Greenheck Hooded Propeller Fans Exhaust and Supply User Manual

PN 455601

®

Hooded Propeller Roof Fans

Exhaust and Supply

Assembly Instructions

Please read these instructions carefully before attempting to assemble the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result

in personal injury and/or property damage!

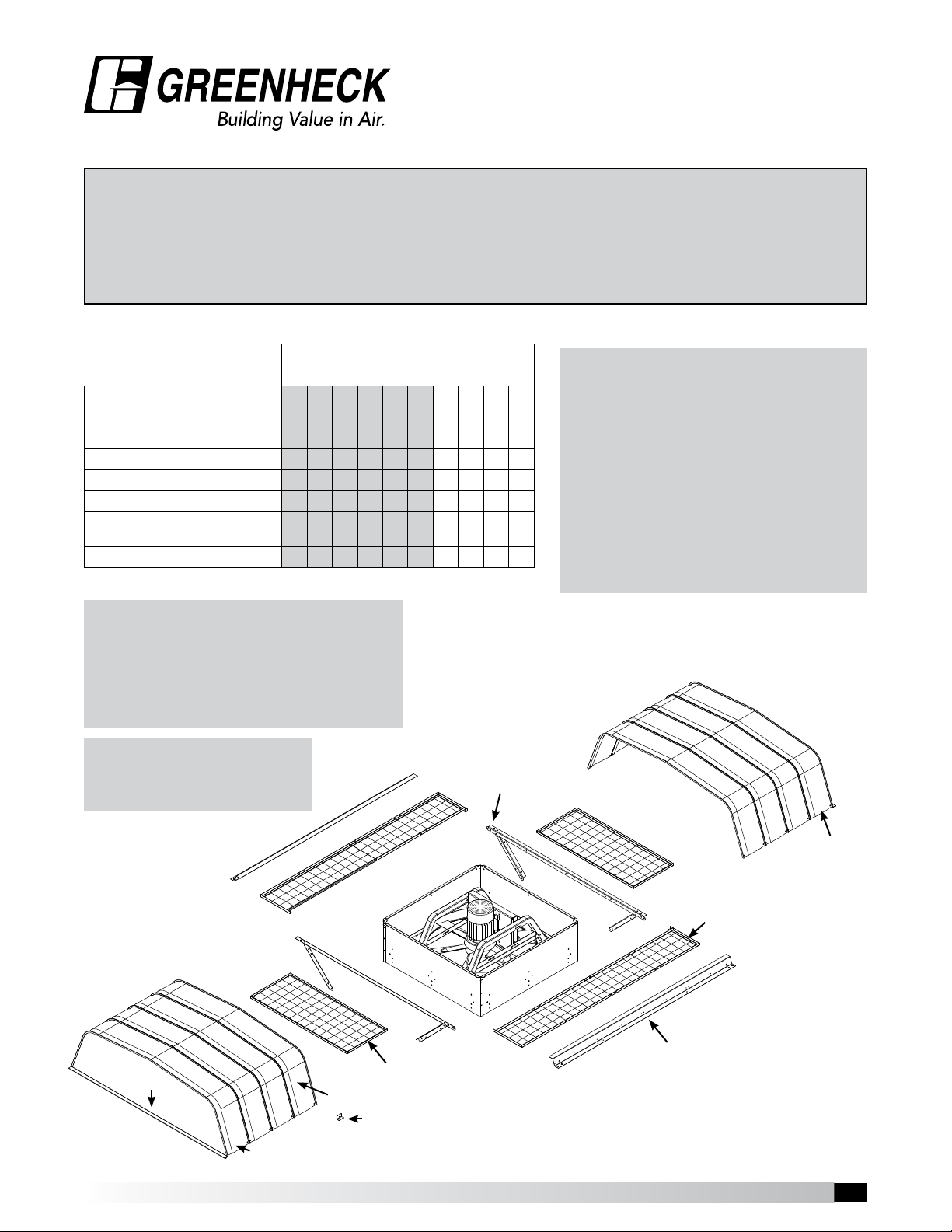

Step 1: Unpack and Inspect Parts

Parts List

Parts Description 18 20 24 30 36 42 48 54 60 72

Fan / Base Assembly 1 1 1 1 1 1 1 1 1 1

Hood Support Rail Assembly 2 2 2 2 2 2 2 2 2 2

Side Birdscreens (Long Screens) 2 2 2 2 2 2 2 2 2 2

Side Birdscreens (Short Screens) 2 2 2 2 2 2 2 2 2 2

Hood Rails 2 2 2 2 2 2 2 2 2 2

Hood Panels including 1 Male &

1 Female hood enclosure panel

Hood Clips for sizes 54 - 72 – – – – – – – 16 18 20

Shaded sizes will always ship fully assembled unless otherwise specified.

Fan Size / Quantity of Parts per Fan Size

4 4 5 6 7 8 9 9 10 11

Exhaust / Supply Fans

Each fan that is shipped knocked down has the

following hardware package containing:

