Page 1

Document number 469620

®

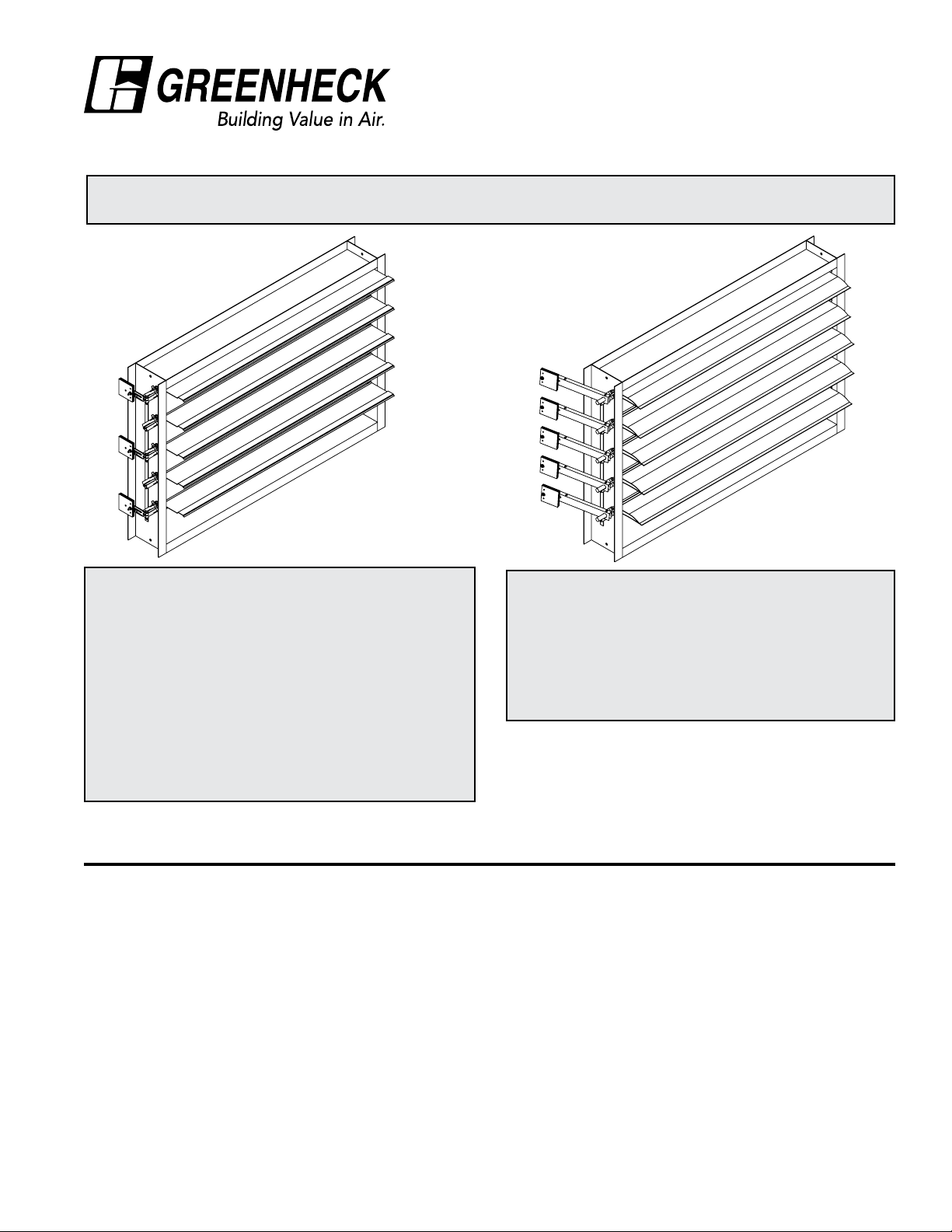

HB series

Installation, Operation, and Maintenance Instructions

This manual is the property of the owner, and is required for future maintenance. Please leave it with the

owner when the job is complete.

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that

all parts of the shipment, including accessories, are

accounted for.

Dampers must be kept dry and clean. Indoor

storage and protection from dirt, dust and the

weather is highly recommended. Do not store at

temperatures in excess of 100°F(37ºC).

Due to continuing research, Greenheck reserves the right to change specifications without notice.

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating, and maintenance instructions

thoroughly before installing or servicing this

equipment.

SAFETY WARNING:

Instructions

The following instructions should be followed when trying to adjust counterbalance weights on HB series

dampers. This is not intended to be used to modification for use as pressure relief damper.

