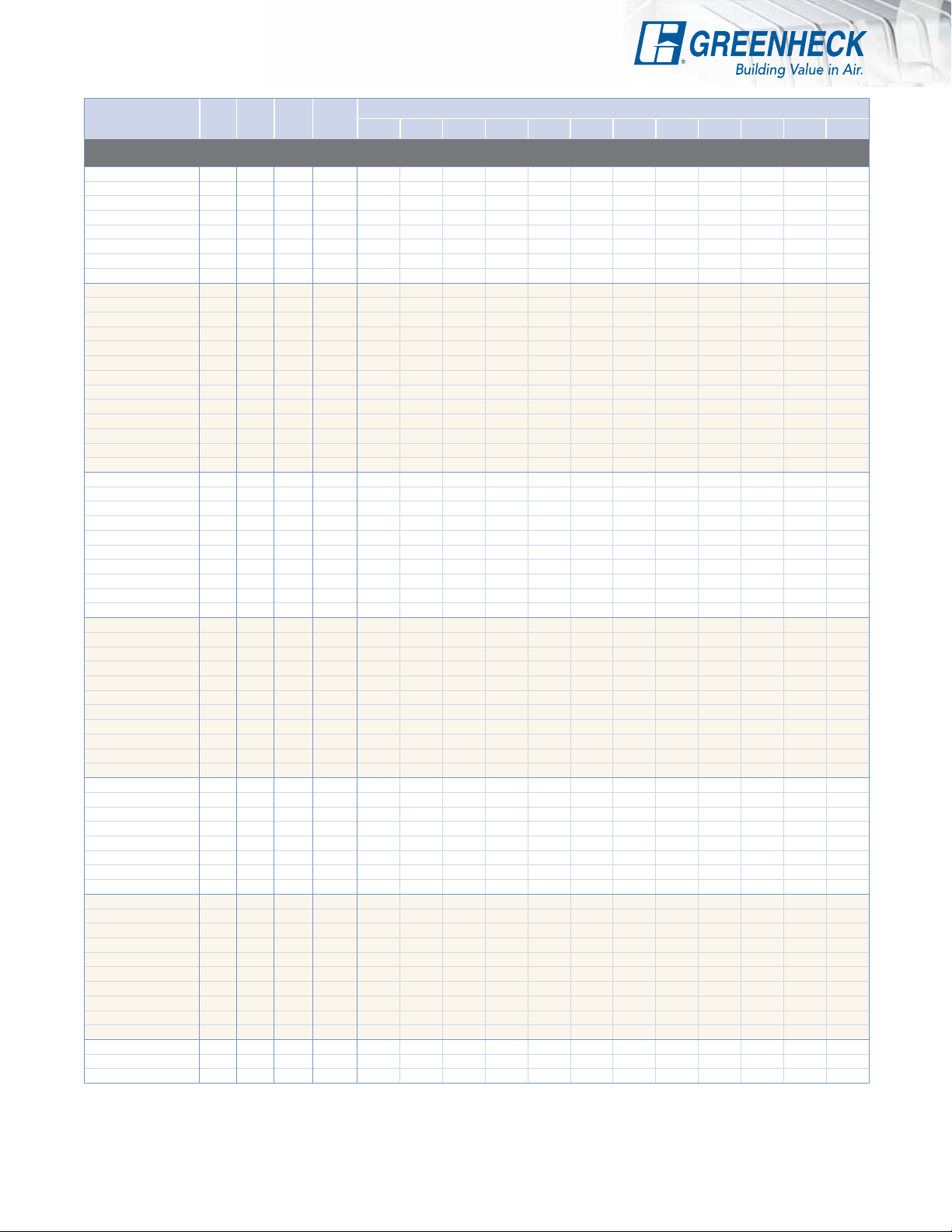

Model Comparison

Exhaust Supply/Reversible

Belt and Direct Drive

Direct Drive Fan Selection

Two propeller and drive frame combinations are available. These models are designed and constructed for

applications with static pressure ranges up to 1 in. wg. Models RE2 and RS2 are available with welded and die

formed steel blades, while models RCE3 and RCS3 offer a cast aluminum propeller. For low sound applications,

it is best to select the largest fan with the lowest RPM to meet the performance requirements. This ensures the

tip speeds will be as low as possible.

Construction

Levels

Fully welded steel

or die formed

steel blades

Level 2

Cast aluminum

airfoil blades

Level 3

*Reversible performance is equivalent in the exhaust and supply mode.

Models - Performance Pages

Exhaust Supply Filtered Reversible

RE2

pg 12

RCE3

pg 13

RS2

pg 14

RCS3

pg 15

— —

*RPDRF

*RPDR

pg 16-17

Size Range

Wheel Diameter

18 to 54 in.

(457 to 1372 mm)

20 to 54 in.

(508 to 1372 mm)

Performance Propellers

Up to 44,000 cfm

(74,756 m

up to 1 in. wg (249 Pa)

Up to 46,000 cfm

(78,155 m

up to 1 in. wg (249 Pa)

3

/hr) and

3

/hr) and

Level 2

Level 3

Belt Drive Fan Selection

Application requirements for sound and static pressure determine propeller type. Propellers are available in

fabricated steel, fabricated aluminum or cast aluminum.

Construction

Levels

Galvanized steel

blades riveted to

the hub

Level 1Level 1

Dual thickness

galvanized steel

blades riveted to

Level 2Level 2

the hub

Fabricated, fully

welded and

gusseted steel

Level 3Level 3

blades

Models - Performance Pages

Exhaust Supply Filtered Reversible

RBE

pg 19-25

RBE

pg 19-25

RBE

pg 19-25

RBS

pg 28-34

RBS

pg 28-34

RBS

pg 28-34

RBF

pg 37-43

RBF

pg 37-43

RBF

pg 37-43

—

—

—

Size Range

Wheel Diameter

20 to 54 in.

(508 to 1372 mm)

20 to 60 in.

(508 to 1524 mm)

24 to 72 in.

(610 to 1829 mm)

Performance Propellers

Up to 30,000 cfm

(50,970 m

up to 5/8 in. wg (156 Pa)

Up to 53,000 cfm

(90,048 m

up to 3/4 in. wg (19 Pa)

Up to 87,000 cfm

(149,513 m

up to 1 in. wg (249 Pa)

3

/hr) and

3

/hr) and

3

/hr) and

Level 1

Level 2

Level 3

Cast aluminum

airfoil blades

Level 3Level 3

RBCE

pg 26-27

RBCS

pg 35-36

RBCF

pg 44-45

*RPBRF

*RPBR

pg 46-49

Belt Drive Blade Designs

L Propeller: Swept, steeply pitched

blade design. These propellers

typically run at lower RPMs and

generate low sound levels making

them the best selection for sound

critical applications or applications

requiring the best combination of

both air and sound performance. Typically used when

the static pressure is 0.5 in. wg (13 mm) or less.

24 to 72 in.

(610 to 1829 mm)

Up to 87,000 cfm

(149,513 m

up to 1 in. wg (249 Pa)

3

/hr) and

Level 3 - Cast

H Propeller: Straight, moderately

pitched blade. It is designed for

applications where static pressures

are above 0.5 in. wg (13 mm). These

propellers typically run at higher RPMs

and generate slightly higher sound

levels than the “L” propellers.

3

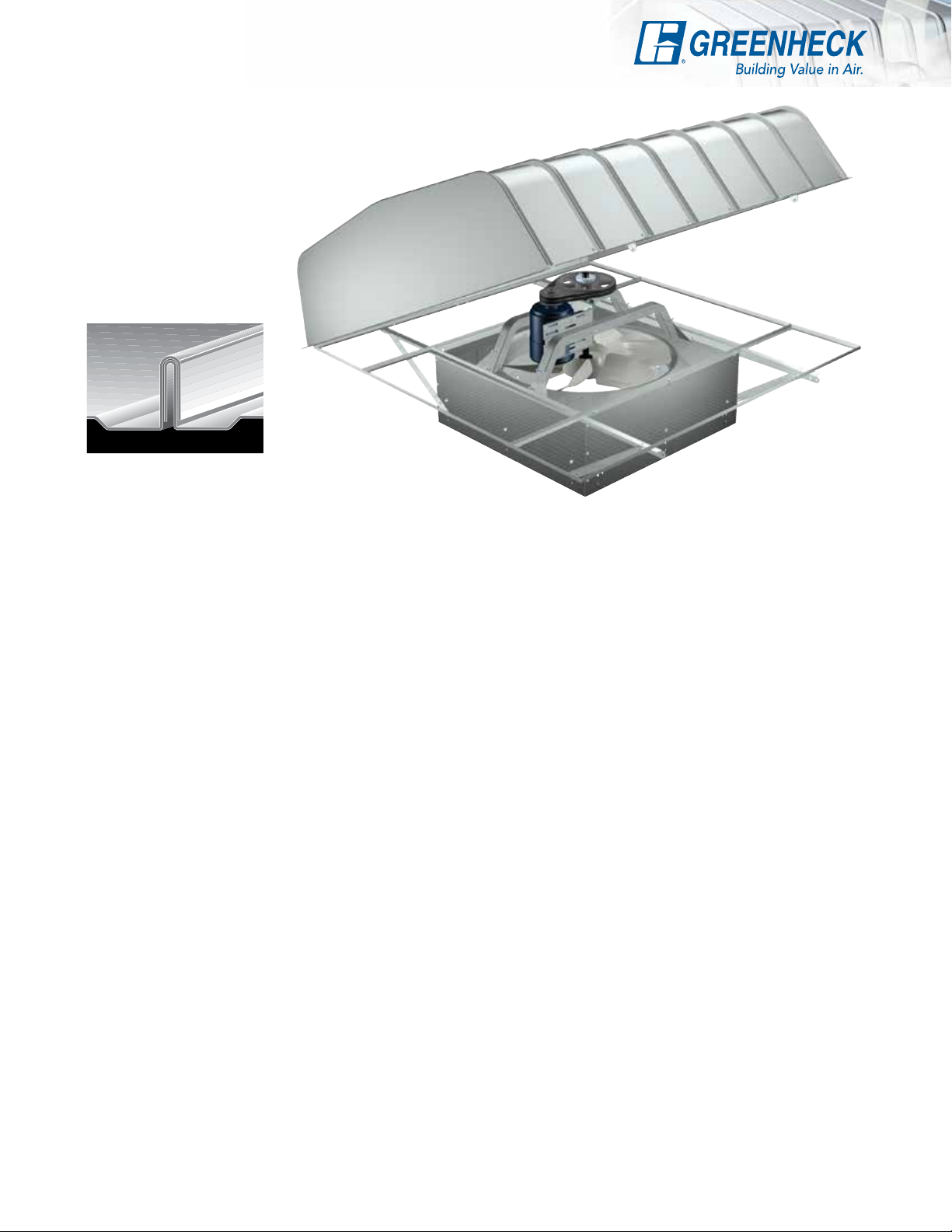

Standard Construction

Features

Superior

Hood Design

Greenheck’s interlocking rib design combines four material thicknesses with I-beam design principles producing

a hood far superior in strength to conventional designs (an important feature in high snow or wind load regions).

Formed channels adjacent to the ribs provide water drainage to ensure weather tightness.

Hoods are available in galvanized steel, painted steel, or aluminum construction. Hood support angles are

heavy-gauge galvanized steel. Hood panels and supporting frame members are shipped loose to the field.

Construction Features

• Fan hoods and bases are constructed of

galvanized, aluminum, steel, or painted steel as

specified. Hood panels are arched and precision

roll-formed for strength and weather tightness.

Hoods are field bolted to heavy-gauge support

angles. Bases include prepunched mounting holes.

• Propellers are constructed with fabricated steel,

fabricated aluminum or cast aluminum blades and

hubs. All propellers are statically and dynamically

balanced. Reversing fan propellers are designed

to produce a high level of efficiency over a broad

selection range. Tapered airfoil blades are cast of

aluminum alloy. The reversible propeller is designed

to move air in both the exhaust or supply modes.