Part # 816529 - Hardware Package

Part # 816526 - Hood Support Fasteners

(16) 3/8” - 16 x 3/4” Spinlock Bolts

(12) 3/8” - 16 Spinlock Nuts

Part # 816527 - Hood Fasteners

(75) #12 x 3/8” Sheet Metal Screws with Washer

(4) 3/8” - 16 x 1-1/2” Spinlock Bolts

(4) 3/8” - 16 Spinlock Nuts

Part # 816528 - Birdscreen / Filter Fasteners

(26) 5/16” - 18 x 3/4” Weld Stud Bolts

(26) 5/16” - 18 Spinlock Nuts

(4) #12 x 3/4” Self-Drilling Screws w/ Washer

Tools required to assemble fans:

• Battery Drill, Electric or Pneumatic preferred.

• 3/8”, 7/16”, 1/2”, and 9/16” Wrenches and Sockets.

• 5/16” Nut Runner Bit for Drill.

• Rubber Mallet.

• Awl for Hole Alignment.

It is recommended that a two man

crew minimum be used for fan/

IMPORTANT!

hood assembly.

Label

Hood

Panels

Hood Clips

(Sizes 54 - 72)

Hood Enclosure Panel

(Male)

Short Birdscreen

Section

Note: Hardware package is designed for the filtered 72” fan.

When used on smaller sizes, there will be some fasteners

left over.

Hood

Support

Rail

Hood

Enclosure

Panel

(Female)

