Page 1

Document Number 469619

®

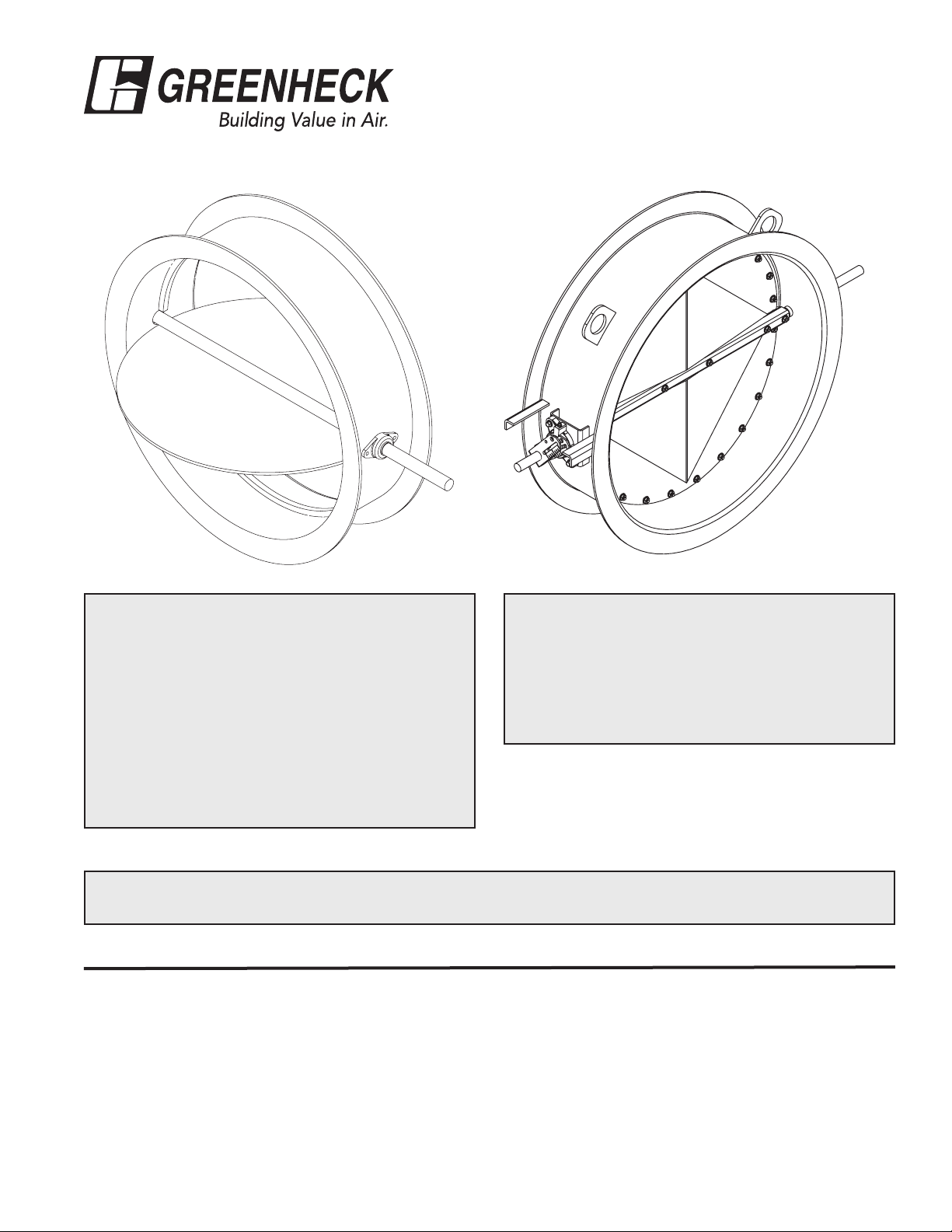

HBTR & HCDR SERIES

Installation, Operation, and Maintenance Instructions

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that

all parts of the shipment, including accessories, are

accounted for.