• Permanently lubricated, sealed ball bearing pillow

block bearings are 100% factory tested and are

designed specifically for air handling applications

with a minimum (L10) life in excess of 100,000 hours

(L50 average life of 500,000 hours) at maximum

cataloged operating speeds.

• Fan shafts are precisely ground and polished

steel sized so the first critical speed is at least

25% over the maximum operating speed. Close

tolerances where the shaft makes contact with the

bearing result in longer bearing life.

• Heavy-duty ball bearing motors are carefully

matched to the fan load.

• Drives shall be sized for a minimum of 150% of

driven horsepower. Pulleys shall be fully machined

cast iron, keyed and securely attached to propeller

and motor shafts. Motor sheaves shall be

adjustable for final system balancing. Belts are

static-free and oil resistant.

• Drive frames (belt drive fans) or motor support

frames (direct drive fans) and panel assemblies are

constructed of heavy-gauge steel.

• Fan panels are constructed of heavy-gauge steel

with a deep-formed inlet venturi. Reversible fans

are constructed of heavy-gauge steel with a double

venturi for efficient airflow.

4

Standard Construction

Features

Access and Service

Periodic maintenance requires accessibility to fan

components such as motors, belts, pulleys and

propellers located under the hood. Greenheck’s

hooded roof propeller fan design incorporates many

service-friendly features which reduce maintenance

time and promotes proper servicing.

These features include:

• Hinged Hood - Sizes 36 and smaller can be

hinged by removing two of the four hood fasteners.

The hood may then be laid over on the roof deck

while servicing.

• Removable Hood - Sizes 36 and larger allow for

complete removal of the hood by removing the four

hood fasteners.

• Removable Birdscreens - Inspection of fan

components is quick and easy by removing the

quick-release

birdscreen sections

on either end of the

unit while leaving

the hood in place.

Birdscreens are

constructed of 1/2

inch galvanized

steel mesh. Filters

are optional. Access for sizes 42 and larger is from

underneath the hood by removing the birdscreen

or filters.

Easy Field Assembly of Hoods

Fans ship in kitted sections—assembled fan module,

hoods and supporting structural components – for

easy assembly. Hood assembly requires no special

tools or training. Each fan comes with complete

illustrated assembly and installation instructions.

Reversible Fans

Ventilation requirements are often subject to daily

or seasonal changes in temperature. Greenheck’s

reversible fans (models RPDR, RPBR, RPDRF, and

RPBRF) are designed for non-ducted systems or

those with short duct runs and offers the ability to

either exhaust or supply air on demand to maintain

comfortable working conditions. By exhausting

excess heat or supplying fresh outside air, the

reversing fan saves cooling costs. Fewer fans

required on the job means lower initial costs and

lower installation costs with fewer roof penetrations.

Filtered Supply

Filtered supply

fans (models RBF,

RBCF, RPDRF, and

RPBRF) with a 2-inch

aluminum mesh,

washable filters

are available for

applications where

contaminants must be removed from supply air.

Basic hood and fan construction is similar to the

non-filtered models.

Filter removal for cleaning or replacement can be

easily done by opening the hood and sliding the filters

out of the open end racks. In fan sizes 36 and larger,

access panels on either end of the hood are provided

to allow filter removal without raising the hood.

One Fan — Two Functions

EXHAUST SUPPLY

Evacuates excess

heat to reduce

cooling costs.

Outside air can

be supplied when

temperatures are

cooler (as at night) to

reduce cooling costs.

5

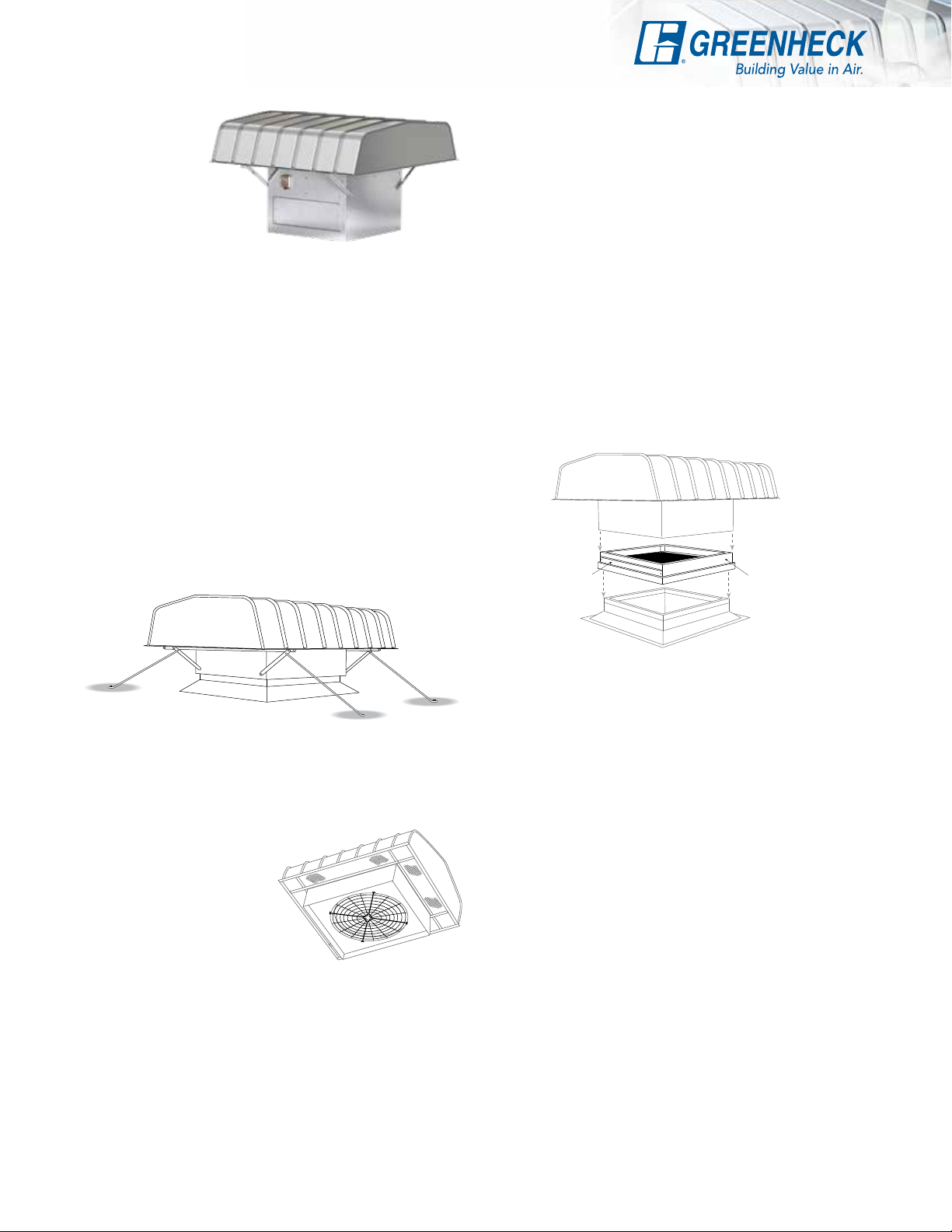

Options and Accessories

Tall Base –

Tall bases are

recommended

for installations

that include a

gravity damper

or a motorized

damper and

greatly simplifies installation and servicing. The

damper components are factory assembled as part

of the tall base and shipped as a single unit reducing

field assembly time and costs. Inspection, service

and cleaning of the damper, actuator and linkages are

made easy with an access door including two cam

latches with plated steel handles and a slide-out rack.

Tall bases provide the necessary minimum spacing

between the propeller and the damper. The tall base

increases the standard height to provide additional

weather tightness from rain and snow intake due to

the elevated hood. There is ample space within the tall

base for ease of initial electrical wiring.

Tie Down Feature – In locations where strong winds

may occur, cable tie-downs are recommended to

secure fans to the roof structure to prevent damage to

the hood. Cables are by others.

Roof Curbs – Prefabricated roof curbs are available

to reduce installation time and costs by ensuring

compatibility between the fan, the curb and the roof

opening. All curbs are available in steel or aluminum

construction and are lined with fiberglass insulation to

prevent condensation and reduce sound levels. See

Greenheck’s roof curb catalog for complete details.

Curb Cap Stripping – Rubber curb cap stripping

attached to the underside of the curb cap is available

to provide a seal between the fan and the roof curb.

Insect Screen Base – Insect screen bases are

available for applications where the building must

be insect free, as in food processing operations.

Construction is steel or aluminum with a fine mesh

aluminum screen. The base includes an access door

to allow easy removal of the screen section

for cleaning and periodic inspection.

Access Door

Insect

Screen

Base

Four galvanized steel brackets are provided as

standard on all hooded propeller roof fans as cable

attachment tie-down points at the ends of each hood

support rail.

Safety Guards – Safety

guards mounted to the fan

inlet are recommended to

protect the fan and nearby

personnel in non-ducted

applications. The installer

should provide a safety

guard if not ordered with

the fan.

Aluminum Housings – Aluminum exterior

construction is available for the hood sections and

bases of all models. Aluminum housings can also be

coated with decorative or protective finishes.

Hood Insulation – Fiberglass insulation attached to

the underside of the hood to minimize condensation

and reduce sound is available in either 1/2-inch or

1-inch thicknesses.

Special Coatings – Special coatings are available

for decorative or protective purposes. Decorative

coatings are applied to exterior surfaces of the hood

and base. Protective coatings are applied to the

entire unit. Coatings include baked polyesters,

enamels, epoxies, phenolics, vinyl, and others.

Protection from corrosive atmospheres requires

individual consideration.

Extended Lubrication Lines – Extended lubrication

lines allow for fan shaft bearing lubrication without

disassembling the unit or removing the hood.

Lubrication lines with grease fittings extend from the

fan shaft bearings to the exterior of the fan base.

Lifting Lugs – Four heavy-gauge steel brackets are

available to provide lifting points when raising the fan

to the roof.

