®

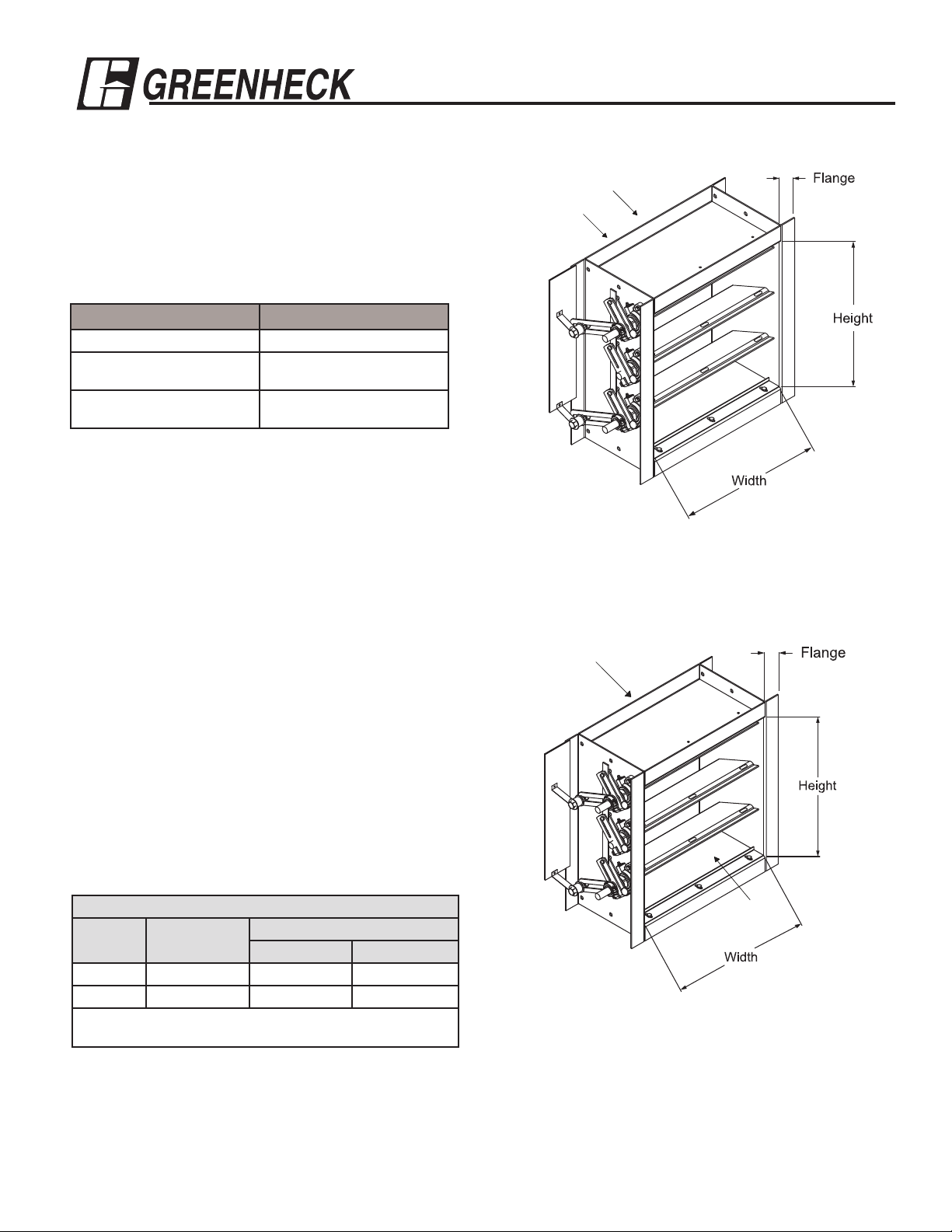

HBS-330 & HBS-331

Application and Design

Models HBS-330 and HBS-331 are heavy duty double flanged

channel frame style dampers with double thickness fabricated

airfoil blades. They are designed to protect against blasts and rapid

pressure changes. Qualified to pressures as high as 5.77 psi covers

many applications in Unified Facilities Criteria (UFC) and General

Services Administration (GSA) codes and standards, including

Charge Weight IIat 82 ft.