Dampers must be kept dry and clean. Indoor

storage and protection from dirt, dust and the

weather is highly recommended. Do not store at

temperatures in excess of 100°F (37ºC).

Due to continuing research, Greenheck reserves the right to change specifications without notice.

This manual is the property of the owner, and is required for future maintenance. Please leave it with the

owner when the job is complete.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating, and maintenance instructions

thoroughly before installing or servicing this

equipment.

SAFETY WARNING:

Storage of Dampers Prior to Installation

The basic intent of a proper storage of heavy duty/industrial control and bubble tight damper is to prevent physical damage,

material corrosion, and deterioration of organic material.

1) Visually inspect the damper for damage. Store indoors, protected from sunlight, moisture and flooding. Protect dampers

from debris and dirt accumulation. Keep all conduit entry plugs and actuator access covers in place.

2) Dampers may be stacked and stored horizontally if wood or equivalent spacers are placed between flanges to protect

finish. Do NOT store with axles vertical. Place dampers on pallets or supports to allow air circulation. Do NOT store with

damper directly on concrete or ground.

3) The damper drive should be stored in a clean dry area. Do not stack drives on top of one another. Add desiccant

to electrical compartment if storage area temperature drops below 38°F. Damage due to moisture is not covered by

actuator warranty.

4) Consult manufacturer if storage time exceeds two years.

Page 2

Installation Guidelines - Failure to follow instructions will void all warranties

The basic intent of a proper installation is to secure the heavy duty/industrial control damper into the opening in such a

manner as to prevent distortion and disruption of damper operation. The following items will aid in completing the damper

installation in a timely and effective manner.

1) Dampers are supplied standard without mounting

holes. Drill or punch as required. If mounting holes are

supplied, use appropiate gasketing between mating

flanges. Closed cell sponge rubber, solid rubber,

maximum 60 durometer, or fiberglass drop warp tape

is recommended. For HBTR series, the seal between

the mating ductwork and the dampers flanges should

be tested to ensure a bubble tight seal is achieved.

If damper is replacing existing damper, clean mating

surfaces prior to installing new damper.

2) Allow minimum of half of the blade diameter, upstream

or downstream, in the duct for blade rotation.

3) Damper can be mounted vertically or horizontally with

axle horizontal. A split shaft collar must be added to

shaft to resist the blade weight if axle centerline is other

than horizontal.

4) Isolate damper from high vibratory loadings.

5) If any NEMA electrical enclosure is supplied, use

appropriate electrical connections so as to maintain the

NEMA rating.

Do’s

1) Use damper lifting lugs as provided.

2) Install all mounting bolts before tightening. Tighten in

even and staggered pattern to evenly compress flange

gasketing.

3) Mating flange must be flat and in the same plane.

4) Verify that damper does not strike mating ductwork or

internal ductwork reinforcing when blade is in the open

position.

5) Provide expansion joints upstream/downstream for

angled ductwork so damper is not subjected to thermal/

wind load forces off the centerline of damper.

Dont’s

1) Do not lift damper with chain/strap with blade propped

open and with chain/strap through frame as this could

damage blade seal.

2) Do not use actuator, linkage, or axles as lifting point.

3) Do not use prybar to match frame holes to mating

ductwork as frame can be warped or pulled out-ofround by excessive force.

4) Do not tighten mounting bolts by starting at one point

and “walking” around the damper as uneven flange

compression can result.

Electrical Guidelines

Electrical and/or pneumatic connections to damper actuators should be made in accordance with wiring and piping

diagrams developed in compliance with applicable codes, ordinances and regulations.

SAFETY CAUTION !

Verify power requirements before wiring

actuator. Greenheck is not responsible

for any damage to, or failure of the unit

caused by incorrect field wiring.

Electrical input may be needed for

this equipment. This work should be

performed by a qualified electrician.

SAFETY DANGER !

Damper Maintenance

Greenheck's dampers are designed to be trouble free and hassle free under normal operation. Dampers are to be installed

square and straight so as to prevent binding during operation. The following annual damper maintenance suggestions will

help to insure proper damper operation and increase the life expectancy of the damper.