6

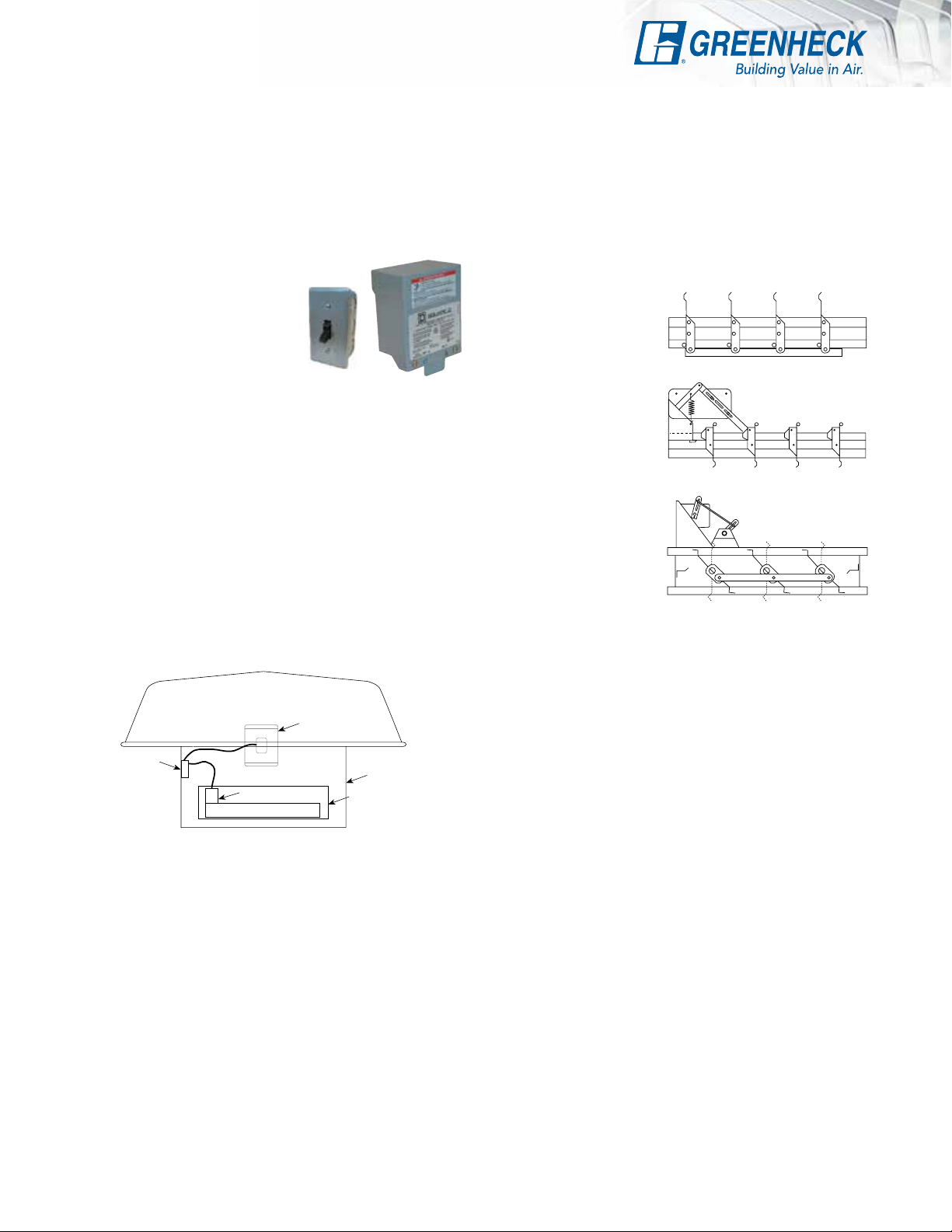

Options and Accessories

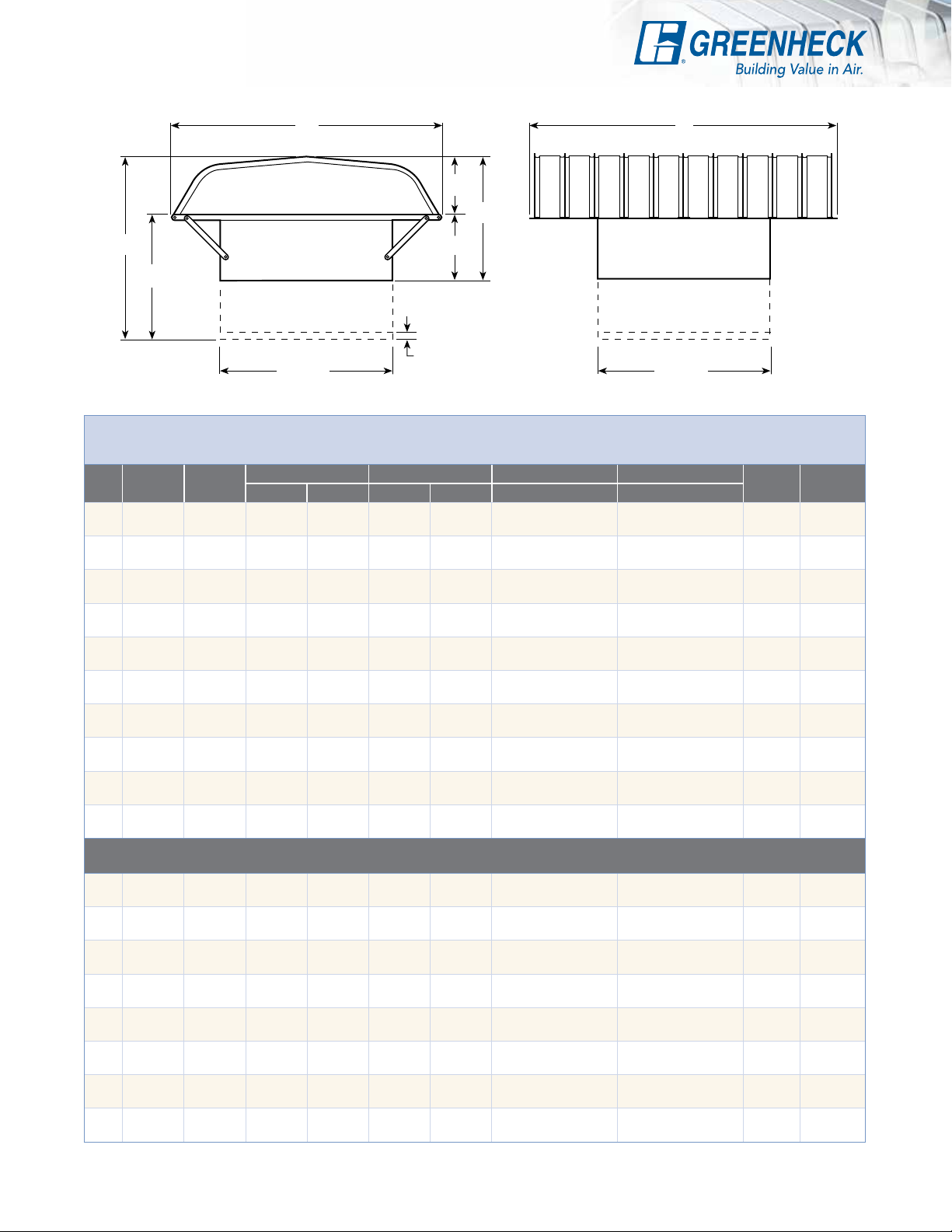

Disconnect Switches – Toggle type and heavy-

duty disconnect switches are available for positive

electrical shut-off and safety in servicing fans. The

following switches are available to meet individual

electrical requirements and can be factory mounted

or shipped loose for field mounting. Wiring from the

motor to the disconnect box is provided with factorymounted disconnect switches.

• NEMA-1 for general purpose

• NEMA-3R for rain resistance

• NEMA-4 for watertight

• NEMA-3R and NEMA-4

for heavy-duty

• NEMA-7 and NEMA-9 for Class 1 and Class 2

hazardous locations and explosion

resistant applications.

UL/cUL 705 – All belt and selected direct drive fans

with totally enclosed, TE standard efficiency, singlespeed motors are available with the UL/cUL 705

listing for electrical.

1-Point Wiring – Available when the following items

are selected: a tall base, common voltages on the

motor and the actuator, and disconnect mounted and

wired. The wires are pulled from the motor and the

actuator on the damper to the disconnect box. (Hardwiring of the components to the disconnect switch is

by others.)

Fan Motor

1 Point Wiring

Junction Box

Actuator

Damper

Tall Base

Access Door

Exception: When a specific voltage is not available

on the actuator, Greenheck will provide a hard-wired

transformer to the actuator. Greenheck will then pull

the wires from the transformer to the disconnect box.

Wiring Pigtail – Available only in conjunction with

factory mounted disconnect switches. Liquid-Tite

wiring extends beyond the fan and allows direct hookup to the power supply. This eliminates field wiring

within the fan. Internal or external power supply can

be specified.

End Switches – Factory-mounted end switches

allow the damper to open completely before the fan

is energized. This reduces back pressure and brake

horsepower load on the fan motor at start-up.

Dampers – Backdraft dampers (also called gravity

dampers) allow airflow in one direction and prevent

reverse airflow for use in the exhaust or intake HVAC

systems. Backdraft dampers can either be operated

by gravity (where pressure or velocity opens and

closes the damper) or motorized to open and close

when required. When the damper is not factory-

installed in a tall base, the damper is to be installed

under the roof curb to provide adequate distance from

the fan.

• Backdraft Dampers

Exhaust and Supply

Gravity or Motorized

Backdraft dampers

Backdraft Damper

Gravity

are constructed with

a galvanized steel

frame and aluminum

blades with vinyl

blade seals. Gravity

dampers open by

Backdraft Damper

Motorized

pressure differential

and close by an

adjustable spring.

• Heavy-duty

Backdraft Dampers

Exhaust and Supply

Motorized

Backdraft Damper - Motor ized

Heavy Duty

These dampers have heavy-galvanized steel frames

and blades are available in standard leakage, low

leakage and insulated low leakage configurations.

Heavy-duty backdraft dampers handle higher

volumes of air than standard backdraft dampers.

Ultra-low leakage dampers with extruded aluminum

blades are available with galvanized steel or

extruded aluminum frames. All low leakage dampers

include vinyl blade and jamb seals.

High Wind and Hurricane Ratings – All certified

rooftop prop models are tested to both Miami-Dade

County and the state of Florida high wind standards

for use in hurricane zones. Sizes up to a 48-inch

prop on unfiltered models and up to a 42-inch prop

on filtered models are available with the high wind

ratings. For more information see Miami-Dade County

NOA-19-0802.02 and Florida Product Approval

FL12917.

Seismic Rated Fans – All certified rooftop prop fans

are tested and certified to the worst-case scenario

seismic conditions for use anywhere in the United

States. All fans are shaker table tested and certified

to California OSHPD seismic standards as well as IBC

2006 and 2009 standards. For more information, see

California OSHPD certification - OSP-0113-10

7

Vari-Green® Options

Vari-Green® Motors

Greenheck’s electronically commutated (EC)

Vari-Green

controllability and energy-efficiency into one

single low maintenance unit. When combined

with Greenheck fans, the VG motor offers variable

volume capability and energy-efficiency without

using a variable frequency drive (VFD). The VariGreen motor has built-in overload and temperature

protection, so it does not require a stand-alone

motor starter for protection.

Dial on Motor Control – A potentiometer (dial on

motor control) is mounted on the motor for easy

speed adjustment for system balance. Simply turn

the dial; there are no belts and pulleys to adjust.

Control Wire Inputs – The motor accepts a 0-10

VDC signal from Building Automated Systems or

other controls to adjust motor speed.

®

(VG) motor combines motor technology,

®

Vari-Green

Transformer – Provides 24V power from the existing

line voltage at the fan to the Vari-Green motor and

controls. Dual voltage primary (120/240V) transformer

provided with the fan.

Remote Dial – Allows for remote, manual airflow

adjustments. Wall plate with dial may be mounted in a

standard 2x4 inch electrical junction box.

Two Speed Control – Control allows motor RPM to

set at two independent speeds (high or low). Meets

minimum airflow requirements with the ability to bump

up to high speed in an emergency to meet maximum

airflow requirements, or reset own to low speed for

energy conservation.

Controls

Constant Pressure Control – Control Vari-Green

motor via static (variable volume) or velocity (constant

CFM) pressure on the inlet or outlet side of the fan.

Available with duct or room probes for use in:

• Multifamily structures – Apartments, condos,

hotels, and utility rooms, residential kitchens

and bathrooms.

• Institutional facilities – Schools, prisons, multistory

office buildings; bathrooms.

Air Quality – VOC – Control a Vari-Green motor via

changes in volatile organic compounds (VOCs). VOCs

are gasses that are emitted from humans, building

materials, perfumes, foods, and furniture off-gassing.

The range is 0-2000 CO2 PPM equivalent.

• Institutional facilities – Schools, courthouses,

hospitals, and bathrooms, waiting rooms,

cafeterias.

• Commercial buildings – Office spaces, conference

rooms, bathrooms, break rooms.

Air Quality - Temperature and Humidity – Control

a Vari-Green motor via changes in temperature,

humidity, or both. The range is 32 to 120˚F and 0 to

100% relative humidity.

• Multifamily structures – Apartments, condos,

hotels, bathrooms, utility rooms.

• Commercial buildings – Office buildings, office

spaces, conference rooms, utility rooms,

bathrooms.