Heavy Duty/Industrial backdraft damper are adjusted

for the specified flow direction at the factory. The

external counterbalance is adjusted for “easy operation”.

These instructions address adjustment of the blade

counterbalance for the following:

• Damper mounting orientation and/or flow direction has

changed in the field

• Damper requires excessive start-open pressure or does

not close

• Blade seal has been removed in the field

• Counterbalance settings have been erroneously

“adjusted” in the field

Single section wide dampers will have external blade

counterbalance on one (linkage) side of damper.

Dampers with two sections will have linkage on both

sides of damper assembly. Arms are usually mounted

on every other axle, starting at the bottom, until the

magnitude of the counterbalance requires arms on every

axle. The steel airfoil models HB-230 and HB-330 will

require more counterbalance weights than model HB-120

with single thickness blade or models HB-110 and HB240 with aluminum blades. The longer arms are angled

so they will nest when installed on every axle. Greenheck

policy is to distribute counterbalance evenly among

blades to minimize linkage loading and to improve blade

closure.

Page 2

Damper Maintenance

Greenheck's dampers are designed to be trouble free and hassle free under normal operation. Dampers are to be installed

square and straight so as to prevent binding during operation. The following annual damper maintenance suggestions will

help to insure proper damper operation and increase the life expectancy of the damper.

Foreign Matter Over the course of time, dirt and grime may collect on damper surfaces. The damper

surfaces should be cleaned to prevent hindrance to airflow.

Moving Parts Make sure that parts such as linkage, bearings, blades, etc. that are intended to move

freely, can do so.

Bearings. Plastic and pressfit ball bearings (without grease fittings) do not require

lubrication. Ball bearings with grease fittings should be lubricated as follows:

Maximum Duct

Temperature

°F °C Lubricant Minimum Frequency

250 121 NLGI Grade 2 lithium

12-hydrostearate grease

Closure Remove foreign materials that may be interfering with blade closure or effective sealing

of the blades with each other or with the frame. Inspect blade seals yearly and replace as

necessary.

Operation While operating the damper through its full cycle, check to see that the blades open and

close properly. If there is a problem, check for loose linkage.

Counterbalance Adjustment Instructions

1. Adjust FULL OPEN blade stop first. On most models,

a bolt with a spacer is used through the top linkage

clevis arm. Open and close damper to verify there

is no interference between axles and the nested

counterweight arm.

twice a year

2. Place damper in the installed mounting position and

flow direction.

3. Adjust blade counterbalance at full open position

first. Fan (flow) must not be operating. Rotate damper

blades open. the crankarms or counterweight arms

are generally 180° from the damper blade centerline.

On very small dampers with aluminum blades, the

crankarm may be inclined towards damper outlet, due

to the torque of the linkage. Adjust counterweight plate

center distance until blades will start to close from

full open position. Moving plate(s) out will increase

counterbalance. It may be necessary to add or delete

a plate. Counterweight plate quantity per arm should

not vary by more than one and the distance outward

from the axle centerline should not vary more than 1/2

inch among counterweight arms.

4. Close damper. Blades should close completely (you

can feel the blade edge seals make contact) without

slamming. NOTE: Counterweight arms are welded to

the axles as shipped. Arm adjustment will require weld

to be removed and to be rewelded after modification.

• If closing too hard, loosen arm fastener to the axle

and rotate top of arm towards upstream of air

entering side. Retighten fastener.

• If not closing, loosen the arm fastener to the axle and

rotate top of arm towards downstream or discharge.

Retighten fastener.

