Greenheck HBS-330 Installation Manual

Document Number 474916

®

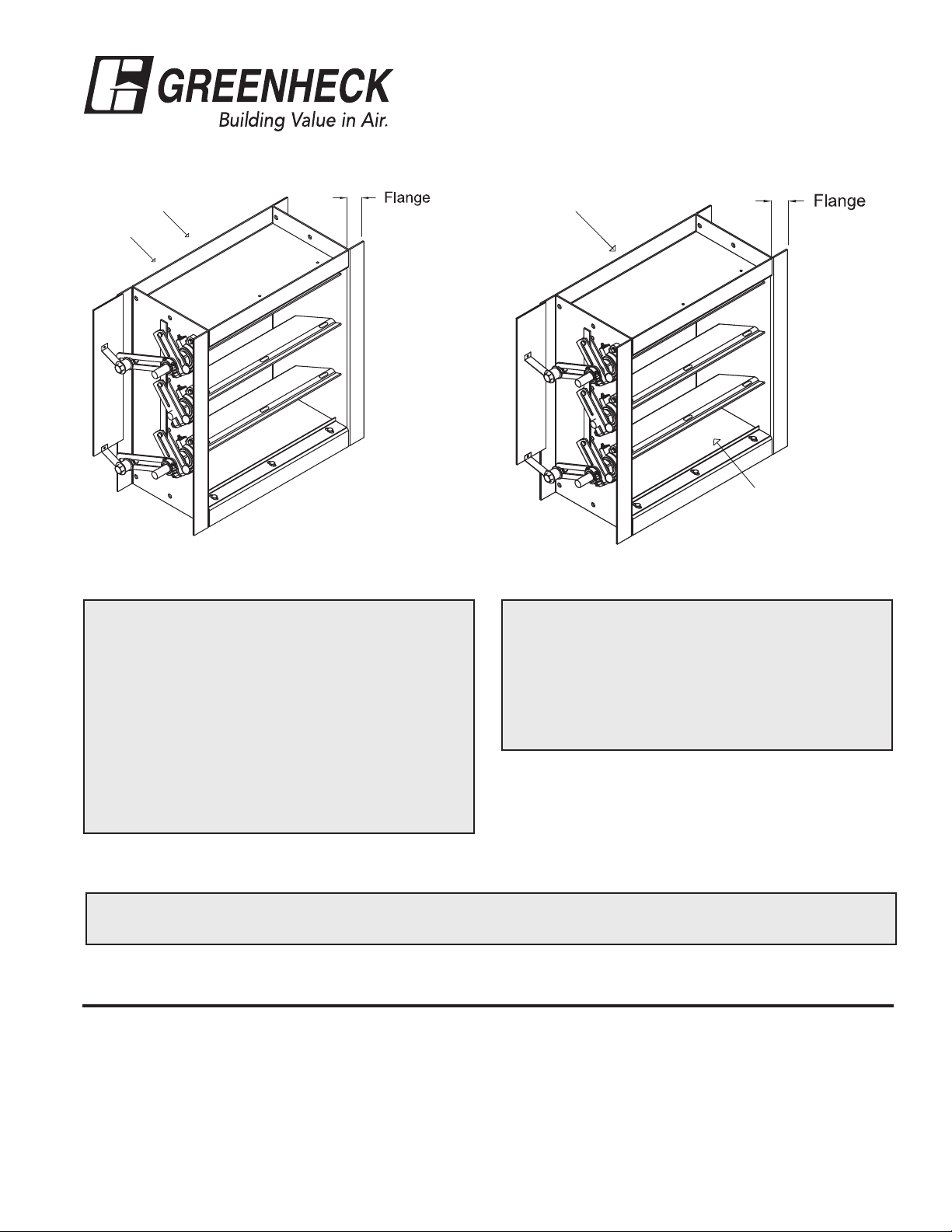

Installation, Operation, and Maintenance Instructions

Flow

Blast

HBS-330/430 HBS-331/431

Blast

HBS SERIES

Flow

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious and

hidden damage. If damage is found, record all necessary

information on the bill of lading and file a claim with

the final carrier. Check to be sure that all parts of the

shipment, including accessories, are accounted for.