8

Reversible Models Only

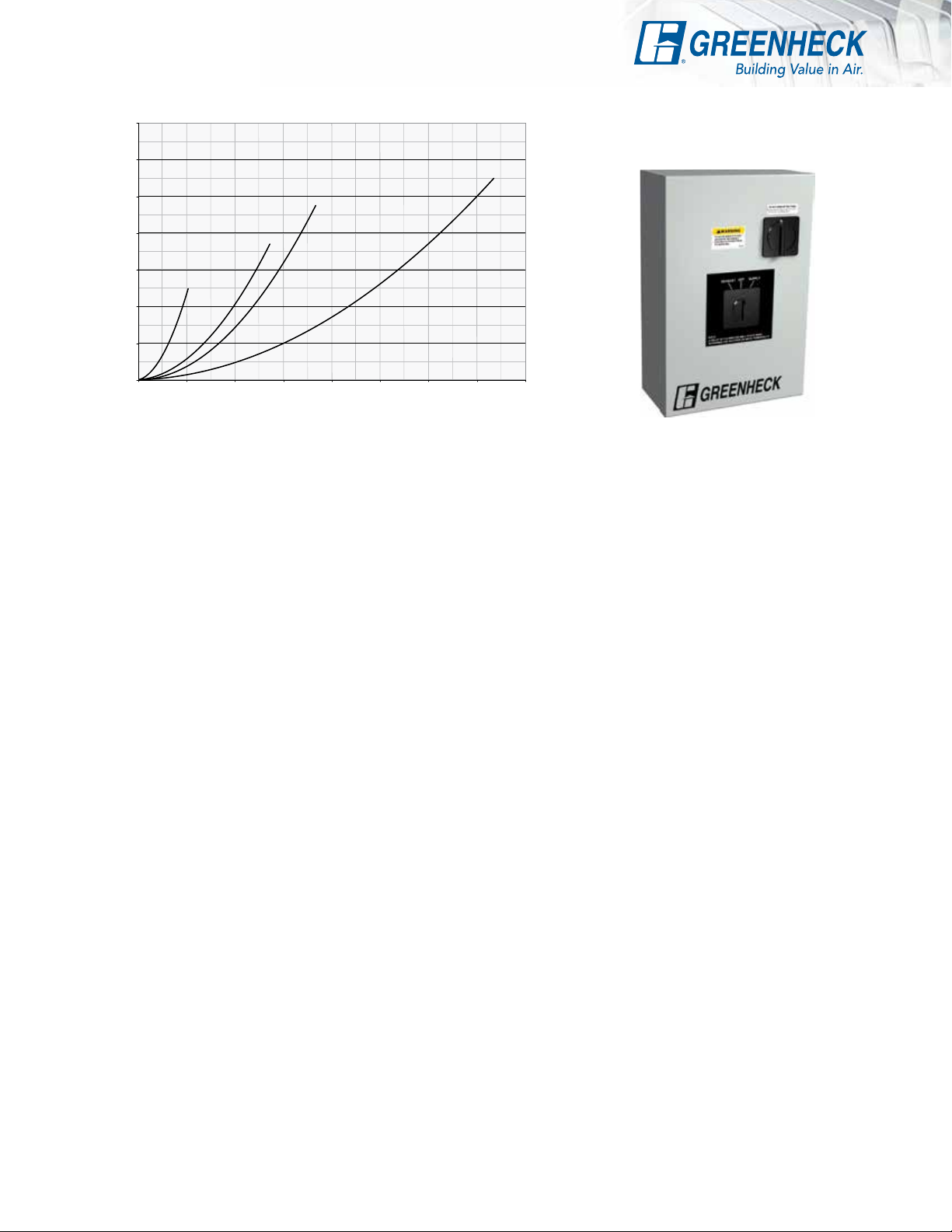

Filter Performance and Control Center

0.7

0.6

0.5

0.4

Static Pressure in. wg

0.3

0.2

0.1

0

24

0 10000 20000 30000 40000 50000 60000 70000 80000

42, 48

30, 36

cfm

Filter Performance

For reversible models, RPDRF and RPBRF, with 2-inch

washable aluminum filters, use the filter performance

graph above to determine the static pressure drop

added by the filters. The filter loss is included in the

performance data and no calculation will need to be

determined for the RBF and RBCF models.

The airflow (CFM) and the desired fan size must be

known to determine the pressure drop added by

the filters.

Example: Size 42-inch RPDRF for 20,000 cfm at

0.125 in. wg.

• On the graph above, locate the 20,000 cfm line and

read upward to its intersection with the 42-inch

curve. Read left to the static pressure (in. wg), in

this case 0.14 in. wg.

• Add 0.14 in. wg from the filter chart to the original

0.125 in. wg for a total of 0.265 in. wg.

• Using the RPDR-42 performance table on page 17,

20,000 cfm at 0.265 in. wg falls into the 5 hp range

at 1025 frpm. In a supply mode you do not want to

exceed 600 frpm to prevent intake of moisture.

54, 60, 72

Reversible Fan Control Center

Model ES-CC control center is designed specifically

for Greenheck’s reversible fan models. Its function

is the selection and control of the exhaust/supply

operation from a convenient remote location.

The ease of installation and operation of the control

center makes it more economical than the design and

construction of a custom control system in the field.

(Wiring between fan and control center is by others).

Controls are housed in a NEMA-1 cabinet constructed

of heavy-gauge steel and coated with Greenheck’s

Permatector

switch is provided to help prevent electrical shock

when the door is opened. Magnetic starters are

included as part of the control center as standard.

Controls

• Mode Selector – The mode selector switch is used

to engage the desired fan function. A time delay is

provided to allow the fan to come to a complete

stop before reversing.

• Options – An indicator light mounted on the control

panel door is available to indicate power to the fan.

TM

finish. A door interlocking disconnect

9

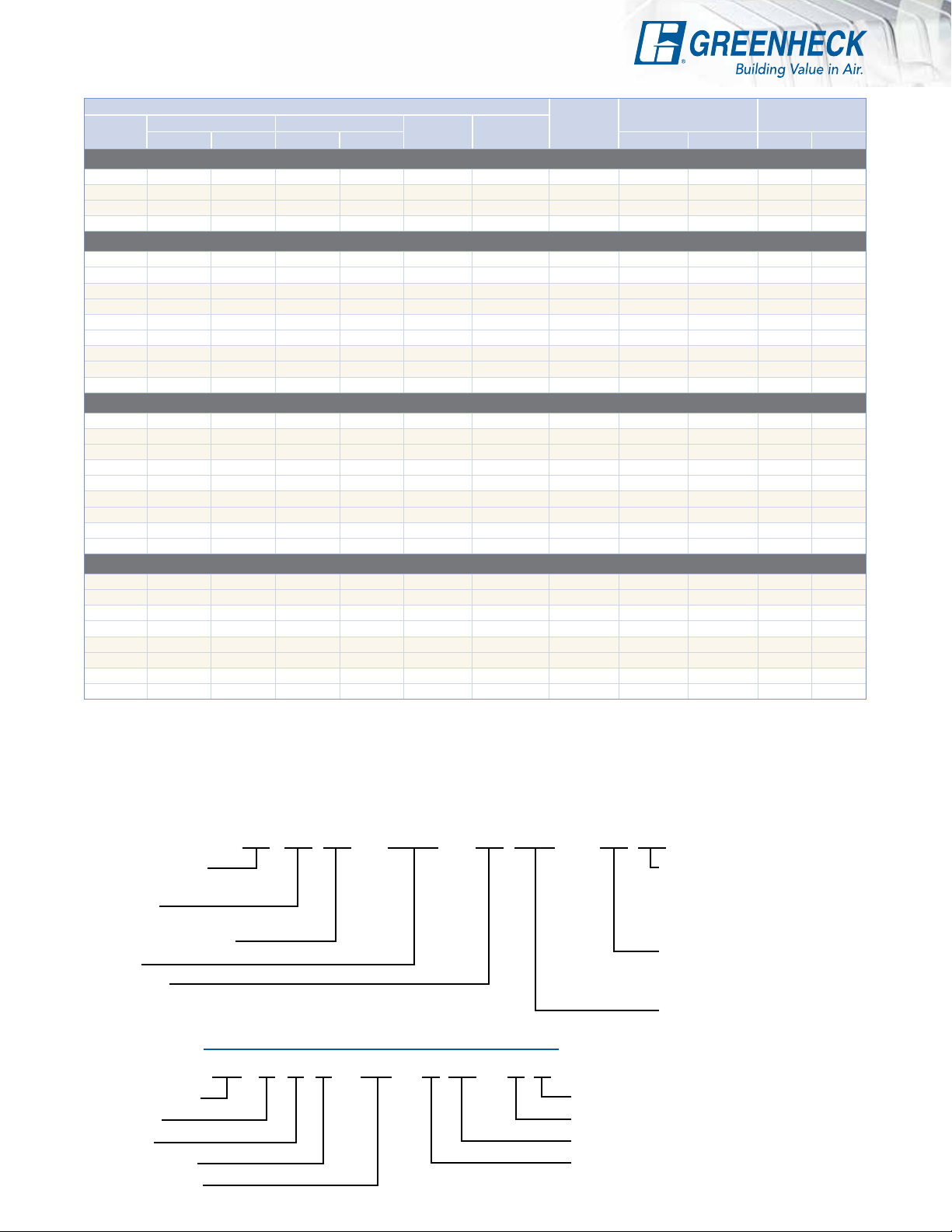

Dimensional Data

W L

C

B

TB

D

TD

Tall Base OptionTall Base Option

2½ in. (63.5mm)

A sq. A sq.

Exhaust / Supply RE2, RS2, RCE3, RCS3, RBE, RBS, RBF, RBCE, RBCS, RBCF

(Belt Drive Sizes 20-72 Direct Drive Sizes 18-54)

Fan

Size

18

20

24

30

36

42

48

54

60

72

A* C

28-1/4

(718)

30-1/4

(768)

34-1/4

(870)

40-1/4

(1022)20(508)

46-1/4

(1175)22(559)

52-1/4

(1327)24(610)

58-1/4

(1480)24(610)

64-1/4

(1632)

70-1/4

(1784)

82-1/2

(2096)29(737)53(1346)

Standard Base Tall Base Standard Hood Filtered Hood

13

(330)

16

(406)

18

(457)

26-1/2

(673)49(1245)

26-1/2

(673)50(1270)

23

(584)

27

(686)

29

(737)

34

(864)

39-1/2

(1003)

42-1/2

(1080)

43-1/2

(1105)

B D TB TD W x L W x L

10

(254)

11

(279)

11

(279)

14

(356)

17-1/2

(445)

18-1/2

(470)

19-1/2

(495)

22-1/2

(572)

23-1/2

(597)

24

(610)

40-1/4

(1022)

44-1/4

(1124)

46-1/4

(1175)

51-1/4

(1302)

56-3/4

(1441)

59-3/4

(1518)

60-3/4

(1543)

66-1/4

(1683)

67-1/4

(1708)

70-1/4

(1784)

27-1/4

(692)

28-1/4

(718)

28-1/4

(718)

31-1/4

(794)

34-3/4

(883)

35-3/4

(908)

36-3/4

(933)

39-3/4

(1010)

40-3/4

(1035)

41-1/4

(1048)

48 x 51

(1219 x 1295)

54 x 51

(1372 x 1295)

66 x 63

(1676 x 1600)

75 x 75

(1905 x 1905)

88 x 87

(2235 x 2210)

86 x 99

(2184 x 2515)

93 x 111

(2362 x 2819)

112 x 111

(2845 x 2819)

124 x 123

(3150 x 3124)

136 x 135

(3454 x 3429)

—

54 x 51

(1372 x 1295)

66 x 63

(1676 x 1600)

78 x 87

(1981 x 2210)

94 x 87

(2388 x 2210)

93 x 99

(2362 x 2515)

112 x 111

(2845 x 2819)

124 x 123

(3150 x 3124)

136 x 135

(3454 x 3429)

136 x 147

(3454 x 3734)

Damper

Size*

18

(457)

20

(508)

24

(610)

30

(762)

36

(914)

42

(1067)

48

(1219)

54

(1372)

60

(1524)

72

(1829)

Roof

Opening*

20-1/2

(521)

22-1/2

(572)

26-1/2

(673)

32-1/2

(826)

38-1/2

(978)

44-1/2

(1130)

50-1/2

(1283)

56-1/2

(1435)

62-1/2

(1588)

74-1/2

(1892)