Long Birdscreen

Section

Hood

Rail

Hooded Propeller Roof Fans • Exhaust and Supply

Model

1

1

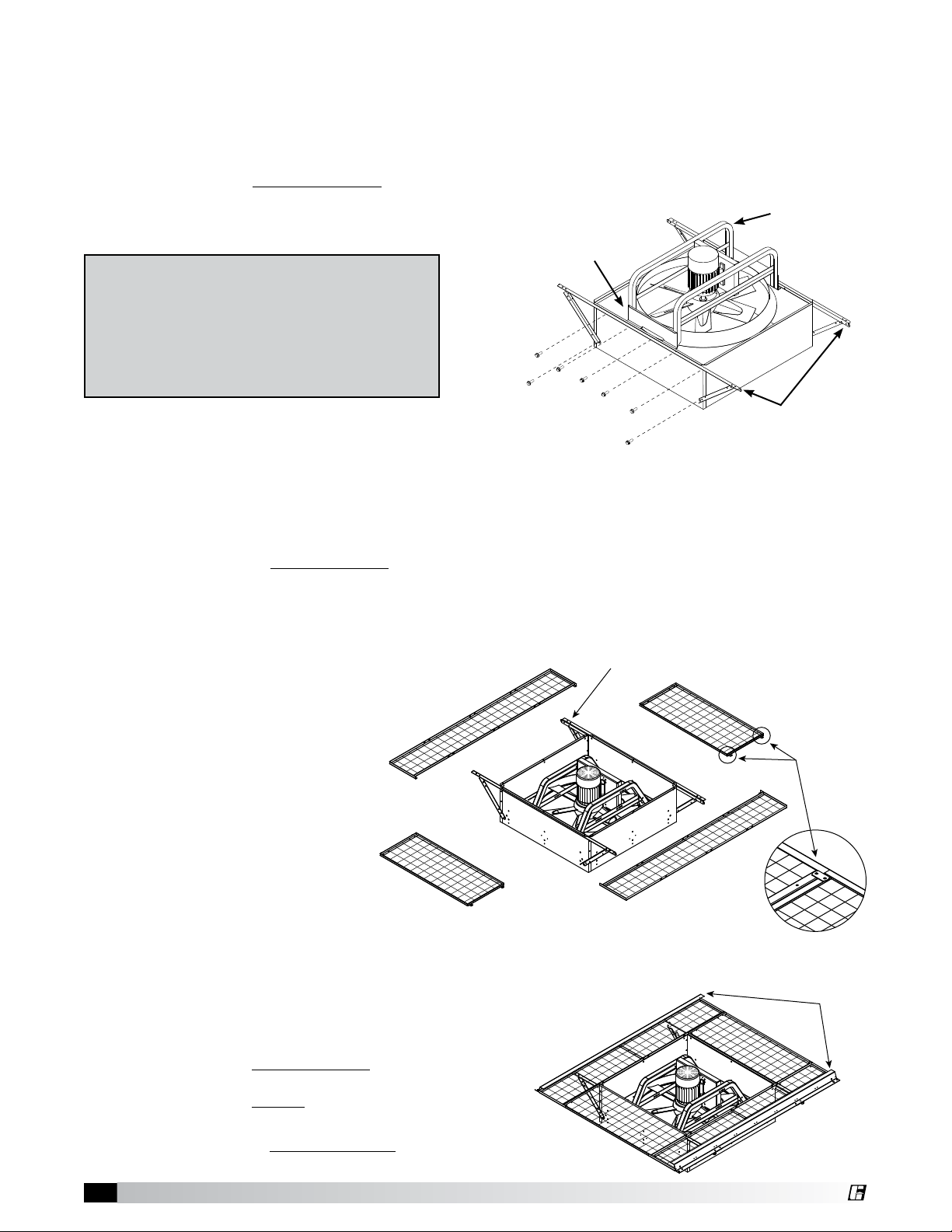

Step 2: Fasten Hood Support Rails

Hardware Required: Hardware Package #816526

3/8” - 16 x 3/4” hex head spinlock bolts & nuts

Quantity: Up to (8) fasteners per side for 72” fans, less required for smaller sizes.

Instructions: WRENCH TIGHTEN the hood support rails to fan base with rails perpendicular

to fan drive frame as shown. Mounting holes in fan base will line up

with holes in hood support rails.

Fan

IMPORTANT!

Panel

Supply Fans (Models RBS, RBCS, RS2, RCS3)

The fan panel bolts are also used for the hood

support rails. Remove fan panel bolts (one

side at a time) and reinstall through the hood

support rails.

Step 3: Install Birdscreen Sections

Hardware Required: Hardware Package #816528

5/16” - 18 x 3/4” weld studs and spinlock nuts

Fan Drive

Frame

Hood support rails

perpendicular to

fan drive frame

Quantity: Only 10 sets required of the 26 sets provided.

Instructions: A) FINGER TIGHTEN the long birdscreen sections to the hood support

rails at the locations indicated using the 10 sets of fasteners.

B) Lay the short birdscreen sections in place and rotate the quick release

fasteners on the underside of the birdscreen to secure. (See Detail 3).

Fastener

Location

Detail 3

Step 4: Install Hood Rails

Hardware Required: Hardware Package #816527

3/8” - 16 x 1-1/2” hex head spinlock bolts and nuts

Quantity: 4 sets

Quick

Release

Fastener

Hood

Rails

Instructions: A) Position the (2) hood rails as shown and

FINGER TIGHTEN the fasteners. These

fasteners will be wrench tightened in

Step 5D after the hood panels are

installed and secured.

B) WRENCH TIGHTEN the fasteners in the

long birdscreen sections.

2

Hooded Propeller Roof Fans • Exhaust and Supply

Detail 4

®

Loading...

Loading...