Foreign Matter Over the course of time, dirt and grime may collect on damper surfaces. The damper surfaces

should be cleaned to prevent hindrance to airflow.

Moving Parts Make sure that parts such as linkage, bearings, blades, etc. that are intended to move freely,

can do so. Lubricating these components can prevent possible rusting and unnecessary friction

increase. Use only a molybdenum spray oil or similar graphite based oil on sleeve bearings as

regular lubricating oil will attract dirt.

Bearings. Synthetic, oil impregnated, carbon sleeve, and ball bearings (without grease fittings)

do not require lubrication. Ball bearings with grease fittings should be lubricated as follows:

Maximum Duct Temperature Lubricant Minimum Frequency

250° F 121° C

600° F 316° C

NLG1 Grade 2 lithium

12-hydrostearate grease

Hi temperature synthetic,

Mobillith SHC100 or equal

twice a year

four times a year

Page 3

Damper Maintenance cont....

Closure Remove foreign materials that may be interfering with blade closure or effective sealing of the

blades with each other or with the frame.

Blade Seals. Inspect annually. Replacement is recommended after 5 years to reduce the

potential of leakage on HBTR series. Damper serial number required when ordering replacement

seal.

Axle Seals. Inspect and adjust as necessary.

Operation While operating the damper through its full cycle, check to see that the blades open and close

properly. If there is a problem, check for loose linkage, especially at the actuator. Tighten the

linkage where required.

Actuator Cycle test actuator per manufacturer’s recommendations.

Damper Troubleshooting

The following is a cause and correction list for common concerns with the damper:

Problem Possible Cause Solution

No power to actuator Verify presence of correct power to actuator.

Actuator failed Power actuator independently of damper.

Damper does not move

Damper attempts to move

but, does not open fully

Actuator attempting to rotate in

wrong direction

Linkage/coupling failed Inspect coupling, keys, and connecting linkage for

No modulating signal Verify presence of modulating signal.

Obstruction in damper linkage

or inside duct

Actuator sizing incorrect

(excessive torque required)

Obstruction in damper linkage

or inside duct

Modulating control not going

full span

Actuator travel stops incorrectly

adjusted

Damper with jamb seals

installed with blades vertical

Check wiring. Run actuator independent of damper

if necessary.

failed or broken components. Replace as required.

Verify signal is compatible with actuator.

Verify if signal is driving actuator in the correct

direction.

Inspect for projecting mounting bolts, debris inside

damper and remove.

Verify that correct operating pressures, velocities,

and temperatures were given to manufacturer for

actuator sizing. Replace actuator if necessary.

Inspect for projecting mounting bolts, debris inside

damper and remove.

Verify control signal span from controller.

Some actuators are equipped with mechanical

stops to limit rotation. Adjust as necessary.

Consult factory, for modifications if vertical blade

orientation not specified on damper with seals.

High noise level

Very high velocity/flow Reduce flow through damper.

No seals on dampers Retrofit with blade seals.

Damper not closing fully Readjust actuator or drive linkage to fully close

damper.

Page 4

Damper Troubleshooting (continued)

Problem Possible Cause Solution

Damper not closing fully Readjust actuator or drive linkage to fully close

damper.

Excessive leakage

across damper

Excessive leakage through

damper frame

Damper not equipped with

blade and jamb seals

Blade edge seals failed Replace blade edge seals.

Stop angles not contacting

blade edges

Caulking failed Recaulk gaps with silicone sealant as required.

No axle seals specified Contact manufacturer for available modifications.

O-ring axle seals worn Replace o-rings as required.

Double gland packing not tight Tighten adjustment nuts on double gland stuffing

Double gland packing worn Replace packing as required.

Retrofit with blade seals.

Close damper. Loosen fasteners and adjust stop

angles so as to contact blade.

box.

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to

change specifications without notice.

Specific Greenheck product warranties are located on greenheck.com within the product

area tabs and in the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

469619• HBTR & HCDR Series Rev. 4, October 2014 Copyright 2014 © Greenheck Fan Corporation

Loading...

Loading...