Reversible RPDR, RPBR, RPDRF and RPBRF

34-1/4

24

(870)

40-1/4

30

(1022)20(508)

46-1/4

36

(1175)21(533)

52-1/4

42

(1327)

58-1/4

48

(1480)

64-1/4

54

(1632)27(686)

70-1/4

60

(1784)27(686)

80-1/4

72

(2038)29(737)53(1346)

All dimensions shown in inches (millimeters); *square dimensions

10

18

(457)

24-1/2

(622)43(1092)

24-1/2

(622)44(1118)

32

(813)

34

(864)

38-1/2

(978)

49-1/2

(1257)

50-1/2

(1283)

(356)

(356)

17-1/2

(445)

18-1/2

(470)

19-1/2

(495)

22-1/2

(572)

23-1/2

(597)

(610)

14

14

24

46-1/4

(1175)

51-1/4

(1302)

55-3/4

(1416)

60-1/4

(1530)

61-1/4

(1556)

66-3/4

(1695)

67-3/4

(1721)

70-1/4

(1784)

28-1/4

(718)

31-1/4

(794)

34-3/4

(883)

35-3/4

(908)

36-3/4

(933)

39-3/4

(1010)

40-3/4

(1035)

41-1/4

(1048)

66 x 63

(1676 x 1600)

74 x 75

(1880 x 1905)

76 x 87

(1930 x 2210)

86 x 99

(2184 x 2515)

100 x 111

(2540 x 2819)

112 x 111

(2845 x 2819)

124 x 123

(3150 x 3124)

136 x 135

(3454 x 3429)

66 x 63

(1676 x 1600)

78 x 87

(1981 x 2210)

94 x 87

(2388 x 2210)

100 x 99

(2540 x 2515)

112 x 111

(2845 x 2819)

124 x 123

(3150 x 3124)

136 x 135

(3454 x 3429)

136 x 147

(3454 x 3734)

24

(610)

30

(762)

36

(914)

42

(1067)

48

(1219)

54

(1372)

60

(1524)

72

(1829)

26-1/2

(521)

32-1/2

(826)

38-1/2

(978)

44-1/2

(1130)

50-1/2

(1283)

56-1/2

(1435)

62-1/2

(1588)

74-1/2

(1892)

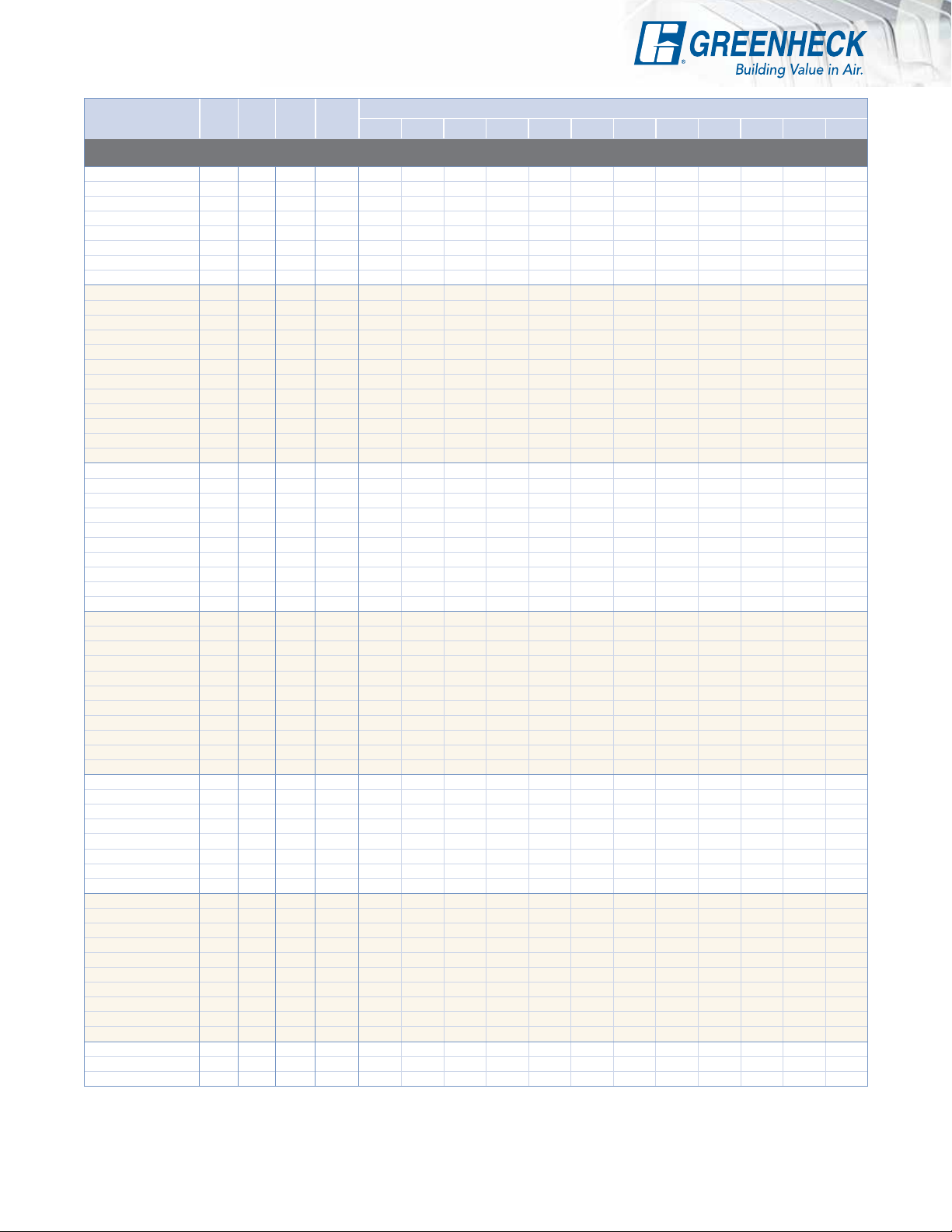

Material Data

Fan Size

Minimum Material Gauges

Base Hood

Galv. Alum. Galv. Alum. Belt Direct Galv. Alum.

Fan Panel

Drive Frame

Channel

Belt Drive

Shaft Size

Max Motor Frame Size

Approximate

Weight (lbs)

Level 1, Models: RBE, RBS and RBF

20 20 0.080 22 0.40 18 11 3/4 145T - 195 165

24 20 0.080 22 0.40 18 11 3/4 145T - 235 200

30 20 0.080 22 0.051 18 11 3/4 184T - 280 240

36 20 0.080 22 0.051 16 11 3/4 184T - 320 275

Level 2, Models: RBE, RBS, RBF, RE2 and RS2

18 20 0.080 22 0.040 18 14 - - 56 185 160

20 20 0.080 22 0.040 18 11 3/4 145T 145T 210 180

24 20 0.080 22 0.040 18 11 3/4 145T 184T 245 210

30 20 0.080 22 0.051 18 11 1 184T 184T 285 245

36 20 0.080 22 0.051 16 11 1 184T 215T 330 280

42 20 0.080 22 0.051 16 10 11⁄4 184T 256T 450 385

48 20 0.080 22 0.051 16 10 11⁄4 184T 256T 645 550

54 18 0.100 22 0.051 16 10 11⁄4 184T 256T 805 685

60 18 0.100 22 0.051 14 10 1

1

⁄2 215T - 935 795

Level 3, Models: RBE, RBCE, RBS, RBCS, RBF, RBCF, RCE3 and RCS3

20 20 0.080 22 0.040 18 11 3/4 - 145T 220 190

24 20 0.080 22 0.040 18 11 3/4 145T 184T 260 225

30 20 0.080 22 0.051 18 11 1 184T 184T 295 250

36 20 0.080 22 0.051 16 11 1 184T 215T 340 290

42 20 0.080 22 0.051 16 10 1

48 20 0.080 22 0.051 16 10 11⁄2 215T 256T 670 570

54 18 0.100 22 0.051 16 10 11⁄2 256T 256T 825 705

60 18 0.100 22 0.051 14 10 13⁄4 256T - 970 825

72 18 0.100 22 0.051 12 10 2 256T - 1145 970

1

⁄2 215T 256T 465 395

Reversible, Models: RPDR, RPBR, RPDRF and RPBRF

24 18 0.064 24 0.040 - - - - - 260 225

30 18 0.064 24 0.040 - - - - - 295 250

36 18 0.064 24 0.040 - - - - - 340 290

42 18 0.080 22 0.051 - - - - - 465 395

48 18 0.080 22 0.051 - - - - - 670 570

54 16 0.100 22 0.051 - - - - - 825 705

60 16 0.100 20 0.051 - - - - - 970 825

72 16 0.100 20 0.051 - - - - - 1145 975

Direct Drive Model Number Code

The model number system is designed to completely identify the fan. The correct code letters must be specified

to designate direct drive with exhaust or supply air configuration. The remainder of the model number is

determined by the size and performance selected from the following pages.

R E 2 - 24 - 6 20 - B 7

R - Fabricated Prop

RC - Cast Prop

E - Exhaust

S - Supply

Construction Level 2 or 3

Fan Size

No. of Blades

Reversible Model Number Code

RP D R F - 24 - 4 17 - A 7

Propeller Roof Fan

Direct Drive

Reversible

Filtered (Optional)