Code Blast Loading

GSA- Level C 4 psi @ 28 psi-msec

UFC 4-010-01 (charge

weight I at 148 ft)

UFC 4-010-01 (charge

weight II at 82 ft)

1. Charge weight I = large mass explosion as would be found in a vehicle bomb specific explosive weights are for US Government "For official use only" clearance

personnel.

2. Charge weight II = medium size mass explosions as would be found in a

briefcase or backpack bomb - specifice weights are for US Government "For

offical use only" clearance personnel.

4.76 psi @ 41.1 psi-msec

5.77 psi @ 29.69 psi-msec

Heavy Blast Suppressor

HBS-330

Flow

Blast

*

*

* Actual Inside Dimension.

** The W dimension is ALWAYS parallel with the damper

blade length.

Ratings

Pressure: 5.77 psi (160 in wg) (40 kPa) blast load

Velocity: 500 - 6400 fpm (2.5 - 32.5 m/s)

Temperature: Minimum: -40°F (-40°C)

Maximum: 250°F (121°C)

Size Limitations

Size Limitations

W x H Minimum Size

Single Section Two Sections*

Inches 6 x 6 36 x 96 77 x 96

mm 152 x 152 914 x 2438 1956 x 2438

* Includes 5 in. (127mm) vertical mullion with removable

cover plate

Maximum Size

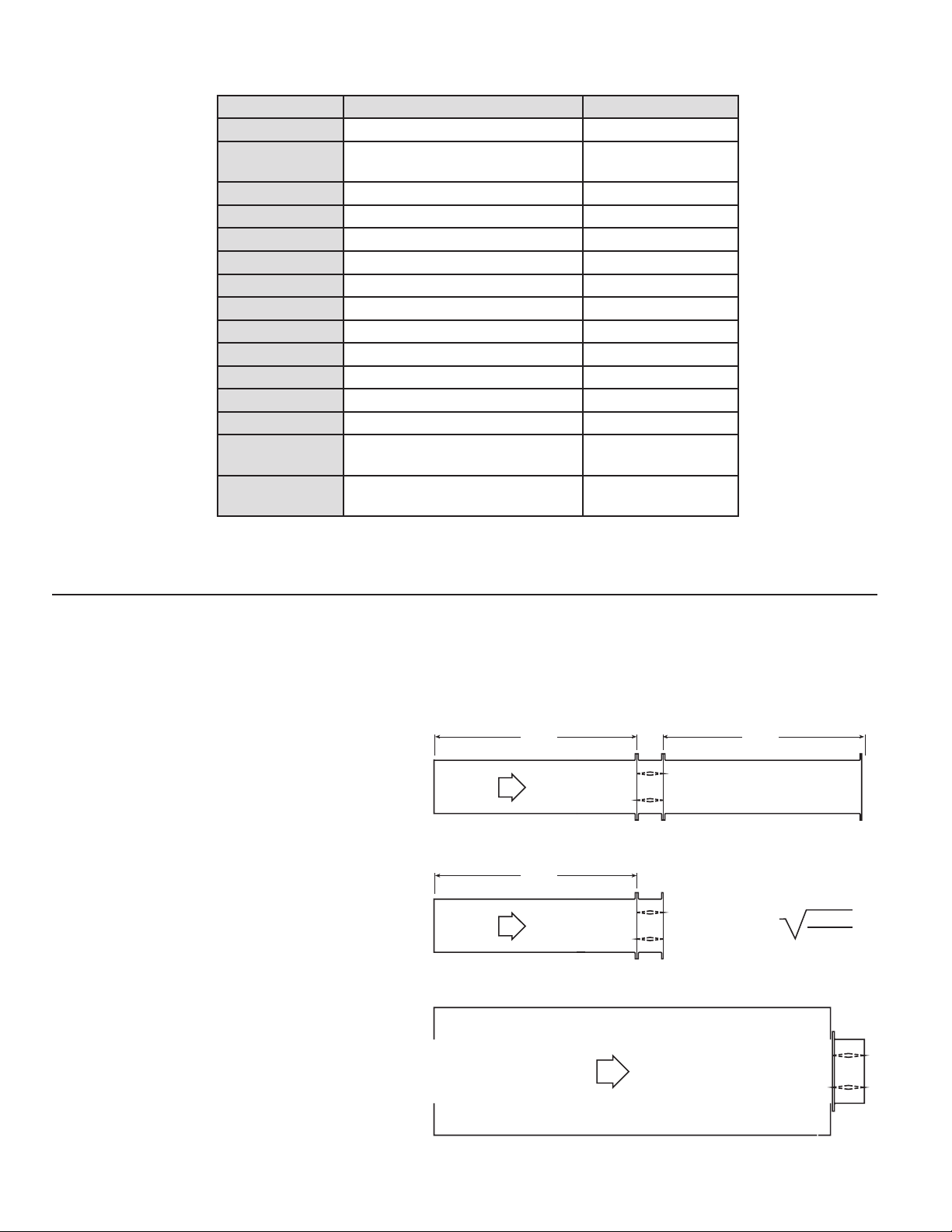

HBS-331

Blast

*

Flow

*

Options Available:

• Bolt holes in flanges

Note: Spring Location is from the perspective of

viewing the damper in the blast direction.

See installation instructions at www.greenheck.com for installation options and special sizing considerations.

5D 6D

5D

D

4 (W) (H

)

3.14

Standard Construction

Construction Standard Optional

Frame Material Galvanized steel 304SS/316SS

Frame Material

Thickness

Frame Type 10 in. x 2 in. (254mm x 51mm) channel -

Blade Material Galvanized steel 304SS, 316SS, Galvaneal

Blade Type Airfoil -

Blade Thickness 16 ga. (1.6mm) -

Axle Diameter 3/4 in. (19mm) -

Axle Material Plated steel 303SS/316SS