Dampers must be kept dry and clean. Indoor storage

and protection from dirt, dust and the weather is highly

recommended. Do not store at temperatures in excess of

100°F (37ºC).

Due to continuing research, Greenheck reserves the right to change specifications without notice.

This manual is the property of the owner, and is required for future maintenance. Please leave it with the owner when the

job is complete.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating, and maintenance instructions

thoroughly before installing or servicing this

equipment.

SAFETY WARNING:

Storage of Dampers Prior to Installation

The basic intent of proper storage of heavy duty/industrial blast damper is to prevent physical damage, material corrosion,

and deterioration of organic material.

1) Visually inspect the damper for damage. Store indoors, protected from sunlight, moisture and flooding. Protect dampers

from debris and dirt accumulation.

2) Dampers may be stacked and stored horizontally if wood or equivalent spacers are placed between flanges to protect

finish. Do NOT store with axles vertical. Place dampers on pallets or supports to allow air circulation. Do NOT store with

damper directly on concrete or ground.

3) Consult manufacturer if storage time exceeds two years.

Installation Guidelines- Failure to follow instructions will void all warranties

The basic intent of a proper installation is to secure the heavy duty/industrial blast damper into the opening in such a manner

as to prevent distortion and disruption of damper operation. The following items will aid in completing the damper installation

in a timely and effective manner.

1) Dampers are supplied standard without mounting holes.

Drill or punch as required. Use appropriate gasketing

between mating flanges. Closed cell sponge rubber, solid

rubber, maximum 60 durometer, or fiberglass drop warp

tape is recommended. If damper is replacing existing

damper, clean mating surfaces prior to installing new

damper.

2) Damper blades remain within the frame depth.

3) The HBS-330 & 430 is installed the same direction as

flow. The HBS-331 & 431 is installed opposite direction as

normal flow. Damper blade centerline MUST be horizontal.

Consult Greenheck for modifications if damper is to be

mounted with blade centerlines vertical.

4) Isolate damper from high vibratory loadings.

5) Damper must be installed square and free of twist or

other misalignment. Out of square, racked, twisted or

misaligned installations can cause the damper to not

operate properly.

Do’s

1) Use damper lifting lugs as provided.

2) Install all mounting bolts before tightening. Tighten in

even and staggered pattern to evenly compress flange

gasketing.

3) Mating flange must be flat and in the same plane.

4) Verify that damper does not strike mating ductwork or

internal ductwork reinforcing when blade is in the open

position.

5) Provide expansion joints upstream/downstream for

angled ductwork so damper is not subjected to thermal/

wind load forces off the centerline of damper.

Dont’s

1) Do not lift damper with chain/strap with blade propped

open and with chain/strap through frame as this could

damage blade seal.

2) Do not use linkage or axles as lifting point.

3) Do not use prybar to match frame holes to mating

ductwork as frame can be warped or pulled out of square

by excessive force.

4) Do not tighten mounting bolts by starting at one point

and “walking” around the damper as uneven flange

compression can result.

Installation Details

Maximum Size and Installation Information

Models HBS-330 and HBS-331 must be installed in accordance with the installation shown herein. Both models are qualified

for installation within concrete/masonry or ductwork. This model is structurally designed to withstand a blast load of up to

5.77 psi (160 in. wg) at 29.69 psi-msec.

Models HBS-430 and HBS-431 must be installed in accordance with the installation shown herein. Both models are qualified

for installation within concrete/masonry or ductwork. This model is structurally designed to withstand a blast load of up to 15

psi (451 in. wg) at 100 psi-msec.