Propeller Diameter

Motor HP**, see list above

Motor RPM*, see list above

Blade Pitch

No. of Blades

Motor HP**

4 = 1/4 10 = 1 50 = 5

3 = 1/3 15 = 1-1/2 75 = 7-1/2

5 = 1/2 20 = 2 100 = 10

7 = 3/4 30 = 3 150 = 15

Motor RPM*

A = 1750 C = 860 F = 860

B = 1160 D = 690

Blade Pitch

11

Direct Drive Exhaust

RE2-18—54

Model Number

Motor HPFan

RPM

Max

BHP

*Sones

0.00 0.10 0.125 0.15 0.20 0.25 0.30 0.375 0.50 0.625 0.75 1.00

RE2 Performance Limits

RE2-18-423-B6 1/6 1160 0.19 12.9 2742 2414 2323 2232 2041 1822 1597 1177

RE2-18-432-B4 1/4 1160 0.29 15.0 3116 2825 2739 2632 2416 2203 1983 1549 656

RE2-18-440-B3 1/3 1160 0.39 16.9 3386 2996 2886 2774 2557 2378 2163 1720

RE2-18-411-A4 1/4 1750 0.30 22 2901 2688 2628 2567 2450 2333 2216 2027 1707

RE2-18-415-A3 1/3 1750 0.38 23 3367 3144 3087 3030 2915 2797 2674 2473 2057 1625

RE2-18-421-A5 1/2 1750 0.58 24 3981 3765 3711 3659 3553 3444 3328 3146 2787 2390 1857 1373

RE2-20-414-B6 1/6 1160 0.20 15.7 3080 2725 2626 2525 2294 1999 1680 1303 781

RE2-20-421-B4 1/4 1160 0.29 17.9 3645 3244 3140 3034 2785 2500 2253

RE2-20-427-B3 1/3 1160 0.39 18.9 3970 3574 3474 3359 3089 2809 2558 2126

RE2-20-404-A4 1/4 1750 0.30 28 3089 2848 2789 2730 2603 2474 2335 2129 1783 1392 1107

RE2-20-408-A3 1/3 1750 0.40 29 3674 3451 3395 3339 3192 3064 2930 2709 2317 1883 1546 903

RE2-20-412-A5 1/2 1750 0.58 30 4373 4155 4101 4037 3900 3766 3633 3425 3006 2531 1986 1477

RE2-20-418-A7 3/4 1750 0.91 32 5145 4913 4855 4795 4671 4547 4417 4218 3764 3287 2784 1922

RE2-20-424-A10 1 1750 1.17 34 5780 5507 5439 5370 5232 5093 4946 4725 4324 3807 3463

RE2-20-435-A15 1-1/2 1750 1.87 36 6483 6222 6157 6092 5936 5774 5606 5338 4911 4495 3955 2613

RE2-24-617-C4 1/4 860 0.28 16.7 4535 3976 3811 3631 3192 2684 2144

RE2-24-621-C3 1/3 860 0.37 19.6 4958 4380 4209 4033 3657 3154 2589

RE2-24-631-C5 1/2 860 0.57 20 5761 5091 4880 4675 4303 3832 3361 2238

RE2-24-620-B7 3/4 1160 0.83 24 6551 6095 5977 5859 5605 5326 5062 4604 3805

RE2-24-627-B10 1 1160 1.15 26 7340 6909 6772 6634 6370 6116 5850 5412 4579

RE2-24-601-A7 3/4 1750 0.80 37 4919 4716 4664 4608 4497 4386 4252 4039 3641 3300 3011 2403

RE2-24-606-A10 1 1750 1.18 40 6559 6338 6283 6228 6107 5974 5841 5631 5227 4799 4350 3497

RE2-24-612-A15 1-1/2 1750 1.72 41 7990 7710 7640 7570 7432 7298 7164 6931 6463 6036 5515 4532

RE2-24-616-A20 2 1750 2.22 42 8958 8723 8665 8606 8489 8355 8210 7991 7598 7157 6658 5501

RE2-30-618-C7 3/4 860 0.86 24 9151 8466 8278 8090 7698 7283 6828 6026 4525 3297

RE2-30-625-C10 1 860 1.15 29

RE2-30-635-C15 1-1/2 860 1.80 33 11552 10704 10497 10289 9821 9289 8615 7635 5280 4396

RE2-30-605-B7 3/4 1160 0.88 31 7628 7235 7135 7028 6815 6565 6304 5900 5162 4381 3619 2214

RE2-30-609-B10 1 1160 1.19 31 9129 8716 8612 8503 8286 8069 7803 7378 6637 5731 4753 3241

RE2-30-615-B15 1-1/2 1160 1.80 33 11481 10986 10863 10739 10502 10266 10025 9609 8808 7956 6936 4815

RE2-30-620-B20 2 1160 2.31 34 12763 12327 12219 12110 11885 11552 11219 10706 9843 8931 7789 5540

RE2-36-608-C7 3/4 860 0.83 28 9860 9164 8969 8775 8357 7916 7431 6714 5296 3823 2471

RE2-36-612-C10 1 860 1.18 30 12054 11324 11115 10906 10447 9960 9470 8710 7230 5332 3779

RE2-36-618-C15 1-1/2 860 1.70 32 14330 13477 13241 13005 12532 12053 11543 10674 9238 7414 5518 2870

RE2-36-600-B10 1 1160 1.18 35 8001 7528 7397 7244 6942 6663 6380 5949 5216 4615 3929 2501

RE2-36-606-B15 1-1/2 1160 1.79 37 12216 11724 11597 11450 11155 10860 10559 10106 9374 8466 7496 5502

RE2-36-609-B20 2 1160 2.23 39 13970 13475 13352 13228 12959 12677 12395 11915 11057 10069 9136 6883

RE2-36-615-B30 3 1160 3.51 41 17695 17217 17098 16978 16739 16434 16097 15589 14632 13650 12637 10360

RE2-42-602-C10 1 860 1.10 31 8248 7498 7326 7146 6774 6440 6113 5624 4774 3819 2896

RE2-42-608-C15 1-1/2 860 1.63 33 13322 12666 12501 12333 11997 11616 11210 10604 9558 8326 7157 4615

RE2-42-612-C20 2 860 2.30 34 16659 15900 15709 15508 15105 14703 14245 13550 12384 11184 9794 7321

RE2-42-618-C30 3 860 3.53 38 20833 19931 19704 19458 18964 18471 17975 17215 15982 14526 13096 10298

RE2-42-627-C50 5 860 5.75 42 24809 24003 23801 23600 23188 22562 21916 20827 19325 17993 16421 12586

RE2-48-405-C15 1-1/2 860 1.69 44 16467 15471 15228 14984 14497 13940 13377 12489 10775 8986 7113 3487

RE2-48-409-C20 2 860 2.35 46 20499 19443 19185 18930 18422 17854 17274 16341 14660 12904 10993 6665

RE2-48-413-C30 3 860 3.40 49 24743 23533 23242 22969 22421 21857 21148 20084 18501 16720 14919 10781

RE2-48-421-C50 5 860 5.89 54 30865 29709 29420 29131 28491 27794 27098 26120 24429 22624 20654 16320

RE2-54-419-F50 5 690 5.77 53 36939 34858 34325 33781 32693 31655 30638 28940 26112 23257 20185 14004

RE2-54-409-C50 5 860 5.54 54 33516 32232 31911 31590 30975 30361 29747 28562 26470 24499 22503 17879

RE2-54-415-C75 7-1/2 860

Performance certified is for model RE2 exhaust for installation type A: free inlet, free outlet. Power rating (Bhp) does not include transmission losses. Performance

ratings include the effects of appurtenances (Birdscreen).

The sound ratings shown are loudness values in fan sones at 5 feet (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for

installation type A: free outlet hemispherical sone levels. The AMCA Certified Ratings Sound Seal applies to sone ratings only.

*Sones shown apply to the highest cataloged cfm at each fan rpm. For selections at other cfm and static pressure points, refer to the CAPS computerized selection

program.

Numbers in blue have a larger Bhp and require the next largest size motor.