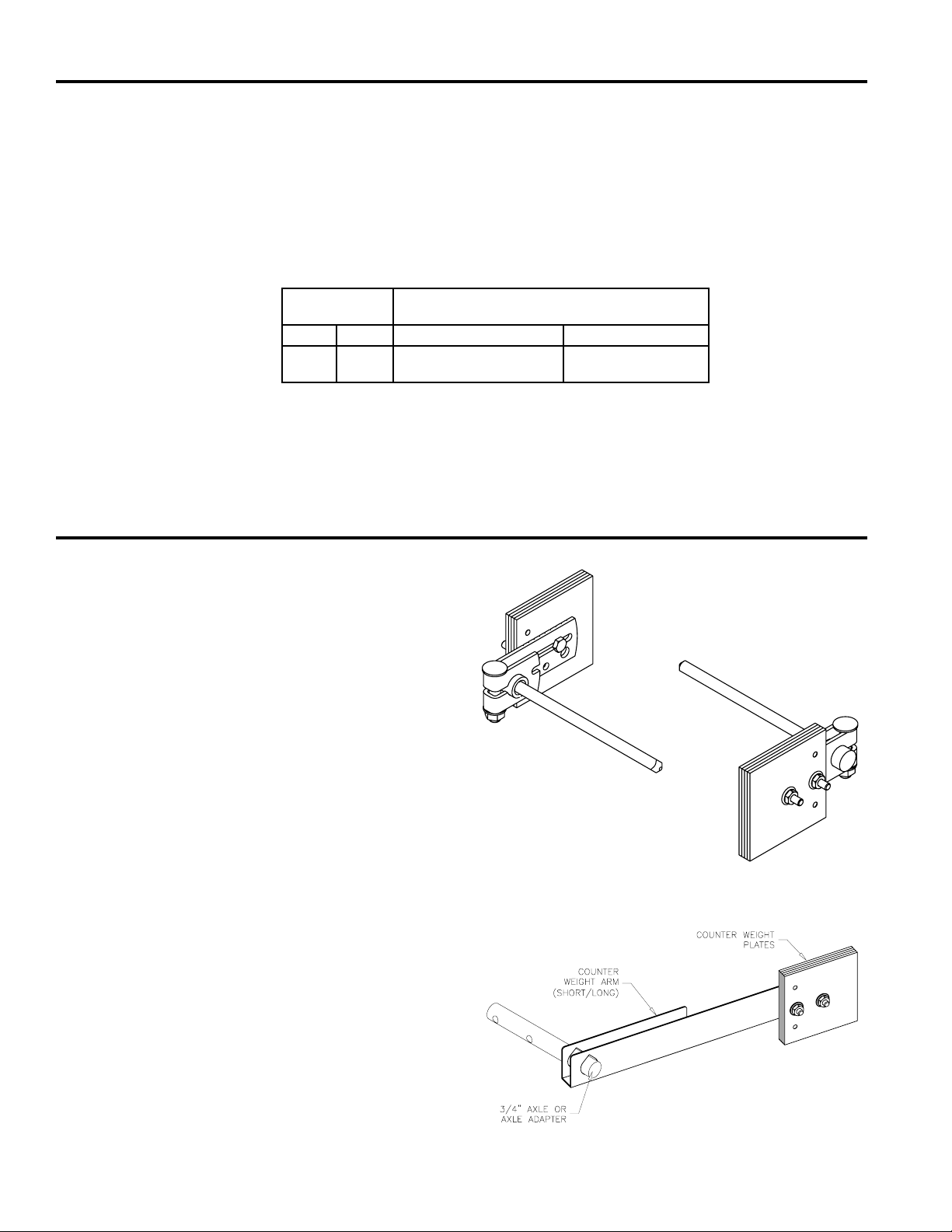

Counterbalance weight assembly

(square axle units)

Counterbalance arm assembly

(long & short arm)

Page 3

Counterbalance Adjustment Instructions cont...

5. Open damper and recheck full open operation.

Readjust per step 3 if necessary. Recheck full closed

position (step 4) as any modification at one position

has a slight impact on the other.

6. Tighten all counterweight and arm fasteners securely.

7. Test damper closure by opening damper blades and

releasing from 1/4, 1/2, 3/4 and full open position.

Damper should close from all positions without

assistance.

Standard Components

Component

Axle Adapter, 3/8” to ¾”

square OD

¾” Crankarm All 652982 687738

3/8”-16x2 Crankarm Bolt All 415882 415924

3/8”-16 Hex Nut for

Crankarm

Short Counterweight Arm

(8½ in. )

Long Counterweight Arm

(12½ in. )

3/8”-16 set screw for

short/long arm

3/8” -16 Weldnut/Hex nut

for short/long arm

Counterweight plate,

2½” x 3½”

Counterweight plate,

3½” x 3½”

¼”-20 Serrated Flange Nut All 415455 415575

¼”-20 x 3/4” Bolt All 415490 415573

¼”-20 x 1¼” bolt/

1½” bolt

Applicable

Model

HB-110, HB-120 370120 416343

All 415457 415799

All 657344 689404

All 657343 683951

All 415050 415763

All 415127 415799

All 653143 687636

All 653142 687635

All 415973 416103

Galvanized

Part Number

Stainless

Part Number

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specications without notice.

Specic Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

469620• HB Series Rev. 2, October 2012 Copyright 2012 © Greenheck Fan Corporation

Loading...

Loading...