Bearings Externally mounted relubricable ball -

Blade Seal None EPDM, Silicone

Linkage Material Galvanized steel 304SS/316SS

Flange 2 in. (51mm) -

Springs 301SS -

Finish Mill Finish Hi Pro Polyester, Epoxy,

Normal Airflow Horizontal Vertical Up or Vertical

HBS-330 & HBS-331

10 ga. (3.5mm) -

Industrial Epoxy

Down

Performance Data

Pressure Drop Data

This pressure drop data was conducted in accordance with AMCA Standard 500 using the three configurations shown. All data

has been corrected to represent standard air at a density of 0.075 lb/ft3 (1.2 kg/m3) .

Actual pressure drop found in any HVAC system is a combination of many factors. This pressure drop information along with an

analysis of other system influences should be used to estimate actual pressure losses for a damper installed in a given HVAC

system.

AMCA Test Figures

Figure 5.3 Illustrates a fully ducted damper. This

configuration has the lowest pressure drop of the

three test configurations because entrance and exit

losses are minimized by straight duct runs upstream

and downstream of the damper.

Figure 5.2 Illustrates a ducted damper exhausting

air into an open area. This configuration has a lower

pressure drop than Figure 5.5 because the entrance

losses are minimized by a straight duct run upstream

of the damper.

Figure 5.5 Illustrates a plenum mounted damper.

This configuration has the highest pressure drop

because of the high entrance and exit losses due to

the sudden changes of area in the system.

Leakage Data

Leakage testing was conducted in accordance with

AMCA Standard 500 and is expressed as cfm/ft2 of

damper face area. All data has been corrected to

represent standard air at a density of 0.075 lb/ft3 (1.2

kg/m3).

Fig. 5.3

Fig. 5.2

Fig. 5.5

AMCA Test Figures

Loading...

Loading...