8.67 55 41470 40161 39834 39507 38758 37868 36978 35722 33672 31561 29317 24635

12

10117 9405 9223 9041 8591 8088 7590 6776 4600 3708 2714

CFM / Static Pressure in Inches WG

Direct Drive Cast Aluminum Exhaust

RCE3-20—54

Model Number

Motor HPFan

RPM

Max

BHP

*Sones

0.00 0.10 0.125 0.15 0.20 0.25 0.30 0.375 0.50 0.625 0.75 1.00

RCE3 Performance Limits

RCE3-20-620-B4 1/4 1160 0.30 15.3 3419 3134 3056 2976 2810 2606 2290 1789 1444 886

RCE3-20-626-B3 1/3 1160 0.40 15.3 3911 3587 3495 3401 3210 3014 2782 2197 1679 1303 667

RCE3-20-634-B5 1/2 1160 0.58 16.8 4289 3954 3857 3732 3520 3319 3031 2393 2037 1369 722

RCE3-20-306-A4 1/4 1750 0.30 18.5 2845 2551 2483 2400 2231 2031 1830 1530 1178

RCE3-20-313-A5 1/2 1750 0.45 19.7 3818 3516 3436 3364 3223 3084 2912 2641 2011 1400 817

RCE3-20-318-A5 1/2 1750 0.60 21 4225 3967 3895 3820 3657 3502 3346 3113 2584 1801 1233

RCE3-20-618-A7 3/4 1750 0.90 24 4867 4667 4618 4568 4477 4387 4296 4134 3803 3355 2828 2215

RCE3-20-623-A10 1 1750 1.21 29 5547 5343 5292 5239 5125 5011 4898 4730 4430 4085 3408 2690

RCE3-24-427-C4 1/4 860 0.28 15.2 4978 4121 3897 3688 3147 2115 1561 792

RCE3-24-626-C3 1/3 860 0.37 14.0 5278 4692 4531 4372 4020 3515 2616 1734 790

RCE3-24-610-B4 1/4 1160 0.30 17.6 4391 3975 3881 3786 3577 3354 3110 2686 1775 1175

RCE3-24-416-B3 1/3 1160 0.40 17.1 5301 4729 4566 4413 4113 3815 3510 2905 1474

RCE3-24-424-B5 1/2 1160 0.59 19.2 6342 5818 5660 5488 5211 4905 4522 3911 2218 1273

RCE3-24-625-B7 3/4 1160 0.88 20 7040 6580 6485 6366 6124 5901 5655 5207 4302 2549 1860

RCE3-24-633-B10 1 1160 1.20 23 8028 7553 7419 7283 6982 6683 6385 5916 4996 3091 2248

RCE3-24-403-A5 1/2 1750 0.52 31 4858 4487 4398 4304 4112 3930 3739 3422 2855 2184 1835

RCE3-24-606-A7 3/4 1750 0.90 32 5784 5530 5460 5391 5252 5115 4983 4797 4448 4058 3524 2549

RCE3-24-414-A10 1 1750 1.18 33 7388 7003 6904 6804 6615 6429 6227 5945 5479 5000 4483 2593

RCE3-24-617-A15 1-1/2 1750 1.78 34 8432 8107 8026 7957 7819 7681 7548 7347 7002 6602 6203 5361

RCE3-24-621-A20 2 1750 2.41 39 9652 9360 9287 9214 9061 8901 8740 8523 8192 7795 7372 6379

RCE3-30-605-C4 1/4 860 0.29 18.2 5609 4739 4534 4352 3931 3462 2740 1740

RCE3-30-607-C3 1/3 860 0.37 17.4 6417 5533 5332 5125 4706 4244 3639 2391

RCE3-30-615-C5 1/2 860 0.56 16.4 7798 6911 6691 6470 6001 5499 5008 3847 1592

RCE3-30-623-C7 3/4 860 0.87 18.3 9114 8217 7980 7737 7244 6742 6146 4948 2561

RCE3-30-630-C10 1 860 1.15 20 9883 8802 8568 8333 7840

RCE3-30-603-B5 1/2 1160 0.60 27 6885 6299 6148 5994 5682 5361 5063 4560 3464 2494 1417

RCE3-30-607-B7 3/4 1160 0.90 25 8656 7970 7800 7651 7357 7053 6746 6278 5408 3923 2591

RCE3-30-612-B10 1 1160 1.20 24 9941 9328 9164 8991 8648 8326 8005 7499 6650 5591 3717

RCE3-30-620-B15 1-1/2 1160 1.76 26 11548 10940 10789 10639 10326 9989 9642 9068 8099 6950 4614

RCE3-30-626-B20 2 1160 2.41 28 12868 12202 12037 11871 11541 11136 10684 10061 9091 7917 5544 2654

RCE3-36-601-C5 1/2 860 0.57 25 9219 8273 8003 7713 7017 6249 5362 4038

RCE3-36-606-C7 3/4 860 0.83 25 11147 10114 9843 9555 8900 8157 7372 5893 3385

RCE3-36-612-C10 1 860 1.14 24 13058 12051 11764 11377 10655 9980 9178 7772 4443

RCE3-36-616-C15 1-1/2 860 1.44 25 14425 13194 12854 12487 11751 10951 10050 8606 5062

RCE3-36-630-C20 2 860 2.35 29 16244 14958 14614 14167 13167 11879 10545 7823 5353 3370

RCE3-36-300-B7 3/4 1160 0.68 26 10426 9166 8849 8481 7719 7073 6168 4452

RCE3-36-404-B10 1 1160 1.18 32 12812 11893 11534 11319 10902 10302 9618 8617 6496 3715

RCE3-36-605-B15 1-1/2 1160 1.81 34 14623 13994 13837 13660 13270 12874 12391 11653 10293 8503 6653

RCE3-36-608-B20 2 1160 2.34 35 16205 15288 15091 14893 14490 14076 13654 13010 11536 9754 7733 3312

RCE3-36-616-B30 3 1160 3.54 39 19458 18590 18361 18114 17618 17092 16548 15729 14193 12433 10488 5629

RCE3-36-630-B50 5 1160 5.76 44 21911 20994 20756 20501 19993 19413 18750 17563 15139 11778 9457 6158

RCE3-42-611-F7 3/4 690 0.87 19.2 13930 12209 11801 11374 10451 9310 8185 6097

RCE3-42-616-F10 1 690 1.20 19.8 15931 14330 13961 13460 12479 11546 10289 8038

RCE3-42-624-F15 1-1/2 690 1.80 23 18324 16430 15881 15299 14228 13122 11927 9962 5122

RCE3-42-630-F20 2 690 2.33 24 19575 17650 17067 16491 15425 14385 13137 10580 5867

RCE3-42-607-C10 1 860 1.17 28 14459 13168 12815 12450 11716 11004 10251 8983 6713 4324

RCE3-42-611-C15 1-1/2 860 1.68 28 17362 16063 15678 15292 14632 13930 13207 11843 9446 6622 3460

RCE3-42-616-C20 2 860 2.32 29 19856 18528 18219 17923 17311 16501 15714 14590 12052 8855 5165

RCE3-42-623-C30 3 860 3.31 32 22468 21128 20720 20295 19447 18603 17730 16393 14043 10986 7237

RCE3-48-408-F7 3/4 690 0.86 21 17457 14601 13762 12833 11140 9125 6274

RCE3-48-607-F10 1 690 1.17 22 18591 16525 15914 15334 14091 12686 11171 8443

RCE3-48-612-F15 1-1/2 690 1.81 23 22289 20196 19595 18955

RCE3-48-617-F20 2 690 2.38 26 24348 21852 21301 20754 19489 18044 16522 13937 7982

RCE3-48-627-F30 3 690 3.45 28 26494 24087 23315 22578 21222 19772 17676 13442 8960

RCE3-48-603-C15 1-1/2 860 1.71 36 19773 18118 17700 17283 16350 15401 14385 12810 9608 5852

RCE3-48-607-C20 2 860 2.27 33 23171 21549 21180 20701 19726 18796 17800 16116 13033 9075

RCE3-48-611-C30 3 860 3.33 33 27514 25664 25232 24791 23872 22864 21742 20236 17002 13351 8463

RCE3-48-620-C50 5 860 5.32 36 31410 29616 29034 28451 27430 26468 25460 23843 20623 16468 10796

RCE3-48-631-C75 7-1/2 860 7.80 42 34013 31658 31127 30585 29379 28063 26606 24292 18161 15030 11775

RCE3-54-330-F50 5 690 5.59 46 36212 33116 32365 31613 30348 29048 27620 25306 21143 14888

RCE3-54-315-C50 5 860 5.60 50 38118 36174 35687 35122 33984 32974 31978 30404 27499 24217 20575 9493

RCE3-54-323-C75 7-1/2 860 8.37 55 42298 40107 39559 39066 38113 37160 36163 34639 31463 28305 25033 16045

CFM / Static Pressure in Inches WG

7302 6710 4215

17695 16301 14743 12309 6140

Performance certified is for model RE2 exhaust for installation type A: free inlet, free outlet. Power rating (Bhp) does not include transmission losses. Performance

ratings include the effects of appurtenances (Birdscreen).

The sound ratings shown are loudness values in fan sones at 5 feet (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for

installation type A: free outlet hemispherical sone levels. The AMCA Certified Ratings Sound Seal applies to sone ratings only.

*Sones shown apply to the highest cataloged cfm at each fan rpm. For selections at other cfm and static pressure points, refer to the CAPS computerized selection

program.

Numbers in blue have a larger Bhp and require the next largest size motor.

13

Direct Drive Supply

RS2-18—54

Model Number

Motor HPFan

RPM

Max

BHP

*Sones

0.00 0.10 0.125 0.15 0.20 0.25 0.30 0.375 0.50 0.625 0.75 1.00

RS2 Performance Limits

RS2-18-424-B6 1/6 1160 0.19 19.3 2891 2638 2569 2479 2248 1987

RS2-18-433-B4 1/4 1160 0.28 22 3401 3131 3050 2949 2705 2389 1970

RS2-18-440-B3 1/3 1160 0.37 23 3779 3515 3345 3184 2870 2514 2139

RS2-18-412-A4 1/4 1750 0.28 31 3065 2908 2869 2828 2744 2646 2534 2299 1867 1453 1120

RS2-18-415-A3 1/3 1750 0.38 32 3575 3414 3372 3322 3222 3121 3011 2825 2365 1705 1367

RS2-18-422-A5 1/2 1750 0.60 33 4191 4010 3965 3921 3838 3755 3672 3476 3060 2486 1933

RS2-20-416-B6 1/6 1160 0.19 22 3242 2926 2843 2747 2499 2093 1686 1182

RS2-20-422-B4 1/4 1160 0.29 25 3916 3590 3503 3408 3154 2819 2324

RS2-20-428-B3 1/3 1160 0.38 26 4426 4065 3956 3845 3553 3217 2721

RS2-20-405-A4 1/4 1750 0.30 37 3240 3013 2954 2895 2781 2669 2503 2247 1856 1402 1017

RS2-20-407-A3 1/3 1750 0.38 38 3610 3401 3339 3276 3151 3025 2898 2698 2182 1717 1309

RS2-20-413-A5 1/2 1750 0.60 40 4572 4384 4337 4289 4168 4047 3929 3759 3267 2666 2041

RS2-20-419-A7 3/4 1750 0.84 41 5501 5288 5235 5181 5068 4955 4838 4636 4204 3493 2521

RS2-20-425-A10 1 1750 1.13 43 6322 6081 6021 5961 5844 5727 5603 5360 4882 4223 2858

RS2-20-436-A15 1-1/2 1750 1.74 45 7281 7060 7005 6950 6797 6590 6384 6078 5478 4613 3190

RS2-24-618-C4 1/4 860 0.30 19.7 5012 4529 4410 4225 3766 3006 2303 1395

RS2-24-622-C3 1/3 860 0.38 23 5548 5060 4930 4747 4237 3498 2597 1486

RS2-24-633-C5 1/2 860 0.56 24 6685 6088 5898 5631 4939 4282

RS2-24-622-B7 3/4 1160 0.90 30 7484 7130 7042 6947 6755 6564 6188 5634 4132 2725

RS2-24-628-B10 1 1160 1.19 31 8420 8059 7969 7875 7635 7377 6936 6215 4722

RS2-24-603-A7 3/4 1750 0.88 45 5590 5393 5344 5295 5183 5054 4925 4691 4252 3785 3268 2414

RS2-24-606-A10 1 1750 1.11 48 6756 6483 6414 6346 6209 6098 6001 5788 5413 4985 4300 3312

RS2-24-612-A15 1-1/2 1750 1.79 49 8444 8220 8164 8108 7995 7863 7726 7520 7168 6712 6066 4691

RS2-24-617-A20 2 1750 2.28 50 9766 9571 9522 9473 9375 9278 9180 8988 8573 8124 7622 5925

RS2-30-619-C7 3/4 860 0.87 29 9970 9435 9295 9143 8840 8429 7901 6696 4374 2697

RS2-30-625-C10 1 860 1.18 33 11577 10998 10827 10653 10305 9897 9394 8224 5457 3057

RS2-30-635-C15 1-1/2 860 1.79 37 13519 12942 12793 12586 12173 11650 10817 9403 5733

RS2-30-605-B7 3/4 1160 0.87 36 8004 7540 7435 7332 7126 6902 6673 6233 5354 4407 3352 1580

RS2-30-609-B10 1 1160 1.14 37 9179 8819 8729 8639 8428 8195 7961 7599 6750 5625 4593 2558

RS2-30-616-B15 1-1/2 1160 1.77 38 12118 11712 11610 11509 11290 11054 10818 10434 9776 8376 6930 4186

RS2-30-621-B20 2 1160 2.37 40 14207 13783 13676 13570 13357 13134 12912 12578 11654 10472 8760 5010

RS2-36-608-C7 3/4 860 0.87 31 10368 9770 9600 9429 9075 8655 8115 7149 5418 3563 2147

RS2-36-613-C10 1 860 1.20 35 12782 12206 12062 11918 11564 11197 10688 9697 7557 5309 3431

RS2-36-619-C15 1-1/2 860 1.77 35 15784 15145 14985 14825 14447 14067 13552 12421 10134

RS2-36-605-B15 1-1/2 1160 1.75 41 12229 11775 11661 11547 11259 10962 10667 10228 9282 8226 7132 4819

RS2-36-609-B20 2 1160 2.29 45 14617 14216 14116 14016 13791 13527 13264 12865 12081 10911 9590 6806

RS2-36-615-B30 3 1160 3.39 47 18477 18083 17984 17885 17688 17491 17273 16871 16101 15051 13502 10029

RS2-42-604-C10 1 860 1.16 34 10410 9823 9634 9429 9028 8661 8297 7759 6722 5524 4352 1892

RS2-42-609-C15 1-1/2 860 1.73 37 14918 14214 14034 13846 13472 13068 12633 11992 10917 9514 8123 4949

RS2-42-613-C20 2 860 2.37 38 18043 17419 17263 17107 16759 16391 16008 15173 13993 12440 10921 7062

RS2-42-619-C30 3 860 3.54 40 22564 21911 21747 21584 21224 20822 20419 19797 18338 16086 14475 10641

RS2-42-628-C50 5 860 5.58 44 28326 27511 27307 27104 26702 26309 25916 25326 22814 20699 18517 13889

RS2-48-406-C15 1-1/2 860 1.70 48 17653 16860 16662 16434 15581 15003 14426 13452 11664 9604 7461 3219

RS2-48-409-C20 2 860 2.26 50 21078 20184 19961 19671 19079 18489 17903 16873 14822 12789 10588 6065

RS2-48-413-C30 3 860 3.34 54 26137 25150 24903 24644 24095 23547 22998 21787 19847 17768 15750 9811

RS2-48-421-C50 5 860 5.87 57 34260 33175 32904 32633 32087 31474 30860 29847 27391 25101 22890 16888

RS2-54-420-F50 5 690 5.90 56 40612 39282 38949 38602 37788 36975 36162 34413 30917 26631 22598 13995

RS2-54-410-C50 5 860 5.90 58 36501 35366 35082 34798 34221 33593 32965 32024 30461 28032 25102 19450

RS2-54-415-C75 7-1/2 860 8.48 59 44221 43095 42813 42532 41969 41406 40758 39766 37897 35653 32852 27125

CFM / Static Pressure in Inches WG

Performance certified is for model RE2 exhaust for installation type A: free inlet, free outlet. Power rating (Bhp) does not include transmission losses. Performance

ratings include the effects of appurtenances (Birdscreen).

The sound ratings shown are loudness values in fan sones at 5 feet (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for

installation type A: free outlet hemispherical sone levels. The AMCA Certified Ratings Sound Seal applies to sone ratings only.

*Sones shown apply to the highest cataloged cfm at each fan rpm. For selections at other cfm and static pressure points, refer to the CAPS computerized selection

program.

Numbers in blue have a larger Bhp and require the next largest size motor.