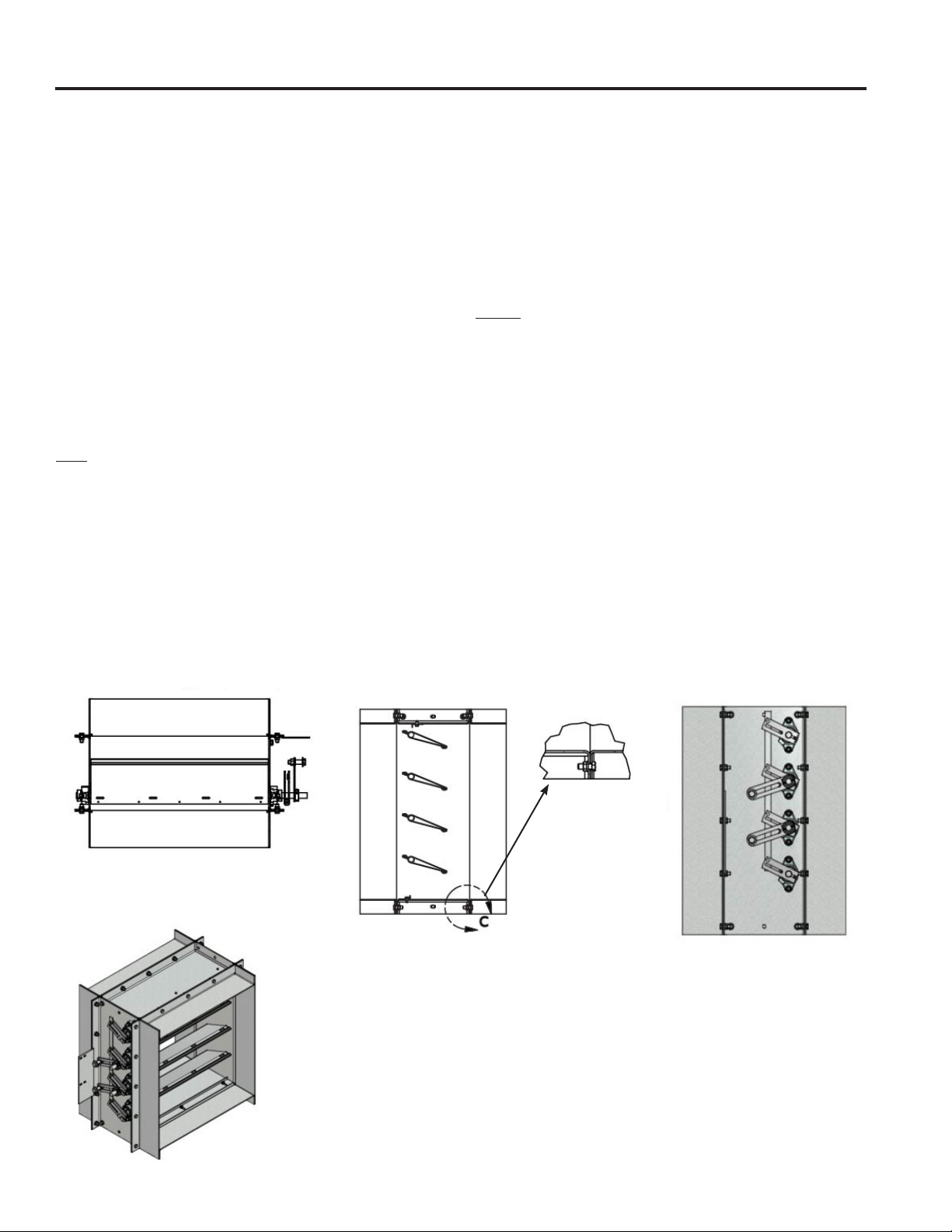

Mounting in Ductwork

Horizontal Section View

2

Typical Vertical

Section View

Typical End View

Notes:

1) Maximum blast loading for the HBS-330 and 331 is 5.77

psi @ 29.69 psi-msec. Maximum blast loading for the

HBS-430 and 431 is 15 psi @ 100 psi-msec.

2) The recommended fastener is a Grade 8 3/8 in. diameter

bolt.

3) It is assumed that the ductwork is designed to withstand

blast loading independent of damper.

Loading...

Loading...