14

Direct Drive Cast Aluminum Supply

RCS3-20—54

Model Number

Motor HPFan

RPM

Max

BHP

*Sones

0.00 0.10 0.125 0.15 0.20 0.25 0.30 0.375 0.50 0.625 0.75 1.00

RCS3 Performance Limits

RCS3-20-427-B4 1/4 1160 0.30 24 3971 3646 3566 3481 3288 2974 2472 1403 676

RCS3-20-434-B3 1/3 1160 0.41 26 4350 4020 3934 3831 3626 3263 2765 1601 693

RCS3-20-628-B5 1/2 1160 0.42 24 4365 4121 4060 4000 3815 3574 3219 2749 1319

RCS3-20-604-A4 1/4 1750 0.27 29 2392 2195 2144 2093 1993 1894 1797 1637 1330 1026 747

RCS3-20-608-A3 1/3 1750 0.36 28 3170 2983 2938 2894 2805 2715 2599 2414 2091 1741 1383

RCS3-20-614-A5 1/2 1750 0.59 31 4364 4209 4171 4132 4033 3940 3847 3707 3329 2880 2458 1545

RCS3-20-620-A7 3/4 1750 0.90 42 5439 5277 5236 5196 5114 5033 4951 4825 4596 4009 3502 2057

RCS3-20-624-A10 1 1750 1.15 38 5955 5791 5750 5709 5627 5544 5461 5326 5074 4601 3978 2213

RCS3-24-621-C4 1/4 860 0.28 17.7 4696 4247 4113 3929 3203 2060 1559

RCS3-24-630-C3 1/3 860 0.40 18.7 5643 5140 4969 4771 4034 2378

RCS3-24-638-C5 1/2 860 0.54 19.3 6250 5580 5345 5037 3366 2359

RCS3-24-607-B4 1/4 1160 0.28 21 3907 3510 3399 3262 2901 2500 2189 1829 1181

RCS3-24-613-B3 1/3 1160 0.38 24 4731 4361 4261 4149 3874 3555 3060 2327 1564 802

RCS3-24-617-B5 1/2 1160 0.53 24 5556 5220 5131 5043 4843 4576 4070 3234 2140 1271

RCS3-24-627-B7 3/4 1160 0.88 29 7131 6806 6725 6628 6433 6224 5913 5211 2839 1719

RCS3-24-634-B10 1 1160 1.13 33 8025 7616 7498 7380 7118 6768 6442 5498 3015 1710

RCS3-24-310-A5 1/2 1750 0.59 33 5900 5444 5342 5247 5058 4874 4680 4328 3332 2403 1773

RCS3-24-315-A7 3/4 1750 0.91 35 7042 6625 6517 6409 6235 6067 5876 5578 4882 3433 2456

RCS3-24-320-A10 1 1750 1.21 38 8010 7639 7548 7460 7284 7086 6857 6607 6072 4932 2841

RCS3-24-617-A15 1-1/2 1750 1.80 47 8381 8161 8106 8051 7940 7822 7705 7529 7179 6472 5686 3751

RCS3-24-621-A20 2 1750 2.40 49 9555 9337 9283 9229 9120 9012 8904 8742 8415 7980 7357 4341

RCS3-30-607-C4 1/4 860 0.28 21 6197 5384 5151 4904 4337 3595 1925

RCS3-30-610-C3 1/3 860 0.37 22 7035 6285 6079 5855 5304 4454 3669 2549

RCS3-30-616-C5 1/2 860 0.56 25 8580 7874 7674 7443 6984 6353 5060 3583

RCS3-30-624-C7 3/4 860 0.85 24 10292 9537 9318 9044 8544 7454 6623 4448

RCS3-30-630-C10 1 860 1.09 28 11435 10613 10364 10123 9658 8667 7313

RCS3-30-605-B5 1/2 1160 0.59 32 7566 6954 6803 6634 6287 5916 5476 4787 3569 2141

RCS3-30-610-B7 3/4 1160 0.91 35 9489 8918 8787 8656 8367 8062 7698 7044 5509 4005 2287

RCS3-30-614-B10 1 1160 1.20 37 10898 10327 10194 10060 9793 9459 9106 8534 6795 5169 3226

RCS3-30-621-B15 1-1/2 1160 1.79 41 12998 12446 12295 12144 11841 11555 11274 10698 8924 6952 4576

RCS3-30-627-B20 2 1160 2.39 43 14636 14117 13987 13858 13537 13186 12829 12200 10188 8239 4621

RCS3-36-604-C5 1/2 860 0.60 29 9756 8708 8434 8118 7479 6809 5763 4230

RCS3-36-609-C7 3/4 860 0.86 31 11505 10507 10227 9957 9340 8594 7575 5892

RCS3-36-615-C10 1 860 1.20 34 13325 12446 12136 11800 11092 10330 9304 7266

RCS3-36-622-C15 1-1/2 860 1.72 35 15294 14240 13980 13679 12913 11905 10567 8033

RCS3-36-630-C20 2 860 2.31 41 16511 15442 15136 14829 14055 12262 10302

RCS3-36-307-B7 3/4 1160 0.88 37 11414 10101 9781 9469 8840 8090 7337 5985

RCS3-36-602-B10 1 1160 1.20 43 11775 10991 10770 10551 10156 9730 9272 8575 6908 5415 3853

RCS3-36-607-B15 1-1/2 1160 1.81 49 14733 13937 13731 13525 13118 12712 12290 11563 10139 8143

RCS3-36-611-B20 2 1160 2.41 51 16777 15980 15764 15548 15099 14634 14176 13475 11940 9961 7326

RCS3-36-618-B30 3 1160 3.54 57 19215 18606 18454 18302 17882 17426 16973 16300 14178 11984 8312

RCS3-36-630-B50 5 1160 5.64 65 22271 21506 21315 21120 20665 20210 19692 18773 15269

RCS3-42-613-F7 3/4 690 0.91 26 14268 12744 12334 11821 10797 9648 8303 5985

RCS3-42-617-F10 1 690 1.18 30 15985 14624 14297 13825 12765 11500 9980 7437

RCS3-42-625-F15 1-1/2 690 1.75 31 18793 17337 16949 16513 15432 13803 12402 9628

RCS3-42-632-F20 2 690 2.35 35 20595 19019 18625 18230 17192 15588 13573 9429

RCS3-42-607-C10 1 860 1.10 38 14105 12834 12537 12249 11645 10913 9940 8487 6225 4105

RCS3-42-613-C15 1-1/2 860 1.76 41 17783 16553 16250 15948 15277 14454 13633 12305 9534 6419

RCS3-42-617-C20 2 860 2.28 45 19923 18809 18546 18284 17735 16972 16127 14605 11679 7984

RCS3-42-625-C30 3 860 3.38 48 23424 22285 21986 21674 21052 20304 19488 17490 14592 10384

RCS3-48-606-F7 3/4 690 0.90 29 16536 14348 13728 13248 12143 10689 9177 6709

RCS3-48-609-F10 1 690 1.15 31 18428 16390 15841 15291 14152 12798 11279 8320

RCS3-48-614-F15 1-1/2 690 1.74 34 22297 19887 19319 18729 17474 16065 14294 10955 4328

RCS3-48-620-F20 2 690 2.41 35 25138 22886 22299 21660 20345 18806 17144 13065

RCS3-48-629-F30

RCS3-48-606-C15 1-1/2 860 1.77 45 20610 19000 18598 18010 17020 16221 15326 13627 10542

RCS3-48-609-C20 2 860 2.24 46 22968 21539 21079 20539 19641 18759 17837 16250 12939 9130

RCS3-48-614-C30 3 860 3.36 49 27791 25756 25318 24881 23969 23021 22007 20375 16674 11984 6696

RCS3-48-623-C50 5 860 5.31 52 32415 30833 30320 29806 28783 27768 26607 24584 20762 15038

RCS3-48-633-C75 7-1/2 860 7.74 53 36140 33689 33277 32865 32000 30758 29457 26963 17880

RCS3-54-330-F50 5 690 5.78 51 40402 38373 37755 37034 35587 34018 32387 29537 22164

RCS3-54-315-C50 5 860 5.50 57 40124 38440 38019 37586 36629 35672 34623 32996 30223 26780 21872

RCS3-54-323-C75 7-1/2 860 8.40 60 46870 45132 44698 44263 43222 42045 40899 39431 36607 32994 28133

3 690 3.49 37 28131 25634 24975 24186 22778 21231 18753 12425

CFM / Static Pressure in Inches WG

3894

Performance certified is for model RE2 exhaust for installation type A: free inlet, free outlet. Power rating (Bhp) does not include transmission losses. Performance

ratings include the effects of appurtenances (Birdscreen).

The sound ratings shown are loudness values in fan sones at 5 feet (1.5 m) in a hemispherical free field calculated per AMCA Standard 301. Values shown are for

installation type A: free outlet hemispherical sone levels. The AMCA Certified Ratings Sound Seal applies to sone ratings only.

*Sones shown apply to the highest cataloged cfm at each fan rpm. For selections at other cfm and static pressure points, refer to the CAPS computerized selection

program.

Numbers in blue have a larger Bhp and require the next largest size motor.

15

Direct Drive Reversible (Exhaust and Supply)

RPDR-24—36

Model Number

Motor HPFan

RPM

Max

BHP

*Sones

0.00 0.10 0.125 0.15 0.20 0.25 0.30 0.375 0.50 0.625 0.75 1.00

RPDR Performance Limits

RPDR-24-625-C4 1/4

RPDR-24-632-C3 1/3 0.35 13.1 5200 4035 3655 3216 2503

RPDR-24-421-B3 1/3

RPDR-24-429-B5

RPDR-24-623-B5 0.56 26 5765 5300 5173 5020 4555 4097

RPDR-24-632-B7 3/4 0.83 24 6933 6334 6165 5996 5149 4513 3700 3227

RPDR-24-417-A7 3/4

RPDR-24-421-A10 1 1.16 53 7647 7298 7206 7101 6892 6680 6453 6051 4994

RPDR-24-428-A15

RPDR-24-622-A15 1.80 52 8459 8169 8096 8024 7869 7709 7548 7177 6426

RPDR-24-432-A20

RPDR-24-625-A20 2.10 55 9177 8864 8786 8708 8538 8354 8170 7752 6927

RPDR-30-618-C5 1/2

RPDR-30-625-C7 3/4 0.75 28 9293 8298 7998 7692 6562 5237 4267

RPDR-30-410-B5 1/2

RPDR-30-416-B7 3/4 0.83 36 9029 8257 8052 7836 7352 6751 5772 4080

RPDR-30-617-B10 1 1.18 53 10105 9540 9381 9217 8891 8450 7888 6985 4932

RPDR-30-625-B15 1-1/2 1.79 44 12391 11716 11522 11305 10868 10409 9843 8328 6174 4161

RPDR-30-630-B20 2 2.19 48 13345 12620 12411 12172 11691 11135 10352 8202 5895

RPDR-30-405-A10 1

RPDR-30-410-A15 1-1/2 1.80 64 10890 10424 10308 10188 9940 9692 9429 9008 8175 6901 5197

RPDR-30-414-A20 2 2.29 69 12763 12291 12173 12049 11782 11515 11249 10808

RPDR-30-420-A30 3 3.40 81 15185 14639 14503 14367 14091 13813 13535 13043

RPDR-30-623-A50 5 5.53 97 17853 17431 17326 17220 17009 16796 16537 16147 15447 14670 13473 10345

RPDR-36-617-F5 1/2

RPDR-36-625-F7 3/4 0.81 13.3 11387 9487 8557 7122 5449

RPDR-36-410-C5 1/2

RPDR-36-611-C7 3/4 0.78 30 10555 9479 9216 8945 8315

RPDR-36-617-C10 1 1.18 36 12506 11442 11138 10824 10129 8613 6952 5276

RPDR-36-625-C15 1-1/2 1.77 45 14569 13180 12821 12391 11104 8909 7581 5713

RPDR-36-409-B10

RPDR-36-605-B10 1.17 47 10869 10079 9866 9654 9235 8811

RPDR-36-610-B15 1-1/2 1.72 51 13614 12775 12584 12393 12011 11614 11218 10457

RPDR-36-614-B20 2 2.32 56 15450 14659 14459 14258 13858 13444 13005 12171 9283

RPDR-36-620-B30 3 3.17 69 17821 17120 16945 16740 16202 15664 15088 13982 10505

1/2

1-1/2

2

1

0.25 18.4 4562 3760

870

0.35 27 5069 4492 4324 4153 3575 2962

0.56 28 6062 5389 5164 4921 4092 3372

1160

0.87 48 6476 6150 6068 5978 5799 5619 5363 4978 4104

1.79 55 8981 8566 8462 8347 8108 7859 7553 6998 5650

1750

2.08 57 9462 8965 8853 8742 8512 8236 7943 7270 5732

870

0.55 30 7219 6498 6308 6096 5621 5004 4139 2889

1160

1.08 57 8271 7738 7621 7503 7255 6969 6684 6308

1750

0.56 11.3 9774 8319 7835 6904 4892

680

0.56 26 9299 7900 7569 7144 5751

870

1.22 42 11904 10843 10577 10319 9810 9210 8464 6474

1160

7801 6997 6741 6426 5603 4578 3485 2076

CFM / Static Pressure in Inches WG

8339 7260 5274

Performance shown is for Model RPDR without ducts or filters. *Sones shown apply to the highest cataloged cfm at each fan rpm. For selections at other cfm

and static pressure points, refer to the CAPS computerized selection program.

Numbers in blue have a larger Bhp and require the next largest size motor.

16

Loading...

Loading...